Académique Documents

Professionnel Documents

Culture Documents

Industry Code of Practice On Ship Recycling

Transféré par

dassi99Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Industry Code of Practice On Ship Recycling

Transféré par

dassi99Droits d'auteur :

Formats disponibles

INDUSTRY CODE OF PRACTICE ON SHIP RECYCLING

This Code of Practice has been developed in good faith using the best information currently available but it to be used at the users own risk. No responsibility is accepted by the publishers or the organisations or persons which have been in any way with the furnishing of opinions, information or data, the compilation, publication or authorised translation, supply or sale of this Code, for the accuracy of any information or advice given herein or for any omission herefrom or consequences whatsoever resulting directly or indirectly from use of the Code or from compliance with or adoption of guidance contained herein.

INDUSTRY CODE OF PRACTICE ON SHIP RECYCLING For further information contact Marisec 12 Carthusian Street London EC1M 6 EZ Tel: 44 20 7417 8844 Fax: 44 20 7417 8877 e-mail:publications@marisec.org

www.marisec.org/recycling

INDUSTRY CODE OF PRACTICE ON SHIP RECYCLING August 2001 1. Foreword

1.1 The Industry Working Party on Ship Recycling was established under the co-ordination of ICS in February 1999 in response to growing concerns expressed by governments, environmental groups and the industry itself regarding: 1.2 the legal position with respect to potentially hazardous substances on vessels sold for recycling; the working conditions and safety provisions for workers in recycling yards; and environmental controls at recycling yards. The Industry Working Party comprises representatives from:

Baltic and International Maritime Council (BIMCO) International Association of Dry Cargo Shipowners (INTERCARGO) International Association of Independent Tanker Owners (INTERTANKO) International Chamber of Shipping (ICS) International Tanker Owners Pollution Federation (ITOPF) International Transport Workers Federation (ITF) Oil Companies International Marine Forum (OCIMF) with active participation, as observers, also from European Community Shipowners Associations (ECSA) International Association of Classification Societies (IACS) 1.3 At its first meeting the industry group, recognising the concerns of various parties, agreed to develop a Code of Practice, outlining a series of recommendations which would constitute good practice in respect of ships destined for recycling. 1.4 In the course of its discussions, the Working Party has come to realise that many parties are involved in the recycling process, each of whom carries a degree of responsibility for the safety, whether human or environmental, of the process of the disposal of time-expired tonnage. Likewise, the Working Party has had to recognise that there are major areas over which the majority of shipping companies have little or no direct influence, including, vitally, the standards applicable in the recycling yards. 1.5 This Code of Practice, therefore, deals primarily with issues which shipowners themselves can reasonably be expected to address. 1.6 Other parties must also be prepared to play their part. The Industry Working Party is willing to co-operate with other groups in seeking solutions to the problems involved and will actively encourage the widespread use of these and other measures designed to improve both worker safety and environmental protection in relation to the recycling industry. 1.7 It is hoped that this preliminary version of the Code of Practice, distributed with a view to test it in practice, will be seen as a contribution towards the safe and environmentally-conscious recycling of ships at the end of their working lives. Comments are invited from both users and other interested and concerned parties as contributions to its future revision

2.

Introduction

2.1 The steady withdrawal of older ships and their replacement by new tonnage is a natural technological process allowing the introduction of safer and more environmentally friendly designs, greater operating efficiency and a general reduction in marine risks. 2.2 In general, ships are not scrapped but recycled, conforming to one of the basic principles of sustainable development. Recycling is defined by the World Wildlife Fund as the processing of waste or rubbish back into raw materials so that it can be made into new items. It is undoubtedly beneficial to the individual, the community and the planet. (Source: WWF-UK Recycling Fact Sheet) 2.3 In the process of recycling ships, virtually nothing goes to waste. The materials and equipment are almost entirely reused. Steel is reprocessed to become, for instance, reinforcing rods for use in the construction industry or as corner castings and hinges for containers. Ships generators are reused ashore. Batteries find their way into the local economy. Hydrocarbons on board become reclaimed oil products to be used as fuel in rolling mills or brick kilns; light fittings find further use on land etc. Furthermore, new steel production from recycled steel requires only one third of the energy used for steel production from raw materials. Recycling makes a positive contribution to the global conservation of energy and resources and, in the process, employs a large, if predominantly unskilled, workforce. Properly handled, ship recycling is, without question, a green industry. 2.4 However, while the principle of ship recycling may be sound, the working practices and environmental standards in the yards often leave much to be desired. While ultimate responsibility for conditions in the yards has to lie with the countries in which they are situated, there is a corresponding responsibility on the shipping industry to do what it can to minimise potential problems in the yards. 2.5 A vessel may be sold and bought several times during its economic life. When a ship operator decides to sell a vessel which, for whatever reason, no longer meets his requirements, he will seek a buyer for his asset and appoint an agent, a broker, to act on his behalf. Brokers specialise in matching the seller with prospective buyers and facilitating communication and negotiations between them. 2.6 For many shipowners, the sale of a ship for whatever reason brings with it considerable commercial risk. If the market falls between the time that the contract is concluded and the delivery of the vessel, the shipowner will be concerned that the end buyer will look very closely at the terms of the contract to find reason to cancel the contract and/or to renegotiate at a lower price. Many shipowners, and their appointed brokers, prefer to avoid this commercial risk by selling to an intermediate buyer who is a specialist in the business and has knowledge and contacts not typically possessed by shipowners, for whom selling a ship is an infrequent activity. The middle buyer will then sell the ship on to the end buyer, perhaps via a broker acting on behalf of a recycling company. In such circumstances, the decision on which recycling company to select rests with the middle buyer rather than the shipowner. 2.7 Generally, potential buyers also appoint brokers, who may be acting on behalf of clients who are seeking vessels to operate in further trading, or on behalf of recycling yards who are seeking to purchase vessels with a potentially high residual scrap value. The sellers broker will be seeking the best return for his client. The sale and purchase of the vessel is generally conducted between the brokers. This may happen several times during the life of the vessel. A shipping company seldom deals directly, or even indirectly, with a recycling yard and, therefore, usually has little opportunity to influence its selection. 2.8 Some brokers, however, specialise in obtaining vessels for recycling. Once a vessel is obtained, these brokers will usually offer the vessel for sale for recycling, sometimes as is (in

