Académique Documents

Professionnel Documents

Culture Documents

Condition 2012-256 - Responsive 2

Transféré par

Bob MackinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Condition 2012-256 - Responsive 2

Transféré par

Bob MackinDroits d'auteur :

Formats disponibles

Obtained by Bob Mackin via Freedom of Information

2010goldrush@gmail.com

twitter.com/bobmackin

Report

City of Vancouver

Burrard Street Bridge

Condition Assessment Report

April 2012

REPORT

i

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

Table of Contents

SECTION PAGE NO.

Table of Contents i

1 Introduction 1

1.1 Project Background 1

1.2 Project Personnel 1

1.3 Inspection 1

1.4 Existing Information 2

1.5 Structural Description 4

1.6 Bridge Description 5

1.7 Condition Rating System 6

2 Inspection Results 6

2.1 Deck Elements 6

3 General Discussion 27

7 Closure 34

s.13(1) and s.17(1)(c) & (f)

s.13(1) and s.17(1)(c) & (f)

s.13(1) and s.17(1)(c) & (f)

City of Vancouver

ii

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

s.13(1) and s.17(1)(c) & (f)

REPORT

1

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

1 Introduction

1.1 Project Background

The Burrard Street Bridge is a civic icon that has been recognized as a significant heritage

structure in the City of Vancouver. Constructed in 1930, the bridge serves as a critical

transportation link between Vancouver south and the downtown core. The bridge comprises

twenty-six concrete girder approach spans, four steel under-trussed spans, and a through trussed

main span.

The City of Vancouver (City) retained Associated Engineering (AE) to provide engineering

services for the Retrofit and Rehabilitation of the Burrard Bridge. AE has undertaken a

targeted condition assessment and close-proximity inspection to verify the existing base-line

condition, provide information needed for concept development and evaluation, as well as repair

data and quantities to enable sound estimating for the tender stage of the project.

We have teamed with Levelton Consultants Ltd. (Levelton), Trans Canada Coatings Consultants

Ltd. (TC3), Donald Luxton & Associates Inc. (DLA), and Iredale Group Architecture (Iredale), to

complete the various aspects of the inspection. This report summarizes our findings from this

targeted condition assessment and close-proximity inspection.

1.2 Project Personnel

David Chen, B.Eng., P.Eng., and Tim Aucott, B.Eng. (Hons.), P.Eng., conducted the inspection;

Russ Raine, BSc, Chemistry, of TC3 and David Smith, MScE., P.Eng., of Levelton joined the

inspection team to inspect key areas of the bridge.

David Chen and Tim Aucott prepared this report, while Shane Cook, M.A.Sc., P.Eng., reviewed it.

Levelton and TC3 have both prepared reports, which focused on their specific aspects of the

inspection. The detailed report from Levelton, prepared by David Smith, will be submitted

separately from this report once the concrete test results are analyzed. The detailed report from

TC3, prepared by Russell Raine, is included in the Appendix E of this report.

1.3 Inspection

AE completed the inspections between April 27 and June 17 in several stages. The first stage

comprised a visual walk over inspection. We visually assessed the approach spans concrete

girders, deck soffit, and concrete bents from the ground level. We also made general observation

on the condition of the bridge deck surface, deck joints, sidewalks, and parapet.

City of Vancouver

2

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

The findings from the visual inspection were verified through a second stage targeted detailed

close-proximity inspection on selected areas of the bridge approach spans. We used an 85' and a

100' boom lift to access the concrete girders, deck soffit, and bents to within touching distance.

Levelton accompanied AE on the inspection of select areas of the concrete approach spans to

investigate the concrete condition and collect samples for testing.

The third stage comprises a targeted detailed close-proximity inspection on the steel under-trussed

spans and the through trussed main span (Spans 22 to 26). Access to the lower portion of the

deck truss spans and main through truss span was facilitated by using the safety line system

installed along the bottom truss chords and the floor beams. We utilized the BC Ministry of

Transportation and Infrastructure's Bridge nspection "Snooper Truck to gain access to the east

half of the upper portion of the deck trusses, as well as the deck soffit of Spans 22 and 23. We also

performed a targeted detailed inspection on the east half of the above deck portions of main

through truss span using an 85' boom lift. TC3 accompanied AE during these inspections to

assess the condition of the protective paint coating on the steel truss elements.

