Académique Documents

Professionnel Documents

Culture Documents

History of MTM

Transféré par

Muhammad Umair KhalidCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

History of MTM

Transféré par

Muhammad Umair KhalidDroits d'auteur :

Formats disponibles

History of MTM

Masood Textile mills were incorporated in 1984 with 4 spinning mills. It is a public limited company with its registered office at Faisalabad and listed in all stock exchanges of Pakistan. It is vertically integrated textile unit. It has its own spinning, knitting, processing

and stitching units. Initially it was engaged only in spinning. But in 1993 company changed its strategy in adding up most process and disposed off three spinning units. In 1995 company made its own garments units with only 35 stitching machines but today it has about 1000 stitching machines of different brands. All credit of this success goes to visionary personality of Mr. Shahid Nazir, the Chief Executive of the company. They strive to lead in creating, developing and manufacturing of knitted apparel products right from basic to highly fashioned garments thus responding to emerging trends in the industry. They translate conceptual ideas of our customers into reality and shape them through our technical bent and professional acumen. The team here strongly believes that Customer satisfaction is the essence of business today. mTm has the technology with expertise, products with knowledge and most importantly the right mindset to achieve total customer satisfaction

Vision Statement

A leading producer of textile products by producing the highest quality of products ad services to its customers. To strive for excellence through commitment, integrity, honesty and team work. Highly ethical company and be repeated corporate citizen to continue playing due role in the social and environmental sectors of the company. To develop and extremely motivated and professional trained work force, witch would drive growth through innovation and renovation. Sustained growth in earning in real terms.

Mission Statement:

Our mission is to be a dynamic, profitable and growth oriented company by providing good return on investment to its shareholders and investors, quality products to its customers, a secured and friendly environment place of work to its employees and to project Pakistans image in the international market. Customer profile Masood Textile Mills has also proud of work with world best Labels like (Stafford, Arizona, St. Johns Bay) (Chaps Ralph Lauren, Calvin Klein) (Vantage, Champs, Tom Taller) Lee, Wrangler

JC Penney War Naco Indus Vanity fair Perry Ellis Levi

Management Hierarchy in MTM

Top Management

Chief executive officer

General manager

Middle Management

Manager

Senior Officer

Deputy Manager

Assistant Manager

Officer

Lower Level Management

Supervisor

Helpers

Foreman

Operators

Quality control system at Masood:

There are quality checks at every stage of manufacturing starting from Raw Cotton, Yarn, Fabric, Processing, Cutting, Stitching and Packing. Before the fabric is cut, it is checked whether it conforms to the customer's standards of shrinkage, finished g/cm2 etc. After each lot of fabric is cut, 100% cut parts inspection is conducted to ensure that only good quality pieces move to the stitching units. During the process of sewing, each and every process is inspected by inline inspectors. The inspectors make sure that only good parts move to the next stage. An individual tracking number is sewn inside each garment. After trimming and pressing of the garments, highly experienced final inspectors inspect each garment. The Quality assurance team monitors the performance of every individual inspector by picking up the inspected garments and checking the quality of these garments. To ensure that the garments are packed as per the requirements of our valued customers, we can even track & check, which case the garment, has been packed in. With the help of this, we plan to achieve the Zero Defect Level. Product Line

Masood Textile Mills produced different high quality export oriented products to the international market. These are as under. Yarn Knitted Fabric Garments (1) Yarn:

Masood Textile Mills Limited produces high quality yarn according to the demand of the market. 80 to 90% yarn is exported rest of the yarn is used is in Masood Textile Mills. (2) Knitted Fabric: One of the largest Fabric facility in Pakistan having the capability to produce all kinds of knitted fabrics in 100% cotton & blends.

(4) Garments:

MTM is a leading apparel company in Pakistan having expertise & machinery capable of transforming customer ideas into superior quality garments, which are taken as the most famous brands in the world. These includes the Loungewear Sportswear Active wear Sleepwear Athletic

SWOT ANALYSIS

SWOT analysis is a tool for auditing an organization and its environment. It is the first stage of planning and helps marketers to focus on key issues.

