Académique Documents

Professionnel Documents

Culture Documents

08 Grp11 Hybrid MCP A

Transféré par

eurospeed2Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

08 Grp11 Hybrid MCP A

Transféré par

eurospeed2Droits d'auteur :

Formats disponibles

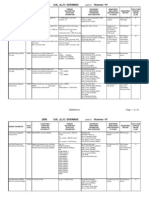

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Secondary Parameters Enable Conditions Time Req'd MIL Illum

Component/System MCP A Phase Current Diagnostics: Drive Motor "A" Phase U-V-W Correlation Drive Motor "A" Phase U-V-W Current Sensor Overcurrent Drive Motor "A" Phase U-V-W Circuit/Open Drive Motor "A" Phase U Current Sensor Circuit Low

Monitor Strategy Description

Malfunction Criteria

P0BFD

To detect electrical failure of phase current sensor. To detect 3 Phase over current and to protect IGBT. Drive Motor "A" Invalid Current

One Trip Sum of 3 phase currents > 75 A Main Relay Wakeup Signal Wakeup Signal Wakeup Signal Closed On On On 8 ms One Trip U, V, or W Phase current sensor Motor Current U Phase current sensor output at highside > 680 A <9A 2ms One Trip 17ms Two Trips < -700 A Wakeup Signal PWMOutputEnable On FALSE 21ms Two Trips U Phase current sensor output at highside > 700 A Wakeup Signal PWMOutputEnable On FALSE 21ms Two Trips

P0C01 P0C05 P0BE7

Circuit Low monitor to detect the failure of U-phase current sensor circuit below valid range Circuit High monitor to detect the failure of U-phase current sensor circuit above valid range

Drive Motor "A" Phase U Current Sensor Circuit High

P0BE8

Drive Motor "A" Phase U Current Sensor Offset Out-of Range

P0BE6 Offset Circuit monitor to detect the failure of U Phase offset current output at U-phase offset current above valid range highside >30 A Wakeup Signal Power Stage P0BE7/P0BE8 Wakeup Signal < -700 A PWMOutputEnable On FALSE 21ms On OPEN NOT ACTIVE 208ms

Drive Motor "A" Phase V Current Sensor Circuit Low

P0BEB

Circuit Low monitor to detect the failure of V-phase current sensor circuit below valid range Circuit High monitor to detect the failure of V-phase current sensor circuit above valid range

Two Trips V Phase current sensor output at highside

Drive Motor "A" Phase V Current Sensor Circuit High Voltage

P0BEC

Two Trips V Phase current sensor output current at highside > 700 A Wakeup Signal PWMOutputEnable On FALSE 21ms Two Trips

Drive Motor "A" Phase V Current Sensor Offset Out-of Range

P0BEA Offset Circuit monitor to detect the failure of V Phase offset current output at U-phase offset current above valid range highside >30 A Wakeup Signal Power Stage P0BEB/P0BEC Wakeup Signal < -700 A PWMOutputEnable On FALSE 21ms On OPEN NOT ACTIVE 208ms

Drive Motor "A" Phase W Current Sensor Circuit Low

P0BEF

Circuit Low monitor to detect the failure of W-phase current sensor circuit below valid range Circuit High monitor to detect the failure of W-phase current sensor circuit above valid range

Two Trips W Phase current sensor output at highside

Drive Motor "A" Phase W Current Sensor Circuit High

P0BF0

Two Trips W Phase current sensor output at highside Wakeup Signal > 700 A PWMOutputEnable On FALSE 21ms Two Trips

Drive Motor "A" Phase W Current Sensor Offset Out-of Range

P0BEE Offset Circuit monitor to detect the failure of W Phase offset current output at U-phase offset current above valid range highside >30 A Wakeup Signal On 208ms

Page 1 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Secondary Parameters Power Stage P0BEF/P0BF0 MCP A IGBT Diagnostics Drive Motor "A" Inverter Performance Drive Motor "A" Inverter Power Supply Circuit/Open MCP A High Voltage (HV) Diagnostics: Drive Motor "A" Hybrid Battery System Voltage High Drive Motor "A" Control Module Hybrid Battery Voltage Sense Circuit Low Voltage Drive Motor "A" Control Module Hybrid Battery Voltage Sense Circuit High Voltage Drive Motor "A" Control Module Hybrid Battery System Voltage P1AEE P1AE8 To detect over voltage and to protect TPIM Average of first and third previous Vdc Circuit HV readings Circuit Low monitor to detect the failure of HV output voltage sensor circuit below valid range HV Sensor Voltage Circuit High monitor to detect the failure of HV output voltage sensor circuit above valid range HV Sensor Voltage To check correlation of HV_MCP with HV_Midpack and HV_Battery Voltages. ABS(MCP HV voltage - HV Battery voltage) OR ABS(MCP HV voltage - MidPack voltage) HV Interlock Status Discrete Input One Trip > 475V WakeUp Signal On Initialization Complete Initialization Complete TRUE 0.4ms Two Trips <0V Inverter State 146ms Two Trips >564V >= 34 V Inverter State Valid HV CAN Msg 104ms One Trip 187ms P0A78 Detects IGBT Saturation Faults P0C0B Detects IGBT Bias Faults Phase A, B, or C Power Supply FAILED (Status Fault Bit) Inverter State Initialization Complete 1 fail Phase A, B, or C High or Low Side Devices OVERDRIVEN (Status Fault Bit) Wakeup Signal Enable Conditions OPEN NOT ACTIVE One Trip On 1042ms One Trip Time Req'd MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

P1AE9

P1AEC

>= 90 V TRUE WakeUp Signal HV CAN Msg Rx On TRUE 304ms Special Type C

Drive Motor "A" HV Interlock (HVIL) Break Detected

P1B05 To detect interlock circuit open.

