Académique Documents

Professionnel Documents

Culture Documents

MS-C-005-Scarify of Existing Grade Rev. 1

Transféré par

sharif339Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MS-C-005-Scarify of Existing Grade Rev. 1

Transféré par

sharif339Droits d'auteur :

Formats disponibles

MS-C-005 Rev.

01

METHOD STATEMENT

FOR SCARIFY OF EXISTING GRADE

Contract No. BA- 0612 UNITED ETHYLENE OXIDE / ETHYLENE GLYCOL PROJECT

UNITED OLEFINS COMPLEX PROJECT Al-Jubail, Al-Sinaiyah, Saudi Arabia

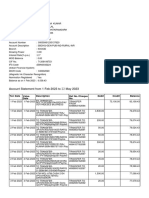

Signature 1 Rev. 25 Jan 03 DATE Print Name A. F. Longalong Prepared By MMG E. V. Lucero Checked By MMG N. A. Jabbour Approved By MMG

Page 1 of 3

MS-C-005 Rev. 01

PURPOSE.

To ensure that site scarifying is conducted in accordance with good working practices, work is verified, checked and inspected to satisfy SATEC/UNITED requirements in accordance with the Project issued Drawings and Project Specifications.

II SCOPE

This Procedure is applicable to MMG work sequence intended for the Scarifying work and the manner in which the essential work items involved will be actually carried out in preparation of the EO/EG Plant of the JUEG Project- Al Jubail.

III REFERENCES

Project QA Manual & Quality Inspection Plan Project Safety Manual PRJ-4-301 : Surveying C02-S01 - Site Preparation Specification Dwg No. 20-CD-7101, Site Preparation Layout & Details IV. RESPONSIBILITY CIVIL / STRUCTURAL SUPERVISOR Ensures compliance by all labours and equipment operators and other associated craftsmen to the requirements of this procedure, project quality control procedures / test plans, relevant drawings, safety procedures and the SATEC/UNITED Specifications in Site Preparation Works (Scarify existing grade and compact). Secure all necessary work permits. QUALITY CONTROL INSPECTOR Monitors daily activities and verifies compliance to SATEC/UNITED Specifications. Conduct activities in accordance with the Project QA Manual and Quality Inspection Plan. Prepare daily QC records and final acceptance documentation where required. Maintain close relationship with the Customers representative. SAFETY SUPERVISOR Ensures that work permits are obtained prior to commencement of any work. Checks personnel and confirm compliance to safety requirements, such as wearing personnel protective equipment. Checks work areas for any unsafe conditions. Liases with the Field Supervisors ensuring that work is carried out in accordance with Project Safety Plan / Procedures. ENGINEERING DEPARTMENT Provide the technical support to MMG Site Operation section. Provide drawings approved for construction use, material specifications, standards and technical specifications. Responsible for

Page 2 of 3

MS-C-005 Rev. 01

SATEC/UNITED review of drawings and data and the resolution of technical execution work problems.

V. PROCEDURE

Ensure the team is briefed by SATEC / UNITED Safety Department and everybody is aware of all risks, & competent to perform the job as required by SATEC/UNITED. A kick-off meeting with Safety Mgr., Constn. Mgr., Supt., Supv. & Crews prior to start of work. MMG to issue Field Inspection Notice for SATEC to check level survey of existing ground & SATEC to sign-off before grading work commences. Ensure that all IFC Erection Drawings and approved procedures associated with scarifying works are issued to personnel supervising the work. Work areas are to be provided with barrier sign for entry of authorized personnel only. Name of authorized personnel to be displayed. Check the stability of adjacent structures. Check, inspect, survey, layout and establish marking at the area to be scarified. Surveying works shall be carried out in accordance with PRJ-4-301 Surveying. A permit from SATEC / UNITED shall be secured to start the work. Safe work plan received by the competent person should be displayed in the area. At least one (1) person is constantly present. The area to be scarified have existing utilities that need to take care i.e. a.) Temporary water line. b.) FW / CW up to the battery limit c.) Cable drums that need to remove by others. d.) Communication cable way and O2 line will be laid along to West Side. The area shall be graded and inspected for soft spot. Having this area already cleared and grubbed by Site Preparation Contractor, we will use grader with scarifying tools to carry out the work. The area shall be scarified at 350mm depth. Scarified area will be watered using water tank with water sprinkler at rear. Water to be used shall be sweet water quality. The watered area shall be compacted using 10 tons vibratory compactor smooth type. The compacted area shall be tested at 95 % maximum dry density in accordance with ASTM D1557. Perform testing and inspection in accordance with project specification. The test & Inspection required should be clearly detailed together with applicable QC Forms Witness & Hold Point should be noted. Once approved clear the area.