relation to its current geographical and physical condition), to one or more cash buyers, usually via another broker, with the contract stipulating the general area of delivery. The cash buyer will select the actual yard, normally at a later date, and his role in obtaining details of the vessels purchased, and passing these details to the recycling yard, is, therefore, vital. 2.9 The chain of communication between the operator who sells a ship and the yard which cuts it up is, therefore, a long one, potentially involving several parties. While the shipowner who is the last operator of the ship can seldom have a direct influence on conditions in recycling yards, or even on the choice of yard, he can and should contribute to ensuring that information is available on any potentially hazardous materials or conditions within the ship, and can determine the general condition of the ship when handed over. This Code of Practice is intended to encourage those objectives. 3. Industry Policy on Recycling

3.1 The organisations involved in the development of this Code of Practice will, as part of a commitment to promote safe operating and environmentally friendly practices in maritime operations: i) encourage the widespread use of this code within the industry;

ii) urge the use of a standard ship recycling contract, such as the BIMCO document, to ensure that full account is taken of all relevant environmental, health and safety considerations; iii) take due note of available technical guidance on ship recycling such as the guidelines developed by Det Norske Veritas (DNV) or the US Environmental Protection Agency (EPA); iv) promote an open dialogue with international and national governmental and nongovernmental agencies and the owners and operators of recycling yards to address mutual problems affecting environmental, health and safety standards; v) encourage the International Maritime Organization to endorse this industry code and contribute to its further development; vi) encourage the ship recycling industry to develop a code of practice appropriate to that industry, as guidance on work practices in relation to shore based activities in recycling yards to ensure acceptable environmental, safety and health standards and to monitor its application; vii) encourage appropriate international bodies to endorse any ship recycling industry code of practice; viii) encourage the authorities in flag states and ship recycling states, as appropriate, to take due account of any guidance developed in accordance with v), vi) and vii) above and to seek to facilitate the application of such guidance; ix) consider, with other interested parties, the development of criteria by which a vessel could, on request, be declared ready for recycling; x) encourage national or regional administrations to work together with governments in ship recycling nations and other interested parties on projects involving the transfer of technology or aid funding to improve facilities and working practices in the yards;

xi) encourage recycling yards to make publicly available details regarding the chosen method for the safe handling of asbestos, PCBs and PABs, halon/freon, oily residues and hazardous atmospheres in enclosed spaces; xii) encourage those administrations with responsibilities for recycling yards to consider introducing a Certificate of Approval for yards meeting acceptable worker safety and environmental control standards including ensuring that the handling and disposal of asbestos, oils and other hazardous substances, whether prior to the ships arrival at the recycling yard or subsequently, have been conducted in an acceptable manner. 3.2 For the present, the organisations involved in the development of this Code of Practice will encourage all shipping companies to: i) Initiate and complete a programme to identify and record, as far as is practicable, on each of their existing ships, any potentially hazardous materials (see Annex 1) inherent in their construction or used in their equipment and machinery. Such a record should be passed to any subsequent owners of the vessel; ii) Make every effort to minimise the amount of potentially hazardous materials on board the ship, including those carried as stores; iii) Ensure that the ship reaches the recycling yard with the minimum quantities of fuel, diesel, lubricating , hydraulic and other oils and chemicals consistent with the safe operation of the vessel; iv) Deliver the ship to the recycling yard in a gas-free condition, with all tanks, except the necessary fuel tanks for the final voyage, cleaned and certified to full hot work and entry standards; v) Make every effort to ensure that an arrival inventory is prepared of asbestos, oils, toxic substances, ozone-depleting substances and all other potentially hazardous materials, including those inherent in the structure of the vessel or used as coatings on the vessel, those contained in machinery, pipelines or cylinders or carried as stores, or accumulations of operational residues, to be handed over, against receipt, to the recycling yard (a recommended inventory form is attached at Annex 2); vi) Ensure that any compartments on the ship which may contain an oxygendeficient atmosphere are clearly marked as such, and that the yard is duly notified of these and other hazardous enclosed spaces and how to test them; vii) Take measures to facilitate the controlled drainage, by the recycling yard, of potentially harmful liquids from the ship. 3.3 For the future, the organisations involved in the development of this Code of Practice commit themselves to: i) Encourage naval architects and shipbuilders to take due account of the ships ultimate disposal when designing and constructing a ship, by using materials which can be safely recycled; minimising the use of materials known to be potentially hazardous to health and the environment; limiting the use of composite materials such as sandwich panels; taking measures to facilitate the removal of such materials;