BPCM Sourcing MCP HVIL Status TRUE Drive Motor "A" Control Module Hybrid Battery Voltage System Isolation Fault P1AF0 Isolation Lost between Battery Pack and Chassis Isolation Ratio (MidPack Voltage / HV Battery Voltage) < 0.27 OR >1.85 No HV Clamp Fault or MidPack Sensor OOR Faults: P1AEE, P1AF4, and P1AF5 NOT ACTIVE AND HV Sensor Voltage > 50V Initialization Complete Initialization Complete Non-MIL

5208ms

Drive Motor "A" Control Module Hybrid Battery Voltage Isolation Sensor Circuit Low Drive Motor "A" Control Module Hybrid Battery Voltage Isolation Sensor Circuit High Motor A Temperature Sensor

P1AF4

Circuit Low monitor to detect the failure of HV MidPack voltage sensor circuit below valid range Circuit High monitor to detect the failure of HV MidPack voltage sensor circuit above valid range

Two Trips MidPack Voltage <0V Inverter State 729ms Two Trips MidPack Voltage >564V Inverter State 521ms

P1AF5

Page 2 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value > 22deg C Secondary Parameters Ignition Off Time PIM Temp Average and Motor Temp Above Minimum Threshold No PIM or Motor Temp OOR Faults: P0AEF, P0AF0, P0BD3, P0BD4, P0BDD, P0BDE, P0A2C and P0A2D. P0A2D Drive Motor "A" Control Module Temperature Sensor Circuit Out of Range High To detect temperature sensor Out of Range high (voltage). Motor Temperature < -40 deg C (near 5V) Wakeup Signal When fault present at start of trip: Cumulative Motor Temp Warmup Time above Motor Temp Warmup Torque Threshold Drive Motor "A" Control Module P0A2C Temperature Sensor Circuit Out of Range Low Drive Motor "A" Over Temperature P0A2F To detect a sustained motor overtemperature condition CAN / SPI / SCI Bus Timeout P1AFC Drive Motor "A" Control Module Lost Communication With SPI Bus Drive Motor "A" Control Module P1AFD Lost Communication With SCI Bus Motor Control Processor Voltage Diagnostics Sensor Reference Voltage "A" Circuit Low Sensor Reference Voltage "A" Circuit High Sensor Power Supply "A" Circuit Low Sensor Power Supply "A" Circuit High P0642 P0643 P06B1 P06B2 Detects Sensor Voltage (5V) below an acceptable threshold. Detects Sensor Voltage (5V) above an acceptable threshold. Detects Sensor Power Supply (15V) below an acceptable threshold. Detects Sensor Power Supply (15V) above an acceptable threshold. One Trip Scaled 5V Supply Voltage Scaled 5V Supply Voltage Scaled 15V Supply Voltage Scaled 15V Supply Voltage < 4.80V > 5.20V < 12.0V > 18.0V < 7.7V Wakeup Signal Wakeup Signal Wakeup Signal Wakeup Signal Wakeup Signal On On On On On 729 ms One Trip 729 ms Two Trips 365 ms Two Trips 1042 ms 365 ms Special Type C Motor Temperature >200 degC To detect temperature sensor Out of Range low (voltage). Motor Temperature > 230 degC (near 0V) Enable Conditions >=360 min Time Req'd 2084ms MIL Illum Two Trips

Component/System

Monitor Strategy Description Motor A Temperature Sensor In-Range Rationality Check

Malfunction Criteria ABS(Motor Temp -Avg PIM Temp Avg)

Drive Motor "A" Control Module P0A2B Temperature Sensor Performance

>-18 degC

NOT ACTIVE Two Trips ON 1042ms

>=1.5min

>= 20 Nm Two Trips

WakeUp Signal Instanteous Motor Temp in Range: No OOR Faults; P0A2C, P0A2D

On

1042ms Two Trips

NOT ACTIVE

3.13 sec One Trip

To detect loss of communication on the SPI bus with the HCP module SPI Receive Timeout flag SPI Diag Timeout # Timeout Counts To detect loss of communication on the SCI bus with Motor "B" Control Module SCI Diag Timeout SCI_Rx_Timeout

TRUE 7

Inverter State

RUN

40 ms Two Trips

TRUE

Wakeup Signal

On

2083ms

Control Module Power Supply "A" P1ADE Circuit Low

Detects Control Module Power Supply (12V) below an acceptable threshold. Scaled 12V Supply Voltage

Page 3 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value > 18.0V Secondary Parameters Wakeup Signal Enable Conditions On Time Req'd 1042 ms MIL Illum Special Type C Non-MIL POWER LOSS State Wakeup Signal On 104ms One Trip TRUE For all: Wakeup Signal For Watchdog Fault Only: No power-on resets or low voltage interrupt faults during powerdown; P1B09 AND P1B13 On 10.4ms

Component/System

Monitor Strategy Description

Malfunction Criteria

Control Module Power Supply "A" P1ADF Circuit High Control Module System Voltage "A" Unstable (Interrupt Fault) MCP A Controller Faults Drive Motor "A" Control Module Internal Performance P1B09