Once key issues have been identified, they feed into marketing objectives. It can be used in conjunction with other tools for audit and analysis, such as PEST analysis and Porter's FiveForce analysis. SWOT stands for strengths, weaknesses, opportunities, and threats. Strengths and weaknesses are internal factors.

Strength could be:

Your specialist marketing expertise. A new, innovative product or service Location of your business Quality processes and procedures Any other aspect of your business that adds value to your product or service.

A weakness could be:

Lack of marketing expertise Undifferentiated products and service (i.e. In relation to your competitors) Location of your business Poor quality goods or services Damaged reputation

Opportunities and threats are external factors. For example:

An opportunity could be:

A developing market such as the Internet. Mergers, joint ventures or strategic alliances Moving into new market segments that offer improved profits A new international market A market vacated by an ineffective competitor

A threat could be: A new competitor in your home market Price wars with competitors A competitor has a new, innovative product or service Competitors have superior access to channels of distribution Taxation is introduced on your product or service

STRENGTHS 1. ISO 9002 Certification. 2. WRAP Certified 3. Vertically integrated. 4. High quality products. 5. Excellent market image in the local and international market. 6. Highly qualified management. 7. Adequate financial resources. 8. Competitive advantage. 9. Adopting technology. 10.Recruitment on merit. information

WEAKNESSES

1. Increased employee turnover 2. Centralized management system 3. High cost of production. 4. Low production capacity. 5. De-motivated Staff. 6. Non-Corporative culture. 7. Insufficient benefits for the employees. 8. Stereotype machinery for processing.

9. Communicational gap

11.Loyal customers. 12.Skilled Labor. 13.Broad and motivational vision. 14.Back Track System

among different departments.

OPPORTUNITIES

THREATS

1. Can expand its division such as entering in weaving sector also. 2. Can introduce its own label in domestic as well in international market 3. Can capture segment. new market

1. Entry of new competitors just like China & India. 2. Buyer changes. 3. Political instability. 4. Changing situation. 5. Change policies. 6. Low price offered by of government geopolitical need and demand

4. Full potential of entertaining the local market. 5. Can reduce the cost by proper utilization of resources. 6. End of quota restrictions by the end of year 2004. 7. Can hire well-educated experienced staff. and

competitor 7. Globalization.

Information Technology Department

Introduction:

IT department of MTM is very well established. It reduced the paper work system. All the work is done on computer. Data is transmitted from one Apparel to another and to the mills is through the wide area networking. (WAN) In wide area networking siss routers is used which replicate the data and send it to the apparel. And they also have an ability to update the whole data in main server. There are three servers in overall Masood, one is online server, and other is stand by and third is replication server. Whole the process of manufacturing can be tracked from computer in MTM. Our customers can also check the status of their ordered product by only using net. MTM is at almost pure Dot Com positions and we can say that IT has

been so much flourished in TM that it will be difficult to survive for MTM without IT at this time. Most of the departments have been computerized except Finance Department.

The system developed by the IT department includes

HRMS AMS GMS IMS FMS

Human Resource Management System Apparel management system Gate Management System Inventory management system Fabric Management System

Objective

MTM Garments Division has very modern fully equipped I.T department. The basic objective of I.T department is to collect, interpret and summarize the data in an easily understands able form. Now we discuss I.T at Masood briefly.

i)

Applications of I.T at MTM: -

Information technology department has different programs for different functions. Those are following.

H.R.M.S

Human resource management system is a program in which all the data about employees is stored. This data is readily available for higher management. HRMS works on following grounds. Employees Evaluation Form Evaluation History of the Employees Complaints against Employees. Department Wise Strength of Employees & Budget. Month Wise Employees Turnover.

Reports About Employees. G.M.S

Gate Management System is a program, which deals with the function of gate office. In this system following functions are performs. Employees In/Out record and time. Visitors In/Out record and time. Candidate Employees In/Out record and time. Temporary Employees In/Out record and time. Every employee of MTM has a card. Which he or she scans while In/Out. Its time is noted. There are certain reports about In/Out system preserve in GMS and are available for higher management.