ii) Encourage equipment suppliers, classification societies and administrations to consider taking measures to facilitate an accurate inventory of hazardous materials used on board ships; iii) Encourage shipbuilders to consider providing a green passport for new ships, based on the inventory of materials used in the vessels construction, including the identification and nature of potentially hazardous materials and their location and safe methods of demolition; (Note: This green passport, which would accompany the ship throughout its working life, should be in a format to register subsequent changes in materials or equipment. The shipowner should maintain the accuracy of the Green Passport and incorporate into it all relevant design and equipment changes, with the final owner delivering it, with the vessel, to the recycling yard.) iv) Encourage suppliers of equipment which contain hazardous substances, such as Halon, to facilitate the safe removal of those substances, or give advice as to how such substances can be safely removed, at the end of the working life of the equipment. 3.4 The organisations involved in the development of this Code of Practice undertake to urge those entering into a contract of sale of a vessel to a recycling yard to consider the following, as far as is reasonable and practical i) the working practices and facilities in the ship recycling yard(s) in question, including; their ability to handle safely, and dispose of properly, any potentially hazardous or environmentally harmful products that may be present in the ship such as asbestos, PCBs, halons, petroleum products and other residues; the provision of appropriate and sufficient personal protection and safety equipment; other information such as safety records, training programmes for workers and assessment of the work quality. ii) the environmental, health and safety benefits of towing a vessel to the yard, fully cleaned and certified to be free of oil, tank residues and other potentially hazardous and toxic material; iii) the possibility, prior to handing over the vessel for recycling, of: the removal and safe disposal of asbestos prior to arrival; the discharge of halon to an approved facility and the use of portable and returnable fire-fighting equipment for the final voyage to the recycling site; the cleaning and certification of all tanks, except the necessary fuel tanks for the final voyage, to full hot work and entry standards; providing advice on the nature of any hazardous materials on board, as indicated in the inventory of hazardous materials, and on correct handling and disposal methods (if required).

ANNEX 1 POTENTIALLY HAZARDOUS MATERIALS WHICH MAY BE ON BOARD VESSELS DELIVERED TO RECYCLING YARDS Note 1: This list is not definitive - see also EU Council Regulation No.259/93 Annexes II, III & IV. A. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. B. 1. 2. 3. 4. Operational Substances and Consumables Cargo Residues including Slops Dry tank Residues Fuel oil, Diesel oil, Gas oil, Lubricating oil, Greases & Anti-seize Compounds Hydraulic oil Waste oils (contents of sludge tank) Antifreeze fluids Kerosene and White Spirit Boiler and Feed Water Treatment Chemicals Boiler and Feed Water Test Re-agents De-ioniser Regenerating Chemicals Evaporator Dosing and Descaling Acid Domestic Water treatment Chemicals Paints and Rust Stabilisers Solvents and Thinners Refrigerants (R12 or R22) HALON CO2 (in cylinders - engine room fire protection) Acetylene, Propane and Butane Hotel Services Cleaners Lead-acid Batteries Battery Electrolyte PCB and / or PCT and / or PBB at levels of 50mg / kg or more Mercury Radio-active Material i.e. liquid level indicators Miscellaneous Medicines Insecticide Sprays Miscellaneous Chemicals such as Alcohol, Methylated Spirits, Epoxy Resins, etc. Plastics as covered by MARPOL Raw and Treated Sewage Toxic Materials (as part of the ships structure) Asbestos Lead-based Paint Coatings on Ships Structure Tin-based Anti-fouling Coatings on Ships Bottoms. Others.

ANNEX 2

INVENTORY OF POTENTIALLY HAZARDOUS MATERIALS ON BOARD (Version August 2001)

Name of Vessel IMO Number Date of Build GT DWT LDT Date of Inventory Date of Delivery Received by On behalf of