Detects Control Module Power Supply (12V) above an acceptable threshold. Scaled 12V Supply Voltage Detects Control Module Power Supply (12V) intermittently below an acceptable threshold. System Status Relay ALU HWIO Fault ALU calculation error, Register Overflow, or OR Stack Address Overrun Watchdog Timer Fault

P0A1B

OR EEPROM not completely written at Powerdown (Watchdog timer fault) Drive Motor "A" Control Module Random Access Memory (RAM) Drive Motor "A" Control Module Read Only Memory (ROM) Drive Motor "A" Control Module EEPROM Error Drive Motor "A" Control Module Programmable Logic Device Not Programmed Drive Motor "A" Control Module Performance - Programmable Logic Device MCP A Not Programmed Drive Motor "A" Control Module Not Programmed Motor A Inverter Temperature Sensors Drive Motor Inverter Temperature Sensor A Circuit Range/Performance P0AEE Phase U Temperature Sensor In-Range Rationality Check P1A50 To detect an error in the MCP A RAM write area. P1A51 P1ADC P1AFA Detects if PLD was not successfully programmed during initialization P1B13 Detects Power On Reset (POR) during WatchDog Timer Test P1A4F Drive Motor "A" Control Module Programmed with Test Code, or Motor B calibration (via Cal ID) POR Fault Flag PLDFault RAM check value

TRUE

NOT ACTIVE One Trip

Outside RAM Address Range Wakeup Signal TRUE TRUE Wakeup Signal Wakeup Signal

On On On

10.4ms One Trip 10.4ms One Trip 10.4ms One Trip

To detect an error in the MCP A ROM using a checksum calculation FlashCellError Detects mismatch between Flash and EEPROM Power Off Levels EEpromCellStatus

TRUE

Wakeup Signal

On

10.4ms Two Trips

TRUE

Wakeup Signal

On

10.4ms One Trip

Calibration contains Test code identifier or Motor B Identifier

TRUE

Always

10.4ms

Two Trips ABS(PIM Temp A - PIM Temp Avg) >15 deg C Ignition Off Time PIM Temp Average and Motor Temp >=360 min > -18 degC 2084ms

PIM or Motor Temp OOR Faults; P0AEF, P0AF0, P0BD3, P0BD4, P0BDD, P0BDE, P0A2C and P0A2D. NOT ACTIVE Drive Motor Inverter Temperature Sensor A Circuit High P0AF0 To detect inverter Phase U temperature sensor Out of Range high (voltage). PIM Temp A Temperature < -40 deg C (near 5V) Two Trips Wakeup Signal ON 1042ms

Page 4 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Secondary Parameters When fault present at start of trip: Cumulative PIM Temp Warmup Enable Conditions Time Req'd MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

>=1.5min

Time above PIM Temp Warmup Torque Threshold >= 20 Nm Drive Motor Inverter Temperature Sensor A Circuit Low Drive Motor Inverter Temperature Sensor C Circuit Range/Performance P0AEF To detect inverter Phase U temperature sensor Out of Range low (voltage). P0BD2 Phase V Temperature Sensor In-Range Rationality Check PIM Temp A Temperature > 230 degC (near 0V) WakeUp Signal Ignition Off Time PIM Temp Average and Motor Temp On >=360 min > -18 degC 1042ms Two Trips ABS(PIM Temp B - PIM Temp Avg) >15 deg C 2084ms Two Trips

AND No PIM or Motor Temp OOR Faults; P0AEF, P0AF0, P0BD3, P0BD4, P0BDD, P0BDE, P0A2C and P0A2D. NOT ACTIVE Drive Motor Inverter Temperature Sensor C Circuit High P0BD4 To detect inverter Phase V temperature sensor Out of Range high (voltage). PIM Temp B Temperature < -40 deg C (near 5V) Two Trips Wakeup Signal When fault present at start of trip: Cumulative PIM Temp Warmup ON 1042ms

>=1.5min

Time above PIM Temp Warmup Torque Threshold >= 20 Nm Drive Motor Inverter Temperature Sensor C Circuit Low Drive Motor Inverter Temperature Sensor E Circuit Range/Performance P0BD3 To detect inverter Phase V temperature sensor Out of Range low (voltage). P0BDC Phase W Temperature Sensor In-Range Rationality Check PIM Temp B Temperature ABS(PIM Temp C - PIM Temp Avg) > 230 degC (near 0V) >15 deg C WakeUp Signal Ignition Off Time PIM Temp Average and Motor Temp On >=360 min > -18 degC 1042ms Two Trips 2084ms Two Trips

AND No PIM or Motor Temp OOR Faults; P0AEF, P0AF0, P0BD3, P0BD4, P0BDD, P0BDE, P0A2C and P0A2D. NOT ACTIVE Drive Motor Inverter Temperature Sensor E Circuit High P0BDE To detect inverter Phase W temperature sensor Out of Range high (voltage). PIM Temp C Temperature < -40 deg C (near 5V) Wakeup Signal When fault present at start of trip: Cumulative PIM Temp Warmup ON 1042ms Two Trips

>=1.5min

Page 5 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Secondary Parameters Enable Conditions Time Req'd MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

