Académique Documents

Professionnel Documents

Culture Documents

Grain Growth in Alpha-Brass

Transféré par

hezihilikCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grain Growth in Alpha-Brass

Transféré par

hezihilikDroits d'auteur :

Formats disponibles

Grain Growth in AlphaBrass

J. E. Burke

Citation: J. Appl. Phys. 18, 1028 (1947); doi: 10.1063/1.1697574

View online: http://dx.doi.org/10.1063/1.1697574

View Table of Contents: http://jap.aip.org/resource/1/JAPIAU/v18/i11

Published by the American Institute of Physics.

Additional information on J. Appl. Phys.

Journal Homepage: http://jap.aip.org/

Journal Information: http://jap.aip.org/about/about_the_journal

Top downloads: http://jap.aip.org/features/most_downloaded

Information for Authors: http://jap.aip.org/authors

Downloaded 25 May 2013 to 132.68.208.79. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

Letters to the Editor

Grain Growth in Alpha-Brass

J. E. BURKE

Institute for the Study of Metals, University of Chicago, Chicago, Illinois

June 30, 1947

A

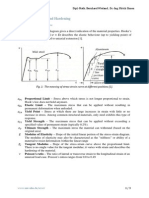

N extensive series of data on isothermal grain growth

in alpha-brass has recently been published by

Walker.l Plotting from these data 10gD (grain diameter in

mm), vs. log time, one obtains a series of isothermal curves.

An example for 42.4 percent deformation prior to recrystal-

lization is shown in Fig. 1. One should like to know whether

time and temperature for this process are related by a

heat of activation Q. If so, times at temperature Tl should

be related to times at temperature T2 by the equation:

In(tt/t2) = (Q/R) (T

2

-1- T

1

-l).

This equation can be solved to give values of t1/t 2 to

convert times at a given temperature to times at any

I

omL

02. LO 40 .. eo 240

FIG, 1. Isothermal grain growth at various temperatures in alpha-brass.

reference temperature. By taking Q as 60,000 cal. per

mole it is found that the data taken at all temperatures

can be on a smooth curve at a single reference

temperature, with only a reasonable experimental scatter.

Figure 2 shows this for the curves of Fig. I, at a reference

temperature of 500C, It thus seems proper to assign a

heat of activation to the process. This curve is not a

straight line.

..

FIG. 2. Solid line: composite grain-growth curve at 500C reference

temperature; Dashed line: composite curve corrected by subtracting

0.03 mm.

1028

Beck, Kremer, and Demer

2

report that their data for

grain growth in high purity aluminum follows the relation-

ship:

D=ktn,

where k is a constant and the exponent n increases linearly

with temperature. Obviously this relationship cannot hold

for short times, for, at 1=0, D has'a finite value, Do.

The present data are expressed reasonably well by.the

rela tionship:

D-Do=klt",

where Do is the grain size at the time of recrystallization,

k is a temperature-dependent constant, and the exponent

n has the value 0.425 until late in the growth process. The

dotted line in Fig. 2 was obtained by subtracting thp

recrystallized grain size reported by Walker for this series

(0.03 mm) from the solid curve through the experimental

points. It can be seen that it is a straight line until thp

late stages of growth, but that the slope definitely falls

off then. Similar results are obtained from other series of

data in Walker's work,

This work was supported by the Office of Research and

Inventions, U. S. N. (Contract No. N60ri-20-IV),

1 Harold L. Walker, University of Illinois Eng. Exp. Sta. Bull.

No. 359 (Nov. 1945).

2 Paul A. Beck, Joseph C. Kremer, and L. Derner, Phys. Rev. 71.

555 (1947).

'Comments on "Grain Growth in Alpha-Brass"

PAUL A. BECK

University of Notre Dame, Notre Dame, Indiana

September 12, 1947

I

N the above note J. E. Burke calculated a heat of

activation value from grain-growth data on brass

obtained by H. L. Walker.l Considering the scatter of the

data, his value of 60 kcal./g of atom is in reasonable

agreement with the heat of activation value of 73.5 kcal./g

atom previously calculated for brass by Beck, Kremer,

and Demer,2 by an essentially identical method, from other

published grain-growth data. Thus, Burke's result tends

to confirm Beck, Kremer, and Derner's conclusions with

regard to the heat of activation value from grain-growth

data on brass.