This form is intended for completion by the shipowner and/or his authorised representatives, including the master, on the vessels last voyage prior to being broken up. It provides an estimate of all known potentially hazardous or contaminating materials and substances which are thought to be on board the vessel, or inherent in its structure, or as an integral part of its machinery and/or equipment, at the point of sale. It should be handed over, together with any relevant attachments, by the shipowner or his representative to the purchaser or his representative on delivery of the vessel for breaking. The document may be supplemented, as appropriate, with more detailed information in respect of any of the categories included in this document. It is provided as guidance to the shipbreaking organisation and his workforce and should not be regarded as a formal statement of precise quantities. It has no contractual force. Information on potentially hazardous materials inherent in the ships structure or its machinery and equipment, such as items listed in part 1 of the inventory, are likely to be supplied by the operating department ashore. However, information such as that related to residues (part 2 of the inventory) or consumables (part 3) cannot be completed until near the end of a vessels final voyage. This form has been developed by and is recommended for use by the following organisations: Baltic and International Maritime Council (BIMCO) International Association of Dry Cargo Shipowners (INTERCARGO) International Association of Independent Tanker Owners (INTERTANKO) International Chamber of Shipping (ICS) International Tanker Owners Pollution Federation (ITOPF) International Transport Workers Federation (ITF) Oil Companies International Marine Forum (OCIMF) with the assistance of the European Community Shipowners Associations (ECSA)

WHILST EVERY CARE HAS BEEN TAKEN TO ENSURE THAT THE INFORMATION PROVIDED IN THIS INVENTORY IS ACCURATE, UP-TO-DATE AND COMPLETE, NEITHER THE SHIPOWNER NOR ANY OF HIS REPRESENTATIVES ACCEPT ANY LIABILITY FOR ANY ERRORS OR OMISSIONS IN THE INVENTORY OR FOR ANY ACTS OR OMISSIONS OF ANY PERSON IN THE HANDLING, REMOVAL OR DISPOSAL OF THESE SUBSTANCES, WHETHER DONE IN RELIANCE ON THE INFORMATION IN THIS INVENTORY OR OTHERWISE. IT REMAINS THE RESPONSIBILITY OF EACH EMPLOYER TO PROVIDE APPROPRIATE TRAINING, GUIDANCE AND PERSONAL PROTECTIVE EQUIPMENT TO ITS EMPLOYEES TO ENSURE THE IDENTIFICATION, LOCATION, HANDLING AND DISPOSAL OF ALL MATERIALS ON BOARD THE VESSEL OR INHERENT IN ITS STRUCTURE, EQUIPMENT OR MACHINERY. IT IS STRESSED THAT THE INFORMATION PROVIDED IN THIS INVENTORY IS NOT A CONTRACTUAL STATEMENT OF PRECISE QUANTITIES OF RESIDUES AND MATERIALS ON BOARD. THE QUANTITIES GIVEN ARE ESTIMATES ONLY AND NO GUARANTEE OF THEIR ACCURACY IS EITHER GIVEN OR IMPLIED.

PART 1

POTENTIALLY DANGEROUS MATERIALS IN THE SHIPS STRUCTURE AND EQUIPMENT

1A. Asbestos (Note: All asbestos containing materials (ACMs) or presumed asbestos containing materials (PACMs) should be prominently labelled as such). Type of Asbestos Materials Location Approximate (Board, Pipe lagging, Contained) Quantity Engine Room/Machinery Rooms Steam supply piping and hangers (General) Steam exhaust piping and hangers (General) Relief & safety valves (General) Miscellaneous piping outer covering and hangers (General) Water pipes and hangers (General) HP Turbine Insulation (General) Boiler drums & casings (General) Heaters, Tanks etc. (General) Other (General) Specific Machinery Locations e.g. Pump Room, Boiler Room

Accommodation Sanitary & Commissary spaces (General) Interior decks including underlay (General) Steam & exhaust pipes (General) Refrigeration pipes (General) Air conditioning ducts (General) Cable transits (General) External bulkheads (General) Internal bulkheads(General) External deckheads (General) Internal deckheads (General) Decks adjoining machinery spaces (General) Other (General) Specific accommodation locations

Deck Steam supply piping (General) Exhaust piping (General) Tank cleaning piping (General) Stripping pump (General) Other (General) Specific deck locations Machinery Brake linings Caution!! Asbestos containing material (ACM) may be found underneath materials that do not contain asbestos. 1B. Paint (on vessels structure) - Additives Additive (Lead, Tin, Cadmium, Organotins (TBTs), Arsenic, Zinc, Chromium, Strontium, Other) Location

1C.

Plastic Materials Type

Location

Approximate Quantity

1D.

Materials containing PCBs, PCTs, PBBs at levels of 50mg / kg or more Material Location

Approximate Quantity

1E.

Gases sealed in ships equipment or machinery Type Location Refrigerants (R12/R22) HALON CO2 Acetylene Propane Butane Oxygen Other (Specify) 1F. Chemicals in ships equipment or machinery Type Anti-seize Compounds Engine Additives Antifreeze Fluids Kerosene White Spirit Boiler/Water Treatment De-ioniser Regenerating Evaporator Dosing and Descaling Acids Paint/Rust Stabilisers Solvents/Thinners Chemical Refrigerants Battery Electrolyte Hotel Service Cleaners Other (Specify) 1G.

Approximate Quantity

Location

Approximate Quantity

Other Substances inherent in ships machinery, equipment or fittings Type Location Lubricating Oil Hydraulic Oil Lead Acid Batteries Alcohol Methylated Spirits Epoxy Resins Mercury Radioactive Materials Other (Specify)

Approximate Quantity

Part 1. completed by Signature

Position On behalf of (Company)

PART 2 2A.