E.P.S

Employees payroll system is design to generate employees salaries and benefit in computerized system this system performs on following ground. Generation of Employees Salary. Generation of Pay Slips. Salary History Employee. Gratuity Record. Leave Encashment Record. This system makes easy the payment procedure and reduces corruption and increase efficiency.

ii)

Apparel Management System (A.M.S)

Apparel Management system of MTM is very unique. It keeps the total record of every piece made by MTM up till now; every garment manufactured at MTM has a barcode no. This is feeded in AMS. And whenever is needed this no is feeded and complete history of that garments is open. AMS works on following grounds. Complete backtrack of garment. On line status of a customers P.O. Worker Evaluation.

In line Inspectors and Final Inspectors Evaluation. Contractual Employees Wages Calculation and Financial Summary. Error Tractability in finished products. Reduction in fabric loses. Reduce duplication of work. Paperless environment. System Security. Unique ID tracking No. of each garments. Back tracks from cotton crop type, yarn, knitting, fabric processing, cutting, stitching, inspection, packing and shipment.

iii)

Local Area Network/Wide Area Network

LAN: - Masood Textiles Apparel Division has about 180 computers. These computers are interlinked via local area network. This network provides fast moving of required data and also facilitates Intranet facility within the company. All employees within the organization can easily communicate through it MTM has a hub, which provides LAN facility according to requirements of the system.

WAN: - Masood Textile Mills (Apparel Division) is linked Masood Textile Mills (Fabric Division) which is 32 Km far from it. All computers of Apparel Division are linked to Fabric Division through a communication Tower. This system works like mobile phone system. Beside that MTM has its on ISP (Internet Service Providing facility). It has satellite Internet system. For this a satellite dish is installed at the factory. Every employee of MTM has free Internet facility. E-Commerce/Web site: Masood Textile is working as a B to B company. It uses

iv)

Internet for its negotiations and transactions with its customer. E-Commerce:-For on line transactions MTM use EC Vision X-expression it is a software use for commerce. MTM negotiates all terms and conditions of product, size, color, P.O., item and transportation details through on-line. It also sends a copy of L.C. online and it use EDI

electronic data interchange for it. Beside that MTM advertises its facilities of production, its customer portfolio and its achievements on-line. Recently MTM wins the best supplier award 2001-2002 from J.C Penny Company used different passwords for different customers to secure their identity.

Web Site: - MTM has its web site named www.masoodtextile.com this web site contains complete history, profile, production facilities, workforce strength, job opportunities and customer order status of the company. www.masoodtextile.com is updated daily and latest company news is also shown on it. e-mail services names ..

Recently

Masood

Textile

launches

its

own

@masoodtextile.com. This facility is developed, managed and controlled through MTMs own IT. Team. This facility is available for all the employees of MTM. They can use this service for sending and receiving e-mails.

Procurements:

It is the acquisition of goods and services at the best possible cost of ownership in the right quantity at the right time in the right place for the direct benefits of the organization.

Functions of procurement: o Receive PPC sheet from store o Take acquisition o Price negotiation o Order place o Shipment of goods o Time line o Follow up tools

o IGP&GRN o Accessories o Payments of purchased goods

Business Model:

Direct Marketing:

MTM directly contact with its customers through mail, telephone, and personal contacts and sell its products directly to the ultimately buyers.

Indirect Marketing:

When it comes to indirect marketing channel, distribution is made through intermediaries. MTM exports its products through many agents in some cases. MTM is using different channels of transportation for the distribution of its products like, ships, airship etc.

