Académique Documents

Professionnel Documents

Culture Documents

ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specification

Transféré par

supady5751Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specification

Transféré par

supady5751Droits d'auteur :

Formats disponibles

ISO 9001:2008

ISO/TS 16949:2009

Added Requirement

Introduction 0.1 General 0.2 Process approach 0.3 Relationship with ISO 9004

Introduction 0.1 General 0.2 Process approach 0.3 Relationship with ISO 9004 0.4 Compatibility with other management systems

0.5 Goal of this Technical Specification

1. Scope

1 Scope1

The goal of this Technical Specification is a quality management system that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain. Manufacturing site must comply to be certified. Supporting functions cannot be certified on a stand-alone basis. Supporting functions such as design centers, corporate headquarters and distribution centers (remote or on-site) form part of the site audit as they support the site, but cannot obtain stand-alone ISO 16949 certification.

1.1 General 1.2 Application

1.1 General1 1.2 Application

2 Normative references ISO 9000:2005 3 Terms and definitions

2 Normative references ISO 9000:2005 3 Terms and definitions 3.1 Terms and definitions for the automotive industry

Header Header

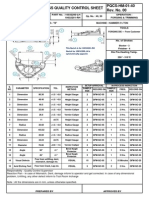

3.1.1 Control Plan

3.1.2 Design Responsible Organization 3.1.3 Error Proofing

A documented description of the systems and processes required for controlling the product see Appendix A of the standard. The organization responsible for establishing new or changing existing product specifications Product and manufacturing process design and development to prevent manufacturing of nonconforming product. Facility for inspection, test or calibration that may include but is not limited to chemical, metalilurgical, dimensional, physical, electrical or reliability testing. A control document is required that contains - Specific tests, evaluations, calibrations that a Lab is qualifified to perform - A list of the equipment, which it uses to perform the above, and - a list of methods and standards to which it performs the above. The process of making or fabricating - Production material - Production or service parts - Assemblies, or - Heat treating, welding, painting, plating, or other finishing services Activities based on process data aimed at the avoidance of maintanance problems by prediction of likely failure modes. Planned action to eliminate causes of equipment failure and unscheduled interruptions in production. Extra costs incurred in additional to contracted delivery. Location that supports sites and at which non-production processes occur. Location at which value-added processes occur.

3.1.4 Laboratory

3.1.5 Laboratory Scope

3.1.6 Manufacturing

3.1.7 Predictive Maintenance 3.1.8 Preventive Maintenance 3.1.9 Premium Freight 3.1.10 Remote Location 3.1.11 Site

3.1.12 Special Characteristic Product characteristic or manufacturing process parameter which can affect safety or compliance with regulations, fit, function, performance, or subsequent processing.

4 Quality management system 4.1 General requirements

4 Quality management Header system 4.1 General requirements 4.1.1 General requirements Ensuring control over outsourced Supplemental processes shall not absolve the organization of responsibility for conformity for all customer requirements. 4.2 Documentation requirements 4.2.1 General 4.2.2 Quality manual Header

4.2 Documentation requirements 4.2.1 General 4.2.2 Quality Manual

4.2.3 Control of Documents 4.2.3 Control of documents

4.2.3.1 Engineering specifications

Required to review, distribute, and implement customer engineering specs and changes w/in 2 weeks, and maintain documents and records of same, with customer approvals. The control of records shall satisfy, statutory, regulatory, and customer retention requirements.

4.2.4 Control of Records

4.2.4 Control of records 4.2.4.1 Records retention

5 Management responsibility 5 Management responsibility Header 5.1 Management commitment 5.1 Management commitment

5.1.1 Process efficiency

Top management required to review product realization and support processes and assure their efficiency.

5.2 Customer focus 5.3 Quality policy

5.2 Customer focus 5.3 Quality policy

5.4 Planning 5.4.1 Quality Objectives

5.4 Planning Header 5.4.1 Quality objectives 5.4.1.1 Quality objectives Top management required to define Supplemental quality objectives and measurements to be included in business plan and used to deploy quality policy.

5.4.2 Quality Management System Planning

5.4.2 Quality management system planning

5.5 Responsibility, authority 5.5 Responsibility, authority and communication and communication 5.5.1 Responsibility and Authority 5.5.1 Responsibility and authority 5.5.1.1 Responsibility for quality

5.5.2 Management Representative

5.5.2 Management representative 5.5.2.1 Customer representative

Managers promptly notified of nonconformance; personnel responsible for conformity to have authority to stop production; all shifts staffed with personnel responsible for conformity. Top management must designate customer representatives with responsibility and authority to ensure customer requirements are addressed.