OPERATIONALLY GENERATED WASTES Dry Tank Residues Description of Residues Location Approximate Quantity

2B.

Bulk (non-oily) waste Type Ballast Water Raw Sewage Treated Sewage Garbage (inc. plastics) Debris Galley Wastes Other (Specify)

Location

Approximate Quantity

2C.

Oily Waste/Oily Residues Type Cargo Residues Tank Scale Bunkers: Fuel Oil Diesel Oil Gas Oil Lubricating Oil Grease Hydraulic Oil Waste Oil (Sludge) Oily Water Oily/Contaminated Sludge Oily/Contaminated Rags Other (Specify)

Location

Approximate Quantity

Part 2. completed by Signature

Position On behalf of (Company)

PART 3 Stores 3A. Gases in store Type Refrigerants (R12/R22) HALON CO2 Acetylene Propane Butane Oxygen Other (Specify) 3B. Chemicals in store Type Anti-seize Compounds Engine Additives Antifreeze Fluids Kerosene White Spirit Boiler/Water Treatment De-ioniser Regenerating Evaporator Dosing and Descaling Acids Paint/Rust Stabilisers Solvents/Thinners Refrigerants Battery Electrolyte Hotel Service Cleaners Other (Specify) 3C.

No. and size of Cylinders

Location

Approximate Quantity

Location

Approximate Quantity

Other Packaged items in store Type Lubricating Oil Hydraulic Oil Lead Acid Batteries Medicines Insecticide Sprays Alcohol Methylated Spirits Epoxy Resins Paint Fire fighting clothing, equipment (e.g. blankets) Other (Specify)

Location

Approximate Quantity

Part 3 completed by Signature

Position On behalf of (Company)

WHILST EVERY CARE HAS BEEN TAKEN TO ENSURE THAT THE INFORMATION PROVIDED IN THIS INVENTORY IS ACCURATE, UP-TO-DATE AND COMPLETE, NEITHER THE SHIPOWNER NOR ANY OF HIS REPRESENTATIVES ACCEPT ANY LIABILITY FOR ANY ERRORS OR OMISSIONS IN THE INVENTORY OR FOR ANY ACTS OR OMISSIONS OF ANY PERSON IN THE HANDLING, REMOVAL OR DISPOSAL OF THESE SUBSTANCES, WHETHER DONE IN RELIANCE ON THE INFORMATION IN THIS INVENTORY OR OTHERWISE. IT REMAINS THE RESPONSIBILITY OF EACH EMPLOYER TO PROVIDE APPROPRIATE TRAINING, GUIDANCE AND PERSONAL PROTECTIVE EQUIPMENT TO ITS EMPLOYEES TO ENSURE THE IDENTIFICATION, LOCATION, HANDLING AND DISPOSAL OF ALL MATERIALS ON BOARD THE VESSEL OR INHERENT IN ITS STRUCTURE, EQUIPMENT OR MACHINERY. IT IS STRESSED THAT THE INFORMATION PROVIDED IN THIS INVENTORY IS NOT A CONTRACTUAL STATEMENT OF PRECISE QUANTITIES OF RESIDUES AND MATERIALS ON BOARD. THE QUANTITIES GIVEN ARE ESTIMATES ONLY AND NO GUARANTEE OF THEIR ACCURACY IS EITHER GIVEN OR IMPLIED.

Vous aimerez peut-être aussi

- Lloyds Register Concise Guide To The Green PassportDocument44 pagesLloyds Register Concise Guide To The Green PassportHashem Gam100% (2)

- Consequences of Maritime Critical Infrastructure Accidents: Environmental Impacts: Modeling-Identification-Prediction-Optimization-MitigationD'EverandConsequences of Maritime Critical Infrastructure Accidents: Environmental Impacts: Modeling-Identification-Prediction-Optimization-MitigationPas encore d'évaluation

- Nairobi Convention: The Wreck Removal Convention 2007Document12 pagesNairobi Convention: The Wreck Removal Convention 2007Dharam TripathyPas encore d'évaluation

- LLMC PDFDocument9 pagesLLMC PDFRajeshNairPas encore d'évaluation

- Scopic ClauseDocument20 pagesScopic ClausePuneet MishraPas encore d'évaluation

- Imo Bunker ConventionDocument16 pagesImo Bunker Conventionpari2005Pas encore d'évaluation

- Commercial QnA 1 YearDocument27 pagesCommercial QnA 1 YearMariyath Muraleedharan KiranPas encore d'évaluation

- Athens Convention on Carriage by SeaDocument22 pagesAthens Convention on Carriage by SeaGaurish SalgaocarPas encore d'évaluation

- MARPOL An IntroductionDocument36 pagesMARPOL An IntroductionBisrat100% (1)

- Maritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHDocument68 pagesMaritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHCarel Mae Cabaron100% (2)

- Study Guide IMODocument26 pagesStudy Guide IMOMaria Novia SoaresPas encore d'évaluation

- OPRC: Obligations of flag States under international conventionsDocument21 pagesOPRC: Obligations of flag States under international conventionsDanMckenziePas encore d'évaluation