Five forces Model:

1): ENTRY & EXIT BARRIER In entry and exit barrier we are choosing following indicators to understand this force a) Legal environment b) Energy crises

Lets start with legal environment regarding textile industry

a)LEGAL ENVIRONMENT Generally speaking legal environment is not in the favor of textile industry. The Textile Industry was one of those five industries of Pakistan that enjoyed 0% rating facility, which means that their products were not subject to any sales tax. This exemption was given by the government through SRO 509 (I)/2007 dated 9th June, 2007. But recently a new SRO 231(I)/2011 dated 15th March, 2011 has been issued to have changes in the previous one. The applicability of the new sales tax regime for textile sector has become applicable from April 1, 2011 instead of date of the promulgation of the Presidential Ordinance or issuance of relevant notification i.e., March 15, 2011. This new SRO finished the facility of 100% zero rating and imposed a tax of 4% if the finished fabrics have been sold to the un-registered persons like wholesale market All Pakistan Textile Mills Association (APTMA) has told that governments actions are not matching with its words for the textile industry. Chairman APTMA said that this government policy is textile industry friendly.

c)ENERGY CRISES In spite of the rates of utilities in Pakistan being higher than competing countries, their tariffs are increased on regular basis making the industry un-competitive. The cost of production has also risen due to instant increase in electricity tariff. As a consequence of load-shedding the textile production capacity of various sub-sectors has been reduced by up to 30 percent which, along with other consequences, has also reduced the export order. Due to load shedding some mill owner uses alternative source of energy like generator which increase their cost of production further. Due to such dramatic situation the capability of competitiveness of this industry in international market affected badly. A spokesman for the All Pakistan Textile Mills Association (APTMA) claimed that 60 to 70 per cent of the industry had been affected and was unable to accept export orders coming in from around the globe, as a result of gas load shedding. Another jerk has been given to the industry in the form of a Two-day weekend for the conservation of energy. Either adequate energy resources are unavailable to the industry or the

prices of fuel are out of range of the industry. The textile industry being an energy intensive sector is vulnerable to a higher rate of energy losses across various production processes resulting in higher energy bills, and productivity losses- all of which have significant financial impact We conclude that in textile industry entry and exit barrier are very high.

2): LEVEL OF COMPETITION Two types of competition is facing by textile industry Internal External

On national stage the level of competition is low because textile industry needs huge investment. Most importantly now a days our country legal and tax policies are not in the favor of textile industry .Now a days Pakistan is also facing severe energy crisis. The high cost of production resulting is because of increasing energy crisis. So on internal level this competition is low because of unattractiveness of this industry. While on international level industry is facing competition from other developing countries like Bangladesh, India. China also competing Pakistan in major export markets i.e. the EU and the USA. Also the current recession in the West has resulted in

a slowdown in demand for textile products. Due to all the other problems faced by the Textile Industry, its production capacity and quality is getting low. So Pakistan is lagging behind its competitors in the sphere of this international and regional competition. This is a huge threat to the Textile Industry of Pakistan. No of player is low to moderate but the rule of game is very high. So, we conclude that in textile industry level of competition is very high.

3): BARGAINING POWER OF BUYERS Bargaining power of buyer is very high because of new emerging trends of WHO. In past USA and EU was the major importer of Pakistani textile goods but not now. Pakistani textile industry is achieving the national quality standards very hardly It is not easy for Pakistani textile industry

to achieving international quality standards. Now a day WHO quality standard is the metals of most immediate concern are chromium, Zinc, iron, mercury and lead. The fate of these chemicals varies, ranging from 100% retention on the fabric to 100% discharge with the effluent. Most of these metals are non-degradable into non-toxic end products. Experts say that textile wastewater contains substantial pollution loads in terms of COD, BOD, TSS, TDS and heavy metals. The values of these parameters are very high as compared to the values in National Environment Quality Standards (NEQS) set by the government. United States cancel more than 50% of textile orders of Pakistan .US also impose a high duties on the import of textile of Pakistan which effect the export in a bad manner. US & EU are the major importer of Pakistan textile which creates a huge difference in export of Pakistan textile after imposing restriction on import of Pakistani textile goods.