5.5.3 Internal Communication 5.6 Management Review

5.5.3 Internal communication 5.6 Management review

Header

5.6.1 General

5.6.1 General

5.6.1.1 Quality management These reviews shall include all system performance requirements of the quality management system and its performance trends as an essential part of the continual improvement process. Part of the management review shall be the monitoring of quality objectives, and the regular reporting and evaluation of the cost of poor quality (see 8.4.1 and 8.5.1). These results shall be recorded to provide, as a minimum, evidence of the achievement of -the quality objectives specified in business plan, and -customer satisfaction with product supplied. MR input must include analysis of actual and potential field failures and their impact on quality, safety, or the environment. Header

5.6.2 Review Input

5.6.2 Review input 5.6.2.1 Review input Supplemental

5.6.3 Review Output 6 Resource management 6.1 Provision of resources 6.2 Human resources 6.2.1 General 6.2.2 Competence, Training and Awareness

5.6.3 Review output 6 Resource management 6.1 Provision of resources

6.2 Human resources Header 6.2.1 General 6.2.2 Competence, training and awareness 6.2.2.1 Product design skills The organization shall ensure that personnel with product design responsibility are competent to achieve design requirements and are skilled in applicable tools and techniques. 6.2.2.2 Training The organization must have a procedure to identify training needs and achieve competence. Personnel must be qualified for tasks performed. The organization must provide OJT to those affecting conformity to product requirements. Personnel must be informed about the consequences of nonconformity.

6.2.2.3 Training on the job

6.2.2.4 Employee motivation and empowerment

The organization must have a process to motivate employees to achieve objectives and improve capabilities, including technological awareness; The organization must have a process to measure employee awareness of how they contribute to quality objectives. The organization must use a multidisciplinary approach to facility planning that optimizes operations, focusing on lean manufacturing and effectiveness of the quality management system. The organization must have contingency plans to satisfy customer requirements in the event of emergencies.

6.3 Infrastructure

6.3 Infrastructure 6.3.1 Plant, facility and equipment planning

6.3.2 Contingency plans

6.4 Work environment

6.4 Work environment 6.4.1 Personnel safety to achieve conformity to product requirements 6.4.2 Cleanliness of premises 7 Product realization 7.1 Planning of product realization 7.1.1 Planning of product realization Supplemental

Product safety and employee safety must be addressed, especially in design and development and in manufacturing. Premises must be clean and orderly. Header

7 Product realization 7.1 Planning of product realization

7.1.2 Acceptance criteria

7.1.3 Confidentiality

Customer requirements and its technical spec references must be included in planning product realization. The organization must define acceptance criteria, where required with customer approval. The organization must ensure confidentiality of customer information.

7.1.4 Change control

7.2 Customer-related processes 7.2.1 Determination of requirements related to the product

7.2 Customer-related processes 7.2.1 Determination of requirements related to the product 7.2.1.1 Customerdesignated special characteristics 7.2.2 Review of requirements related to the product 7.2.2.1 Review of requirements related to the product Supplemental 7.2.2.2 Organization manufacturing feasibility

The organization shall have a process to control and react to changes that impact product realization. The effects of any change, including those changes caused by any supplier, shall be assessed and verificaiton and validation activities shall be defined, to ensure compliance with customer requirements. Changes shall be validated before implementation. For proprietary designs, impact on form, fit and function (including performance and/or durability) shall be reviewed with the customer so that all effects can be properly evaluated. When required by the customer, additional verification/identification requirements, such as those required for new product introduction, shall be met. NOTE 1: Any product realization change affecting customer requirements requires notification to, and agreement from, the customer. NOTE 2: The above requirement applies to product and manufacturing Header

The organization must demonstrate conformity to customer requirements for fulfilling special characteristics.

7.2.2 Review of requirements related to the product

Waiving formal reviews shall require customer authorization.

The organization must investigate, confirm, and document the manufacturing feasibility of the proposed product in the contract review process, including risk analysis.

7.2.3 Customer Communication

7.2.3 Customer communication

7.2.3.1 Customer communication Supplemental 7.3 Design and development 7.3 Design and development 7.3.1 Design and Development Planning 7.3.1 Design and development planning 7.3.1.1 Multidisciplinary approach

The organization must have the ability to communicate necessary information in a customer-specified language and format.

The organization must use a multidisciplinary approach to prepare for product realization, including: accounting for special characteristics, FMEAs, and control plans.

7.3.2 Design and Development Inputs

7.3.2 Design and development inputs 7.3.2.1 Product design input The organization shall identify, document, and review product design input requirements, including the following: -customer requirements (contract review) such as special characteristics (see 7.3.2.3), identification, traceability, and packaging; -use of information: the organization shall have a process to deploy information gained from previous design projects, competitor analysis, supplier feedback, internal input, field data, and other relevant sources, for current and future projects of a similar nature; -targets for conformity to product requirements, life, reliability, 7.3.2.2 Manufacturing The organization shall identify, process design input document, and review manufacturing process design input requirements, including: -product design output data, -targets for productivity, process capability, and cost, -customer requirements,if any, and -experience from previous developments.

7.3.2.3 Special characteristics

The organization must identify special characteristics, such as product characteristics and process parameters, and: include them in the control plan, comply with customerspecified definitions and symbols, & identify process control documents with the customer's special symbol to include the steps affecting special characteristics. NOTE The manufacturing process design includes the use of errorproofing methods to a degree appropriate to the magnitude of the problems and commensurate with the risks encountered. Product design outputs shall be expressed in terms that can be verified and validated against product design input requirements. The product design output shall include: -design FMEA, reliability results; -product special characteristics and specifications; -product error-proofing as appropriate; -product definition, incuding drawings or mathematically based data; -product design review results; and -diagnostic guidelines where applicable.