- Comparison Between Rotterdam Hague Visby and HamburgDocument5 pagesComparison Between Rotterdam Hague Visby and HamburgAnkit Bordia100% (2)

- Difference Between Hague Visby HamburgDocument16 pagesDifference Between Hague Visby HamburgAnil RainaPas encore d'évaluation

- Hague-Visby Rules - WikipediaDocument20 pagesHague-Visby Rules - WikipediaHarel Santos RosaciaPas encore d'évaluation

- Differences between towage and salvage contractsDocument5 pagesDifferences between towage and salvage contractsGirish Menon100% (1)

- Ship BreakingDocument110 pagesShip Breakingreebenthomas100% (1)

- Afs ConventionDocument9 pagesAfs ConventionThomas JosePas encore d'évaluation

- Importance of Classification SocietiesDocument3 pagesImportance of Classification SocietiesUmairPas encore d'évaluation

- Classification Society - Capt - Saujanya SinhaDocument3 pagesClassification Society - Capt - Saujanya SinhaJitender MalikPas encore d'évaluation

- The Running Down Clause in Marine Insurance Contracts in Nigeria: An Overview.Document15 pagesThe Running Down Clause in Marine Insurance Contracts in Nigeria: An Overview.Tchinenye Elekwachi Okorie100% (1)

- Assignmant On ConventionsDocument98 pagesAssignmant On ConventionsRayhanSharifPas encore d'évaluation

- 07 UNCLOS Note To IMEI Class 1 StudentsDocument4 pages07 UNCLOS Note To IMEI Class 1 StudentsNishanth NishPas encore d'évaluation

- General AverageDocument18 pagesGeneral Averagemsirl101Pas encore d'évaluation

- Hague RulesDocument3 pagesHague RulesGlen Mac100% (1)

- Colregs Rule 02 ResponsibilityDocument1 pageColregs Rule 02 ResponsibilitykumarPas encore d'évaluation

- Seaworthiness and Reasoanable DispacthDocument14 pagesSeaworthiness and Reasoanable DispacthKaiyisah MalikPas encore d'évaluation

- Asm Master Oral Notes - As Per New SyllabusDocument262 pagesAsm Master Oral Notes - As Per New Syllabusshanti prakhar100% (1)

- MS Act 1958 PDFDocument354 pagesMS Act 1958 PDFसचिनरावत100% (1)

- Lof and Scopic HistoryDocument22 pagesLof and Scopic HistoryBansal SunilPas encore d'évaluation

- Convention For The Safe and Environmentally Sound RecyclingDocument23 pagesConvention For The Safe and Environmentally Sound RecyclingDharam TripathyPas encore d'évaluation

- Amendments to MLC 2006 on Captive SeafarersDocument5 pagesAmendments to MLC 2006 on Captive SeafarersAbdel Nasser Al-sheikh YousefPas encore d'évaluation

- Chapter 15 Principles of General Average PDFDocument22 pagesChapter 15 Principles of General Average PDFMuhammad Ashari Fitra RachmannullahPas encore d'évaluation

- Statutory and Mandatory CertificatesDocument14 pagesStatutory and Mandatory CertificatesGAMMA FACULTYPas encore d'évaluation

- LO4 - 2d Insurance H&M-P&IDocument28 pagesLO4 - 2d Insurance H&M-P&ISapna DasPas encore d'évaluation

- Contract Carriage Liability SeaDocument15 pagesContract Carriage Liability SeaDevarajan GovindaswamyPas encore d'évaluation

- Types of insurances for oil tankersDocument11 pagesTypes of insurances for oil tankersRanjeet SinghPas encore d'évaluation

- Carriage of Goods by SeaDocument7 pagesCarriage of Goods by SeaSatishfied Buzz100% (1)

- Commercial & Shipping LawDocument174 pagesCommercial & Shipping LawRavikiranPas encore d'évaluation

- Both To Blame Collision ClauseDocument2 pagesBoth To Blame Collision ClauseAnkit MauryaPas encore d'évaluation

- War Risk ClausesDocument4 pagesWar Risk Clausesxrobertk9073Pas encore d'évaluation

- Shipping Business Entities and RolesDocument5 pagesShipping Business Entities and Rolestahhan3107Pas encore d'évaluation

- Convention On Limitation of Liability For Maritime ClaimsDocument15 pagesConvention On Limitation of Liability For Maritime ClaimsRozaline Jacquet-BalianPas encore d'évaluation

- Charterers Liability CoverDocument13 pagesCharterers Liability CoverJayakumar Sankaran100% (1)

- Insurable Interest in Maritime LawDocument18 pagesInsurable Interest in Maritime LawSebin JamesPas encore d'évaluation

- Xtra 1st Class PDFDocument12 pagesXtra 1st Class PDFnishantPas encore d'évaluation

- Anti Fouling System ConventionDocument27 pagesAnti Fouling System ConventionSheshraj Vernekar100% (2)

- Amitava Banarjee Q-ADocument61 pagesAmitava Banarjee Q-AvaruagjPas encore d'évaluation