The fourth stage of the inspection consists of additional detailed inspections on specific bridge

elements and targeted material testing. We conducted detailed visual inspection of the Pier 1

Stairwell and the Pier 4 Overhead Gallery. During the Pier 1 Stairwell inspection, representatives

from Levelton, DLA, and Iredale were on site to make observation on the concrete condition as well

as the heritage and architectural features. AE and Levelton performed a targeted detailed condition

survey of the bridge west sidewalk; a limited chain-drag inspection was conducted on the west

sidewalk, and concrete samples were collected for testing. Levelton also took bridge deck concrete

sample at pre-selected locations along the deck for testing.

1.4 Existing Information

The City provided AE with the following record information prior to the commencement of the

inspection.

1.4.1 Reports and Information

Burrard Bridge Brief Summary of Previous Seismic Upgrades by Buckland and

Taylor Ltd. April 2011.

Not responsive

Report

Burrard Street Bridge

Condition Assessment Report

3

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

Not responsive

s.13(1) and s.17(1)(c) & (f)

City of Vancouver

4

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

1.5 Structural Description

The Burrard Bridge currently carries five traffic lanes, two bike lanes, and a pedestrian sidewalk

over False Creek. The bridge comprises a 24.4 m wide cast-in-place (CIP) reinforced concrete

deck with integral concrete sidewalks, concrete parapets, continuous concrete fascia beams, and

an asbestos-modified asphalt overlay. A General Arrangement drawing showing span

arrangements and typical deck cross sections is provided in Appendix A.

The approach spans vary in length between 5.5 m and 27.1 m and the girders vary between a two-

span continuous to a four-span continuous arrangement. The approach span superstructure

consists of three CIP reinforced concrete girders with integral reinforced concrete diaphragms and

cantilevered outriggers.

Concrete girders are supported by sliding bearings at the south abutment and the south end of the

Pier Bent 4; girders are supported by rocker bearings at the north abutment. Steel pin bearings or

rocker bearings are supporting the concrete girders on each side of the reinforced concrete pier

bents below the expansion joints. The superstructure of the approach spans has been seismically

retrofitted through the installation of longitudinal and lateral restrainers at the expansion joint

locations.

The abutments are CIP reinforced concrete supported from spread footing. There is a staircase

adjacent to each of the four wing walls, the staircases at the south abutment connect to unpaved

trails beneath the bridge and the staircases at the north abutment connect to the sidewalk of an

unnamed service road beneath the bridge.

The approach span pier bents comprise square, reinforced concrete columns with integral cross

beams supported from spread footings. The bents have either a two or a three column

arrangement and were likely designed this way to accommodate a railway line beneath the bridge.

The pier bents at the expansion joint locations (Bents 4, 7, 10, 13, 16, 19, and 24) have been

seismically retrofitted through the installation of new concrete shear walls, footing overlays, and

concrete jacketing of the cross beam and column; in addition, Bent 4 has bearing seat extension

brackets installed.

The truss spans consist of four simply supported deck truss spans (Spans 22, 23, 25, 26) and one

simply supported through-truss main span (Span 24). The truss span superstructure consists of

riveted, built-up, painted steel sections connected via gusset plates at the node locations. The top

and bottom chords, truss verticals, truss diagonals, and portal cross-beams (S24 only) are formed

from built up box sections, some of which have latticed top and bottom cover. The top plan

bracings of the trough-truss span and bottom plan bracings of the deck truss spans comprise built

up I-sections with latticed webs. The top plan bracings and intermediate diaphragms of the deck

truss spans, as well as the bottom plan bracings and the portal diaphragms of the trough-truss

span, comprise back-to-back angles.

Report

Burrard Street Bridge

Condition Assessment Report

5

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

The end cross bracing diaphragms of the deck truss spans comprise built-up box sections that

connect into the gussets at the ends of the truss chords. The bottom chord gusset plates at the

end of each truss span are integral with the vertical member and the bearing assembly at the pier

bearing locations. The truss spans are supported by CIP reinforced concrete piers bearing on piles

at Pier 1 and on spread footings at Piers 2 through 6.

