Académique Documents

Professionnel Documents

Culture Documents

PB 2

Transféré par

Christian Aguilar DiazDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PB 2

Transféré par

Christian Aguilar DiazDroits d'auteur :

Formats disponibles

Oxidation and Oxidizing Refining of Metis 208 Theory of Metallurgical Processes

209

Table V. HEATS OF FORMATION OF OXIDES OF IMPURITIES FROM ELEMENTS

AiMoiate Na 3 As0 4 is formed according to the reactions 2Pb -f 0 2 = 2PbO + AZ 3PbO + 2 [As] = (As203) + 3 [Pb] + AZ (As203) + 3 (Na20) = (3NaaO. Asa08) + AZ (3Na 2 0. As203) + 2PbO = (3Na20 As205) -f 2 [Pb] + AZ (81) (82) (83) (84)

Q298 per mole Oxide MeO 52 A 138.0 39.8 82.2 02 104.8 92.0 79.6 166.4 Oxide

Q298 per mole MeO 156.2 167.1 138.8 7.3 02 104.1 111.4 1 138.8 i 14.6

PbO Bi 2 0 3 Cu 2 0 ZnO

As 2 0 3 Sb 2 0 3 Sn0 2 Ag 2 0

iiuiing up equations (82), (83) and (84), we obtain 5PbO + 2 [As] + 3(Na20) (3Na 2 0. As205) + 5 [Pb] + AZ5 (85) BOSe oquilibrium constant is

K c

As the table indcales, silver, bismuth and copper have a lessef affinity for oxygen than lead; therefore, it may be expectod that Zn, As, Sb and Sn are, while Bi, Cu, Ag and Au are not oxidi/.od by the lead oxide. Of the three remaining impurities, the first to oxidize is tin, which forms, together with the lead oxides, a powder- or paste-like (depending on Sb and As contents) mass of a light-yellow (for purely tin skimmings) or dark-yellow (for skimmings with Sb and As) colour. Tin skimmings consist of lead stannates (Sn0 2 -nPbO) and partly of tin and lead antimonates. After tin is removed, As 4 0 6 and Sb 2 0 3 vapours seprate from molten lead, and formed on the bath surface are lead arsenates coloun-tl from lemon-yellow to light-brown, and lead antimonates, colourod from dark-brown to black. The relative amount of arsenates in the dross gradually falls, that of the antimonates rises. After arsenio and antimony are removed, lead oxidizes to litharge, which floata to the surface of the bath as a green-yellow powder. At present, lead is refined not through oxidation by air, but by saltpetre, with the addition of caustic soda to bind the acid and amphoteric oxides by a strong base (Na 2 0), the process being called the alkali refining of lead. The reaction between PbO and Me' (impurities) proceeds onJy at points of contact of the surface layer of oxides with the metal, On heating, saltpetre docomposes with the evolution of atomic oxygen according to the reactions NaN0 3 = NaNO ; + O 2NaN0 2 = Na 2 0 + N 2 + 3 0 Saltpetre is charged by means of a special device which allows tlio molten layer'of alkali and salt to be kept in contact with the crudo lead. Molten lead is pumped from below through the molten saltpetre and alkali. The lead then oxidizes to PbO, which interacty with the impurities (for example, with arsenic); the As 2 0 3 obtained il slagged, forming stable chemical compoundssaltswith Na 2 0.