4): BARGAINING POWER OF SUPPLIER Bargaining power of supplier is low because of the new emerging trends of WHO .Now the buyers have very much power to exercise as compare to suppliers. So, bargaining power of supplier level is low. 5): THREAT OF SUBSTITUTE In textile industry threat of substitute is low because people dont have any option to purchase another product to satisfy their need. As USA cut off 50% textile trade from Pakistan but it does not mean that USA find a

substitution for textile products .In fact they shift to another suppliers as China ,Bangladesh or India. So we conclude that threat of substitute is low for masood textile

Vous aimerez peut-être aussi

- Masood Textile Mills Internship ReportDocument117 pagesMasood Textile Mills Internship ReportTouqeer Ahmad100% (3)

- Case Study MTM-1aDocument45 pagesCase Study MTM-1aclickmateen0% (2)

- Nishat Textile MillsDocument24 pagesNishat Textile Millssohail0% (1)

- Masood Textile Mills ReportDocument42 pagesMasood Textile Mills ReportZeeshan Haider Awan100% (4)

- Nishat Textile Mills Limited: An Analysis of Pakistan's Leading Textile CompanyDocument15 pagesNishat Textile Mills Limited: An Analysis of Pakistan's Leading Textile Companyfarooq56Pas encore d'évaluation

- Internship Report On MTM (Masood Textile Mills Limited)Document55 pagesInternship Report On MTM (Masood Textile Mills Limited)Does it Matter?83% (6)

- Internship Report MTMDocument45 pagesInternship Report MTMusmanaltafPas encore d'évaluation

- Internship Report OnDocument49 pagesInternship Report OnAnoshKhan67% (3)

- Alkaram ReportDocument12 pagesAlkaram ReportMunir Ahmed Khan0% (2)

- Gul Ahmed Textile Industry AnalysisDocument24 pagesGul Ahmed Textile Industry AnalysisNoor Pervez0% (1)

- Marketing Strategies of InterloopDocument12 pagesMarketing Strategies of InterloopRana AhmadPas encore d'évaluation

- Gul AhmedDocument44 pagesGul AhmedMalik ShahzebPas encore d'évaluation

- Internship ReportDocument52 pagesInternship ReportAsad Khan80% (5)

- NishatDocument40 pagesNishatmailk Ali100% (3)

- Nishat Mills LimitedDocument38 pagesNishat Mills LimitedTalha KhanPas encore d'évaluation

- Chenab Textile Mills FaisalabadDocument27 pagesChenab Textile Mills FaisalabadMubashar100% (2)

- HRMDocument25 pagesHRMAsma Shoaib100% (1)

- Nishat Linen (Anusha)Document25 pagesNishat Linen (Anusha)Abc XyzPas encore d'évaluation

- 8 INTERNSHIP REPORT MTM Textile Mill Limited MBADocument88 pages8 INTERNSHIP REPORT MTM Textile Mill Limited MBAawaishaneef100% (1)

- Alkaram SWOT AnalysisDocument2 pagesAlkaram SWOT AnalysisAnonymous O3Ntgg9Pas encore d'évaluation

- Nishat Textile Mills (Strategic Management)Document5 pagesNishat Textile Mills (Strategic Management)flavia1286Pas encore d'évaluation

- PEST of Gul AhmedDocument6 pagesPEST of Gul AhmedEemane33% (3)

- Nishat LinenDocument22 pagesNishat LinenM. Amir Riaz0% (1)

- Nishat MillsDocument13 pagesNishat Millswajji1234560% (5)

- Nishat MillsDocument26 pagesNishat Millssabeen ansariPas encore d'évaluation

- Team Member Details and Company OverviewDocument28 pagesTeam Member Details and Company OverviewMuhammad Mubashir0% (1)

- Final Presentation Management Project InterloopDocument36 pagesFinal Presentation Management Project InterloopShakir Abdullah0% (1)

- Nishat MillsDocument29 pagesNishat Millsfarheenkazmi100% (1)

- Cotton Web ReportDocument30 pagesCotton Web ReportHumaRiaz33% (3)

- INTERNSHIP Report On NishatDocument27 pagesINTERNSHIP Report On NishatIftikharUlHassan100% (4)

- Intership Report Textile-CompanyDocument82 pagesIntership Report Textile-CompanyImran Khan Afridi0% (2)

