Académique Documents

Professionnel Documents

Culture Documents

10.study of The Workers Perspective Concerning The Impact of (M.as'ad Abdurrahman)

Transféré par

alfian553159Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10.study of The Workers Perspective Concerning The Impact of (M.as'ad Abdurrahman)

Transféré par

alfian553159Droits d'auteur :

Formats disponibles

International Seminar on Infrastucture Development in Cluster Island Eastern Part of Indonesia, Baubau, Indonesia

STUDY OF THE WORKERS PERSPECTIVE CONCERNING THE IMPACT OF HEALTH AND SAFETY PROGRAMS TO THEIR PRODUCTIVITY CASE STUDY: SMALL AND MEDIUM CONSTRUCTION FIRMS IN MAKASSAR

M. Asad Abdurrahman1, Rusdi U. Latief2, and St. Hijraini N3. ABSTRACT: The construction industry has risks to safety in its practice. However, workers and managers in construction industry generally do not respond well to the health and safety (HS) program. For example, the assumption that the use of safety equipment has negative impact on their productivity, so they tend to ignore the safety devices that should be provided. This study aims to identify the perceptions of construction workers against the elements of health and safety program that has dominant influence to workers productivity. The second aim is to explore the benefit of safety program interventions with respect to worker productivity. The finding shows that among eleven programs that has been identified, the use of personal protective equipment and engineering controls that are assessed have more positive impact on productivity. Overall, 73.47% of respondents considered that the HS program has no impact on worker productivity. Furthermore, 4.15% of respondents considered that the HS program actually has negative impact on their productivity. Keywords: safety, construction, productivity

PROCEEDINGS AIMS AND SCOPES INTRODUCTION Safety and occupational health issues in sectors which prone to accidents such as the construction industry, has not been a part of Indonesian culture. This is reflected in data that the number of work accidents in 2009 in Indonesia is more than 54.000 cases. Among them, the totals of 20,086 cases are caused by violations of occupational health and safety (OHS) regulation (Solo Pos, 2010). On the other hand, research conducted by International Labor Organization pertaining to OHS standards reveals that Indonesia ranks 152 out of 153 countries which examined. This reflects that the safety practice in Indonesia is severe (PNRI, 2009). A study by National Occupational Safety and Health Commission reveals that construction industry has the highest fatality rate in Australia. Between 2002 and 2003, 50 out of 10,000 workers were death (NOHSC 2005). This figure is two-fold higher than the average of all industrial accidents in Australia. Furthermore, Construction, Forestry, Mining and Energy Union (CFMEU) revealed that 50 workers died from construction workplace accidents in the past decade (CFMEU 2003). The figures above show that individuals who work in the construction industry dealing with hazardous and life-threatening working conditions.

In construction site, the problem of running a safe job is complicated by the fact that the nature of the work, the environment that it is conducted in, and the people involved constantly change. The safety requirements can be totally different from one construction task to another, and the requirements constantly change as the work moves from one stage to another. As the physical environment is transformed, new hazards and obstacles are created with various levels of risk. Construction workers generally consider the use of safety equipments are in contrast to their productivity, so they tend to ignore the safety equipments which should be provided. However, when accidents happen, the consequences have worse impact on their productivity. On the other hand, not only the victims of accidents that affect productivity, but the productivity of workers around the crash site were also affected due to the accident which distracts them from the tasks. RESEARCH METHODOLOGY A survey research method is applied in this study. The respondent is the construction workers who are considered able to assess of the risk of workplace accidents based on their experience. The characteristic of the sample is work experience more than 5 years in construction work. This characteristic is intended to

M. Asad Abdurrahman, Hasanuddin University, Makassar 90245, INDONESIA Rusdi U. Latief, Hasanuddin University, Makassar 90245, INDONESIA 3 St. Hijraini N., Hasanuddin University, Makassar 90245, INDONESIA

2

55

M.Asad Abdurrahman, et al.

