Académique Documents

Professionnel Documents

Culture Documents

10) Itp - Tank Fabrication PDF

Transféré par

Andy ChongDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10) Itp - Tank Fabrication PDF

Transféré par

Andy ChongDroits d'auteur :

Formats disponibles

DOC NO DATE PAGE NO 02 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

1.0

GENERAL The enclosed ITPs shall be followed for the works to be performed by the Contractor under this Tender. The provisions indicated for stagewise inspection by HPCL are a minim um and the contractor shall develop a detailed ITP and obtain approval for the same prior to commencement of work. Contractor to carry out 100% examination of all activities. LEGEND HP: Hold point; A point which require sin section / verification and acceptance by HPCL before any further processing is permitted. The Contractor shall not process the activity/ item beyond a Hold point without written approval by HPCL. Witness Point; An activity which requires witnessing by HPCL when the activity is performed. Review of Contractors documentation. Surveillance Inspection by HPCL; Monitoring or making observations to verify whether or not materials/ items or services conform to specified requirements. Surveillance activities may include audit, inspections, witness of testing, review of quality documentation & records, etc. 100% examination by Contractor.

2.0

W:

Rw: S:

WC:

Responsibility for execution of the inspection/ testing is with the Contractor.

Prepared by CONTRACTOR .

Name : Design: Hindustan Petroleum Crop. Ltd.

Concurred by

Name : Design: Hindustan Petroleum Crop. Ltd

Approved by

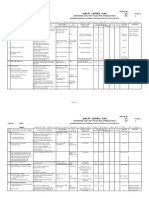

DOC NO DATE PAGE NO 03 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

S. No. STORAGE TANKS A. 1. 2.

ACTIVITY

VISHAL

HPCL

PRIOR OF FABRIATION Acceptance of the tanks foundation Incoming Material Owners Supply WC Rw Contractors supply, including check testing Welding Filler Material Approval /Qualification a) Manufacturing Test Certificate/Documents b) Testing, if any i) Carbon Steel WPS/PQR(Sample Copy attached from Previous HPCL Site Records) a) b) c) Procedure: i) WPS to be written for all the Weld Joints for for Bottom /Shell/Fl. Roof/A ppertunance etc Testing : i) Carbon Steel WC HP Approval of Final WPS / PQR WC HP

WC WC WC WC* WC

HP Rw HP Rw* W

3.

4.

5. 6. 7. 8. B 1. 2.

a) Welder performance Qualification Test b) Certification& Approval of welder Review of joint numbering in drawings mention Reference of 4.a.i. Suitability of plate bending machine Fabrication, erection, testing procedure for job FABRICATION / ERECTION OF BOTTOM Plate size, marking and cutting Blast cleaning & painting of underside of bottom plates

WC WC WC WC WC WC WC WC

W HP HP Rw HP HP W HP

Prepared by CONTRACTOR .

Concurred by Name : Design: Hindustan Petroleum Crop. Ltd.

Approved by Name : Design: Hindustan Petroleum Crop. Ltd

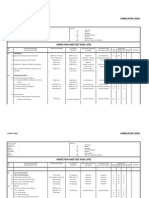

DOC NO DATE PAGE NO 04 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

S. No. 3. 4. 5. 6. 7. 8. 9. 10. 1. 2. 3. 4.

ACTIVITY Plate layout, overlap and fit up Sequence of welding Size and positioning of backing plate for annular plates Banking of electrodes Inter-pass cleaning Visual check of welding DPT/RADIOGRAPHY of annular plate butt welds and bottom plate butt welds (As applicable) Vacuum box test for bottom plate welding SHELL Plate size, marking and cutting Plate binding, curvature check, stacking Shell course alignments and fit-up of vertical and circumferential joints before welding a)Check Shell diameter @0,45,90,135,180,225,270,315,360 & circumference for circularity with strapping tap, perpendicularity, straight edge before welding and documenting (Each Shell wise & w.r.t. precede & ascend) Visual check of welding and back chipping a) inner side welding visual check b) Check shell diameter @0,45,90,135,180,225,270,315,360 & circumference for circularity with strapping tap, perpendicularity, straight edge before welding and documenting (Each Shell wise & w.r.t. precede & ascend) Location size and alignment of nozzles and other openings

VISHAL WC WC WC WC WC WC WC WC WC WC WC WC

HPCL S S W S S W HP HP Rw W W HP

5. 6.