7.3.3 Design and Development Outputs

7.3.3 Design and development outputs 7.3.3.1 Product design outputs Supplemental

7.3.3.2 Manufacturing process design output

7.3.4 Design and Development Review

7.3.4 Design and development review 7.3.4.1 Monitoring

The manufacturing process design output shall be expressed in terms that can be verified against manufacturing process design input requirements and validated. The manufacturing process design output shall include: -specifications and drawings -manufacturing process flow chart/layout, -manufacturing process FMEAs, -control plan (see 7.5.1.1), -work instructions, -process approval acceptance criteria, -data for quality, reliability, maintainability, and measurability, -results of error-proofing activities, as appropriate, and -methods of rapid detection and feedback of product/manufacturing process nonconformities. Management review input shall include measurements at specified stages of design and development, including quality risks, costs, lead times, critical paths, and others.

7.3.5 Design and Development Verification 7.3.6 Design and Development Validation

7.3.5 Design and development verification 7.3.6 Design and development validation 7.3.6.1 Design and development validation Supplemental

Design and development validation shall be performed in accordance with customer requirements, including program timing. When required, the organization shall have a prototype program and control plan. The organization shall use, wherever possible, the same suppliers, tooling, and manufacturing processes as used in production. All performance testing activities shall be monitored for timely completion and conformity to requirements. While services may be outsourced, the organization shall be reponsible for the outsourced services, including technical leadership.

7.3.6.2 Prototype program

7.3.6.3 Product approval process

The organization shall conform to a product and manufacturing process approval procedure recognized by the customer. NOTE Product approval should be subsequent to the verification of the manufacturing process. The product and manufacturing rocess approval procedure shall also be applied to suppliers. Design and development changes include all changes during the product program life. (see 7.1.4) Header

7.3.7 Control of Design and Development Changes 7.4 Purchasing 7.4.1 Purchasing Process

7.3.7 Control of design and development changes 7.4 Purchasing 7.4.1 Purchasing process 7.4.1.1 Statutory and regulatory conformity

All purchased products and materials must conform to statutory and regulatory requirements. The organization shall perform supplier quality management system development with the goal of supplier conformity with this Technical Specification. Conformity with ISO 9001:2008 is the first step in achieving this goal. NOTE The priortization of suppliers for development depends on, for example the supplier's quality performance and the importance of the product supplied.

7.4.1.2 Supplier quality management system development

Unless otherwise specified by the customer, suppliers to the organization shall be third party, registered to ISO 9001:2008 by an accredited third7.4.1.3 Customer-approved When specified by the contract (e.g. sources customer engineering drawing, specification), the organization shall purchase products, materials, or services from approved sources. The use of customer-designated sources, including tool/gauge suppliers, does not relieve The organization of responsibility for quality of the purchased products.

7.4.2 Purchasing Information

7.4.2 Purchasing information

7.4.3 Verification of Purchased Product

7.4.3 Verification of purchased product 7.4.3.1 Incoming product conformity to requirements

7.4.3.2 Supplier monitoring

The organization shall have a process to assure the quality of purchased product (see 7.4.3), utilizing one or more of the following methods: -receipt of, and evaluation of, statistical data by the organization, -receiving inspection and/or testing, such as sampling based on performance; -second or third party assessements or audits of supplier sites, when coupled with records of acceptable delivered product conformity to requirements; -part evaluation by a designated laboratory; -another method agreed with the customer. Suppliers shall be monitored through the following indicators: -product conformity; -customer disruptions, including field returns; -delivery schedule performanc (including incidents of premium freight); -special status customer notifications related to quality or delivery issues. The organization shall promote supplier monitoring of the performance of their manufacturing processses. Header

7.5 Production and service provision 7.5.1 Control of Production and Service Provision

7.5 Production and service provision 7.5.1 Control of production and service provision

7.5.1.1 Control plan

The organization shall: -develop control plans (see Annex A) at the system, subsystem, component, and/or material level for the product supplied, including those for processes producing bulk materials as well as parts, and -have a control plan for pre-launch and production that takes into account the design FMEA and manufacturing process FMEA outputs. The control plan shall: -list the controls used for the manufacturing process control, -include the methods for monitoring of control exercised over special characteristics (see 7.3.2.3) defined by both the customer and the organization, -include the customer-required information, if any, and -initiate the specified reaction plan (8.2.3.1) when the process becomes unstable or not statistically capable. Control plans shall be reviewed and updated when any change occurs affecting product, manufacturing Work instructions must be available for all processes affecting product conformity.

7.5.1.2 Work instructions

7.5.1.3 Verification of job set-ups

Job set-ups shall be verified, and work instructions will be available for job setups.

7.5.1.4 Preventive and predictive maintenance

The organization shall identify key process equipment and develop effective planned total preventive mainteance (more)

7.5.1.5 Management of production tooling

The organization shall provide resources for tool and gauge design, fabrication, identification, maintenance, and change.

7.5.1.6 Production scheduling

Production shall be scheduled to meet customer requirements.

7.5.1.7 Feedback of information from service

A process for communicating "service concerns" shall be established to ensure awareness of quality issues outside its organization.