provide information that can be regarded as an expert judgment. The numbers of participant are 52 respondents. Statistical test was conducted to examine whether the respondents have similar perceptions in providing an assessment. CONSTRUCTION ACCIDENT FIGURES The construction industry is highly competitive so that principal contractors are willing to award contracts to subcontractors with poor or untested safety practices. Once the subcontractors have started work on the site, unrealistic progress programs are then enforced on them. This situation creates a culture where the objective of many contractors is to get the job finished as quickly as possible and move on to the next project. Safe work practices are commonly being seen as time-consuming,

Overexertion; bodily movement, stepping down, n= 39 Overexertion; manual handling of load, n= 159 Burns, explosion, n= 12 Overexertion; repetitive, static, n= 32 Vechicle accident, n= 5 Fall on same level, n= 50 Hit/cut by handtool, implement, material, n= 62 Caught, crushed, pull into, n= 37 Hit/cut by machinepart, powertool, n= 34 Fall from roof, structure, etc., n= 30 Hit by vechicle, n=5 Fall from ladder, scaffolding, stairs, etc., n=28 0

believe that their work environment is dangerous, 57% of respondents suffered injuries due to accidents during 2002, and 41% of respondents working on the project site where a person suffered serious injuries in that year (Cole 2003) Helander (in Sohail 1999) examined 739 deaths that occurred in the UK construction industry and found that 52% of deaths caused by fall from roofs, ladders and scaffolding, 19.4% caused bya falling object and caused heavy equipment at 18.5%. He also found that 5% of construction accidents occur during excavation work. Based on case studies in England, America, France, Canada and Sweden, he compared the construction industry accident with the accident in manufacture industries based on workers categories. The supervisor occupies a very high level of accidents due to falls from height and stepping on dangerous objects. The highest

6 Index

10

12

14

Hospital days

Time off

Maim

Fracture/amputation

Fig. 1: Construction Mechanisms of Injury (Larsson & Field, 2000) level in plumber category is by falling object. As for the mason, the highest level is the result of the overexertion/strenuous movement. Goldsmith (1987) in his study for the design and implementation of safety programs, establish the sources of accidents at construction sites which requires greater attention in safety programs. Those sources are: 1. Scaffolding and the stage, 2. Mechanical and electrical equipment which rotates/moves

PT. Jamsostek (in Tim Pengelola DPKK, 1999) describes workplace accident characteristic in Indonesian construction industry as follows: 30% caused by moving objects, 29% caused by falling objects, 26% caused by slipped and hit by object, 10% caused by fall from height, and 5% caused by electric shock, fire and explosion A study carried out by Australian Workers Union in 2002 to its 180 members reveals that 60% of respondents

56

Study of the Workers Perspective Concerning the Impact of Health and Safety Programs to Their Productivity Case Study: Small and Medium Construction Firms in Makassar

3. Electric hand tools (especially saws, grinders, hammers, and drills), 4. Crane, chains, ropes, cables 5. Welding 6. Jackhammer 7. Wooden stairs 8. Hole 9. Waste material Occupational Safety and Health Administration (OSHA) in the United States reported a study of 3.496 deaths on construction workers during 1985-1989. This study considers the variation of the number of deaths over 5 years, the influence of geographical factors and worker characteristics, such as industry groups, age, etc. This study also examines the causes of death and factors that cause accidents. Statistics from OSHA database are compared with the Bureau of Labor Statistics data, the National Institute for Occupational Safety and Health and the National Safety Council, which further classify the causes of accidents, namely: fall from height, struck down, physical contact, and electric shock. This study demonstrates the use of more detailed codification of the accident by using OSHA data. Overall, 33% of construction deaths are caused by falls, 22% by falling objects and 17% by a falling electric shock. OSHA report shows that 99% of falls is falling from a height at different levels, which mainly occurred on the roof and scaffolding; electric shocks are mostly related to connecting surface cable and only 7% of struck by object incidents involving moving materials. In addition, 67% of fall accidents involving the carpenters. In the report, OSHA groups the types of building construction works that the source of accidents as follows: plumbing, painting, electrical work, masonry work, plaster, timber works, roofing, concrete work, operation of heavy equipment, and demolition. WorkCover (1999), an organization for occupational safety development established by the Department of Labor, New South Wales, Australia identified the hazards on building construction work by classifying the type of work as follows: metal roofing and electrical work, formwork mobile scaffolding, masonry, concrete works, and demolition. In addition, Marosszeky (1998) in his presentation on site safety meter, classify the types of building construction works as a source of accidents as follows: roofing, demolition, concrete work, reinforcement, formwork, plumbing, electrical work, masonry, and scaffolding