- Project Report on Strategic Analysis of Nishat MillsDocument18 pagesProject Report on Strategic Analysis of Nishat MillsOsama YaqoobPas encore d'évaluation

- Organizational Behavior Term Project on Human Resource Management Practices at Gul Ahmed TextilesDocument9 pagesOrganizational Behavior Term Project on Human Resource Management Practices at Gul Ahmed TextilesSanaullah Bughio33% (3)

- Report On of Sitara TextileDocument25 pagesReport On of Sitara Textilemoonusman80% (15)

- Gul Ahmed - PresenatationDocument27 pagesGul Ahmed - Presenatationzubair_ahmed_imports0% (1)

- Internship Report at Nishat ApparelDocument34 pagesInternship Report at Nishat ApparelQareena Ch100% (2)

- ChenOne lifestyle storeDocument38 pagesChenOne lifestyle storeSyed Muhammad Tayyab50% (6)

- Afroze ReportDocument23 pagesAfroze ReportWaleed KhalidPas encore d'évaluation

- Nishat Textile Mills Limited Marketing ReportDocument7 pagesNishat Textile Mills Limited Marketing Reportfarooq56Pas encore d'évaluation

- Internship+Report+on+Sitara+Textile+Industries+ (PVT) +limitedDocument34 pagesInternship+Report+on+Sitara+Textile+Industries+ (PVT) +limitedrachita_mehta100% (3)

- HRM ProjectDocument26 pagesHRM ProjectZubair SaleemPas encore d'évaluation

- Internship Report FerozeDocument29 pagesInternship Report FerozeWaleed Anjum100% (1)

- Final Gul Ahmed ReportDocument62 pagesFinal Gul Ahmed ReportZia QadirPas encore d'évaluation

- Nishat (1) HamzaDocument14 pagesNishat (1) HamzaImtsal KhalidPas encore d'évaluation

- Report On Ideas by Gul Ahmed-UpdatedDocument17 pagesReport On Ideas by Gul Ahmed-UpdatedAKPas encore d'évaluation

- Presentation On Afroze TextilesDocument25 pagesPresentation On Afroze TextilesSanam NarejoPas encore d'évaluation

- ChenOne Executive Summary: Fashion Chain Stores in Pakistan and Middle EastDocument47 pagesChenOne Executive Summary: Fashion Chain Stores in Pakistan and Middle EastBilal Naseer88% (8)

- Group 3 - OrSC341-2 - Cotton Web PVT LTDDocument24 pagesGroup 3 - OrSC341-2 - Cotton Web PVT LTDHaroonNasir100% (1)

- Alkaram Textile's SWOT and PEST AnalysisDocument19 pagesAlkaram Textile's SWOT and PEST AnalysisShah Mehmood100% (1)

- Nishat TexitleDocument52 pagesNishat TexitleZeshan Tanha100% (2)

- Table of Content: No Topic Page #Document33 pagesTable of Content: No Topic Page #Salman MohiuddinPas encore d'évaluation

- Final ReportDocument13 pagesFinal Reportarsiking86% (7)

- HRM Final ReportDocument14 pagesHRM Final ReportSohail AyubPas encore d'évaluation

- 8 INTERNSHIP REPORT MTM Textile Mill Limited MBADocument85 pages8 INTERNSHIP REPORT MTM Textile Mill Limited MBAyumna100% (1)

- Main BodyDocument42 pagesMain BodyMd. Piar AhamedPas encore d'évaluation

- Course: MIS401 Section: 01 Submitted To: Dr. Md. Rakibul HoqueDocument16 pagesCourse: MIS401 Section: 01 Submitted To: Dr. Md. Rakibul HoqueAffan AhmedPas encore d'évaluation

- CHAPTER NO 3 Tectile MillsDocument16 pagesCHAPTER NO 3 Tectile MillsKhan JeePas encore d'évaluation

- MTM Project Report on Operations, Marketing & SWOTDocument11 pagesMTM Project Report on Operations, Marketing & SWOThanan bajwaPas encore d'évaluation