7.5.1.8 Service agreement with customer

The organization shall verify the effectiveness of resources utilized to meet service agreements with customers.

7.5.2 Validation of Processes 7.5.2 Validation of for Production and Service processes for production Provision and service provision 7.5.2.1 Validation of processes for production and service provision Supplemental 7.5.3 Identification and 7.5.3 Identification and Traceability traceability 7.5.3.1 Identification and traceability Supplemental 7.5.4 Customer Property 7.5.4 Customer property 7.5.4.1 Customer-owned production tooling 7.5.5 Preservation of product

Scope of validation is increased to all processes for production and service provision.

The limitation "where appropriate" is removed from the requirement for suitable identification. Customer-owned tools and equipment shall be permanently marked.

7.5.5 Preservation of Product

7.5.5.1 Storage and inventory

The condition of stock in inventory shall be assessed at planned intervals, and inventory shall be managed to control obsolete product in a manner similar to nonconforming product.

7.6 Control of monitoring and measuring Equipment

7.6 Control of monitoring and measuring equipment 7.6.1 Measurement system analysis

Statistical studies must be used to analyze variation in measuring and test systems; must meet customer requirements or be approved by customer. 7.6.2 Calibration/verification Calibration records must include records standards against which equipment is calibrated, revsions following engineering changes, any out of spec readings and the likely impact of same, statements of conformity after calibration, and notification to customer if suspect product has been shipped. 7.6.3 Laboratory Header requirements 7.6.3.1 Internal laboratory A laboratory facilty must have a defined scope, which must be included in the quality management system documentation. The lab shall specify and implement specific requirements (more)

7.6.3.2 External laboratory

External laboratories used must have a defined scope, and be acceptable to the customer. Header

8 Measurement, analysis and improvement 8.1 General

8 Measurement, analysis and improvement 8.1 General 8.1.1 Identification of statistical tools

Appropriate statistical tools shall be determined during advanced quality planning and included in the control plan.

8.1.2 Knowledge of basic statistical concepts

Basic statistical concepts shall be understood and utilized throughout the organization.

8.2 Monitoring and 8.2 Monitoring and measurement measurement 8.2.1 Customer Satisfaction 8.2.1 Customer satisfaction 8.2.1.1 Customer Performance indicators for customer satisfaction Supplemental satisfaction shall include: delivered part quality performance, customer disruptions, delivery schedule performance, and customer notifications about quality or delivery issues. The organization shall monitor the performance of manufacturing processes to demonstrate compliance with customer requirements for product quality and efficiency.

8.2.2 Internal Audit

8.2.2 Internal audit

8.2.2.1 Quality management The organization shall verify system audit compliance with this Technical Specification. 8.2.2.2 Manufacturing The organization shall audit each process audit manufacturing process to determine its effectiveness.

8.2.2.3 Product audit

The organization shall audit products at appropriate stages of production and delivery to verify conformity to all specified requirements (more) Internal audits shall cover all quality management related processes, activities and shifts, and shall be scheduled according to an annual plan. The organization shall have auditors who are qualified to audit the requirements of this Technical Specification.

8.2.2.4 Internal audit plans

8.2.2.5 Internal auditor qualification

8.2.3 Monitoring and Measurement of Processes

8.2.3 Monitoring and measurement of processes

8.2.3.1 Monitoring and measurement of manufacturing processes

The organization shall perform process studies on all new manufacturing processes, document them, and include objectives for successful operation; the organization shall maintain and implement a control plan, and install a correction plan in the event a process becomes unstable or incapable (more...)

8.2.4 Monitoring and Measurement of Product

8.2.4 Monitoring and measurement of product 8.2.4.1 Layout inspection and functional testing

A layout inspection must be conducted for each product, and the results made available to customers. The organization shall provide resources and qualified personnel to maintain appearance.

8.2.4.2 Appearance items

8.3 Control of nonconforming product

8.3 Control of nonconforming product 8.3.1 Control of nonconforming product Supplemental 8.3.2 Control of reworked product

Parts with unidentified or suspect status shall be classified as nonconforming. Instructions for rework shall be accessible and utilized.

8.4 Analysis of data

8.5 Improvement 8.5.1 Continual Improvement

8.3.3 Customer information Customers shall be informed promptly when a nonconforming product has been shipped. 8.3.4 Customer waiver The organization shall obtain a waiver to permit further processing of product different from that which is approved (more) 8.4 Analysis of data 8.4.1 Analysis and use of Trends in quality and operational data performance shall be analyzed in support of priorities for prompt solutions, customer-related decisionmaking and planning, and an information system for timely reporting of product information arising from usage. 8.5 Improvement Header 8.5.1 Continual improvement 8.5.1.1 Continual The organization shall define a process improvement of the for continual improvement. organization

8.5.1.2 Manufacturing process improvement 8.5.2 Corrective Action 8.5.2 Corrective action 8.5.2.1 Problem solving

Manufacturing process improvement shall focus on control and reduction of variation. The organization shall have a defined process for problem solving leading to root cause identification and elimination. The organization shall use errorproofing methods in their corrective action process. The organization shall apply corrective actions to other similar products and processes. The organization shall analyze customer-rejected parts and maintain accessible records; the organization shall perform analysis and corrective action. Heading The control plan shall cover phases of prototype, pre-launch, and production. The control plan shall include at a minimum 5 basic elements (more)

