Académique Documents

Professionnel Documents

Culture Documents

Metal Ferrous Metal Duplex Stainless Steel

Transféré par

Tomy GeorgeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metal Ferrous Metal Duplex Stainless Steel

Transféré par

Tomy GeorgeDroits d'auteur :

Formats disponibles

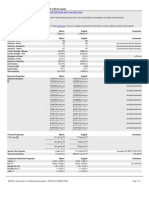

Outokumpu 2205 Duplex Stainless Steel

Categories: Metal; Ferrous Metal; Duplex; Stainless Steel

Material Notes: Duplex stainless combining high mechanical strength with good corrosion resistance. Applications:

l l l l l l l l l l l l l

Pulp and paper industry Desalination plants Flue-gas cleaning Cargo tanks and pipe systems in chemical tankers Seawater systems Firewalls and blast walls on offshore platforms Bridges Components for structural design Storage tanks Pressure vessels Heat exchangers Water heaters Rotors, impellers and shafts

Available in hot rolled plate (Quarto), hot rolled strip/sheet (CPP), cold rolled strip/sheet, cold rolled narrow strip, bar, and rod forms. Key Words: Vendors: EN 1.4462; ASTM S32205, S31803; JIS SUS 329J3L No vendors are listed for this material. Please click here if you are a supplier and would like information on how to add your listing to this material. Metric 7.80 g/cc Metric 750 MPa 767 MPa 540 MPa

@Temperature250C

Physical Properties Density Mechanical Properties TensileStrength,Ultimate TensileStrength,Yield ElongationatBreak ModulusofElasticity PoissonsRatio FatigueStrength ShearModulus ImpactTest

English 0.282 lb/in

Comments RT

English Comments 109000 psi Outokumpu Typical, Hot Rolled Plate (Quarto); EN 10002-1 111000 psi In Fatigue, R=smin/smax=0.1;RT;2 million cycles, 50% probability of failure 78300 psi EN min.; EN 10002-5

@Temperature482F

550 MPa

@Temperature200C

79800 psi

@Temperature392F

EN min.; EN 10002-5 EN min.; EN 10002-5 EN min.; EN 10002-5

570 MPa

@Temperature150C

82700 psi

@Temperature302F

590 MPa

@Temperature100C

85600 psi

@Temperature212F

460 MPa 497 MPa 510 MPa 300 MPa

@Temperature250C

66700 psi EN min., 0.2% Strain, RT; EN 10002-1 72100 psi In Fatigue, 0.2% Strain, R=smin/smax=0.1;RT;2 million cycles, 50% probability of failure 74000 psi Outokumpu Typical, 0.2% Strain, Hot Rolled Plate (Quarto); EN 10002-1 43500 psi EN min., 0.2% Strain; EN 10002-5

@Temperature482F

315 MPa

@Temperature200C

45700 psi

@Temperature392F

EN min., 0.2% Strain; EN 10002-5 EN min., 0.2% Strain; EN 10002-5 EN min., 0.2% Strain; EN 10002-5 Outokumpu Typical, Hot Rolled Plate (Quarto); EN 10002-1 RT

335 MPa

@Temperature150C

48600 psi

@Temperature302F

360 MPa

@Temperature100C

52200 psi

@Temperature212F

35.0 % 200 GPa 172 GPa

@Temperature400C

35.0 % 29000 ksi 24900 ksi

@Temperature752F

180 GPa

@Temperature300C

26100 ksi

@Temperature572F

186 GPa

@Temperature200C

27000 ksi

@Temperature392F

194 GPa

@Temperature100C

28100 ksi

@Temperature212F

0.300 510 MPa

@# of Cycles 2.00e+6

0.300 74000 psi

@# of Cycles 2.00e+6

RT R=smin/smax=0.1;RT; 50% probability of failure calculated EN min., -40CEN10045-1 ENmin.,20CEN10045-1

77.0 GPa 40.0 J 60.0 J

11200 ksi 29.5 ft-lb 44.3 ft-lb

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM /

Page 1 / 2

Electrical Properties ElectricalResistivity Thermal Properties CTE, linear SpecificHeatCapacity ThermalConductivity Processing Properties AnnealingTemperature Component Elements Properties Carbon,C Chromium,Cr Iron,Fe Molybdenum,Mo Nickel,Ni Nitrogen,N