Time above PIM Temp Warmup Torque Threshold >= 20 Nm Drive Motor Inverter Temperature Sensor E Circuit Low Drive Motor "A" Inverter Phase U Over Temperature P0BDD To detect inverter Phase W temperature sensor Out of Range low (voltage). P0C11 To detect an in-range overtemperature condition that can potentially damage inverter P0C12 To detect an in-range overtemperature condition that can potentially damage inverter P0C13 To detect an in-range overtemperature condition that can potentially damage inverter Sensor output exceeds fault threshold, and does not decrease below reset threshold > 91 deg C fault PIM Temp C In Range: >85 deg C reset P0BDD or P0BDE Sensor output exceeds fault threshold, and does not decrease below reset threshold > 91 deg C fault PIM Temp B In Range: >85 deg C reset P0BD3 or P0BD4 Sensor output exceeds fault threshold, and does not decrease below reset threshold > 91 deg C fault PIM Temp A In Range: >85 deg C reset P0AEF or P0AF0 PIM Temp C Temperature > 230 degC (near 0V) WakeUp Signal On 1042ms Two Trips Two Trips

NOT ACTIVE

5208ms Two Trips

Drive Motor "A" Inverter Phase V Over Temperature

NOT ACTIVE

5208ms Two Trips

Drive Motor "A" Inverter Phase W Over Temperature

NOT ACTIVE

5208ms

Motor A Resolver Sensors Discrete Drive Motor "A" Position Sensor Circuit Drive Motor "A" Position Sensor Circuit Range/Performance Drive Motor "A" Position Sensor Circuit Loss of Tracking Drive Motor "A" Position Sensor Circuit Overspeed Drive Motor "A" Position Sensor Learn Incorrect P0A3F To detect Loss of Signal or converter error ( line open, short) in the Motor Resolver R/D converter error (loss of signal) circuit Sample Counts >70 cts To detect a Degradation of Signal fault in the angle data read by the Motor Resolver R/D converter error (degradation of circuit. signal) Sample Counts >70 cts To detect a Loss of Tracking fault in the Motor Resolver circuit. P1B0D To detect when Motor A has exceeded operational maximum speed P1B0F To detect an unvalidated Resolver Offset Learn (OL) Value ABS(Motor speed) initially then ABS(Motor Speed) AND >10000 rpm Wakeup Signal On 104 ms Non-MIL >50 < 192 V <15 A > 5 ms Key Off Wakeup Signl ABS(Motor RPM) Valid Stored Offset TRUE ON < 20 TRUE 10.4ms R/D converter error (loss of tracking) Sample Counts One Trip Resolver Initialization Delay 500ms 146 ms One Trip Resolver Initialization Delay 500ms 146 ms One Trip >70 cts >11500 rpm Resolver Initialization Delay 500ms 146 ms One Trip

P0A40

P1B03

Offset Learn DIDN'T complete because: ABS(Motor RPM) OR Filtered DC Voltage ALLPhase Curr Max-Min Delta For Time Period OR Offset Learn Completes AND ABS(Offset Correction Angle)

> 25 deg

Page 6 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code P0C17 Threshold Value Secondary Parameters Enable Conditions Time Req'd MIL Illum Two Trips >50 < 192 V <15 A > 5 ms Wakeup Signal ABS(Motor RPM) Valid Stored Offset ON < 20 FALSE 10.4ms

Component/System Drive Motor "A" Position Sensor Not Learned

Monitor Strategy Description

Malfunction Criteria

To detect an unvalidated Resolver Offset Offset Learn DIDN'T complete Learn Value and No Stored Previously Valid because: Value ABS(Motor RPM) OR Filtered DC Voltage ALLPhase Curr Max-Min Delta For Time Period OR Offset Learn Completes AND ABS(Offset Correction Angle)

> 25 deg Non-MIL

Drive Motor "A" Position Exceeded P0C4E Learning Limit

To detect a Resolver Correction value greater than an acceptable limit

Offset Learn COMPLETES AND ABS(Offset Correction Angle) >25deg

Key Off Wakeup Signal ABS(Motor RPM)

TRUE ON < 20

10.4ms

Motor A Resolver Sensors Circuit Drive Motor "A" Position Sensor Circuit "A" Low Drive Motor "A" Position Sensor Circuit "A" High Drive Motor "A" Position Sensor Circuit "B" Low Drive Motor "A" Position Sensor Circuit "B" High Motor A Crank Pulse Faults Drive Motor "A" Control Module P1AC6 Crankshaft Position Sensor Circuit Drive Motor "A" Control Module Crankshaft Position Sensor Performance Torque Security Faults Drive Motor A Torque Delivered Performance P1AC7 Detects Invalid 58X Crank Sensor Signal CPC Signal NOT VALID Engine Movment Detected OR Edges Seen > 5rpm >0 in crank or run 3125 ms Two Trips Detects Lack of Response from 58X Crank Sensor Crank Synchronization NO ACTIVITY Wakeup Signal On 2083ms Two Trips P0C52 P0C53 P0C5C P0C5D To detect Resolver Circuit S1/3 Out of Range Low To detect Resolver Circuit S1/3 Out of Range High To detect Resolver Circuit S2/4 Out of Range Low To detect Resolver Circuit S2/4 Out of Range High Resolver S13 Circuit Reference Voltage Resolver S13 Circuit Reference Voltage Resolver S24 Circuit Reference Voltage Resolver S24 Circuit Reference Voltage One Trip < 0.5 v > 3.0 v < 0.5 v > 3.0 v Wakeup Signal Wakeup Signal Wakeup Signal Wakeup Signal On On On On 521ms One Trip 208ms One Trip 521ms One Trip 208ms