8.5.2.2 Error-proofing

8.5.2.3 Corrective action impact 8.5.2.4 Rejected product test/analysis

8.5.3 Preventive Action

8.5.3 Preventive action Annex A (normative) Control plan A.1 Phases of the control plan A.2 Elements of the control plan

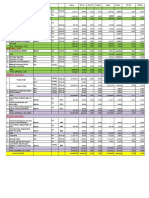

Compliance with TS16949

Rating 1= no compliance 2= partial 3= full 4= via subcon NA=not applicable N/A N/A N/A N/A N/A

Rationale/Evidence

Assesso r

ESD = Chip design OK, Board design to be verified. Refer to clause 7.

Some manufacturing sites are TS-certified; others need to be verified. This means that NV, even if it outsourcs the manufacture of parts, is subject to site audits.

N/A N/A

N/A N/A N/A N/A

Definition only

Definition only

Definition only

Definition only

Definition only

Definition only

Definition only

Definition only

Definition only Definition only Definition only Definition only

N/A 3 2 UL 9001 Certified Outsourcing controls exist; Evidence of NV acknowledgement of responsibility for adherence to customer requirements needs to be verified.

N/A 3 3 UL 9001 Certified UL 9001 Certified

UL 9001 Certified

Change review infrastructure exists; evidence needed to demonstrate compliance with customer time frames and record of approval. UL 9001 Certified Not known that this is happening, but the infrastructure exists to meet this requirement, if identified during Contract Review.

3 2

N/A 3 UL 9001 Certified

Reportedly product realization and distribution efficiencies are reviewed in MR; need to verify review of design for efficiency. UL 9001 Certified

3 N/A

N/A 3 2

UL 9001 Certified Top management concerned with quality; need to verify objectives, measurements, inclusion in business plan, and use in deploying quality policy. UL 9001 Certified

UL 9001 Certified

3 2

UL 9001 Certified "Hold" practices in place, a process is documented, but needs to be reviewed. SiOps managers receive a weekly digest of CARs created. UL 9001 Certified Marketing, CPMs, and CQEs are assigned to address customer requirements, but documented understandings of roles and responsibilities are not clear across functions. UL 9001 Certified

3 2

3 N/A

UL 9001 Certified

Some quality objectives and customer satisfaction data reviewed; cost of good/poor quality requires review.

3 2

UL 9001 Certified Not enough information to form definite opinion; needs to be reviewed. UL 9001 Certified UL 9001 Certified

3 N/A 3 N/A 3 3 3

UL 9001 Certified UL 9001 Certified Evidenced by successful, timely product introductions.

Training procedure exists; verify if it addresses automotive requirements. Further definition of OJT per TS required. Evidence of OJT apparently available at least for some functions. Need to validate that consequences of nonconformity are being communicated.

Recognition for technical accomplishments; on-site technical symposia; presently no measurement of awareness level. (Employee survey)

3 2/3

UL 9001 Certified Support functions include design for manufacturing and quality principles. (Larry Sladewski and Bob Jafari) Supply chain resiliency plans are being developed with each supplier.

3 2

UL 9001 Certified ISO 14K certified, plus EHS and safety programs; need to verify safety status at CMs. Needs work in some areas.

2 N/A 3 2

UL 9001 Certified Current MRD process needs to be verified. POR = technical spec; controls need to be verified. Verify Contract Review includes customer acceptance criteria. Emptoris database and controls need to be verified.

CRB, PCN, ECO processes seem to be under control; customer communication process is questionable.

N/A N/A 3

UL 9001 Certified

Need to research how to address special characteristics.

UL 9001 Certified

NV has a product waiver process, but it does not apply to documentation. Reportedly Contract Review partially addresses feasibility; requires confirmation. Status of risk analysis unknown.

1/2

UL 9001 Certified

2/3

Appears technically feasible.

3 3 1/2

UL 9001 Certified UL 9001 Certified Multidisciplinary approach frequently utilized; application to special characteristics, FMEAs, and control plans unknown. (Forward-looking lessons learned) UL 9001 Certified Part of regular practices, but capture of lessons learned may be informal; needs to become formalized as deliverables within the PD/NPI processes.

3 2

Part of regular practices, but capture of lessons learned may be informal; needs to become formalized as deliverables within the manufacturing process design phase.

Infrastructure and procedures for marking and traceability exist; ability to extend to processes, and to specialize to ind

3 1

UL 9001 Certified Some currently in practice, some not; need to insert all deliverables in the formal NPI/PD process.

Some currently in practice, some not; need to insert all deliverables in the formal NPI/PD process.

3 1

UL 9001 Certified Some currently in practice, some not; need to insert all deliverables in the formal NPI/PD process. UL 9001 Certified UL 9001 Certified Validation processes currently exist and will most likely satisfy the standard. However field return data is not currently formalized. Evidenced through the ES, QS, and PS sample production that parallels developmental phases. Additional samples are produced outside of the ES, QS, and PS flow.