FISHER TEST This statistic tool performs a simple analysis of variance on data for two or more samples. The analysis provides a test of the hypothesis that each sample is drawn from the same underlying probability distribution against the alternative hypothesis that underlying probability distributions are not the same for all samples.

(1)

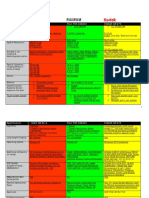

RESULT FINDINGS Among eleven programs that has been identified, the use of personal protective equipment and engineering controls that are assessed have more positive impact on productivity. Figure 2 shows the element of HS program that affect workers productivity. costly, and something that slows down the work (Durham et al. 2002). It is widely accepted that the occupational health and safety performance of the construction industry is unacceptable (WorkCover NSW 2001, Cole 2003). The construction industry is one of the major industries with significant injury risk and has an unacceptably high level of workplace fatalities, injuries and disease (McWilliams 2001). Study by Larsson and Field (2000) examined the risks within the industries in Victoria, Australia. The study found that construction workers have the higher incidence of injury among the other industries. Figure 1 shows the distribution of the Victorian construction mechanisms of injury. Falls from roof, ladders and scaffolding represent the most prominent accidents at work. Injuries sustained in contact with powertools, machinery, handtools, vehicle, and material are also very severe.

57

M.Asad Abdurrahman, et al.

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0%

Personal Protective Equipment

Good Housekeeping

Engineering Control

HS Communication

Procedure and Regulations

Hazards Isolation

HS Supervision

HS Training

Casualties Management

Ergonomic Environment

Fig. 2: Impact of Health and Safety Elements to Workers Productivity The use personal protective equipment makes workers feel protected against the hazards so that they can have the high mobility, but some personal protective equipment such as harnesses is deemed to obstruct or interfere with the mobility of workers. Control engineering is an attempt to design or use certain tools in order to minimize the hazard. The workers feel more secure and high mobility when working at height using steel as compared to bamboo scaffolding. Ergonomic environment and good housekeeping also have a positive impact, but to get the ideal conditions for the both elements, it is necessary to provide labor time; therefore, these elements are not considered have significant impact in increasing the duration of the work. Procedures and HS regulations, and isolation of hazards such as the use of barriers to cut off the hazard are not considered have a significant positive effect due to meet the requirements and make the isolation requires long duration. In general, HS training, HS supervision and HS communication, casualties management and administrative controls are not correlated with labor

Positive Impact

No Impact

Negative Impact

productivity in the short term, but the positive impact of these elements will be gained in the long term.

Fig. 3: Worker Perceptions about Impact of HS Program on Productivity Overall, 73.47% of respondents considered that the HS program has no impact on worker productivity. Furthermore, 4.15% of respondents considered that the HS program actually has negative impact on their productivity (Figure 3). Based on the perception of respondents about the notion of productivity as described above, it can be explained that the workers need a longer working duration if they need to meet safety standards. Statistical analysis using Fisher test with =10% shows that F < Fcrit and all P-value of this analysis is

58

Administrative Controls

Study of the Workers Perspective Concerning the Impact of Health and Safety Programs to Their Productivity Case Study: Small and Medium Construction Firms in Makassar

less than 0.1 which indicate that respondents had similar perceptions in assessing the parameters in the questioner. CONCLUSION Occupational health and safety program is intended to minimize the risks and potential hazards. This program is not intended to directly to increase labor productivity. Thus, health and safety program has no correlation to the productivity of labor. In certain circumstances, health and safety program actually contra to labors productivity.