Burke states that the relationship,

(1 )

found by Beck, Kermer, and Derner for isothermal grain

growth in high purity aluminum cannot hold for short

times, for at t=O, D has a finite value, Dr, the grain size as

Burke uses t to denote the time

for grain growth. The zero point of his time scale is at the

moment when recrystallization is just complete. However,

in the nomenclature used by Beck, Kremer, and Derner t

denotes the total time of annealing, which includes the

time for recrystallization. * Clearly, Burke's objection is

based on a misunderstanding of the nomenclature.

JOURNAL OF APPLIED PHYSICS

Downloaded 25 May 2013 to 132.68.208.79. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

Since most of the annealing periods used by Beck,

Kremer, and Demer are very long in comparison with the

time for recrystallization, the error committed by using

"grain-growth time" instead of "totartime," as a result of

the above misunderstanding, is negligible, except for the

shortest annealing periods at the lowest annealing temper-

atures. Consequently, the whole matter would be lacking

in significance were it not for another mistake in Burke's

note. He uses the time data from Walker's paper as if

these meant "time for grain growth" in the above sense.

;\ctually, Walker, like Beck, Kremer, and Demer, uses the

"total time" of annealing. As some of the times of recrystal-

lization in Walker's work are relatively long (such as

16 min. at 450C), the error resulting from this misinterpre-

tation is significant.

The dotted line in Burke's Fig. 2 gives 10g(D-Dr ) as a

function of logt, where t is supposed to be the time for

grain growth, but it is actually the total time of annealing

of Walker's specimens, as explained above. Although the

initial portion of this line was so selected across the

"reasonable scatter" of the transposed experimental points

that it is straight, Burke admits that deviation from the

straight line definitely occurs at longer annealing periods.

Nevertheless, he considers that the data are reasonably

well expressed by the relationship:

(2)

A comparison of relationships (1) and (2), by \,Ising

Beck, Kremer, and Derner's grain-growth data on high

purity aluminum at 400C, is given in Fig. 1. It is clear

that the plot of 10gD vs. logt closely approximates a

straight line. Plotting the same data as D -;- D r vs. t. (to is

used here to designate "grain-growth time" in order to

avoid confusion) results in a curve which asymptotically

approaches the above straight line at very large to values.

Similar curves are obtained for other annealing tempera-

tures. Obviously, relation (2) does not fit the grain-growth

data for high purity aluminum, but formula (1) does.

It can be easily shown that the initial portion of the

curve in the figure approaches a slope of n = 1. If t. ap-

proaches zero, D/D. approaches 1, that IS D/Dr= l+d,

where d is a very small number, and

D-Dr=dD

r

. (3)

In Eq. (1) the constant k can be eliminated if one puts

D=Dr for t=R, where R is the time for just complete

recrystallization. The following formula is then obtained:

D/D

r

= (t/R)n

or, substituting to = t - R,

(4)

From (4), with the above relations,

and from this, for a small value of to,

d=(n/R)t

a

(5)

By substituting (5) into (3) one obtains

D -Dr=n(Dr/R)t . (6)

VOLUME 18, NOVEMBER, 1947

~ ~ - .

07

os.

P.L.

L3 .---

.--

.-0-;;:

./" 02

----

..-----

/

,

/N=I

~ ..

Llli ./

'02.

,

~ ~ 5 /

L

)04' /

In../ 1/

,

) : ~ 2 I

I

'"

I 5 6 5 31 151

to AND Lg.M1N.. LOG SCAU

FIG. 1.

Formula (6) shows that for small values of to the relation-

shi p between D - D. and to is linear. This means that at

very short times in the logarithmic plot the curves for all

temperatures approach the slope of n = 1. At long annealing

times they approach the D = k t

n

straight lines, where the

slope, n, increases with the temperature.*

* A fuller discussion of these questions is included in a detailed

paper by Beck. Kremer. Derner. and Holzworth to be published in

Metals Technology. September. 1947.