3 3 2

A product approval by customer exists, but not known if it meets TS. Status with suppliers unknown.

UL 9001 Certified, but gaps need to be reviewed.

N/A 3 3 UL 9001 Certified Already part of corporate product and environmental compliance program. Capability to determine ISO status of suppliers exists. Many already ISO-registered, except 2 substrate suppliers and SLT/warehouse at JSI. Developing TS-compliant supplier base can be done in time.

2/3

NV can agree to use customerspecified sources; acknowledgement of responsibility for quality when using customer-specified sources needs to be verified.

UL 9001 Certified

3 3

UL 9001 Certified Warehouse procedures address conformity of incoming product.

Suppliers are monitored; exact metrics used need to be verified.

3 3

UL 9001 Certified UL 9001 Certified

Systems for controlling prelaunch production exist. Review needed to determine if it accounts for FMEA outputs.

Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification.

Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. Assumed to exist within production environments at SiOps suppliers that are TS certified, but needs to be verified. Where applicable at NV support sites, need verification. UL 9001 Certified

Validation processes exist; need to verify scope and reporting.

3 3

UL 9001 Certified Identification and traceability practices are already uniform. UL 9001 Certified Need to verify that product validation boards are identified and controlled. UL 9001 Certified

3 2

Inventory management already covered by spec.

3 1

UL 9001 Certified Formalizing NV's GR&R on all process and test metrology needs to be done.

Calibration by SE Labs is in place for all NV equipment. Need to verify that this process exists for all suppliers, and meets the TS requirements.

TBD 1 Engineering laboratories are considered out of scope. Controls are limited, not subject to audit. Gold standards and reference units are used in production environments; need to verify use of standards and compliance to ASTM in laboratories. Accreditation to ISO/IEC 17025 may serve as a External labs practices need to be verified to be in compliance with TS; e.g. REL test labs.

N/A 3 2 UL 9001 Certified Statistical tools used in quality planning e.g. JMP; control plans apply to actual production sites, but advance quality planning practices are questionable. Evidenced by use in analyses and presentations across spectrum of support site activities.

3 3 3

UL 9001 Certified UL 9001 Certified Continual evaluation of customer satisfaction evidenced by records of surveys and analyses.

UL 9001 Certified

Internal audit process established in accordance with ISO 9001. Representatives gather and analyze data on effectiveness of CMs; need to verify coverage of actual manufacturing processes. Representatives conduct supplier audits; need to review audit of specific products at stages of production. Internal audit plan covers appropriate scope with annual plan.

Trained and experienced ISO auditors available for any special training required for this TS. UL 9001 Certified

Representatives oversee CMs in fulfillment of this requirement; need to verify scope of their activities.

3 N/A

UL 9001 Certified Not applicable to support site; need to check application to manufacturing site. Not applicable to support site; need to check application to manufacturing site. UL 9001 Certified Consistent with NV practice, although need to check for documentation of same. Extent of rework documentation needs to be reviewed. Consistent with NV policy and practice. Consistent with NV policy and practice.

N/A

3 2

3 3

UL 9001 Certified Weekly digest of quality and operational data available to support planning and decisionmaking.

N/A 3 2

UL 9001 Certified Company practices Plan-DoCheck-Act cycle of ISO.

3 3

Representatives oversee CMs to improve manufacturing processes. UL 9001 Certified 8D process is institutionalized as part of the CAR system.

Practice philosophy of eliminating the root cause of errors. Need to globalize corrective actions is documented; review for examples. Established RMA procedure and Failure Analysis capabilitiy, along with relevant records.

3 TBD 3

UL 9001 Certified

Implemented through the X, V, and P staged release program. Applicable to production environment.

N/A

Vous aimerez peut-être aussi

- Mark PriestleyDocument373 pagesMark PriestleyPritam Sarkar100% (2)

- Project Report On HTML Based Web Development BlogDocument30 pagesProject Report On HTML Based Web Development BlogCricTalk50% (2)

- ACT100Document35 pagesACT100Adam Ong100% (3)

- 4M RecordDocument3 pages4M Recordpulkit gargPas encore d'évaluation

- Project Plan For Implementation of The Quality Management SystemDocument6 pagesProject Plan For Implementation of The Quality Management SystemSafa CharfiPas encore d'évaluation

- Seven Steps To Mastering Business Analysis - SummaryDocument15 pagesSeven Steps To Mastering Business Analysis - SummaryValentino DoriaPas encore d'évaluation

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751Pas encore d'évaluation

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaPas encore d'évaluation

- Process Validation Record: Format No.: - DateDocument2 pagesProcess Validation Record: Format No.: - DateRaja DuraiPas encore d'évaluation

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahPas encore d'évaluation

- PFMEA Review - MOM FormatDocument2 pagesPFMEA Review - MOM FormatMASU BRAKE PADS QAPas encore d'évaluation

- Potential Failure Mode and Effects Analysis Process FmeaDocument24 pagesPotential Failure Mode and Effects Analysis Process Fmearodeth marquezPas encore d'évaluation

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapPas encore d'évaluation

- % Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostDocument10 pages% Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostmuthuselvanPas encore d'évaluation