P0C19

Fail Case 1: Test of three phase current correlation

The sum of three phase currents is Current Ignition switch threshold: 75 A higher than current threshold during more than threshold time

48 fail One Trip counts out of 60 sample counts Executes in a 2.08ms loop

Page 7 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Time threshold: 100ms Fail Case 2: Static Variable test Verify the calculated check sum (CRC) is not equal to previous saved check sum (CRC) SPI rolling count fails to update more than threshold time Ignition switch in crank or run Secondary Parameters Enable Conditions Time Req'd Detects in 100ms 2.08 ms loop MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

Fail Case 3: Monitor torque command by checking the SPI communication status

Threshold time: Ignition switch 90msec

in crank or run

45 fail counts out of 50 sample counts Detects in 90ms 2.08 ms loop 96 fail counts out of 120 sample counts

Fail Case 4: Check the DC current flow direction with respect to torque command/motor speed

Current DC current fails to show correct threshold: sign and magnitude more than current threshold during more than threshold time

MCP power stage

Active

10 A to 80 A (function of motor speed.); Executes in a 2.08ms loop Time threshold: 200 ms Fail Case 5: Check the secured motor The absolute error between torque achieved error with respect to torque calculated motor torque achieved command and motor torque command is higher than torque threshold during more than threshold time Torque threshold: MCP power stage Active Detects in 200ms 96 fail counts out of 120 sample counts

52 Nm Executes in a 2.08ms loop

Page 8 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Time threshold: 200 ms Fail Case 6: Check the Task1 reported The absolute error between Task1 Torque threshold: motor torque achieved vs. torque command reported motor torque achieved and motor torque command is higher than torque threshold during more than threshold time 52 Nm Executes in a 2.08ms loop Time threshold: 200 ms Drive Motor A Torque Delivered Performance P0C19 Fail Case 7: Check the secured calculated three phase short motor torque vs. the reported task1 motor torque The absolute error between secured calculated three phase short torque vs. Task1 reported motor torque is higher than torque threshold during more than threshold time Torque threshold: MCP power stage Motor 3-phase short Detects in 200ms 96 fail One Trip counts out of 120 sample counts Ignition switch in crank or run Detects in 200ms 96 fail counts out of 120 sample counts Secondary Parameters Enable Conditions Time Req'd MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

52 Nm Executes in a 2.08ms loop Time threshold: 200 ms Fail Case 8: Check the secured calculated three phase open motor torque vs. the reported task1 motor torque The absolute error between secured calculated three phase open torque vs. Task1 reported motor torque is higher than torque threshold during more than threshold time Torque threshold: MCP power stage Motor 3-phase open Detects in 200ms 96 fail counts out of 120 sample counts

52 Nm Executes in a 2.08ms loop

Page 9 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value Time threshold: 200 ms Drive Motor A Control Module Programmable Logic Device Security Code P1AFB Fail Case 1: Detect the validity of the Seeds The number of identical seed in 191 counts sent by PLD consecutive loops sent from PLD is higher than threshold Ignition switch in crank or run Detects in 200ms One Trip 191 fail counts out of 250 sample counts 0.083 ms to 0.5 ms (function of motor speed.); Secondary Parameters Enable Conditions Time Req'd MIL Illum

Component/System

Monitor Strategy Description

Malfunction Criteria

Fail Case 2: Detect the validity of response by PLD when MCP sends repeated bad keys to PLD

The number of bad response from 191 counts PLD when MCP is sending bad key is higher than threshold

Ignition switch

in crank or run

191 fail counts out of 250 sample counts 0.083 ms to 0.5 ms (function of motor speed.);

Drive Motor "A" Control Module Shutdown Performance

P1AF8

Detect the duration MCP used to conduct shut down path verification after key-on initialization.

The number of Task 2 loops used in shut down path verification is higher than threshold

40 counts

Initialization

ON

40 fail One Trip counts out of 50 sample counts 10 ms loop

Communication Diagnostics Lost Communication With Battery Pack Control Module Lost Communication With ECM/PCM U1875 Detects that CAN serial data communication Missed BPCM Messages has been lost with the BPCM on Bus A Detects that CAN serial data communication Missed ECM Messages has been lost with the ECM Ignition switch Run 12 Type B seconds 12 Type B seconds

U1876

Ignition switch

Run

APPENDIX Inverter Temperature Sensor Mapping Grid SAE

Page 10 of 11

08 GRP11 Two - Mode Hybrid Electric Motor Control Processor - A (MCP- A)

Fault Code Threshold Value A C E B D F BPCM= Batt Pack Ctrl Module ALU= Arithmetic Logic Unit Secondary Parameters Enable Conditions Time Req'd MIL Illum

Component/System Drive Motor A

Monitor Strategy Description Phase U Phase V Phase W Phase U Phase V Phase W

Malfunction Criteria PIM_A PIM_B PIM_C PIM_A PIM_B PIM_C

Drive Motor B

HWIO= Hardware Input/Output OOR= Out of Range IGBT= Insulated Gate Bipolar Transistors (Phase Current Controllers)

Page 11 of 11

Vous aimerez peut-être aussi

- 08 Grp11 Hybrid MCP BDocument10 pages08 Grp11 Hybrid MCP Beurospeed2Pas encore d'évaluation

- 08 GRP08a SGCMDocument18 pages08 GRP08a SGCMeurospeed2Pas encore d'évaluation

- Códigos Voyager DieselDocument4 pagesCódigos Voyager DieselJuan Carlos LlonaPas encore d'évaluation

