Académique Documents

Professionnel Documents

Culture Documents

Bolt Strength PDF

Transféré par

Silambarasi MurugesanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bolt Strength PDF

Transféré par

Silambarasi MurugesanDroits d'auteur :

Formats disponibles

TECHNICAL DATA

STRENGTH OF BOLTS, SCREW PLUGS, AND DOWEL PINS

IBolt strength

1)When a bolt takes the tensile load

C C C C C Pt=tMAs C (1) C C 2) =Qd2t /4 C (

TECHNICAL DATA COMPARISON

OF DIE STEEL BY MANUFACTURERS HARDNESS OF MAJOR STEEL PRODUCTS AND CORRESPONDING TOOLS

Hardness in use HRC

13 28 33 40 HPM7 (HPM2T) HPM38 HPM77 PSL FDAC HPM1 CENA1 (HPM50) YCS3 SGT DAC CRD SLD (SLD8) HPM31 PX5 GO40F S-STAR G-STAR NAK101 DH2F NAK55 NAK80 YK30 GOA DHA1 DC1 DC11 DC53 PD613 DC12 YXM1 SUS440C HPM38 HPM38S YAG HPM75

*CENA1 is an updated steel for HPM50.

Pt :Axial tensile load [kgf] b:the bolts yield stress [kgf/mm2] [kgf/mm2] t :the bolts allowable stress (t=b/safety factor ) As: Effective bolt area [mm2] As=Qd2/4 (shaft diameter) [mm] d :Bolts effective diameter

IUnwin safety factor based on tensile strength Material Steel Cast iron Copper, soft metals

Allowable stress= Standard strength Safety factor

Comparison of die steel by manufacturers

Classification Steel types related to the foreign standards

JIS AISI DIN

Repeated load Static load Impact load Pulsating Reversed 3 4 5 5 6 5 8 10 9 12 15 15

Hitachi Metals, Ltd. Daido Steel Co., Ltd.

Uddeholm Kobe Steel Co., Ltd. Aichi Steel Works, Ltd. Nippon Koshuha Steel Co., Ltd. Sanyo Special Steel Co., Ltd.

UHB11 KTSM2A KTSM21 KTSM3A KTSM31 KTSM3M AUK1 AUK11 KPM1 KPM2 KPM25 KPM30 KSP1 QPD5 PC55 PCM28

NACHI

SC group SCM440 group

Standard strength:The yield strength for ductile materials The breaking stress for brittle materials

Pre hardened steel

SCM (revised)

HOLDAX IMPAX NIMAX STAVAX RAMAX RoyAlloy CORRAX

P20 group

(Example) The correct size is required for a socket head cap screw to take a repeat load (pulsating) with P= 200 kgf. (The materials of a socket head cap screw are: SCM435, 38~43HRC, strength category of 12.9.) Using formula (1) As=Pt / t =200/22.4 =8.9 [mm2] The bolt with an effective area larger than this is 2 M5 would be selected. required, and a 14.2 [mm ] Although, if we take into consideration the endurance strength, looking at the strength category of 12.9, we would choice the M6 with an allowable load of 213kgf. 2) For stripper bolts which recieve the impact load, the size is decided by the fatigue strength. (Likewise for a load of 200kgf, the stripper bolt would be SCM435, 33~38HRC, with a strength category of 10.9.) In the table to the right, the allowable load for a load over 200kgf for a strength category of 10.9 is as M8 at 318 (kgf) . Therefore, the MSB10 would be selected, with a screw diameter of 10mm like the M8. Please use dowel pins also to take the shearing load. The yield stress for a strength category of 12.9 isb=112 [kgf/mm2] The allowable stresst=b/safety factor (safety factor of 5 from the above table) =112/5 =22.4[kgf/mm2] IThe bolt endurance strength (For screws, the endurance strength is 2 million times use.) Strength category Effective 12.9 10.9 Bolt size bolt area As Fatigue strength* Allowable load Fatigue strength* Allowable load 2 kgf/mm2 kgf kgf/mm2 kgf mm 79 9.1 8.78 114 M 4 13.1 111 7.8 14.2 160 M 5 11.3 149 7.4 20.1 213 M 6 10.6 318 8.7 36.6 326 M 8 8.9 423 7.3 58 429 M10 7.4 548 6.5 84.3 565 M12 6.7 690 6 702 M14 115 6.1 895 5.7 911 M16 157 5.8 1250 5.1 1274 M20 245 5.2 1659 4.7 1659 M24 353 4.7