VI

DOCUMENTS

a. Request for Inspection Form 20ZPPM-6301.

-----------------------------------

END----------------------------------------------Page 3 of 3

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hot TapDocument1 pageHot Tapsharif339Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- JASMINE SchedaDocument1 pageJASMINE Schedasharif339Pas encore d'évaluation

- Method Statement For Hot Tapping Rev 0 PDFDocument9 pagesMethod Statement For Hot Tapping Rev 0 PDFsharif339Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Method Statement For Hot Tapping Rev 0 PDFDocument9 pagesMethod Statement For Hot Tapping Rev 0 PDFsharif339Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Hot TapDocument1 pageHot Tapsharif339Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hot TapDocument1 pageHot Tapsharif339Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Dear Sir /madam, Please Find My C.V For Project Engineer Position For Further Queries Please Feel Free To With Regards SharifDocument1 pageDear Sir /madam, Please Find My C.V For Project Engineer Position For Further Queries Please Feel Free To With Regards Sharifsharif339Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Owners Manual - JBL - SB150 EnglishDocument9 pagesOwners Manual - JBL - SB150 EnglishBhavies BK100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hempel Price SheetapplicationinstructionsDocument4 pagesHempel Price SheetapplicationinstructionsDurgaiah RathnamPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Work Over of RigDocument3 pagesWork Over of Rigsharif339Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Phulka 12Document1 pagePhulka 12sharif339Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- AakashSureshchandraParikh (7 0)Document5 pagesAakashSureshchandraParikh (7 0)sharif339Pas encore d'évaluation

- Owners Manual - JBL - SB150 EnglishDocument9 pagesOwners Manual - JBL - SB150 EnglishBhavies BK100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Completion of DrillingDocument1 pageCompletion of Drillingsharif339Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- AjayHanda (16 0)Document3 pagesAjayHanda (16 0)sharif339Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Choa Chu Kang: Bus & Train Ser Vices Guide Bus & Train Ser Vices GuideDocument9 pagesChoa Chu Kang: Bus & Train Ser Vices Guide Bus & Train Ser Vices Guidesharif339Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Social Visit Pass PaperDocument0 pageSocial Visit Pass Papersharif339Pas encore d'évaluation

- AmitPMilmile (11 0)Document4 pagesAmitPMilmile (11 0)sharif339Pas encore d'évaluation

- AnilKumarNaharia (23 0)Document7 pagesAnilKumarNaharia (23 0)sharif339Pas encore d'évaluation

- Bganesh (11 0)Document3 pagesBganesh (11 0)sharif339Pas encore d'évaluation

- AakashSureshchandraParikh (7 0)Document5 pagesAakashSureshchandraParikh (7 0)sharif339Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Dipakajadhav (8 0) PDFDocument3 pagesDipakajadhav (8 0) PDFsharif339Pas encore d'évaluation

- Offshore HVACDocument45 pagesOffshore HVACRajakumar Bajji Subburaman100% (1)

- EP SPass Form8Document12 pagesEP SPass Form8Min ZawPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Amanvasir@live - Co.uk: 6 Years + 10 Months of ExperienceDocument4 pagesAmanvasir@live - Co.uk: 6 Years + 10 Months of Experiencesharif339Pas encore d'évaluation

- Guide To Purchasing Equipment: Finance Division Purchasing OfficeDocument16 pagesGuide To Purchasing Equipment: Finance Division Purchasing Officesharif339Pas encore d'évaluation

- Production Rel Decision MakingDocument97 pagesProduction Rel Decision Makingsharif339Pas encore d'évaluation

- Experience Details Project Engineer (Mechanical and Drilling (Feb 2007-May 2008) in Neptune Marine Oil and Gas Private Limited, SingaporeDocument4 pagesExperience Details Project Engineer (Mechanical and Drilling (Feb 2007-May 2008) in Neptune Marine Oil and Gas Private Limited, Singaporesharif339Pas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- EmptyDocument1 pageEmptysharif339Pas encore d'évaluation

- BP Oil Grangemouth Refinery LTD, Stirlingshire, ScotlandDocument1 pageBP Oil Grangemouth Refinery LTD, Stirlingshire, Scotlandsharif339Pas encore d'évaluation