WC WC WC

W W HP

7.

WC

HP

Prepared by CONTRACTOR .

Name : Design: Hindustan Petroleum Crop. Ltd.

Concurred by

Name : Design: Hindustan Petroleum Crop. Ltd

Approved by

DOC NO DATE PAGE NO 05 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

S. No. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. R.F. pads fit-up / welding

ACTIVITY

VISHAL WC WC WC WC WC WC WC WC WC WC WC WC

HPCL W W HP W W HP HP HP W S HP HP

PWHT of shell, RF pads, nozzles, manhole etc (If Applicable) Radiography marking (for random radiography only) Curb angle and Wind girder fit-up / welding DPT of Nozzles, etc. (as applicable) RF pads pneumatic test Shell to bottom fit-up Shell to bottom I/S welding root run visual/ oil chalk test Shell to bottom O/S welding visual and PT Fabrication and erection of stair ways Radiography a) Radiography interpretation b) Check shot for Radiography FLOATING ROOF

1. 2. 3. 4. 5. 6.

Temporary staging, spacing and levels Plate size, straightening and cutting Plate layout, overlap, fit-up welding Availability of approved calculations for design of buoys Buoys / pantoon fabrications Vacuum testing of roof plates welds

WC WC WC WC WC WC

Rw Rw Rw HP S HP

Prepared by CONTRACTOR .

Concurred by Name : Design: Hindustan Petroleum Crop. Ltd.

Approved by Name : Design: Hindustan Petroleum Crop. Ltd

DOC NO DATE PAGE NO 06 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

S. No. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. C. 1. 2. 3. 4.

ACTIVITY Location of sleeve support Pad plate welding with roof and sleeve support Fixing and welding of Buoys Initial Lift Support Fixing through sleeve Seal welding of support sleeve from beneath after dewatering Air test of Buoys / Pantoons Pantoon welding Location, fixing and welding of man-holes, drains etc. Shell to pontoon clearance Air Test of Pontoons for Leakproofness Seal fixing Floating Roof testing, as required e.g. flooding etc. Primary roof drains installation & testing TESTING Correctness testing arrangements especially size of Blind Flanges / vents/ drains/ temporary piping Mechanical/ Inspection clearance Earthing of ladder & shell Settlement reading through Dumpy Level during water filling

VISHAL WC WC WC WC WC WC WC WC WC WC WC WC WC WC

HPCL S S W W S S HP S W HP HP HP HP HP

WC WC WC WC

HP HP W HP

Prepared by CONTRACTOR .

Name : Design: Hindustan Petroleum Crop. Ltd.

Concurred by

Name : Design: Hindustan Petroleum Crop. Ltd

Approved by

DOC NO DATE PAGE NO 07 OF 07

PROJECT

TITLE

INSPECTION TEST PLAN FOR TANK FABRICATON

S. No. 5. 6. 7. 8. 9. Hammer test Air pressure test Vacuum test

ACTIVITY

VISHAL WC WC WC WC WC

HPCL HP HP HP HP Rw

Roof collapsibility test in case of floating roof ranks Vis-a-vis to FR Dessign approved Calibration of tanks from statutory authorities INSPECTION & TEST DOCUMENTS Review Test and Inspection documents

WC

Rw

Prepared by CONTRACTOR .

Name : Design: Hindustan Petroleum Crop. Ltd.