REFERENCES Anonym, OHS Risk Management Handbook, HB 205 2004, Standards Australia International Ltd, Sydney, Australia Cole, T. 2003, Reform Occupational Health and Safety, Final Report of the Royal Commission into the Building and Construction Industry, Volume Six, Canberra Construction, Forestry, Mining and Energy Union (CFMEU) 2003, Safety on Australian Construction Sites, <http://www.cfmeu.asn.au/ construction/pdfs/safetyFeb03.pdf> Goldsmith, David 1987, Safety Management in Construction and Industry, McGraw Hill, New York Larsson., T and Field, B 2000, The distribution of occupational injury risks in the state of Victoria, a report prepared for the Victorian WorkCover Authority, Australia Marosszeky, Marton 1999, Improving Construction Industry Safety, Construct IT Seminar, Department of Real Estate & Construction, The University of Hong Kong.

McWilliams, G. 2001, Reducing serious injury risk in the construction industry: a report prepared for the Victorian WorkCover Authority, Monash University Accident Research Centre, Melbourne. National Occupational Health and Safety Commission (NOHSC) 2004, Occupational Health and Safety Risk Management Handbook Standards Australia, ASHB 2052004 National Occupational Safety and Health Commission (NOHSC) 2005, National Workers Compensation Statistics Databases, Australia Occupational Safety and Health Administration 1990, Analysis of Construction Fatalities The OSHA Database 1985-1989, U.S Department of Labour, Washington D.C. Portal Nasional Republik Indonesia (PNRI), 2009, http://www.indonesia.go.id/id/index.php?option=co m_content&task=view&id=9491&Itemid=691, web access date 20 March 2010 Sohail, Muhammed 1999, Review of Safety in Construction and Operation for the WS&S Sector a literature review, Part II Task No: 166, WELL Study, United Kingdom Solo Pos 2010, http://www.solopos.com/2010/channel /nasional/2009-54398-kasus-kecelakaan-kerjaterjadi-di-indonesia-11664, web access date 25 March 2010 Tim Pengelola DPKK 1999, Modul Keselamatan dan Kesehatan Kerja Pada Bidang Konstruksi, cetakan III, Sektor Pekerjaan Umum/Konstruksi, Departemen Pekerjaan Umum, Jakarta WorkCover 1999, Occupational Health and Safety Information Manual for Supervisors in the NSW Construction Industry, WorkCover NSW, New South Wales

59

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Pindyck TestBank 7eDocument17 pagesPindyck TestBank 7eVictor Firmana100% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Sampul BelakangDocument1 pageSampul Belakangalfian553159Pas encore d'évaluation

- 13.the Driving Cycle of Light Vehicles On An Urban Road (Reza Hasrul)Document4 pages13.the Driving Cycle of Light Vehicles On An Urban Road (Reza Hasrul)alfian553159Pas encore d'évaluation

- 11.traditional Shipping Transport Safety Case Study Phinisi Fleet (From The View of Safety and Strength) (Johny Malisan)Document15 pages11.traditional Shipping Transport Safety Case Study Phinisi Fleet (From The View of Safety and Strength) (Johny Malisan)alfian553159Pas encore d'évaluation

- 02.raft Floating Breakwater For Steep Beaches Protection (A. Arsyad Thaha)Document6 pages02.raft Floating Breakwater For Steep Beaches Protection (A. Arsyad Thaha)alfian553159Pas encore d'évaluation

- 03.study Analysis The Quality and Quantity of River Water Pampang Makassar South Sulawesi (H.arfan)Document9 pages03.study Analysis The Quality and Quantity of River Water Pampang Makassar South Sulawesi (H.arfan)alfian553159Pas encore d'évaluation