The CIP concrete deck is supported by a system of longitudinally spanning stringers and

transversely spanning floor beams. The deck truss spans have seven interior stingers and four

exterior stringers (two at each deck overhang) between floor beams. The through-truss span has

seven interior stringers between floor beams. The stringers are connected to the webs of the floor

beams via a riveted web splice; Stringers A, F, and K in the deck truss spans are supported by

additional brackets on the floor beam web. Floor beams coincide with node locations and are

simply supported from the top of the top chord in the deck truss spans. For the through-truss span

the floor beams are connected directly into the lower truss cord nodes.

A seismic retrofit of the truss spans, included installation of new stringer support brackets beneath

the expansion joint at Pier 2 and Pier 5, as well as the replacement of the deck truss end

diaphragm bracing, bottom lateral bracings, and installation of seismic isolation bearings, was

previously undertaken.

1.6 Bridge Description

We have numbered the bridge spans, bents, and piers from south to north to correlate with the

record drawings and previous inspection reports. To be consistent with the record drawings and

previous inspection reports, we did not assigned number 21 on approach pier bents. Piers

supporting the truss spans (Spans 22 to 26) are number from south to north as Piers 1 through

Pier 6. Refer to the General Arrangement drawings provided in Appendix A for details. The

bridge is described as following:

South approach spans (Spans 1 to 21) - CIP concrete girders supported on the south

abutment, Bents 1 to 20, and Pier 1.

South deck trusses (Spans 22 and 23) - painted steel trusses supported on Piers 1 to 3.

Trough truss (Span 24) - painted steel truss supported on Piers 3 and 4.

North deck trusses (Spans 25 and 26) - painted steel trusses supported on Pier 4 to 6.

North approach spans (Spans 27 to 31) - CIP concrete girders supported on Pier 6, Bents

22 to 25, and the north abutment.

Longitudinally, we have numbered the approach span concrete diaphragms, cantilevered outriggers

and deck bays from south to north. Transversely, approach span concrete girders, diaphragms,

and bent columns are labelled as "West, "Middle, and "East.

City of Vancouver

6

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

For each of the five truss spans, we have numbered the truss nodes from south to north (starting

with Node 0); the numbering is not continuous across spans. The trusses are identified as either

the East Truss or the West Truss, and elements at the top of the truss, such as the top chord are

defined as "Upper, whereas elements at the bottom of the truss, such as the bottom chord or

bottom plan bracing are defined as "Lower. Each truss element is defined by the nodes that it

spans between (For example: L0W to U1W describes the first diagonal member of the West truss

starting at node Lower 0 and ending at node Upper 1). The floor beams are coincident with the

truss nodes and numbered from south to north to correspond with the nodes. The truss stringers

are labelled as "A through "K from west to east.

1.7 Condition Rating System

We rated the individual components of the bridge using the City of Vancouver's bridge inspection

system. The system rates the condition of each component as:

Good (4).

Fair (3).

Poor (2).

Very Poor (1).

The percentage of each individual component falling within that condition state has been recorded.

A City of Vancouver bridge inspection form for the Burrard Street Bridge is included in Appendix B.

The letter "E on the inspection form denotes that the component is in an excellent or as

new condition.

The letter "N on the inspection form denotes that the inspection team could not adequately

inspect the component.

The letter "X on the inspection form denotes a component that is not present at the

location considered. This condition occurs when components such as wing walls or

retaining walls are not present at all four corners of a bridge.

2 Inspection Results

The bridge is generally in a fair condition. The following sections of the report provide a breakdown

of the inspection findings on an element by element basis.