Concurred by

Name : Design: Hindustan Petroleum Crop. Ltd

Approved by

Vous aimerez peut-être aussi

- Storage Tank Inspection API 650Document27 pagesStorage Tank Inspection API 650Pandu Damay Putra92% (12)

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsP SHANKAR BABU100% (16)

- Method Statement For Field Erection Storage TanksDocument29 pagesMethod Statement For Field Erection Storage TanksTee Klong Rung100% (1)

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Storage Tank Fabrication & Erection ProcedureDocument15 pagesStorage Tank Fabrication & Erection ProcedureSenthil Kumaran100% (9)

- Tank 7 Repair Procedure Rev1Document6 pagesTank 7 Repair Procedure Rev1Mohd Shafuaaz Kassim33% (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument10 pages5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- C840 373465-1 PDFDocument18 pagesC840 373465-1 PDFEsteban Mora100% (1)

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Job Procedure For Eriction of TankDocument13 pagesJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- 1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLDocument15 pages1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLsenthilkumarsk88% (8)

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- ITP For Storage TankDocument6 pagesITP For Storage Tankittiphon3194% (17)

- ITP For Storage TankDocument6 pagesITP For Storage TankAhmed Ben HmidaPas encore d'évaluation

- Prepration of ITP For Storage Tanks Fabrication & ErectionDocument27 pagesPrepration of ITP For Storage Tanks Fabrication & ErectionRamuAlagappan93% (15)

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Document6 pagesQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Checklist For Under Ground Water Piping InstallationDocument1 pageChecklist For Under Ground Water Piping InstallationBelal Alrwadieh100% (1)

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Document30 pagesLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Grammar Revision ExercisesDocument4 pagesGrammar Revision ExercisesNicoletaPas encore d'évaluation

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test Proceduresbmmla91% (22)

- Itp TankDocument4 pagesItp TankAmber Chavez100% (2)

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuPas encore d'évaluation

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciPas encore d'évaluation

- Procedure Erection Storage TankDocument7 pagesProcedure Erection Storage Tanknur hudaPas encore d'évaluation

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage Tankgst ajahPas encore d'évaluation

- API 650 12th Edition 2013 - NDT RequirementDocument1 pageAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Erection Procedure (Storage Tank)Document8 pagesErection Procedure (Storage Tank)TURNO100% (1)

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Tanks Installation ManualDocument53 pagesTanks Installation ManualVasuddyas Dsauuyas100% (11)

- Tank Erection Method Statement For Mot Oil Storage TanksDocument13 pagesTank Erection Method Statement For Mot Oil Storage Tanksmeshahan78% (9)

- Ub Engineering LimitedDocument1 pageUb Engineering LimitedproxywarPas encore d'évaluation

- Sample QAPDocument3 pagesSample QAPsniperiPas encore d'évaluation

- 8) Qap Itp For Gen Civil & RCC (10 Pages)Document10 pages8) Qap Itp For Gen Civil & RCC (10 Pages)uday64668Pas encore d'évaluation

- 02 MechanicalDocument44 pages02 MechanicalSigit Bintan100% (1)

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDDocument12 pagesProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikPas encore d'évaluation

- A. Position: Welding Inspector (QA/QC Inspector) ResponbilityDocument8 pagesA. Position: Welding Inspector (QA/QC Inspector) Responbilitydidi sudiPas encore d'évaluation

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaPas encore d'évaluation

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiPas encore d'évaluation

- (ANX-1) Inspection Test Plan (ITP) ListDocument10 pages(ANX-1) Inspection Test Plan (ITP) Listwaragainstlove50% (4)

- Itp Non AsmeDocument7 pagesItp Non AsmeAkhilesh Kumar100% (1)

- ITP For Storage Tank According To API650Document5 pagesITP For Storage Tank According To API650Maneesh KumarPas encore d'évaluation

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiPas encore d'évaluation

- APIINSPECTORDocument10 pagesAPIINSPECTORdada khalandarPas encore d'évaluation

- Plant Inspector: Company Nameoryx GTLDocument4 pagesPlant Inspector: Company Nameoryx GTLsanketPas encore d'évaluation

- Presentation Repair of Storage TankDocument28 pagesPresentation Repair of Storage TankAbdul ManafPas encore d'évaluation

- Resume An Welding InspectorDocument7 pagesResume An Welding InspectorspearboraPas encore d'évaluation