- Service Integration and Management (SIAM™) Professional Body of Knowledge (BoK), Second editionD'EverandService Integration and Management (SIAM™) Professional Body of Knowledge (BoK), Second editionPas encore d'évaluation

- Ehtejaj e TabresiVol12Document362 pagesEhtejaj e TabresiVol12Muhammad Umair KhalidPas encore d'évaluation

- Bay Al-Inah Bay Al-Wafa Hatt Wa Ta-Jjal Indexation of Loan and RibaDocument14 pagesBay Al-Inah Bay Al-Wafa Hatt Wa Ta-Jjal Indexation of Loan and RibaMuhammad Umair Khalid0% (1)

- Mush Arak AhDocument5 pagesMush Arak AhMuhammad Umair KhalidPas encore d'évaluation

- Cover Letter For Bank JobDocument1 pageCover Letter For Bank JobMuhammad Umair KhalidPas encore d'évaluation

- Reducing Project Duration TechniquesDocument17 pagesReducing Project Duration TechniquesMuhammad Umair KhalidPas encore d'évaluation

- Agico Aug 16Document1 pageAgico Aug 16Muhammad Umair KhalidPas encore d'évaluation

- AFM ProjectDocument23 pagesAFM ProjectMuhammad Umair KhalidPas encore d'évaluation

- Graduate Admission Form: Muhammad Umair KhalidDocument2 pagesGraduate Admission Form: Muhammad Umair KhalidMuhammad Umair KhalidPas encore d'évaluation

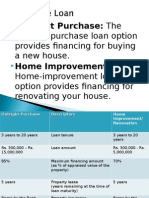

- Outright Purchase: TheDocument14 pagesOutright Purchase: TheMuhammad Umair KhalidPas encore d'évaluation

- HBL PresentationDocument23 pagesHBL PresentationMuhammad Umair KhalidPas encore d'évaluation

- Outright Purchase: TheDocument14 pagesOutright Purchase: TheMuhammad Umair KhalidPas encore d'évaluation

- Chapter 12Document25 pagesChapter 12Muhammad Umair KhalidPas encore d'évaluation

- Effects of trade liberalization on Pakistan's textile sectorDocument1 pageEffects of trade liberalization on Pakistan's textile sectorMuhammad Umair KhalidPas encore d'évaluation

- Punjabi LifestyleDocument4 pagesPunjabi LifestyleMuhammad Umair KhalidPas encore d'évaluation

- Description Project Financing: Total Capital Cost Total Project CostDocument32 pagesDescription Project Financing: Total Capital Cost Total Project CostMuhammad Umair KhalidPas encore d'évaluation

- Ajk BillDocument2 pagesAjk BillMuhammad Umair KhalidPas encore d'évaluation

- Student's Corner: Your Best ChoiceDocument1 pageStudent's Corner: Your Best ChoiceMuhammad Umair KhalidPas encore d'évaluation

- HBRDocument3 pagesHBRMuhammad Umair KhalidPas encore d'évaluation

- Job OpportunityDocument1 pageJob OpportunityMuhammad Umair KhalidPas encore d'évaluation

- Power Management System PMA 300: SIEMENS Marine Solutions Automation On ShipsDocument20 pagesPower Management System PMA 300: SIEMENS Marine Solutions Automation On ShipshamzehPas encore d'évaluation

- Introduction To Smart MetersDocument15 pagesIntroduction To Smart Meterskamalanath123Pas encore d'évaluation

- Transit Development Plan Final DraftDocument34 pagesTransit Development Plan Final DraftinforumdocsPas encore d'évaluation

- Eaton Wavelinx BrochureDocument24 pagesEaton Wavelinx BrochureGustavo HernándezPas encore d'évaluation

- Important Essays Outlines: Democracy in PakistanDocument56 pagesImportant Essays Outlines: Democracy in PakistanYasir MasoodPas encore d'évaluation

- Speed LaundryDocument31 pagesSpeed LaundryNomijut90% (10)