Fatigue strength*is an edited excerpt taken fromthe measured values of the endurance limit for small screws, bolts, and meter screws for nuts" (Yamamoto) .

SUS group SUS group (free cutting) *Includes free cutting components SUS group SKD61 group (free cutting) *Includes free cutting components Precipitation hardened steel group(free cutting) *Includes free cutting components Precipitation hardened steel group SKS93 SKS3 SKD61 SKD1 H13 D3 D2 D2 group A2 M2

S6-5-2 X40CrMoV51 X210Cr12

33 33 35

PROVA400

U630 KTSM41 KTSM40EF KTSM40E SK301 KDA KAP KAP2 K3M KS3 KDA KD1 KD11S KD21 KD12 H51

QSH6 QD6F

H13 group P21 group P21

X40CrMoV51

40 40 40 55~62 55~62 50 58 58 60 58 60 57 52 53 43

PCM40 QK3M QKS3 QD61 QC1 QC11 QCM8 QC12 QH51 QCD5 (powder) SPC5 QPD1 QPD5 QM300 SK3M SKS3 HDS61 CDS1 CDS11 MCR12 CDS12 SKH9 FAXR2 PROVA400

ARNE ORVAR SVERKER3

SKS3 SKD61 SKD1 SKD11

SKD11 Quench-and-temper steel SKD11 (revised) *8 Cr series SKD12 SKH51 SUS group SUS group Maraging steel Aging-treated steel Non-magnetic steel

SLEIPNER RIGOR

KAD181

AUD15 SKD12

MH51 ELMAX S-STAR MAS1C STAVAX KAS440 (powder)

KSP2 KSP3 KSP1 KMS18-20

IScrew plug strength

Allowable load P is required for screw plug MSW30 to recieve an impact load.(The . MSW30:S45C, the tensile strength b of 34~43HRC is 65kgf / mm2) When the root diameter section of Shear area A=root diameter d1MQML the MSW is ruptured due to (root diameter d1M-P) (M-P) QL= (30-1.5) QM12 A= shearing strain, =1074 [mm2] the allowance load P =tMA Yield stress0.9Mtensile strength b=0.9M65=58.2 =3.9M1074 Shear stress 0.8Myield stress =4188.6 [kgf] =46.6 Allowable shear stress t=shear stress/safety factor 12 =46.6/12=3.9 [kgf/mm2] When the tap is made of soft material, an allowable shear is required from the root diameter of the female screw.

Materials Nonferrous metal Untreated

(AI-alloi) SS400(SS41) S45C S50C SKD11 DC53

Machined materials Thermal refined

(Be-Cu) SCM435 HPM2T S45C HPM7 PX5 HPM38 S-STAR STAVAX 20 30 NAK55 HPM1 NAK80 CENA1 FDAC DH2F 40 SKS3

Quenched/Tempered

DC53 (Carbide) SKD11 SUJ2 SKH51

M Root diameter d1 P

Processing method

Equipment Required tools Tools

Parts materials

For press die

(AI)

(Electroforming ) /outside ( Agehardened ) MAS1C

ORVAR SUPREME

( Electroforming ) /inside

Tools materials

CU For plastic BsBM2 Mold

SKD61 STAVAX RIGOR

SKD61 50

YAG HPM38 S-STAR STAVAX RIGOR 60 70

HRC

10

Boring on flanks and bottom

General purpose milling cutter NC milling cutter Machining center Drilling machine