- CQI 9 Internal Audit Observations 07.04.11Document2 pagesCQI 9 Internal Audit Observations 07.04.11Asif AliPas encore d'évaluation

- OCP of HR Process-03Document2 pagesOCP of HR Process-03sathyabalaramanPas encore d'évaluation

- Production Validation TemplateDocument1 pageProduction Validation Templatesathyabalaraman100% (1)

- APQP Elements: 1 Customer OrderDocument13 pagesAPQP Elements: 1 Customer OrderShanmugam BalasubramaniamPas encore d'évaluation

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanPas encore d'évaluation

- Customer Satisfaction Measurment ProcedureDocument1 pageCustomer Satisfaction Measurment ProcedureAnkur GuptaPas encore d'évaluation

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SPas encore d'évaluation

- 1514170838520541Document102 pages1514170838520541kt44974085Pas encore d'évaluation

- 04 Alternate Process ControlDocument24 pages04 Alternate Process ControlRaja DuraiPas encore d'évaluation

- NcManagement - SA1 - 2021Document13 pagesNcManagement - SA1 - 2021Nagarajan100% (1)

- 02 Manufacturing Process Design InputsDocument3 pages02 Manufacturing Process Design InputsRaja DuraiPas encore d'évaluation

- VDA 6 - 3 Questionnaire Summary of Changes PDFDocument6 pagesVDA 6 - 3 Questionnaire Summary of Changes PDFAnonymous CW8L9FkuPas encore d'évaluation

- Control PlanDocument4 pagesControl PlanRakesh PandeyPas encore d'évaluation

- Format No - Qf-As-02 - Daily Production Log BookDocument2 pagesFormat No - Qf-As-02 - Daily Production Log BookDisha ShahPas encore d'évaluation

- NC Analysis Report 3L5Y-Blank FormatDocument160 pagesNC Analysis Report 3L5Y-Blank Formatshobha shelarPas encore d'évaluation

- 390018-Lito Garcia Junio-Production Team LeaderDocument3 pages390018-Lito Garcia Junio-Production Team LeaderATKPas encore d'évaluation

- Lesson LearnedDocument1 pageLesson LearnedR KumarPas encore d'évaluation

- Qualityprinciplesandconcepts 141214012537 Conversion Gate01 PDFDocument32 pagesQualityprinciplesandconcepts 141214012537 Conversion Gate01 PDFSuhendi SSPas encore d'évaluation

- COMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingDocument4 pagesCOMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingISODCC DSPIPas encore d'évaluation

- Form30TM Advanced Product Quality Planning-APQPDocument1 pageForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiPas encore d'évaluation

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharPas encore d'évaluation

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarPas encore d'évaluation

- Control PlanDocument6 pagesControl PlanFahmy Khoerul HudaPas encore d'évaluation

- Roles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017Document18 pagesRoles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017DhinakaranPas encore d'évaluation

- IATF Additional Requirement LocationsDocument6 pagesIATF Additional Requirement LocationsSudhagar50% (2)

- CSR - Audit ChecklistDocument2 pagesCSR - Audit Checklistmahesk_dmPas encore d'évaluation

- Cohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NameDocument2 pagesCohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NamePrakash kumarTripathiPas encore d'évaluation

- ZED PresentationDocument13 pagesZED PresentationSatbir SinghPas encore d'évaluation

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush NarangPas encore d'évaluation

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaPas encore d'évaluation

- MRM Agenda April 2018-July 18Document4 pagesMRM Agenda April 2018-July 18ukavathekarPas encore d'évaluation

- PFMEA Question PaperDocument4 pagesPFMEA Question PaperGarv The PridePas encore d'évaluation

- 4M Change RecordDocument6 pages4M Change RecordRAHUL SINGHPas encore d'évaluation

- 8 D For ShrinkageDocument6 pages8 D For ShrinkageSachin KumbharPas encore d'évaluation

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamPas encore d'évaluation

- DS-09-01 R0 Communication During ChangeDocument1 pageDS-09-01 R0 Communication During ChangeDhinakaranPas encore d'évaluation

- AQLChart PDFDocument2 pagesAQLChart PDFAnonymous tv3qpx2Pas encore d'évaluation

- PQCS Tube Flange Rough - ForgingDocument1 pagePQCS Tube Flange Rough - ForgingBalram JiPas encore d'évaluation

- Corrective Actions For Not Ok Charcteristics: Months - July13Document1 pageCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarPas encore d'évaluation

- IATF Rules Dec2016Document14 pagesIATF Rules Dec2016anthony dunnPas encore d'évaluation

- Marathan Motor (I) PVT LTD.: 5S Committee-PlantDocument4 pagesMarathan Motor (I) PVT LTD.: 5S Committee-PlantRishi GautamPas encore d'évaluation

- APQPDocument85 pagesAPQProhitbaggaPas encore d'évaluation

- Grafica XRDocument1 pageGrafica XRAlfonso CruzPas encore d'évaluation

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingDocument1 pageVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshPas encore d'évaluation

- Layout Inspection TemplateDocument2 pagesLayout Inspection TemplatesathyabalaramanPas encore d'évaluation