(Na 3 As0 4 ) a [Pbp [As] 2 lPbOP(Na 2 0)3

AZ = AZ-hAZ + AZ4 een, the thermodynamic potential of the overall reaction (85) lkZl) is numerically much greater than that of reaction (82) (AZ) I M M HUSO it is summed up with the thermodynamic potential of the lifiction of formation of arsenate from oxides (Na 2 0 and As 2 0 3 ). i result, the equilibrium constant of reaction (85) is considerably yniicr than that of reaction (82) and the residual concentration of ni lead drops substantially. Also oxidized are other impurities, Mth nutimonate Na 3 Sb0 4 and stannate Na 3 Sn0 3 being formed. A.s a result, the impurities (As, Sb, Sn, Zn) are efficiently reil and their respective contents drop to a few thousandths of a |il cent. A high rate of the process is attained by the use of saltpetre ii oxidizer, of an alkali for slagging the impurities and the pror mu of a vigorous circulation of lead through a layer of molten di. Oxidation of Components in the Manufacture and Remelting o Alloys Oxidation of alloy components in the manufacture, remelting or IDBcial oxidizing refining of alloys involves the same physico hemical principies as those of the oxidizing refining of metis. A feature of these phenomena is that the concentrations of the rumponents in the alloy are much greater than those of the impurii es in the metal. Uualitatively, the phenomena are basically the same as in oxidiMu',- refining of metis. The oxidation of impurities is of particular Importance to alloys composed oE components far apart in the order l their affinity for oxygen, as in silicon bronzes, brasses, alloys

0877

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

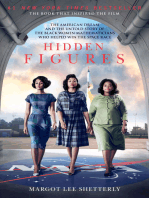

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Metal Losses in Pyrometallurgical Operations - A Review: Advances in Colloid and Interface Science August 2017Document44 pagesMetal Losses in Pyrometallurgical Operations - A Review: Advances in Colloid and Interface Science August 2017Christian Aguilar DiazPas encore d'évaluation

- Smu251 PDF EngDocument10 pagesSmu251 PDF EngChristian Aguilar DiazPas encore d'évaluation

- XPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFDocument7 pagesXPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFChristian Aguilar DiazPas encore d'évaluation

- Contribution ICT Economy ActivityDocument37 pagesContribution ICT Economy ActivityChristian Aguilar DiazPas encore d'évaluation

- Mystic Powerpoint TemplateDocument51 pagesMystic Powerpoint TemplateEDINSONPas encore d'évaluation

- Acoustic Guitar Jump StartDocument10 pagesAcoustic Guitar Jump StartChristian Aguilar DiazPas encore d'évaluation

- XPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFDocument7 pagesXPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFChristian Aguilar DiazPas encore d'évaluation

- Classic Being Polite 2 1Document17 pagesClassic Being Polite 2 1Christian Aguilar DiazPas encore d'évaluation

- ResumeDocument5 pagesResumeChristian Aguilar DiazPas encore d'évaluation

- The Mineralogical Characterization of Tellurium in Copper AnodesDocument11 pagesThe Mineralogical Characterization of Tellurium in Copper AnodesChristian Aguilar DiazPas encore d'évaluation

- Classic Staying Safe 2 1Document17 pagesClassic Staying Safe 2 1Christian Aguilar DiazPas encore d'évaluation

- TT-197 FinalDocument2 pagesTT-197 FinalFabian Sedano MangualayaPas encore d'évaluation

- Mathematical Modeling of Sulfide Flash Smelting ProcesDocument14 pagesMathematical Modeling of Sulfide Flash Smelting ProcesChristian Aguilar DiazPas encore d'évaluation

- 206 Theory of Metallurgical Processes: # 51. Oxidizing Refining of LeadDocument1 page206 Theory of Metallurgical Processes: # 51. Oxidizing Refining of LeadChristian Aguilar DiazPas encore d'évaluation

- BateriaDocument14 pagesBateriaChristian Aguilar DiazPas encore d'évaluation

- Ani MeshDocument44 pagesAni MeshChristian Aguilar DiazPas encore d'évaluation

- Ultrafine Zinc Oxide Powders Prepared by Precipitation Mechanical MillingDocument4 pagesUltrafine Zinc Oxide Powders Prepared by Precipitation Mechanical MillingChristian Aguilar DiazPas encore d'évaluation

- High Bismuth DrossDocument4 pagesHigh Bismuth DrossLucas CarbinattoPas encore d'évaluation