Drills Reamers End mills Cutting tools Drills Taps Reamers Cutting tools Drills Reamers Taps Cutting tools

Drills

High-speed steel

SKHWn-Co SKHWn-Co SKHWn-Co CBN D

Reamers Cemented carbide Taps High-speed steel Cemented carbide High-speed steel Cemented carbide Boron Diamond

IDowel pin strength

The correct size for a dowel pin is required in order for it to hold repeated shear load (pulsating) of 800kfg. (Material of the dowel pin is SUJ2, hardness of 58HRC~.) P=AM =QD2/4 D= (4P) (Q) / = (4M800) ( / 3.14M19.2) 7.3 The applicable yield stress of SUJ2 b=120 [kgf/mm2] Allowable shear strength=bM0.8/safety factor =120M0.8/5 =19.2 [kgf/mm2]

Cutting Boring

Drill press Boring machine Jig borer General purpose lathe

End mils Cutting tools

(Nonferrous metal)

(Carbide)

Machining cylinders

NC lathe Turning center Surface grinder

White fused alumina WA Brown fused alumina A Pink fused almina

PA

Use dowel pins so that screw parts have no loading.

Grinding

Cylindrical grinder Jig grinder Profile grinder Forming grinder E D M Electrode master Wire Magnets grindstone

Magnets grindstone

Green silicon carbide GC Black silicon carbide C Electrodeposited boron CBN Electrodeposited diamond D (Nonferrous metal) (Carbide) (Nonferrous metal)

A size of D8 or more is selected for a MS dowel pin. Also, the tools and stock etc can be reduced if the size of the dowel pin is consistently large. Everything noted here are only examples of strengths. In actual practice, the hole pitch precision, the perpendicular angle of the hole, surface coarseness, circularity, the plate materials, parallelism, whether its tempered or not, the precision of the injection molding machine, production quantity, tool wear, etc must be taken into consideration. Therefore these values should only be used as a guide. (These are not guaranteed figures.)

Electrode master Wire

Electrolytic copper Brass Copper tungsten Silver tungsten

Cu-W Cu-Zn W

Electroerosion

WEDM Brass Tungsten

Vous aimerez peut-être aussi

- Proper Bolt Tightening Force and TorqueDocument1 pageProper Bolt Tightening Force and TorqueLuisLauShPas encore d'évaluation

- Proper Bolt Axial Tightening ForceDocument1 pageProper Bolt Axial Tightening ForcePrabhu SelvaRajPas encore d'évaluation

- SN DiagramDocument7 pagesSN DiagramManas Kotru100% (1)

- Failure Theories: Lecture 7 - Stress Controlled FatigueDocument26 pagesFailure Theories: Lecture 7 - Stress Controlled FatigueabiyPas encore d'évaluation

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127Pas encore d'évaluation

- ContentDocument23 pagesContentajay katrojPas encore d'évaluation

- Design of Weir Plate: X Q X B 2 / T 2Document3 pagesDesign of Weir Plate: X Q X B 2 / T 2Husin SaputraPas encore d'évaluation

- Queen Cross Product Specifications SheetDocument2 pagesQueen Cross Product Specifications SheetProbo HapsoroPas encore d'évaluation

- Gear4 02Document101 pagesGear4 02pratapslairPas encore d'évaluation

- Design of Corriguteed Sheet PDFDocument41 pagesDesign of Corriguteed Sheet PDFflorinelvvPas encore d'évaluation

- Screw ForcesDocument10 pagesScrew ForceskasreedharPas encore d'évaluation

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanPas encore d'évaluation

- Air Valve BrochureDocument27 pagesAir Valve Brochuredamith030Pas encore d'évaluation

- Circular PlatesDocument9 pagesCircular PlatesAvinash Januzaj ChateePas encore d'évaluation

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDocument7 pagesBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNPas encore d'évaluation