- Inspection and Test Plan For SwitchgearDocument12 pagesInspection and Test Plan For SwitchgearShahadat HossainPas encore d'évaluation

- MWP-C-CS-PC-0009 Tank Erection Procedure-BDocument16 pagesMWP-C-CS-PC-0009 Tank Erection Procedure-BKing王Pas encore d'évaluation

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863Pas encore d'évaluation

- L 1 Asad Ahmad Qaqc Piping Welding Ins PDFDocument9 pagesL 1 Asad Ahmad Qaqc Piping Welding Ins PDFyasiriftikharPas encore d'évaluation

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- Loctite 592™: % of Initial Strength Environment °C 720 HDocument2 pagesLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongPas encore d'évaluation

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizedavidemolPas encore d'évaluation

- Use Caution When Specifying "Seal Welds": Design FileDocument4 pagesUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaPas encore d'évaluation

- TGN-PE-02 Temper Bead WeldingDocument9 pagesTGN-PE-02 Temper Bead WeldingNatrajiPas encore d'évaluation

- G. Lawrence, B. Messer, V. Oprea, Fluor Corporation, Calgary, Alberta, Canada, and C.W. Patrick, T. Phillips, Fluor Corporation, Sugar Land, TexasDocument1 pageG. Lawrence, B. Messer, V. Oprea, Fluor Corporation, Calgary, Alberta, Canada, and C.W. Patrick, T. Phillips, Fluor Corporation, Sugar Land, TexasAndy ChongPas encore d'évaluation

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizedavidemolPas encore d'évaluation

- Fundamentals of WeldingDocument9 pagesFundamentals of Weldingkinnu_ak7829Pas encore d'évaluation

- Pipework SpecificationDocument111 pagesPipework Specificationwentroprem100% (2)

- Weedina JORC AnnouncementDocument7 pagesWeedina JORC AnnouncementAndy ChongPas encore d'évaluation

- Thread Sealing 101 Tech ArticleDocument4 pagesThread Sealing 101 Tech ArticleAndy ChongPas encore d'évaluation

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizedavidemolPas encore d'évaluation

- T22 CPS Macros OverviewDocument10 pagesT22 CPS Macros OverviewAndy ChongPas encore d'évaluation

- Why Do Gasketed Joints Leak?: Why Bolts Loosen Embedment RelaxationDocument4 pagesWhy Do Gasketed Joints Leak?: Why Bolts Loosen Embedment RelaxationcuraajPas encore d'évaluation

- CSWIP WI 6 92 SUP01 3rd Edition November 2009Document3 pagesCSWIP WI 6 92 SUP01 3rd Edition November 2009Kazim NawazPas encore d'évaluation

- Best Practices 24Document4 pagesBest Practices 24Andy ChongPas encore d'évaluation

- 138.65 Shell and Tube I&oDocument6 pages138.65 Shell and Tube I&oAndy ChongPas encore d'évaluation

- Assembly & Installation Installation Overview: ThreadingDocument11 pagesAssembly & Installation Installation Overview: ThreadingAndy ChongPas encore d'évaluation

- Tank Fabrication SpecsDocument21 pagesTank Fabrication Specsjlcheefei9258100% (1)

- PSV Dresser Type 1511 ManualDocument40 pagesPSV Dresser Type 1511 ManuallangtuPas encore d'évaluation

- PSV Dresser Type 1511 ManualDocument40 pagesPSV Dresser Type 1511 ManuallangtuPas encore d'évaluation

- CSWIP-WI-1-91 9th Edition November 2010Document8 pagesCSWIP-WI-1-91 9th Edition November 2010Thamaraikani ManiPas encore d'évaluation

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- Loctite 592™: % of Initial Strength Environment °C 720 HDocument2 pagesLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongPas encore d'évaluation

- kwt2006 01Document11 pageskwt2006 01Andy ChongPas encore d'évaluation

- Hot Dip Galvanising 1Document12 pagesHot Dip Galvanising 1Alex LevinPas encore d'évaluation

- WFP 2-12-Att-2-R1 - 3Document1 pageWFP 2-12-Att-2-R1 - 3Andy ChongPas encore d'évaluation