- Engine Control SystemDocument7 pagesEngine Control SystemFaisal Al HusainanPas encore d'évaluation

- Bosch Cj120Document7 pagesBosch Cj120Thiago BronoskiPas encore d'évaluation

- ASAC - Da CATALOGO PRODUCTO PDFDocument2 pagesASAC - Da CATALOGO PRODUCTO PDFKevin MonroePas encore d'évaluation

- 1267379259Document7 pages1267379259sinasayedanaPas encore d'évaluation

- L7250 (Smooth) - HA13627 - Hitachi Motor DriverDocument46 pagesL7250 (Smooth) - HA13627 - Hitachi Motor Drivertrandito100% (5)

- 220v DC Motor Speed Control Using Ic RegulatorDocument14 pages220v DC Motor Speed Control Using Ic RegulatorZagorchilloPas encore d'évaluation

- Fanuc Drive AlramDocument4 pagesFanuc Drive AlrammntcepplPas encore d'évaluation

- Datasheet Smooth L7250Document46 pagesDatasheet Smooth L7250tosti77Pas encore d'évaluation

- Tda 1085 CDocument12 pagesTda 1085 CKucora IstvanPas encore d'évaluation

- TDA1085CDDocument13 pagesTDA1085CDCristiano BruschiniPas encore d'évaluation

- International Rectifier IRVR101: LIN Controlled Alternator Voltage RegulatorDocument15 pagesInternational Rectifier IRVR101: LIN Controlled Alternator Voltage RegulatorJohari JoePas encore d'évaluation

- Combined Overcurrent and Earth-fault Relay GuideDocument12 pagesCombined Overcurrent and Earth-fault Relay GuideNesarkiran BagadePas encore d'évaluation

- WG I Monitor Backspin Relay and Probe Manual Rev 7 0Document14 pagesWG I Monitor Backspin Relay and Probe Manual Rev 7 0elch310scridbPas encore d'évaluation

- 2006 File 9Document19 pages2006 File 9eurospeed2Pas encore d'évaluation

- Static Excitation EquipmentDocument54 pagesStatic Excitation EquipmentKumar Aravind100% (14)

- Spaj 140 CDocument8 pagesSpaj 140 CaktifiantoPas encore d'évaluation

- Whitelegg EP DatasheetDocument1 pageWhitelegg EP DatasheetselvamuthukumarPas encore d'évaluation

- A3930 1 Datasheet PDFDocument21 pagesA3930 1 Datasheet PDFKaan GünayPas encore d'évaluation

- Static Excitation Equipment GuideDocument54 pagesStatic Excitation Equipment Guide3KaiserE100% (1)

- ATV31HU55N4A: Variable Speed Drive ATV31 - 5.5kW - 500V 3-Phase Supply - EMC Filter - IP20Document3 pagesATV31HU55N4A: Variable Speed Drive ATV31 - 5.5kW - 500V 3-Phase Supply - EMC Filter - IP20Lê HiệpPas encore d'évaluation

- DG Application AMF / Synchroniser: Conzerv Systems PVT LTDDocument4 pagesDG Application AMF / Synchroniser: Conzerv Systems PVT LTDjaikolangaraparambilPas encore d'évaluation

- Drive a stepper motor with the SAA1042 semiconductorDocument6 pagesDrive a stepper motor with the SAA1042 semiconductorKevin StrongPas encore d'évaluation

- Eltek Smps SpecDocument2 pagesEltek Smps SpecJohn100% (2)

- Uc 3854Document12 pagesUc 3854Leandro CoradiPas encore d'évaluation

- SM72441 Programmable Maximum Power Point Tracking Controller For Photovoltaic Solar PanelsDocument10 pagesSM72441 Programmable Maximum Power Point Tracking Controller For Photovoltaic Solar PanelsShahid SiddiquePas encore d'évaluation

- SVT GreskeDocument17 pagesSVT GreskeIvcha100% (6)

- Tda1085c DDocument12 pagesTda1085c DpamururamuPas encore d'évaluation

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadPas encore d'évaluation

- 3ph Ac Motor ControlerDocument11 pages3ph Ac Motor Controleradamkam1111Pas encore d'évaluation

- HS8108Document8 pagesHS8108Miloš ZorićPas encore d'évaluation

- DatasheetDocument12 pagesDatasheetselocaPas encore d'évaluation

- Uc 3909Document14 pagesUc 3909Amarnath M DamodaranPas encore d'évaluation

- Fan 6961Document13 pagesFan 6961Ariel NavarretePas encore d'évaluation

- SerialSpindle AlarmDocument11 pagesSerialSpindle AlarmserkandmPas encore d'évaluation

- AP8012 OFF-LINE SMPS SWITCHERDocument10 pagesAP8012 OFF-LINE SMPS SWITCHERShubham AdkePas encore d'évaluation

- Trouble Diagnosis Trouble Diagnosi Blower Motor Circuit: To EsmDocument6 pagesTrouble Diagnosis Trouble Diagnosi Blower Motor Circuit: To EsmAlex RonPas encore d'évaluation

- PM & Start Up One Stamford Forum 02182013Document12 pagesPM & Start Up One Stamford Forum 02182013DLFlowtechPas encore d'évaluation

- TV de Proyección Sony Model KP - 53v85Document106 pagesTV de Proyección Sony Model KP - 53v85vaneritoPas encore d'évaluation