- 08 Ion Selective Electrodes-pH MeterDocument16 pages08 Ion Selective Electrodes-pH MeterHassan GillPas encore d'évaluation

- New Dispersion Design Concepts For 1k Waterborne Protective CoatingsDocument20 pagesNew Dispersion Design Concepts For 1k Waterborne Protective CoatingsLong An DoPas encore d'évaluation

- Silicon Carbide - Vs-Tungsten Carbide: Contributed by Zoeller Engineering DepartmentDocument1 pageSilicon Carbide - Vs-Tungsten Carbide: Contributed by Zoeller Engineering DepartmentDikaAnindyajatiPas encore d'évaluation

- O-Levels Combined Science 2023 AnswersDocument6 pagesO-Levels Combined Science 2023 AnswersEarth LegendPas encore d'évaluation

- ThesisDocument139 pagesThesisVENKAT REDDY BANDAPas encore d'évaluation

- HiiiiDocument10 pagesHiiiiVenkatesan B.Pas encore d'évaluation

- Biologically Important Molecules Study Guide PDFDocument4 pagesBiologically Important Molecules Study Guide PDFsarahbeth1980Pas encore d'évaluation

- Acids & BasesDocument4 pagesAcids & BasesGrand Meme VinesPas encore d'évaluation

- Lube OilDocument15 pagesLube Oilhala mrayanPas encore d'évaluation

- Triton Ficha TecnicaDocument2 pagesTriton Ficha TecnicaBruno FilipePas encore d'évaluation

- 11 Chemistry Revision Book 2017 2018 Chapter 12 PDFDocument20 pages11 Chemistry Revision Book 2017 2018 Chapter 12 PDFManoj kumarPas encore d'évaluation

- Smvo 4Document10 pagesSmvo 4selrajanPas encore d'évaluation

- 6242 01 Que 00070118Document16 pages6242 01 Que 00070118a盈仪Pas encore d'évaluation

- Test 1 PharmacognosyDocument5 pagesTest 1 PharmacognosyPrem Shankar Gupta100% (2)

- Catalytic Methanol CarbonylationDocument27 pagesCatalytic Methanol CarbonylationMartin Dubois100% (1)

- SynDocument13 pagesSynnuanfo100% (1)

- AbstractDocument2 pagesAbstractcheryl singlaPas encore d'évaluation

- Chemical Oxygen Demand (Cod) : TitleDocument6 pagesChemical Oxygen Demand (Cod) : TitleWaleed KhalidPas encore d'évaluation

- Polymerization MethodDocument5 pagesPolymerization MethodAzmiHafifiPas encore d'évaluation

- Indolmicin PDFDocument3 pagesIndolmicin PDFMaria-LuizaGhidrasanPas encore d'évaluation

- ZuzanaDocument58 pagesZuzanaAlexanderPas encore d'évaluation

- Ipecacuanha Tincture, StandardisedDocument2 pagesIpecacuanha Tincture, StandardisedJjangyiPas encore d'évaluation

- AtomDocument4 pagesAtomanjaliPas encore d'évaluation

- Chemistry CSEC June 2015 P1Document9 pagesChemistry CSEC June 2015 P1Toni-Krys HardyPas encore d'évaluation

- Chevron Handbook Drilling FluidsDocument277 pagesChevron Handbook Drilling FluidsAtiq uRehman100% (2)

- Chemistry: Number Key Number KeyDocument17 pagesChemistry: Number Key Number KeyVarun PanickerPas encore d'évaluation

- cHEM 11 uNIT 5 OrgchemDocument68 pagescHEM 11 uNIT 5 OrgchemAce CardenoPas encore d'évaluation

- Wirtz Cork and Product BrochureDocument9 pagesWirtz Cork and Product BrochureKy VuPas encore d'évaluation

- SEN CloggingDocument44 pagesSEN CloggingsatyajitPas encore d'évaluation

- Acids, Bases and Salts MCQDocument16 pagesAcids, Bases and Salts MCQprayas thakrePas encore d'évaluation