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis Guidemirza_munir_baig995Pas encore d'évaluation

- Calculate Bolt StrengthsDocument14 pagesCalculate Bolt Strengthsgeorge sanchesPas encore d'évaluation

- Main Pivot Pin Diameter CalculationDocument2 pagesMain Pivot Pin Diameter Calculationjdutia83100% (1)

- Experimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersDocument9 pagesExperimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersKartikAgrawalPas encore d'évaluation

- BARNES Associated Spring Raymond 2010Document260 pagesBARNES Associated Spring Raymond 2010Francois LarouchePas encore d'évaluation

- Manhole. API 650-2021Document3 pagesManhole. API 650-2021jose luisPas encore d'évaluation

- Design of JointsDocument41 pagesDesign of JointsVivek LevinPas encore d'évaluation

- Formula & ConstantsDocument1 pageFormula & ConstantsNallathambiPas encore d'évaluation

- Fea SR CouplingsDocument67 pagesFea SR CouplingsAna Isabel Aguilar ReyesPas encore d'évaluation

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600Pas encore d'évaluation

- Torque For BoltDocument18 pagesTorque For BoltZoebairPas encore d'évaluation

- ASME SecVIII Div-2 Hydro TestDocument2 pagesASME SecVIII Div-2 Hydro Testsouren1975Pas encore d'évaluation

- MegyesseDocument500 pagesMegyessehamzaPas encore d'évaluation

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesPas encore d'évaluation

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocument17 pagesAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarPas encore d'évaluation

- Elliptical Pressure Vesel Stress AnalysisDocument36 pagesElliptical Pressure Vesel Stress Analysisliviu333nt6132Pas encore d'évaluation

- Effect of Carbon Content and Temperature on Fatigue Properties of Steel AlloysDocument10 pagesEffect of Carbon Content and Temperature on Fatigue Properties of Steel AlloysRizki FebriyantoPas encore d'évaluation

- Tolerance Chart: (Maximum Permissible Error)Document3 pagesTolerance Chart: (Maximum Permissible Error)arufatoPas encore d'évaluation

- Development of Design Charts For Bolts Preloaded Up To The Plastic RangeDocument3 pagesDevelopment of Design Charts For Bolts Preloaded Up To The Plastic RangeGüneş DilberPas encore d'évaluation

- 6 Series Weld FittingsDocument10 pages6 Series Weld FittingsNilesh MistryPas encore d'évaluation

- PDF2 L Hydraulic CylinderDocument56 pagesPDF2 L Hydraulic CylinderShyam Srinivasan100% (1)

- Din 580 - 582 - Maximum Permissible Loads PDFDocument9 pagesDin 580 - 582 - Maximum Permissible Loads PDFAntohi CatalinPas encore d'évaluation

- Steam 67Document2 pagesSteam 67jonathan_leal09Pas encore d'évaluation

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinPas encore d'évaluation

- En 10025 S235JR SteelDocument2 pagesEn 10025 S235JR SteelAgung Nak OtomotifPas encore d'évaluation

- Fundamentals FatigueDocument13 pagesFundamentals Fatiguelemuel mabilinPas encore d'évaluation

- US211M Flow Meter: Quantitative ControllerDocument4 pagesUS211M Flow Meter: Quantitative Controllerhw606Pas encore d'évaluation

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaPas encore d'évaluation

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 pagesInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoquePas encore d'évaluation

- Eccentric Column BucklingDocument10 pagesEccentric Column BucklingMukeshChopraPas encore d'évaluation

- Coupling UW16.2 KL Ver 1.1Document4 pagesCoupling UW16.2 KL Ver 1.1gopaltryPas encore d'évaluation

- Cause and Effect Table PDFDocument3 pagesCause and Effect Table PDFKamal DeshapriyaPas encore d'évaluation

- External Pressure Calculation Results SummaryDocument8 pagesExternal Pressure Calculation Results SummaryAndika DearsonPas encore d'évaluation