- ABB - Residual Voltage RelayDocument12 pagesABB - Residual Voltage Relaygadgil_vikrantPas encore d'évaluation

- MX321 ManualDocument4 pagesMX321 ManualFernando MendozaPas encore d'évaluation

- Fan 7314Document14 pagesFan 7314Kamal NonekPas encore d'évaluation

- AVR AS440 Data SheetDocument4 pagesAVR AS440 Data SheetMazhar Hussain100% (2)

- PCA82C250Document18 pagesPCA82C250Dario GomezPas encore d'évaluation

- Stamford MX321 Voltage RegulatorDocument4 pagesStamford MX321 Voltage RegulatorThomas Pendergrass100% (1)

- Uchc 2012 PM 1Document12 pagesUchc 2012 PM 1DLFlowtechPas encore d'évaluation

- Fanuc Module Error CodesDocument1 pageFanuc Module Error CodesQuang Nguyễn đứcPas encore d'évaluation

- SVAR Power FactorDocument5 pagesSVAR Power FactorRyan HarrisPas encore d'évaluation

- Submittal - LS Power Chambersburg - G3096 - 5.15.20Document419 pagesSubmittal - LS Power Chambersburg - G3096 - 5.15.20kohatian27796105100% (2)

- M/V™ Series Servo Drive: Description Power RangeDocument12 pagesM/V™ Series Servo Drive: Description Power RangeElectromatePas encore d'évaluation

- DTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsDocument2 pagesDTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsJorge RaulPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsD'EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Analog Circuit Design Volume Three: Design Note CollectionD'EverandAnalog Circuit Design Volume Three: Design Note CollectionÉvaluation : 3 sur 5 étoiles3/5 (2)

- Offshore Electrical Engineering ManualD'EverandOffshore Electrical Engineering ManualÉvaluation : 4 sur 5 étoiles4/5 (9)

- ZF4HP16 OptraDocument241 pagesZF4HP16 OptraDavid Chalker100% (36)

- ZF4HP16 OptraDocument241 pagesZF4HP16 OptraDavid Chalker100% (36)

- TF 66 71Document0 pageTF 66 71Serdar AsPas encore d'évaluation

- TF518 GD PDFDocument2 pagesTF518 GD PDFeurospeed280% (5)

- 604 46 PDFDocument1 page604 46 PDFeurospeed2Pas encore d'évaluation

- 518 Non Lockup Valve Body: Upper Body Bottom ViewDocument2 pages518 Non Lockup Valve Body: Upper Body Bottom Vieweurospeed2Pas encore d'évaluation

- 604 96Document1 page604 96eurospeed2Pas encore d'évaluation

- 604 99 PDFDocument1 page604 99 PDFeurospeed2Pas encore d'évaluation

- Five 1/4" (.250) One: Upper Body Bottom ViewDocument1 pageFive 1/4" (.250) One: Upper Body Bottom Vieweurospeed2Pas encore d'évaluation

- 45rfe GD PDFDocument2 pages45rfe GD PDFeurospeed2100% (3)

- 604 82Document1 page604 82eurospeed2Pas encore d'évaluation

- 500 518 618 No ReverseDocument1 page500 518 618 No Reverseeurospeed2Pas encore d'évaluation

- 604 89-91 Valve BodyDocument1 page604 89-91 Valve Bodyeurospeed2Pas encore d'évaluation

- 500/518 Lockup RH: Upper Body Bottom ViewDocument2 pages500/518 Lockup RH: Upper Body Bottom Vieweurospeed2Pas encore d'évaluation

- 518 Non Lockup Valve Body: Upper Body Bottom ViewDocument2 pages518 Non Lockup Valve Body: Upper Body Bottom Vieweurospeed2Pas encore d'évaluation

- 500 518 Tech NotesDocument4 pages500 518 Tech Noteseurospeed2Pas encore d'évaluation

- 48 Re 03 05Document2 pages48 Re 03 05eurospeed2Pas encore d'évaluation

- 48RE PromoDocument1 page48RE Promoeurospeed2Pas encore d'évaluation

- 413 470 670 Tech NotesDocument1 page413 470 670 Tech Noteseurospeed2Pas encore d'évaluation

- 604 46 PDFDocument1 page604 46 PDFeurospeed2Pas encore d'évaluation

- TF500 GD PDFDocument2 pagesTF500 GD PDFeurospeed2Pas encore d'évaluation

- 45 RfeDocument1 page45 Rfeeurospeed2Pas encore d'évaluation

- 06 70 RWD 4 Speeds Dodge Jeep OD Direct Clutch Changes PDFDocument1 page06 70 RWD 4 Speeds Dodge Jeep OD Direct Clutch Changes PDFeurospeed2Pas encore d'évaluation

- 06 124 45RFE No Shift Code1781 PDFDocument1 page06 124 45RFE No Shift Code1781 PDFeurospeed2Pas encore d'évaluation

- 06 77 RWD 4 Speeds Dodge Jeep No 4th or LockUp PDFDocument1 page06 77 RWD 4 Speeds Dodge Jeep No 4th or LockUp PDFeurospeed2Pas encore d'évaluation

- 06 74 RWD 4 Speeds Dodge Jeep Front Seal Wrong Size PDFDocument1 page06 74 RWD 4 Speeds Dodge Jeep Front Seal Wrong Size PDFeurospeed2Pas encore d'évaluation