2.1 Deck Elements

Levelton has completed a detailed condition assessment with concrete sample tests on the deck

soffit, west sidewalk, and west exterior parapet. Levelton's assessment and test results are

summarized and discussed in a separate report by Levelton to follow.

s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f)

s.13(1) and s.17(1)(f)

s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

s.13(1) and s.17(1)(f) s.13(1) and s.17(1)(c), (d) & (f)

Report

Burrard Street Bridge

Condition Assessment Report

33

P:\20112789\00_Burrard_Rehab_Des\Engineering\12.00_Inspections\RPT_CAR_18April2012_Final\rpt_van_conditionassessment_20120418_dc.doc

6 Monitoring and Further Work

During the inspection, we observed numerous previously recorded, concrete cracks on the deck

soffit which have developed into concrete spalls within the past four years. This observation, along

with the respectable amount of localized concrete delamination and active water seepage at

construction joints and concrete cracks on the deck soffit, indicates that the deterioration of the

concrete deck of the Burrard Street Bridge has been progressing since the 2007 Inspections by

Delcan Corporation. As the deck concrete continues to age, it will likely require major repair in the

near future. Therefore, we recommend that the City to investigate renewal or rehabilitation options

for the concrete deck of the Burrard Street Bridge. The City should also consider incorporating

major bridge deck rehabilitation for Burrard Street Bridge in future financial planning.

s.13(1) and s.17(1)(c), (d) & (f)

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- FIFA Seattle AgreementDocument230 pagesFIFA Seattle AgreementBob Mackin100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Claims Legal Services Org ChartDocument45 pagesClaims Legal Services Org ChartBob MackinPas encore d'évaluation

- READ: Whitecaps Contract With B.C. Pavilion CorporationDocument28 pagesREAD: Whitecaps Contract With B.C. Pavilion CorporationBob MackinPas encore d'évaluation

- Unfinished Business by Darryl PlecasDocument50 pagesUnfinished Business by Darryl PlecasBob MackinPas encore d'évaluation

- Petition To The CourtDocument19 pagesPetition To The CourtBob MackinPas encore d'évaluation

- Mullen Report PDFDocument57 pagesMullen Report PDFBob MackinPas encore d'évaluation

- Filed Notice of Civil Claim - SFU FootballDocument10 pagesFiled Notice of Civil Claim - SFU FootballBob MackinPas encore d'évaluation

- 2022 BCSC 854 R. v. JamesDocument70 pages2022 BCSC 854 R. v. JamesBob MackinPas encore d'évaluation

- TheBreaker HTH 2021 15020Document72 pagesTheBreaker HTH 2021 15020Bob MackinPas encore d'évaluation

- Obtained by Thebreaker - News Via Freedom of InformationDocument3 pagesObtained by Thebreaker - News Via Freedom of InformationBob MackinPas encore d'évaluation

- Inbc Business Case 2021 Copy - Obtained by Thebreaker - NewsDocument123 pagesInbc Business Case 2021 Copy - Obtained by Thebreaker - NewsBob MackinPas encore d'évaluation

- Fraser Health Contact Tracing FOIDocument4 pagesFraser Health Contact Tracing FOIBob MackinPas encore d'évaluation

- OOP 2020 07060 Horgan PDFDocument35 pagesOOP 2020 07060 Horgan PDFBob MackinPas encore d'évaluation

- OOP 2020 07060 Horgan PDFDocument35 pagesOOP 2020 07060 Horgan PDFBob MackinPas encore d'évaluation

- 2020 Dec 23 Mackin CasestudyDocument40 pages2020 Dec 23 Mackin CasestudyBob Mackin100% (1)

- 2020 Dec 23 Mackin CasestudyDocument40 pages2020 Dec 23 Mackin CasestudyBob Mackin100% (1)

- MessageGuide Fall2020Document11 pagesMessageGuide Fall2020Bob MackinPas encore d'évaluation

- F20 0691 Blackline MackinDocument14 pagesF20 0691 Blackline MackinBob MackinPas encore d'évaluation

- CR Jason Michael Hauk Botchford 2019-0297-0066Document2 pagesCR Jason Michael Hauk Botchford 2019-0297-0066Bob MackinPas encore d'évaluation

- Obtained by Thebreaker - News Via Freedom of InformationDocument5 pagesObtained by Thebreaker - News Via Freedom of InformationBob MackinPas encore d'évaluation

- Back Propagation Neural NetworkDocument10 pagesBack Propagation Neural NetworkAhmad Bisyrul HafiPas encore d'évaluation