Metric 0.0000800 ohm-cm 0.0000850 ohm-cm

@Temperature100C

English 0.0000800 ohm-cm 0.0000850 ohm-cm

@Temperature212F

Comments RT

0.0000900 ohm-cm

@Temperature200C

0.0000900 ohm-cm

@Temperature392F

0.000100 ohm-cm

@Temperature300C

0.000100 ohm-cm

@Temperature572F

Metric 13.0 m/m-C

@Temperature100C

English 7.22 in/in-F

@Temperature212F

Comments

14.5 m/m-C

@Temperature400C

8.06 in/in-F

@Temperature752F

0.500 J/g-C 0.530 J/g-C

@Temperature100C

0.120 BTU/lb-F 0.127 BTU/lb-F

@Temperature212F

RT

0.560 J/g-C

@Temperature200C

0.134 BTU/lb-F

@Temperature392F

0.590 J/g-C

@Temperature300C

0.141 BTU/lb-F

@Temperature572F

15.0 W/m-K 16.0 W/m-K

@Temperature100C

104 BTU-in/hr-ft-F 111 BTU-in/hr-ft-F

@Temperature212F

RT

17.0 W/m-K

@Temperature200C

118 BTU-in/hr-ft-F

@Temperature392F

18.0 W/m-K

@Temperature300C

125 BTU-in/hr-ft-F

@Temperature572F

20.0 W/m-K

@Temperature400C

139 BTU-in/hr-ft-F

@Temperature752F

Metric 1020 - 1100C 1020 - 1100C Metric 0.020 % 22.0 % 69.01 % 3.10 % 5.70 % 0.17 %

English 1870 - 2010F 1870 - 2010F English 0.020 % 22.0 % 69.01 % 3.10 % 5.70 % 0.17 %

Comments Quench Annealing Stress Relief Annealing Comments

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format. Users requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM /

Page 2 / 2

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- 007 Magmatip Filling Results enDocument7 pages007 Magmatip Filling Results enpurushothaman1234566Pas encore d'évaluation

- MCQ 4 GroundwaterDocument6 pagesMCQ 4 GroundwaterAnonymous EvbW4o1U7100% (4)

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youPas encore d'évaluation

- AISI1040Document2 pagesAISI1040Anonymous qRbPsLpuNPas encore d'évaluation

- 11 - TW Thermo-KineticsDocument14 pages11 - TW Thermo-Kineticsthomas_v501925Pas encore d'évaluation

- Aisi 1008 PDFDocument2 pagesAisi 1008 PDFIbsonhPas encore d'évaluation

- Aluminum 2024 T6Document4 pagesAluminum 2024 T6Thiru Kumaran0% (1)

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosPas encore d'évaluation

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xPas encore d'évaluation

- Minfm35736 en 10273 Grade p295gh Normalized or Normalized Formed NDocument7 pagesMinfm35736 en 10273 Grade p295gh Normalized or Normalized Formed Nmh hPas encore d'évaluation

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgePas encore d'évaluation

- MaterialData 6877Document2 pagesMaterialData 6877Maxi PianelliPas encore d'évaluation

- 304Document2 pages304julianmorantesPas encore d'évaluation

- C95300Document2 pagesC95300Romeo DequitoPas encore d'évaluation

- Minfm31326 en 10210 1 Grade ST 52 3Document6 pagesMinfm31326 en 10210 1 Grade ST 52 3bksinghsPas encore d'évaluation

- Aisi 1045Document1 pageAisi 1045edraelmx100% (1)

- AISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundDocument2 pagesAISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundGiancarlo PassalacquaPas encore d'évaluation

- ASM Material Data SheetDocument3 pagesASM Material Data SheetAscanio BarbosaPas encore d'évaluation

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezPas encore d'évaluation

- VDM Data Sheet Nicrofer 6025 HT - e PDFDocument0 pageVDM Data Sheet Nicrofer 6025 HT - e PDFeugenio.gutenbertPas encore d'évaluation