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DPas encore d'évaluation

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Document50 pagesSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanPas encore d'évaluation

- Audit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsDocument3 pagesAudit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsganrashPas encore d'évaluation

- Manufacturing Facilities A Complete Guide - 2019 EditionD'EverandManufacturing Facilities A Complete Guide - 2019 EditionPas encore d'évaluation

- Event Business Plan TemplateDocument1 pageEvent Business Plan Templatesupady5751Pas encore d'évaluation

- ISO STD Development ProcessDocument1 pageISO STD Development Processsupady5751Pas encore d'évaluation

- Notary Jurat 1Document1 pageNotary Jurat 1supady5751Pas encore d'évaluation

- Six Sigma Black Belt KnowledgeDocument16 pagesSix Sigma Black Belt Knowledgesupady5751Pas encore d'évaluation

- Online Grading SystemDocument31 pagesOnline Grading SystemShen ShenPas encore d'évaluation

- Unit - 8Document32 pagesUnit - 8Sai Raja GPas encore d'évaluation

- M 001 ManualDocument22 pagesM 001 ManualPravish XtasyPas encore d'évaluation

- Materials Managemen TDocument21 pagesMaterials Managemen TAkash NiwalPas encore d'évaluation

- Gap Analysis ISO 9001 Checklist - SafetyCultureDocument9 pagesGap Analysis ISO 9001 Checklist - SafetyCulturegerardo vega francoPas encore d'évaluation

- MegaMart Online Shopping Application ReportDocument40 pagesMegaMart Online Shopping Application ReportNikhil TewariPas encore d'évaluation

- Army TankDocument389 pagesArmy Tankgeorge lucasPas encore d'évaluation

- Project Report: "Webblog" Techindustan Private Ltd. MohaliDocument119 pagesProject Report: "Webblog" Techindustan Private Ltd. MohaliNikola TeslaPas encore d'évaluation

- Recreation & Sport Facility Design Guide: JULY 2018Document11 pagesRecreation & Sport Facility Design Guide: JULY 2018MaH TiR100% (1)

- Quickstart Service For PanoramaDocument9 pagesQuickstart Service For PanoramaAchmad AzisPas encore d'évaluation

- Seaway 07.04 0003 ADocument63 pagesSeaway 07.04 0003 AAstera VeritasPas encore d'évaluation

- IT312 Systems Integration and Architecture PDFDocument55 pagesIT312 Systems Integration and Architecture PDFJayzon UmangayPas encore d'évaluation

- Software Engineering and Project Management NotesDocument22 pagesSoftware Engineering and Project Management NotesPari BhandarkarPas encore d'évaluation

- ISBT Guidelines For Validation of Automated Systems in Blood Establishments PDFDocument25 pagesISBT Guidelines For Validation of Automated Systems in Blood Establishments PDFGloryPas encore d'évaluation

- School Library Management SystemDocument52 pagesSchool Library Management SystemBiplab AcharjeePas encore d'évaluation

- Hardware DevelopmentDocument11 pagesHardware DevelopmentTariku MantafoPas encore d'évaluation

- RAD Document For Fixed Asset Management SystemDocument48 pagesRAD Document For Fixed Asset Management SystemmebreaPas encore d'évaluation

- Template-FYP Project Report - 13122018Document24 pagesTemplate-FYP Project Report - 13122018Afaq KhaliqPas encore d'évaluation

- Landscape DesignDocument37 pagesLandscape DesignScott Andrew SerranoPas encore d'évaluation

- Software Engineering Questions and Answers Set 7 - Questions & AnswersDocument3 pagesSoftware Engineering Questions and Answers Set 7 - Questions & AnswersKripa SindhuPas encore d'évaluation

- Oregon Department of Transportation: State of Oregon RFP DASPS-1153-15 Attachment P: System RequirementsDocument70 pagesOregon Department of Transportation: State of Oregon RFP DASPS-1153-15 Attachment P: System RequirementsCOMACO DATAPas encore d'évaluation

- FDD - FCUBS12.0.3 - CASA - Transaction - RestrictionDocument38 pagesFDD - FCUBS12.0.3 - CASA - Transaction - RestrictionVoleti SrikantPas encore d'évaluation

- Jss Science and Technological University (Formerly SJCE), MysuruDocument31 pagesJss Science and Technological University (Formerly SJCE), MysuruDhananjay JahagirdarPas encore d'évaluation

- Sandra Furterer - Systems Engineering - Holistic Life Cycle Architecture Modeling and Design With Real-World Applications-CRC Press (2021)Document400 pagesSandra Furterer - Systems Engineering - Holistic Life Cycle Architecture Modeling and Design With Real-World Applications-CRC Press (2021)lynn zigaraPas encore d'évaluation

- Visvesvaraya Technological University: "Jnanasangama", Belagavi, Karnataka, India-590 014Document9 pagesVisvesvaraya Technological University: "Jnanasangama", Belagavi, Karnataka, India-590 014vidya sPas encore d'évaluation

- 2 & 16 Mark Questions and AnswersDocument27 pages2 & 16 Mark Questions and Answersprasath_676303Pas encore d'évaluation