- ContentDocument4 pagesContentalfian553159Pas encore d'évaluation

- Sampul DepanDocument1 pageSampul Depanalfian553159Pas encore d'évaluation

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maDocument2 pagesStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildPas encore d'évaluation

- Profile On Sheep and Goat FarmDocument14 pagesProfile On Sheep and Goat FarmFikirie MogesPas encore d'évaluation

- PC210 8M0Document8 pagesPC210 8M0Vamshidhar Reddy KundurPas encore d'évaluation

- Employees' Pension Scheme, 1995: Form No. 10 C (E.P.S)Document4 pagesEmployees' Pension Scheme, 1995: Form No. 10 C (E.P.S)nasir ahmedPas encore d'évaluation

- Evaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisDocument19 pagesEvaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisJunior Adan Enriquez CabezudoPas encore d'évaluation

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariPas encore d'évaluation

- 1 PBDocument14 pages1 PBSaepul HayatPas encore d'évaluation

- Schmidt Family Sales Flyer English HighDocument6 pagesSchmidt Family Sales Flyer English HighmdeenkPas encore d'évaluation

- Year 9 - Justrice System Civil LawDocument12 pagesYear 9 - Justrice System Civil Lawapi-301001591Pas encore d'évaluation

- Transparency Documentation EN 2019Document23 pagesTransparency Documentation EN 2019shani ChahalPas encore d'évaluation

- RevisionHistory APFIFF33 To V219Document12 pagesRevisionHistory APFIFF33 To V219younesPas encore d'évaluation

- Securitron M38 Data SheetDocument1 pageSecuritron M38 Data SheetJMAC SupplyPas encore d'évaluation

- Portrait of An INTJDocument2 pagesPortrait of An INTJDelia VlasceanuPas encore d'évaluation

- 30 Creative Activities For KidsDocument4 pages30 Creative Activities For KidsLaloGomezPas encore d'évaluation

- Seminar On Despute Resolution & IPR Protection in PRCDocument4 pagesSeminar On Despute Resolution & IPR Protection in PRCrishi000071985100% (2)

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaDocument3 pagesArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarPas encore d'évaluation

- 5 Deming Principles That Help Healthcare Process ImprovementDocument8 pages5 Deming Principles That Help Healthcare Process Improvementdewi estariPas encore d'évaluation

- MDOF (Multi Degre of FreedomDocument173 pagesMDOF (Multi Degre of FreedomRicky Ariyanto100% (1)

- SAS SamplingDocument24 pagesSAS SamplingVaibhav NataPas encore d'évaluation

- 004-PA-16 Technosheet ICP2 LRDocument2 pages004-PA-16 Technosheet ICP2 LRHossam MostafaPas encore d'évaluation

- Office Storage GuideDocument7 pagesOffice Storage Guidebob bobPas encore d'évaluation

- Tinplate CompanyDocument32 pagesTinplate CompanysnbtccaPas encore d'évaluation

- Basic DfwmacDocument6 pagesBasic DfwmacDinesh Kumar PPas encore d'évaluation

- Ss 7 Unit 2 and 3 French and British in North AmericaDocument147 pagesSs 7 Unit 2 and 3 French and British in North Americaapi-530453982Pas encore d'évaluation

- Resume Jameel 22Document3 pagesResume Jameel 22sandeep sandyPas encore d'évaluation

- BSCSE at UIUDocument110 pagesBSCSE at UIUshamir mahmudPas encore d'évaluation

- CoDocument80 pagesCogdayanand4uPas encore d'évaluation

- Functions of Commercial Banks: Primary and Secondary FunctionsDocument3 pagesFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaPas encore d'évaluation

- Innovations in Land AdministrationDocument66 pagesInnovations in Land AdministrationSanjawe KbPas encore d'évaluation