- 2 4Document14 pages2 4rafaelki100% (2)

- Aisi 316Document2 pagesAisi 316denihendrawanPas encore d'évaluation

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080Pas encore d'évaluation

- Aluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum AlloyDocument3 pagesAluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum Alloyvishwanadh kPas encore d'évaluation

- 2CDC002157D0201Document7 pages2CDC002157D0201260380sdPas encore d'évaluation

- Petrotest Product 26-0400+etc enDocument11 pagesPetrotest Product 26-0400+etc enShadi Al HabbalPas encore d'évaluation

- The Online Materials Database Sandvik 254 SMO Seamless Tube and PipeDocument2 pagesThe Online Materials Database Sandvik 254 SMO Seamless Tube and PipeSukhDeolPas encore d'évaluation

- Valbruna Grade Steel TypeDocument3 pagesValbruna Grade Steel TypeLebasPas encore d'évaluation

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalPas encore d'évaluation

- Water Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansDocument4 pagesWater Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansgoodtiPas encore d'évaluation

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANPas encore d'évaluation

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozPas encore d'évaluation

- Physical Properties: Physical Property British Units Metric Units Density Melting RangeDocument4 pagesPhysical Properties: Physical Property British Units Metric Units Density Melting RangesuiafwgehjdfPas encore d'évaluation

- Aisi 5140 PDFDocument2 pagesAisi 5140 PDFTasha AnaPas encore d'évaluation

- Overview of Materials For Polypropylene, Extrusion Grade: To View All Available Suppliers For This MaterialDocument2 pagesOverview of Materials For Polypropylene, Extrusion Grade: To View All Available Suppliers For This Materialvongoctu2016Pas encore d'évaluation

- Properties s45cDocument3 pagesProperties s45ctomas duranPas encore d'évaluation

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSPas encore d'évaluation

- PTFE DatasheetDocument2 pagesPTFE DatasheetthodatisampathPas encore d'évaluation

- (PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsDocument2 pages(PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsMakhdum Muhardiana PutraPas encore d'évaluation

- Apmr 2023 05 31 - 08 55 46Document3 pagesApmr 2023 05 31 - 08 55 46triggs1971Pas encore d'évaluation

- Rubberexp ConnectallDocument6 pagesRubberexp ConnectallThaiminh VoPas encore d'évaluation

- Stainless Steel 310/310S (UNS S31000/ UNS S31008) : Element SS 310 SS 310SDocument5 pagesStainless Steel 310/310S (UNS S31000/ UNS S31008) : Element SS 310 SS 310SRajaram GanesanPas encore d'évaluation

- Bohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelDocument2 pagesBohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelAgustine SetiawanPas encore d'évaluation

- 2013 Aluminum Electrolytic CatalogDocument290 pages2013 Aluminum Electrolytic CatalogGavih AryadiPas encore d'évaluation

- Daewoo - fr-280 Service ManualDocument16 pagesDaewoo - fr-280 Service ManualFrancisco Orozco100% (1)

- Nylon MC901Document2 pagesNylon MC901V ShankarPas encore d'évaluation

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xPas encore d'évaluation

- Ed Uccp 201501Document39 pagesEd Uccp 201501XUAN CUONG PHAN0% (1)

- 1.3343 HS6-5-2CDocument3 pages1.3343 HS6-5-2CmustafabodurPas encore d'évaluation

- Chiller RecipDocument4 pagesChiller RecipHerni SuharniriyantiPas encore d'évaluation

- Green Field Building-ConstructionDocument7 pagesGreen Field Building-Constructionsushant_jhawerPas encore d'évaluation

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismPas encore d'évaluation

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderPas encore d'évaluation

- Inconel - Alloy 330 - UNS N08330Document8 pagesInconel - Alloy 330 - UNS N08330Javeed A. KhanPas encore d'évaluation

- Datasheet For Steel Grades Carbon Steel Sae j403Document5 pagesDatasheet For Steel Grades Carbon Steel Sae j403Ranjeet DongrePas encore d'évaluation