- Curriculum Guide Ay 2021-2022: Dr. Gloria Lacson Foundation Colleges, IncDocument9 pagesCurriculum Guide Ay 2021-2022: Dr. Gloria Lacson Foundation Colleges, IncJean Marie Itang GarciaPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughPas encore d'évaluation

- Ecs h61h2-m12 Motherboard ManualDocument70 pagesEcs h61h2-m12 Motherboard ManualsarokihPas encore d'évaluation

- Myanmar 1Document3 pagesMyanmar 1Shenee Kate BalciaPas encore d'évaluation

- Union Test Prep Nclex Study GuideDocument115 pagesUnion Test Prep Nclex Study GuideBradburn Nursing100% (2)

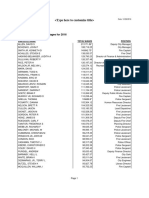

- 2016 W-2 Gross Wages CityDocument16 pages2016 W-2 Gross Wages CityportsmouthheraldPas encore d'évaluation

- EAC Inquiry SDCDocument9 pagesEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Pas encore d'évaluation

- Predator U7135 ManualDocument36 pagesPredator U7135 Manualr17g100% (1)

- Faa Data On B 777 PDFDocument104 pagesFaa Data On B 777 PDFGurudutt PaiPas encore d'évaluation

- Report FinalDocument48 pagesReport FinalSantosh ChaudharyPas encore d'évaluation

- DS Agile - Enm - C6pDocument358 pagesDS Agile - Enm - C6pABDERRAHMANE JAFPas encore d'évaluation

- Adjective & VerbsDocument3 pagesAdjective & VerbsDennis BerkPas encore d'évaluation

- List of Sovereign States and Dependent Territories by Birth RateDocument7 pagesList of Sovereign States and Dependent Territories by Birth RateLuminita CocosPas encore d'évaluation

- AssignmentDocument47 pagesAssignmentHarrison sajorPas encore d'évaluation

- Stone As A Building Material: LateriteDocument13 pagesStone As A Building Material: LateriteSatyajeet ChavanPas encore d'évaluation

- Instructions For Preparing Manuscript For Ulunnuha (2019 Template Version) Title (English and Arabic Version)Document4 pagesInstructions For Preparing Manuscript For Ulunnuha (2019 Template Version) Title (English and Arabic Version)Lailatur RahmiPas encore d'évaluation

- Sankranthi PDFDocument39 pagesSankranthi PDFMaruthiPas encore d'évaluation

- Understanding and Teaching Fractions: Sybilla BeckmannDocument26 pagesUnderstanding and Teaching Fractions: Sybilla Beckmannjhicks_mathPas encore d'évaluation

- 788 ManualDocument16 pages788 Manualn0rdPas encore d'évaluation

- MME 52106 - Optimization in Matlab - NN ToolboxDocument14 pagesMME 52106 - Optimization in Matlab - NN ToolboxAdarshPas encore d'évaluation

- Bba VDocument2 pagesBba VkunalbrabbitPas encore d'évaluation

- PE MELCs Grade 3Document4 pagesPE MELCs Grade 3MARISSA BERNALDOPas encore d'évaluation

- Project Formulation and Appraisalpdf PDFDocument12 pagesProject Formulation and Appraisalpdf PDFabhijeet varadePas encore d'évaluation

- Internship Report Format For Associate Degree ProgramDocument5 pagesInternship Report Format For Associate Degree ProgramBisma AmjaidPas encore d'évaluation

- Module 1 Lesson 2Document31 pagesModule 1 Lesson 2Angela Rose BanastasPas encore d'évaluation

- Mathematics BQP 2022Document43 pagesMathematics BQP 2022muhammadmansuri815Pas encore d'évaluation

- ADC of PIC MicrocontrollerDocument4 pagesADC of PIC Microcontrollerkillbill100% (2)

- CSE 202.04 Inspection of Concrete StructuresDocument67 pagesCSE 202.04 Inspection of Concrete StructuresJellyn BasePas encore d'évaluation

- Alkosign Product CatalogeDocument20 pagesAlkosign Product CatalogeShree AgrawalPas encore d'évaluation