- Difference Between Towage & SalvageDocument11 pagesDifference Between Towage & SalvagegeorgesagunaPas encore d'évaluation

- Deepesh Merchant Jan 2013 - Apr 2013Document117 pagesDeepesh Merchant Jan 2013 - Apr 2013Rajesh Kumar Chaubey100% (1)

- 1) Previous Papers and Solutions-ASM INDIA-MASTER EXAMDocument401 pages1) Previous Papers and Solutions-ASM INDIA-MASTER EXAMshanti prakharPas encore d'évaluation

- 884 UNCLOS Class1 303Document804 pages884 UNCLOS Class1 303unisam youPas encore d'évaluation

- Domestic and International Carriage of Goods GLUE 3064: CharterpartyDocument47 pagesDomestic and International Carriage of Goods GLUE 3064: CharterpartyYong HyPas encore d'évaluation

- Cargo Insurance and Exclusion ClausesDocument21 pagesCargo Insurance and Exclusion ClausesManoj VarrierPas encore d'évaluation

- Marine InsuranceDocument8 pagesMarine InsuranceJoachim SaldanhaPas encore d'évaluation

- Salvage & Towage-1Document21 pagesSalvage & Towage-1GunasundaryChandramohanPas encore d'évaluation

- International Convention For The Safety of Life at Sea (SOLAS), 1974Document24 pagesInternational Convention For The Safety of Life at Sea (SOLAS), 1974Rohit MishraPas encore d'évaluation

- Towage and SalvageDocument5 pagesTowage and SalvageSagar AnchanPas encore d'évaluation

- An Insight To SOLAS ConventionDocument7 pagesAn Insight To SOLAS ConventionsasikumarmarinePas encore d'évaluation

- Maritime Labour ConventionD'EverandMaritime Labour ConventionÉvaluation : 5 sur 5 étoiles5/5 (1)

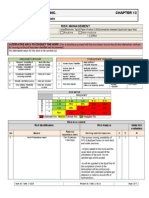

- Risk Assessment for LPSG Steam Pipe Hot Work in ERDocument6 pagesRisk Assessment for LPSG Steam Pipe Hot Work in ERdassi99Pas encore d'évaluation

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99Pas encore d'évaluation

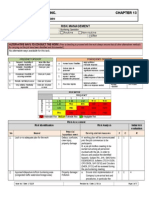

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Final Impa Pilot Ladder PosterDocument1 pageFinal Impa Pilot Ladder Posterdassi99Pas encore d'évaluation

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Pas encore d'évaluation

- DOT TANK INSPECTION RISK ASSESSMENTDocument6 pagesDOT TANK INSPECTION RISK ASSESSMENTdassi99100% (1)

- E1 - Purging & Gas Leakage Test SequencesDocument6 pagesE1 - Purging & Gas Leakage Test Sequencesdassi99Pas encore d'évaluation

- Qual 001 Supplier-Subcontractor Quality HistoryDocument1 pageQual 001 Supplier-Subcontractor Quality Historydassi99Pas encore d'évaluation

- Qual 002 Evaluation of Supplier - SubcontractorDocument1 pageQual 002 Evaluation of Supplier - Subcontractordassi99Pas encore d'évaluation

- RA 002 - BunkeringDocument5 pagesRA 002 - Bunkeringdassi99Pas encore d'évaluation

- Quick Reference - EnglishDocument44 pagesQuick Reference - Englishdassi99Pas encore d'évaluation

- Point Fortin - Umm Bab Port OptimoorDocument7 pagesPoint Fortin - Umm Bab Port Optimoordassi99Pas encore d'évaluation

- JAN 701B HandoutsDocument22 pagesJAN 701B Handoutsdassi990% (1)

- Installation Guide EnglishDocument11 pagesInstallation Guide Englishdassi99Pas encore d'évaluation

- LMAA Spring Seminar Owners' Damages for Repudiation Without Available MarketDocument16 pagesLMAA Spring Seminar Owners' Damages for Repudiation Without Available Marketdassi99Pas encore d'évaluation

- All About ECDISDocument12 pagesAll About ECDISdassi99Pas encore d'évaluation

- Piezoelectricity:: Principle Knock SensorsDocument1 pagePiezoelectricity:: Principle Knock Sensorsdassi99Pas encore d'évaluation

- Practical TestDocument4 pagesPractical Testdassi99100% (1)

- DNV CertificateDocument1 pageDNV Certificatedassi99Pas encore d'évaluation

- Shipping Law Handbook - Part E CollisionDocument21 pagesShipping Law Handbook - Part E Collisiondassi99Pas encore d'évaluation

- Cause and Effect Diagram - HHISHI (01-LIST - 1040438Document2 pagesCause and Effect Diagram - HHISHI (01-LIST - 1040438dassi99Pas encore d'évaluation

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDocument1 page4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- WISE Cargo User Manual - Ver 6 (A4)Document36 pagesWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Gas System Double WallDocument1 pageGas System Double Walldassi99Pas encore d'évaluation

- Calculating Damages by Clive AstonDocument10 pagesCalculating Damages by Clive Astondassi99100% (1)

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDocument3 pagesThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99Pas encore d'évaluation