- MEP Internship Training Report Main PageDocument40 pagesMEP Internship Training Report Main PageHhPas encore d'évaluation

- Lit 12012371 PDFDocument120 pagesLit 12012371 PDFNgoc Son PhamPas encore d'évaluation

- Medium Voltage Switchgear GlossaryDocument26 pagesMedium Voltage Switchgear GlossaryVin0% (1)

- Reducing Energy Costs With Peak ShavingDocument17 pagesReducing Energy Costs With Peak ShavingWahyu BhinukoPas encore d'évaluation

- Accenture Power Surge Ahead How Distribution Utilities Can Get Smart With Distributed GenerationDocument16 pagesAccenture Power Surge Ahead How Distribution Utilities Can Get Smart With Distributed GenerationGautam DPas encore d'évaluation

- Challenges and Future of Uganda's Electricity SectorDocument11 pagesChallenges and Future of Uganda's Electricity SectorLucie Bulyaba100% (1)

- Industrial Power Management SystemDocument2 pagesIndustrial Power Management SystemKrishna PardeshiPas encore d'évaluation

- Spectrum Power 7 MGMS Application GuideDocument22 pagesSpectrum Power 7 MGMS Application Guidefayssal salvadorPas encore d'évaluation

- Upcoming World Energy Engineering Congress Program OverviewDocument24 pagesUpcoming World Energy Engineering Congress Program OverviewAee AtlantaPas encore d'évaluation

- Qatar Power Transmission System Expansion Phase-12 Substations Test ReportDocument11 pagesQatar Power Transmission System Expansion Phase-12 Substations Test ReportratheeshkumardPas encore d'évaluation

- Present Condition of Power Sector in Nepal: Narendra Bhupal MallaDocument7 pagesPresent Condition of Power Sector in Nepal: Narendra Bhupal Mallaanamika shrivastavPas encore d'évaluation

- A Strategy For Transmission Network Expansion Planning Considering Multiple Generation ScenariosDocument10 pagesA Strategy For Transmission Network Expansion Planning Considering Multiple Generation ScenarioshuamanahuiPas encore d'évaluation

- The Smart Grid Enabling Energy EfficiencDocument317 pagesThe Smart Grid Enabling Energy EfficienchodPas encore d'évaluation

- Manipur Tariff NewDocument98 pagesManipur Tariff NewPavan KhetrapalPas encore d'évaluation

- RevisionDocument24 pagesRevisionjitendraPas encore d'évaluation

- CHP Presentation Cat Gas and Diesel Generator Sets Performance Cost and Application DifferencesDocument77 pagesCHP Presentation Cat Gas and Diesel Generator Sets Performance Cost and Application DifferencesripalPas encore d'évaluation

- Suriname PDFDocument43 pagesSuriname PDFAtish BisseswarPas encore d'évaluation

- Pakistan+Solar+Consumer+Study+Overview 26thmay2015 LQDocument14 pagesPakistan+Solar+Consumer+Study+Overview 26thmay2015 LQZia MustafaPas encore d'évaluation

- G11 FINAL RESEARCH ROBLOPEREZPASCUAPEDERNAL NewwDocument25 pagesG11 FINAL RESEARCH ROBLOPEREZPASCUAPEDERNAL NewwCordero, Reymond R.Pas encore d'évaluation

- Battery Storage The New Clean PeakerDocument11 pagesBattery Storage The New Clean PeakerMatthew KellyPas encore d'évaluation

- 2022 IRP Initial Public DraftDocument79 pages2022 IRP Initial Public DraftMegan BantaPas encore d'évaluation

- ETAP 12.6 - Tutorial para o ProgramaDocument82 pagesETAP 12.6 - Tutorial para o Programacoringa1340% (5)

- Tata Power-DDL - Journey 5203d3b5f0Document32 pagesTata Power-DDL - Journey 5203d3b5f0shubhamPas encore d'évaluation

- Tutorial Eusipco Tonello PDFDocument150 pagesTutorial Eusipco Tonello PDFchandanjha2010Pas encore d'évaluation