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaPas encore d'évaluation

- Hastelloy G 35Document16 pagesHastelloy G 35Ir Go JarPas encore d'évaluation

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanPas encore d'évaluation

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudPas encore d'évaluation

- Polishing Film Lestar 209-210-002Document1 pagePolishing Film Lestar 209-210-002Tomy GeorgePas encore d'évaluation

- ASTM and Grain Size MeasurementsDocument6 pagesASTM and Grain Size MeasurementsTomy George100% (1)

- Chroma MHT BrochureDocument4 pagesChroma MHT BrochureTomy GeorgePas encore d'évaluation

- Macro TestDocument2 pagesMacro TestTomy GeorgePas encore d'évaluation

- Illumination ModesDocument3 pagesIllumination ModesTomy GeorgePas encore d'évaluation

- Illumination ModesDocument3 pagesIllumination ModesTomy GeorgePas encore d'évaluation

- Standard - Light Landing Stage On Supply and Tug - Proposed ModificationsDocument2 pagesStandard - Light Landing Stage On Supply and Tug - Proposed ModificationsTomy GeorgePas encore d'évaluation

- Chemical Etching ReagentDocument2 pagesChemical Etching ReagentTomy GeorgePas encore d'évaluation

- Ethanol - Wikipedia, The Free EncyclopediaDocument19 pagesEthanol - Wikipedia, The Free EncyclopediaTomy GeorgePas encore d'évaluation

- Formular Formula - HTMDocument3 pagesFormular Formula - HTMTomy GeorgePas encore d'évaluation

- SwiftTech SwiftGoDocument4 pagesSwiftTech SwiftGoTomy GeorgePas encore d'évaluation

- Izod Impact Strength Test - Wikipedia, The Free EncyclopediaDocument2 pagesIzod Impact Strength Test - Wikipedia, The Free EncyclopediaTomy GeorgePas encore d'évaluation

- Area of Plane Shapes: Area B × H Area ADocument2 pagesArea of Plane Shapes: Area B × H Area ATomy GeorgePas encore d'évaluation

- New en StdsDocument1 pageNew en StdsTomy GeorgePas encore d'évaluation

- Arc (Geometry)Document3 pagesArc (Geometry)Tomy GeorgePas encore d'évaluation

- Circular SegmentDocument2 pagesCircular SegmentTomy GeorgePas encore d'évaluation

- Arc Welding Filler Metal Selection ChartDocument7 pagesArc Welding Filler Metal Selection Chartepriyono0% (1)

- Dish End InspectionDocument2 pagesDish End InspectionTomy George80% (5)

- Arc Circle.Document1 pageArc Circle.Tomy GeorgePas encore d'évaluation

- Welding Electrode ClassificationsDocument2 pagesWelding Electrode Classificationscmpatel_00Pas encore d'évaluation

- Electrical System ChecksDocument1 pageElectrical System ChecksTomy GeorgePas encore d'évaluation

- AIEEE 2010 Solution CPDocument23 pagesAIEEE 2010 Solution CPPJ BhattacharyaPas encore d'évaluation

- Fabrication of Pressure 32-68Document38 pagesFabrication of Pressure 32-68DIPAK VINAYAK SHIRBHATE100% (1)

- FCAW - Cored Wires OverviewDocument3 pagesFCAW - Cored Wires OverviewTomy GeorgePas encore d'évaluation

- FCAW - Cored Wires OverviewDocument3 pagesFCAW - Cored Wires OverviewTomy GeorgePas encore d'évaluation

- Self-Shielded vs. Gas-Shielded Flux-Cored ElectrodesDocument1 pageSelf-Shielded vs. Gas-Shielded Flux-Cored ElectrodesTomy GeorgePas encore d'évaluation

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgePas encore d'évaluation

- Invertec V 205 Tig PartsDocument12 pagesInvertec V 205 Tig PartsTomy GeorgePas encore d'évaluation

- Ctod ProcedureDocument33 pagesCtod ProcedureTomy GeorgePas encore d'évaluation

- Astm C131Document8 pagesAstm C131chatransito10% (1)

- Petrology NotesDocument110 pagesPetrology NotesRaj Sunil KandregulaPas encore d'évaluation