- RTCM Auto Acquisition Vs Manual Guard Ring ARPADocument10 pagesRTCM Auto Acquisition Vs Manual Guard Ring ARPAdassi99Pas encore d'évaluation

- Winch Drum SpoolingDocument2 pagesWinch Drum Spoolingdassi99Pas encore d'évaluation

- Anodamine HPFGDocument69 pagesAnodamine HPFGmasgrahaPas encore d'évaluation

- Steam Power Board Problems PDFDocument6 pagesSteam Power Board Problems PDFKim Niño FelisminoPas encore d'évaluation

- Best Environmental Management Practice In: The Tourism SectorDocument20 pagesBest Environmental Management Practice In: The Tourism SectorjosePas encore d'évaluation

- Boiler Design and Operation ParametersDocument88 pagesBoiler Design and Operation ParametersKrishnan Santhanaraj100% (3)

- Attachment REPORTDocument39 pagesAttachment REPORTsemPas encore d'évaluation

- ASME PTC Performance Test Codes GuideDocument3 pagesASME PTC Performance Test Codes GuideVijayakumar SengottuveluPas encore d'évaluation

- 15 Basic Steps in Boiler Design - Meee Services - Mechanical DesignDocument8 pages15 Basic Steps in Boiler Design - Meee Services - Mechanical DesignAkiPas encore d'évaluation

- Power Plant SolutionsDocument38 pagesPower Plant SolutionsAnthropophobe NyctophilePas encore d'évaluation

- Acetone ProductionDocument8 pagesAcetone ProductionZahraa GhanemPas encore d'évaluation

- 418000E4422 R0 Write Up On Electro Hydraulic ControllerDocument10 pages418000E4422 R0 Write Up On Electro Hydraulic ControllerkoinsuriPas encore d'évaluation

- Care for clothes with LG Front Loading Washing MachinesDocument15 pagesCare for clothes with LG Front Loading Washing Machinesmohan_subramanyanPas encore d'évaluation

- Skema Jawapan Test2 Renewable EnergyDocument1 pageSkema Jawapan Test2 Renewable Energymohamad ashaziqPas encore d'évaluation

- Type of Boiler Install in ChinaDocument67 pagesType of Boiler Install in ChinaDarren LeongPas encore d'évaluation

- Pump capacity specifications for paper mill processDocument6 pagesPump capacity specifications for paper mill processhungPas encore d'évaluation

- LESER-Safety-Relief-Valve-High Performance Catalog en 07 2016Document102 pagesLESER-Safety-Relief-Valve-High Performance Catalog en 07 2016Mukiara LuffyPas encore d'évaluation

- Report On Boiler Modification For 100% Over Bed FiringDocument92 pagesReport On Boiler Modification For 100% Over Bed Firingparthi20065768Pas encore d'évaluation

- HAZOP Study Part IIDocument18 pagesHAZOP Study Part IIBoy farhanPas encore d'évaluation

- INSTRUCTIONS FOR INSTALL, OPERATION, AND SERVICING - NEW YORKER CL SERIES Cast Iron Oil Fired Boiler CLDocument52 pagesINSTRUCTIONS FOR INSTALL, OPERATION, AND SERVICING - NEW YORKER CL SERIES Cast Iron Oil Fired Boiler CLEdwin GeeqPas encore d'évaluation

- Automatic Level Control SystemsDocument10 pagesAutomatic Level Control Systemshafidhrahadiyan2100% (1)

- C2Document201 pagesC2AnecitoPas encore d'évaluation

- Aarambh Sample Paper - Class-Ix (Viii To Ix)Document12 pagesAarambh Sample Paper - Class-Ix (Viii To Ix)A MenonPas encore d'évaluation

- SC VSC 7000 Steamer Ss 0318Document2 pagesSC VSC 7000 Steamer Ss 0318jeremy_chan_35Pas encore d'évaluation

- Fona Hygenius Operator's ManualDocument80 pagesFona Hygenius Operator's ManualMicro Soft50% (2)

- Maintenance Schedule of Stenter Machine: ObjectsDocument14 pagesMaintenance Schedule of Stenter Machine: ObjectsAbel TayePas encore d'évaluation

- CIRCOR D-Series Technical BrochureDocument12 pagesCIRCOR D-Series Technical BrochureJAYPas encore d'évaluation

- 30 MW Power Generation ProcessDocument11 pages30 MW Power Generation ProcessMohan PPas encore d'évaluation

- Mechanical Progress Report SAMPLEDocument14 pagesMechanical Progress Report SAMPLERebecca WattsPas encore d'évaluation

- ISPE - SFC Pharma Water SysDocument18 pagesISPE - SFC Pharma Water SyskrunaljjPas encore d'évaluation

- Comparing Air and Steam Stripping Methods for Removing Organic PollutantsDocument10 pagesComparing Air and Steam Stripping Methods for Removing Organic PollutantsJose María Ureta UrzúaPas encore d'évaluation

- Adelaide Uni Mech Eng risk assessment guideDocument5 pagesAdelaide Uni Mech Eng risk assessment guideLove100% (1)