- As 5056-2006 Metallic Coatings - Powder Metal (And Composites) Applied by Mechanical Means at Ambient TemperaDocument7 pagesAs 5056-2006 Metallic Coatings - Powder Metal (And Composites) Applied by Mechanical Means at Ambient TemperaSAI Global - APACPas encore d'évaluation

- Art of Programming ContestDocument219 pagesArt of Programming ContestshilswapanPas encore d'évaluation

- Harman Kardon AVR 3000 Owners ManualDocument52 pagesHarman Kardon AVR 3000 Owners ManualvyshyPas encore d'évaluation

- USFDA 510K ProcessDocument51 pagesUSFDA 510K ProcessSathesh Kumar100% (1)

- Chapter 5 - Application LayerDocument43 pagesChapter 5 - Application Layerዜና ማርቆስPas encore d'évaluation

- Vehicle InfotronicsDocument156 pagesVehicle Infotronicssarthak ggargPas encore d'évaluation

- UbiCom NotesDocument3 pagesUbiCom NotesJohn CenaPas encore d'évaluation

- OnboardDiagnostics AudiDocument183 pagesOnboardDiagnostics AudiMd Jafri AhmedPas encore d'évaluation

- Traffic SymbolDocument27 pagesTraffic SymbolraviPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Browning Regal Form 8972EDocument180 pagesBrowning Regal Form 8972Egenas7265Pas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- CCNA Exploration 2: Chapter 2 Toets Antwoorden / CCNA Routing Protocols and Concepts Exam 2 AnswersDocument6 pagesCCNA Exploration 2: Chapter 2 Toets Antwoorden / CCNA Routing Protocols and Concepts Exam 2 AnswersHei NekenPas encore d'évaluation

- FibracousticDocument2 pagesFibracousticPratik ThakkarPas encore d'évaluation

- Pressure Sensor DatasheetDocument36 pagesPressure Sensor Datasheetwqs_19Pas encore d'évaluation

- GH TXu Yyfls 73 IDumDocument15 pagesGH TXu Yyfls 73 IDumdabu choudharyPas encore d'évaluation

- Unit I Wireless Channel Propagation and Model 9Document9 pagesUnit I Wireless Channel Propagation and Model 9sharklasersPas encore d'évaluation

- FBQ1000 P0a3r M enDocument17 pagesFBQ1000 P0a3r M enScott FeichterPas encore d'évaluation

- Baumer MEX5 DS EN 1210 PDFDocument3 pagesBaumer MEX5 DS EN 1210 PDFAulia Rachma SetyawatiPas encore d'évaluation

- Osa Suite OverviewDocument2 pagesOsa Suite OverviewKevin KimPas encore d'évaluation

- Superior Diagnosis: Digital TransformationDocument4 pagesSuperior Diagnosis: Digital TransformationRidho PoetraPas encore d'évaluation

- IEC 61724-1 - Monitoreo de Sistemas FotovoltaicosDocument62 pagesIEC 61724-1 - Monitoreo de Sistemas FotovoltaicosJhonny Richard Verdugo RodríguezPas encore d'évaluation

- Material Handling Control Procedure PDF FreeDocument9 pagesMaterial Handling Control Procedure PDF FreeAli KayaPas encore d'évaluation

- 01 Andrew Context Sensitive Solutions For Rock SlopesDocument121 pages01 Andrew Context Sensitive Solutions For Rock SlopesDinny Kus AndianyPas encore d'évaluation

- Metadata Extraction Tool ChangesDocument4 pagesMetadata Extraction Tool ChangesHotland SitorusPas encore d'évaluation

- Commissioning Procedures For ConveyorsDocument2 pagesCommissioning Procedures For ConveyorsNur KhamidPas encore d'évaluation

- Painting NitDocument5 pagesPainting NitrkukgPas encore d'évaluation

- IBM 4690 User Guide v1998Document40 pagesIBM 4690 User Guide v1998Richard ChuaPas encore d'évaluation

- Avtron Load BanksDocument53 pagesAvtron Load BanksPaul RasmussenPas encore d'évaluation

- Vijeo XD User Manual PDFDocument130 pagesVijeo XD User Manual PDFALEXANDRU ZANOAGAPas encore d'évaluation

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- Analog Design and Simulation Using OrCAD Capture and PSpiceD'EverandAnalog Design and Simulation Using OrCAD Capture and PSpicePas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)