- F ChartDocument7 pagesF Charthemal4379Pas encore d'évaluation

- ChemistryDocument10 pagesChemistryMaame Ama FrempongPas encore d'évaluation

- Research StatementDocument5 pagesResearch StatementEmad AbdurasulPas encore d'évaluation

- Catalogo Cadenas de Ingenieria PDFDocument136 pagesCatalogo Cadenas de Ingenieria PDFGlicerio Bravo GaticaPas encore d'évaluation

- The Avio 200 ICP-OES: A Unique Double-Monochromator Optical SystemDocument2 pagesThe Avio 200 ICP-OES: A Unique Double-Monochromator Optical SystemUswatul HasanahPas encore d'évaluation

- PCF8833 1Document112 pagesPCF8833 1Raphael AlvesPas encore d'évaluation

- Chemsheets As 1005 Ionisation EnergiesDocument2 pagesChemsheets As 1005 Ionisation Energiesangel ranaPas encore d'évaluation

- EE6501 Power System Analysis12Document19 pagesEE6501 Power System Analysis12NAENWI YAABARIPas encore d'évaluation

- Topic 4. Binary DistillationDocument123 pagesTopic 4. Binary DistillationAngela Lorena DíazPas encore d'évaluation

- Calculation Check Temporary Tower - LG SlidingDocument9 pagesCalculation Check Temporary Tower - LG Slidingสายัญ บุญพาPas encore d'évaluation

- E 777 - Gidarakos 2005 - Ultimate - C and HDocument5 pagesE 777 - Gidarakos 2005 - Ultimate - C and HTamara Aulia RachimPas encore d'évaluation

- Rajshahi University of Engineering and Technology, RajshahiDocument9 pagesRajshahi University of Engineering and Technology, RajshahiShakil Ahmed100% (1)

- DBT 203 Metal Extractive Technology: Topic 1: Extracting Metal From OresDocument24 pagesDBT 203 Metal Extractive Technology: Topic 1: Extracting Metal From OresSollehah SuhaimiPas encore d'évaluation

- Eye TrackingDocument13 pagesEye TrackingRohit KoulPas encore d'évaluation

- Department of Education: OpticsDocument3 pagesDepartment of Education: Opticsronald100% (1)

- Physics Past Paper - P4 - 2013-20 PDFDocument308 pagesPhysics Past Paper - P4 - 2013-20 PDF123 456Pas encore d'évaluation

- Types of Life TablesDocument6 pagesTypes of Life TablesMarielle DelfinPas encore d'évaluation

- Aparato de Sonda para Medir PDFDocument13 pagesAparato de Sonda para Medir PDFmarcosPas encore d'évaluation

- Signal Flow GraphDocument38 pagesSignal Flow Graphgaurav_juneja_4Pas encore d'évaluation

- Application of FRC in Construction of The Underground Railway TrackDocument8 pagesApplication of FRC in Construction of The Underground Railway TrackClaudio PazPas encore d'évaluation

- Design of Induction Coil of A Coreless Induction Furnace To Melt AluminumDocument6 pagesDesign of Induction Coil of A Coreless Induction Furnace To Melt AluminumKyawZawPas encore d'évaluation

- EO Using Small Satellites CapabilitiesDocument36 pagesEO Using Small Satellites CapabilitiesМРязанскийPas encore d'évaluation

- Transformasi Dalam MatematikDocument39 pagesTransformasi Dalam MatematikMas Izwatu Solehah MiswanPas encore d'évaluation

- D.Sc. (Technology) Pysarenko Cand. Sc. (Technology) Voynalovich Cand. Sc. (Technology) Maylo Postgraduate PysarenkoDocument11 pagesD.Sc. (Technology) Pysarenko Cand. Sc. (Technology) Voynalovich Cand. Sc. (Technology) Maylo Postgraduate PysarenkoГеоргий ПисаренкоPas encore d'évaluation

- V-Ray Render Elements - Rendering and Compositing in PhotoshopDocument11 pagesV-Ray Render Elements - Rendering and Compositing in PhotoshopBruno AbiPas encore d'évaluation

- Calculating The Heating Value of BiogasDocument5 pagesCalculating The Heating Value of BiogasAnonymous MVHQ97KEoPPas encore d'évaluation