- Lug PaperDocument11 pagesLug PaperSrinivas PradhaanPas encore d'évaluation

- ASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Document14 pagesASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Biyong SantocildesPas encore d'évaluation

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonPas encore d'évaluation

- 4 Heat TreatmentokDocument22 pages4 Heat TreatmentokPramod AthiyarathuPas encore d'évaluation

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonagherghePas encore d'évaluation

- Hinge DesignDocument2 pagesHinge Designpare222Pas encore d'évaluation

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965D'EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerPas encore d'évaluation

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocument1 pageProper Bolt Axial Tightening Force and Proper Tightening Torquecmms88Pas encore d'évaluation

- Bolt Tightening ForceDocument1 pageBolt Tightening Forceiwanguna71Pas encore d'évaluation

- Bolt, Screw Plug and Dowel Pin Strength Technical DataDocument1 pageBolt, Screw Plug and Dowel Pin Strength Technical DatahlsimonPas encore d'évaluation

- 9allpg Diploma AnnamaliayDocument18 pages9allpg Diploma AnnamaliayMark HowardPas encore d'évaluation

- Class Xii - Differntiation & Integration Formulae.Document1 pageClass Xii - Differntiation & Integration Formulae.Mandeep Singh Plaha59% (22)

- LWRDocument24 pagesLWRSilambarasi MurugesanPas encore d'évaluation

- Class Xii - Differntiation & Integration Formulae.Document1 pageClass Xii - Differntiation & Integration Formulae.Mandeep Singh Plaha59% (22)

- Strength of MateriaDocument7 pagesStrength of MateriaSilambarasi MurugesanPas encore d'évaluation

- Deflection According To Aci and BsDocument16 pagesDeflection According To Aci and Bsronison78100% (4)

- Proof StressDocument1 pageProof StressSilambarasi MurugesanPas encore d'évaluation

- Bolt Strength PDFDocument1 pageBolt Strength PDFSilambarasi MurugesanPas encore d'évaluation

- Simply Supported Beam Formulae: (Reprinted From Design Data, PSG Tech, 1995)Document1 pageSimply Supported Beam Formulae: (Reprinted From Design Data, PSG Tech, 1995)Silambarasi MurugesanPas encore d'évaluation

- Bolt Strength PDFDocument1 pageBolt Strength PDFSilambarasi MurugesanPas encore d'évaluation

- Irc SP51 PDFDocument20 pagesIrc SP51 PDFSilambarasi Murugesan100% (1)

- Design Horizontal Curved Concrete Box-GirderDocument97 pagesDesign Horizontal Curved Concrete Box-Girderkledang88% (8)

- Simply Supported Beam Formulae: (Reprinted From Design Data, PSG Tech, 1995)Document1 pageSimply Supported Beam Formulae: (Reprinted From Design Data, PSG Tech, 1995)Silambarasi MurugesanPas encore d'évaluation

- EMEDocument38 pagesEMErajwinder234Pas encore d'évaluation

- EAS107 Lab 1Document14 pagesEAS107 Lab 1Mohd Ashraf Mohd Ismail100% (1)

- HM225.Xx Flow Around Bodies EnglishDocument1 pageHM225.Xx Flow Around Bodies EnglishsaintanddevilPas encore d'évaluation

- Gaur Et Al-2017-ChemistrySelectDocument10 pagesGaur Et Al-2017-ChemistrySelectChandan Kumar ChoubeyPas encore d'évaluation

- Microscope and Microscopy A New Dimension in DiaDocument1 pageMicroscope and Microscopy A New Dimension in DiaSourab KumarPas encore d'évaluation

- Grade 9 Lesson on Heat, Work and ThermodynamicsDocument3 pagesGrade 9 Lesson on Heat, Work and ThermodynamicsGerald E Baculna40% (5)

- Foldable Helmet Project ReportDocument43 pagesFoldable Helmet Project ReportArnaz Asa Sholeh100% (2)