- 06 76 RWD 4 Speeds Dodge Jeep OD Section Set Up PDFDocument1 page06 76 RWD 4 Speeds Dodge Jeep OD Section Set Up PDFeurospeed2Pas encore d'évaluation

- 06 68 RWD Dodge Jeep RWD Dodge 4 Speeds PDFDocument1 page06 68 RWD Dodge Jeep RWD Dodge 4 Speeds PDFeurospeed2Pas encore d'évaluation

- 06 70 RWD 4 Speeds Dodge Jeep OD Direct Clutch Changes PDFDocument1 page06 70 RWD 4 Speeds Dodge Jeep OD Direct Clutch Changes PDFeurospeed2Pas encore d'évaluation

- Basic Physics II - Course OverviewDocument2 pagesBasic Physics II - Course OverviewNimesh SinglaPas encore d'évaluation

- Graduation SpeechesDocument9 pagesGraduation SpeechesSeun IsraelPas encore d'évaluation

- PACIFICO B. ARCEO, JR, Jr. vs. People of The Philippines, G.R. No. 142641, 17 July 2006Document1 pagePACIFICO B. ARCEO, JR, Jr. vs. People of The Philippines, G.R. No. 142641, 17 July 2006Sonson VelosoPas encore d'évaluation

- Altered Mental Status: by Diana King, MD, and Jeffrey R. Avner, MDDocument9 pagesAltered Mental Status: by Diana King, MD, and Jeffrey R. Avner, MDchintya claraPas encore d'évaluation

- Virl 1655 Sandbox July v1Document16 pagesVirl 1655 Sandbox July v1PrasannaPas encore d'évaluation

- 50 Apo Fruits Corp V Land Bank of The PhilippinesDocument5 pages50 Apo Fruits Corp V Land Bank of The PhilippinesRae Angela GarciaPas encore d'évaluation

- Drama GuidelinesDocument120 pagesDrama GuidelinesAnonymous SmtsMiad100% (3)

- RIZALDocument36 pagesRIZALRichard GonowonPas encore d'évaluation

- Legion of Mary - Some Handbook ReflectionsDocument48 pagesLegion of Mary - Some Handbook Reflectionsivanmarcellinus100% (4)

- Notification of Workplace Violence Form Sarawak General HospitalDocument2 pagesNotification of Workplace Violence Form Sarawak General HospitalRomuald Leo PiongPas encore d'évaluation

- Datos Practicos TIMKENDocument128 pagesDatos Practicos TIMKENneodymioPas encore d'évaluation

- Taxation of RFCs and NFCs in PHDocument4 pagesTaxation of RFCs and NFCs in PHIris Grace Culata0% (1)

- Gliding Birdflight Basis AviationDocument172 pagesGliding Birdflight Basis AviationErnest DevensonPas encore d'évaluation

- Bollinger, Ty M. - Cancer - Step Outside The Box (2009)Document462 pagesBollinger, Ty M. - Cancer - Step Outside The Box (2009)blah80% (5)

- Junkspace: Hilary PowellDocument5 pagesJunkspace: Hilary PowellPilar PinchartPas encore d'évaluation

- Y3 Module 1 QuizDocument6 pagesY3 Module 1 QuizMohd HattaPas encore d'évaluation

- Math 226 Differential Equation: Edgar B. Manubag, Ce, PHDDocument18 pagesMath 226 Differential Equation: Edgar B. Manubag, Ce, PHDJosh T CONLUPas encore d'évaluation

- Ovl QC Manual-2012Document78 pagesOvl QC Manual-2012Sonu SihmarPas encore d'évaluation

- Judge fined for cancelling bail without causeDocument2 pagesJudge fined for cancelling bail without causeNARAG LAW OFFICEPas encore d'évaluation

- 2011 Daily Bible ReadingsDocument5 pages2011 Daily Bible ReadingsTraci GuckinPas encore d'évaluation

- Pat Garrett and Billy The Kid by Rudy WurlitzerDocument115 pagesPat Garrett and Billy The Kid by Rudy WurlitzerA. TmoqPas encore d'évaluation

- Qualitative data measurements are measurements of categorical variables and can be displayed as types. Qualitative data are non-numerical measurementsDocument22 pagesQualitative data measurements are measurements of categorical variables and can be displayed as types. Qualitative data are non-numerical measurementsnew rhondaldPas encore d'évaluation

- 320 Lecture 26Document8 pages320 Lecture 26marcelofilgueirasPas encore d'évaluation

- Yoga Poses For Back Pain ReliefDocument11 pagesYoga Poses For Back Pain Reliefshiv yoga100% (2)

- Wicked Arrangement WickednessDocument8 pagesWicked Arrangement WickednessbenchafulPas encore d'évaluation

- Chapter 14 ECON NOTESDocument12 pagesChapter 14 ECON NOTESMarkPas encore d'évaluation

- Terpenoid and PerfumeDocument5 pagesTerpenoid and PerfumeJillian Mae DacerPas encore d'évaluation

- STAT2112 Q2 Performance Task 1 - Attempt ReviewDocument4 pagesSTAT2112 Q2 Performance Task 1 - Attempt ReviewRussianOmeletePas encore d'évaluation

- Semester 1 FinalDocument29 pagesSemester 1 FinalBudi NugrohoPas encore d'évaluation

- Understanding Culture, Society and PoliticsDocument71 pagesUnderstanding Culture, Society and PoliticsAl Cheeno AnonuevoPas encore d'évaluation