1 Harold L. Walker. University of Illinois Eng. Exp. Sta. Bull.

No. 359 (1945).

2 Paul A. Beck. Joseph C. Kremer. and L. Derner. Phys. Rev. 71.

555 (1947).

Electron Micr-oscope and Electron-Diffraction

Study of Slip in Metal Crystals

R. D. HEIDENREICH AND W. SHOCKLEY

Bell Telephone Laboratories. Inc . Murray Hill. New Jersey

August 20. 1947

T

HE process of plastic deformation in metal crystals

has been the subject of many investigations, both

experimental and theoretical, over a long period of years.

The new experimental results to be described briefly in

this letter have been presented orally before two different

groups* but have not appeared in print. A fuller account of

the methods and results will appear in a British publication.

The current experiments concerning the structure of slip

bands were carried out using 99.99 percent aluminum cast

in the form of small single crystals (20X6X2 mm). The

as-cast crystals were mechanically polished through 4/0

French emery to produce a flat, 6 X 20 mm surface and then

electropolished to remove the heavily worked layer. The

samples were then annealed 3--4 hours above 600C,

1029

Downloaded 25 May 2013 to 132.68.208.79. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

Vous aimerez peut-être aussi

- JMPT 2013 Secondary Deformation of Hot Stamping SpecimensDocument9 pagesJMPT 2013 Secondary Deformation of Hot Stamping SpecimenshezihilikPas encore d'évaluation

- Heat Treatment With Salt Bath FurnacesDocument12 pagesHeat Treatment With Salt Bath FurnacesVaikuntam Ramamurthy100% (1)

- Convection With Phase ChangeDocument12 pagesConvection With Phase ChangeaminPas encore d'évaluation

- 117 Section 5 How To Make It in Brass PDFDocument6 pages117 Section 5 How To Make It in Brass PDFhezihilikPas encore d'évaluation

- Matrixcookbook PDFDocument72 pagesMatrixcookbook PDFeetahaPas encore d'évaluation

- False Failure in Flexural Fatigue Tests PDFDocument11 pagesFalse Failure in Flexural Fatigue Tests PDFhezihilikPas encore d'évaluation

- FatigueDocument14 pagesFatigueumair_aePas encore d'évaluation

- Ternary PDFDocument10 pagesTernary PDFhezihilikPas encore d'évaluation

- Fracture of A Superplastic Ternary Brass PDFDocument9 pagesFracture of A Superplastic Ternary Brass PDFhezihilikPas encore d'évaluation

- KizilyalliDocument19 pagesKizilyallihezihilikPas encore d'évaluation

- Qm1 Hw9 ItayDocument3 pagesQm1 Hw9 ItayhezihilikPas encore d'évaluation

- Mmsm1 Handout PlasticityDocument3 pagesMmsm1 Handout PlasticityKuldeep SinghPas encore d'évaluation

- Internal Friction of Materials Anton PuskarDocument342 pagesInternal Friction of Materials Anton PuskarhezihilikPas encore d'évaluation

- Convection With Phase ChangeDocument12 pagesConvection With Phase ChangeaminPas encore d'évaluation

- The Structural Effect of HeatingDocument1 pageThe Structural Effect of HeatinghezihilikPas encore d'évaluation

- Thermo EquationsDocument3 pagesThermo EquationshezihilikPas encore d'évaluation

- Article - Screw Threads DesignDocument7 pagesArticle - Screw Threads DesignjdfdfererPas encore d'évaluation

- An Overview of Utilization of Slag and SludgeDocument18 pagesAn Overview of Utilization of Slag and SludgehezihilikPas encore d'évaluation

- 4 Kramer Good Foundry PracticesDocument25 pages4 Kramer Good Foundry PracticeshezihilikPas encore d'évaluation

- Chap 2Document20 pagesChap 2hezihilik40% (5)

- 4 Kramer Good Foundry PracticesDocument25 pages4 Kramer Good Foundry PracticeshezihilikPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Coherent and Incoherent ScatteringDocument22 pagesCoherent and Incoherent ScatteringAlberto Rasa'Pas encore d'évaluation

- Chemistry Investigatory ProjectDocument18 pagesChemistry Investigatory ProjectDinesh Singh Choudhary0% (1)

- Tolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and VisibleDocument3 pagesTolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and Visibleivan cuadradoPas encore d'évaluation

- Mirrax Esr Heat Treatm - RecDocument4 pagesMirrax Esr Heat Treatm - RechamidharvardPas encore d'évaluation

- BSC 1st Year Notes ChemistryDocument33 pagesBSC 1st Year Notes ChemistrySandipan SahaPas encore d'évaluation

- 2-In-1 Laundry Detergent With Softener HCLF06Document1 page2-In-1 Laundry Detergent With Softener HCLF06EL PAPI -X5Pas encore d'évaluation

- Multi-Adaptable Night Tactical Imaging System (MANTIS) GuideDocument2 pagesMulti-Adaptable Night Tactical Imaging System (MANTIS) Guidegoma12345100% (1)

- Makoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesDocument49 pagesMakoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesQMDhidnwPas encore d'évaluation

- Introductory Chemistry Atoms First 5th Edition Russo Solutions Manual 1Document10 pagesIntroductory Chemistry Atoms First 5th Edition Russo Solutions Manual 1seanjacksonkwzgnbxift100% (28)

- Catálogo de Gaviones Tejidos PRODAC (Inglés) PDFDocument9 pagesCatálogo de Gaviones Tejidos PRODAC (Inglés) PDFpapolamPas encore d'évaluation

- R&AC Assigment-cum-Turorial Questions - Unit-V - 2017Document6 pagesR&AC Assigment-cum-Turorial Questions - Unit-V - 2017sivakrishna100% (1)

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- 21st Century General Chemistry 1Document382 pages21st Century General Chemistry 1Sreedevi Krishnakumar100% (1)

- Mohamed Abdel-Hameed Ahmed: Curriculum VitaeDocument3 pagesMohamed Abdel-Hameed Ahmed: Curriculum VitaeHatem HusseinPas encore d'évaluation

- Cooler Condenser Design for Vapor-Gas MixturesDocument1 pageCooler Condenser Design for Vapor-Gas MixturesNind's Chef0% (1)

- Understanding the nonlinear dynamics of liquid flow with surge tanksDocument12 pagesUnderstanding the nonlinear dynamics of liquid flow with surge tanksLouie Fajardo AbadPas encore d'évaluation

- A Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyDocument5 pagesA Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyArdiellaputriPas encore d'évaluation

- 1N4099 1N4135, 1N4614 1N4627Document4 pages1N4099 1N4135, 1N4614 1N4627tommy99Pas encore d'évaluation

- Slug Catcher Design InstructionDocument6 pagesSlug Catcher Design Instructionanon_268215282Pas encore d'évaluation

- Solution Manual To Options, Futures and Other Derivatives, 5th, by John Hull, John C. HullDocument3 pagesSolution Manual To Options, Futures and Other Derivatives, 5th, by John Hull, John C. HullSaumya SharmaPas encore d'évaluation

- Engine Oil Volatility Noack Evaporation MethodDocument5 pagesEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Requisition To Test For Compressive Strength of Cement Concrete Cubes For Building and Bridge WorksDocument8 pagesRequisition To Test For Compressive Strength of Cement Concrete Cubes For Building and Bridge WorksShivkumarKambalePas encore d'évaluation

- ASG Newformat FREDDocument88 pagesASG Newformat FREDSigmaPas encore d'évaluation

- GGR240L Use and Care ManualDocument2 pagesGGR240L Use and Care ManualBobDewillePas encore d'évaluation

- Piping Spring HangersDocument2 pagesPiping Spring HangersyogacruisePas encore d'évaluation

- Ion ExchangeDocument25 pagesIon ExchangeArie Ikhwan SaputraPas encore d'évaluation

- AucosticsDocument98 pagesAucosticswendodavidPas encore d'évaluation

- Rumen MicrobiologyDocument15 pagesRumen MicrobiologyJ Jesus Bustamante GroPas encore d'évaluation

- 1732Document30 pages1732rikechPas encore d'évaluation

- Mid-Term Test 2012Document9 pagesMid-Term Test 2012Muhammad FauzanPas encore d'évaluation