- Double Pipe Heat ExchangersDocument36 pagesDouble Pipe Heat Exchangersshreyasnil50% (2)

- Friction Loss in PipeDocument12 pagesFriction Loss in Pipenextdarklord50% (2)

- Static Mixer: A Contactor For Dissolving Ozone Gas in FluidsDocument4 pagesStatic Mixer: A Contactor For Dissolving Ozone Gas in Fluidsmember1000Pas encore d'évaluation

- Investigation of Self-Similarity Solution For Wake Flow of A CylinderDocument5 pagesInvestigation of Self-Similarity Solution For Wake Flow of A CylinderpundoPas encore d'évaluation

- Plastic Spur Gear Pair FailureDocument14 pagesPlastic Spur Gear Pair FailureDan Wolf100% (1)

- 11Document9 pages11nyogtPas encore d'évaluation

- SWELLEX ROCK BOLTS in - Weak - and - Soft - rocks-CHUNLIN - LIDocument93 pagesSWELLEX ROCK BOLTS in - Weak - and - Soft - rocks-CHUNLIN - LILoaiza DerlyPas encore d'évaluation

- LP-Sept. 5 - Electric SymbolsDocument4 pagesLP-Sept. 5 - Electric SymbolsDiona Bangga - ModestoPas encore d'évaluation

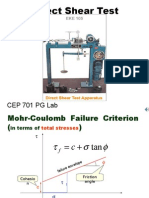

- Direct Shear TestDocument32 pagesDirect Shear TestVinay YadavPas encore d'évaluation

- 90-10 Copper-Nickel Vs - Sea-Cure Stainless SteelDocument7 pages90-10 Copper-Nickel Vs - Sea-Cure Stainless Steelpipedown456Pas encore d'évaluation

- Mechanical Resonance - Theory and ApplicationsDocument10 pagesMechanical Resonance - Theory and ApplicationsEbrahim Abd El HadyPas encore d'évaluation

- ME 215 HW 5, Chapter 5, Due 20 April 2020, Midnight Local TimeDocument3 pagesME 215 HW 5, Chapter 5, Due 20 April 2020, Midnight Local TimeSunnyPas encore d'évaluation

- Chapter 2Document35 pagesChapter 2tùng thanhPas encore d'évaluation

- Fluid Flow ProjectsDocument271 pagesFluid Flow ProjectsNathalia Delgado100% (1)

- Chapter 4 - PermeabilityDocument44 pagesChapter 4 - PermeabilityAfnan HamimiPas encore d'évaluation

- Liquid Vapor Equilibrium NotesDocument10 pagesLiquid Vapor Equilibrium NoteshumejiasPas encore d'évaluation

- What Is The Relation Between Elastic Constant E, C and K. - Sarthaks Econnect - Largest Online Education CommunityDocument4 pagesWhat Is The Relation Between Elastic Constant E, C and K. - Sarthaks Econnect - Largest Online Education CommunityraghuPas encore d'évaluation

- Medium/Phase Dispersed Phase GAS Liquid SolidDocument2 pagesMedium/Phase Dispersed Phase GAS Liquid SolidIrvandar NurviandyPas encore d'évaluation

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiPas encore d'évaluation

- Geotechnics: Marcin Cudny, Lech BałachowskiDocument52 pagesGeotechnics: Marcin Cudny, Lech Bałachowskisharath1199Pas encore d'évaluation

- ANS 002 Determination of Cristallinity of PET by DSCDocument2 pagesANS 002 Determination of Cristallinity of PET by DSCTiwiPas encore d'évaluation

- ChemisorptionDocument19 pagesChemisorptionsharmatanima23Pas encore d'évaluation

- Design and Stress Analysis of Perforated Plates Under Uni-Axial CompressionDocument14 pagesDesign and Stress Analysis of Perforated Plates Under Uni-Axial CompressionNaveenprakashPas encore d'évaluation