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013Pas encore d'évaluation

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- Research Paper by Udhaiyah PriyaDocument69 pagesResearch Paper by Udhaiyah PriyaUdhaiyah PriyaPas encore d'évaluation

- Burgers Uıde Lovers Business PlanDocument54 pagesBurgers Uıde Lovers Business PlanMohamed Abdel HamidPas encore d'évaluation

- Roman LDocument4 pagesRoman Lapi-549448040Pas encore d'évaluation

- Notice25712 PDFDocument71 pagesNotice25712 PDFsudhir kumarPas encore d'évaluation

- Sentences Types QuizDocument3 pagesSentences Types QuizAsiale AlmoceraPas encore d'évaluation

- Architecture Is The Learned Game, Correct and Magnificent, of Forms Assembled in The Light.Document26 pagesArchitecture Is The Learned Game, Correct and Magnificent, of Forms Assembled in The Light.Shrea ZopePas encore d'évaluation

- Joe Dalton Riffs TabDocument2 pagesJoe Dalton Riffs TabPoss HumPas encore d'évaluation

- Design Like You Give A Damn ReviewDocument4 pagesDesign Like You Give A Damn ReviewTânia Fernandes0% (1)

- Cross ArmsDocument46 pagesCross Armshalel111Pas encore d'évaluation

- Make Your Own Cband Satellite TVDocument7 pagesMake Your Own Cband Satellite TVVignesh KarnikaPas encore d'évaluation

- Interchange 5e Level 1 Students Book Unit 15Document16 pagesInterchange 5e Level 1 Students Book Unit 15Juan Carlos PabonPas encore d'évaluation

- ZATHURA: A Space Adventure Activity KitDocument13 pagesZATHURA: A Space Adventure Activity KitHoughton Mifflin HarcourtPas encore d'évaluation

- Class 7 Science Olympiad Achievers Section Practice PapersDocument5 pagesClass 7 Science Olympiad Achievers Section Practice PapersSPas encore d'évaluation

- Presentation To FADocument28 pagesPresentation To FAtakit mallikPas encore d'évaluation

- Vcop Pyramids 1Document6 pagesVcop Pyramids 1Haslina ZakariaPas encore d'évaluation

- The Merchant's Tale EssayDocument8 pagesThe Merchant's Tale EssayRosa Morey RodriguezPas encore d'évaluation

- Satipatthana VipassanaDocument50 pagesSatipatthana VipassanapeperetruPas encore d'évaluation

- Project Construction ManagementDocument2 pagesProject Construction ManagementMarian NikkaPas encore d'évaluation

- Activity 5 The Voyage Around The WorldDocument2 pagesActivity 5 The Voyage Around The WorldClariza PascualPas encore d'évaluation

- Jamstix ManualDocument58 pagesJamstix ManualmrnogoodPas encore d'évaluation

- Papango Eng Amer LittDocument26 pagesPapango Eng Amer LittReden OriolaPas encore d'évaluation

- MIT Wind Ensemble & MIT Festival Jazz Ensemble - Infinite Winds - 1400booklet - RRDocument8 pagesMIT Wind Ensemble & MIT Festival Jazz Ensemble - Infinite Winds - 1400booklet - RRDelFondo EstudiosPas encore d'évaluation

- Hill ArchitectureDocument5 pagesHill ArchitectureShubamGargPas encore d'évaluation

- Lista-Arome-Modificata F.M.Document3 pagesLista-Arome-Modificata F.M.Cosmin FlorinPas encore d'évaluation

- 518 - My Life Is in You, Lord: Lead SheetDocument2 pages518 - My Life Is in You, Lord: Lead Sheetpaxbass5Pas encore d'évaluation

- Allegro and Perpetual Motion From Suzuki Book 1Document16 pagesAllegro and Perpetual Motion From Suzuki Book 1peprintoPas encore d'évaluation

- Electrical Plan ComputationDocument1 pageElectrical Plan ComputationMarc Adrienne MarquezPas encore d'évaluation