Académique Documents

Professionnel Documents

Culture Documents

Ohe Rdso Eti Ohe49

Transféré par

hardeepsingh_08Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ohe Rdso Eti Ohe49

Transféré par

hardeepsingh_08Droits d'auteur :

Formats disponibles

MAstER

i. Clnuse-3(1).

" TR : :1 0 n-1 !Hj R" hn I I he R\I b s l. i t II t (' d wit. hi'I S : 306 - 1 BR3" '

2 Clnuse-3(iv) last line. PaRe-2: .. "

Substitute the word "castings" with

3. (x i ). PaRe-2:

"IS:2tl86(Pt.I)-1977" sha LJ ue substituted with

"IS:2486(Pt.I)-1993."

.

"IlS:32HH(Pt.II-197!J" nhHl1 lip ,,,ith "IlS:32RB(PI..11

- IBH3".

5. . Clause-7. 3. 2nd line. PaRe-7:

Substi.tllte "lS::W6-19i8" I"itll "IS::lOH-19B:1."

6. 2nd line.

Substitute the word "Clause" with "class".

7r Clause-7.7. PaRe-7:

Add a foot note as under:

"Nol.C'; r.10cl.ricfll rC'Rlnl.lvllv IInrif'r pnrft-90f

\

LS: IB!J7-1BBJ RIlHll IIC)" 1)(\ applicable for catenary

dropper clip (RI-11921 bridle wire dr6pper clip

(RT-1194)".

8 Clnuse-8. G 2. Page-8:

S\1PCrf,lllolls shall

<If'1 ("0 1.C'd

9. Clullse':"g.2. last sentence. Page-9:

j)C' 1I" tC" I nsl. sI"n t('nc(' " Non - t (' n s i () n .i b i n""t. R f.l. r e uSlln11v

cHRl.lnRR."

"'-.

:', ."

10. 1st line. Pnge-9:

. '. ,. ,

Substitute t.be word "non-tensions" \olith "non-tension .ioints"

"

...

..

1

..

1

, .N

........

..

...

'

. "

;/

.' .:

.,

, ; ,1 f).

r '.

:: ':, ....

:f.

"

'. '_ ;'<', ;(17 .

,. , ;'

.....

, ' ',',

"'.';.'" , .

. ,-','!

':

'18.

L .. '

"'J ,

'I'.

,

r

'.I'" I

. " :',} I;

. .... J. I

.... '.

.

I'

j

'! ,'.

-:..\;.', .

.: .. ,'..

., 'Ii f

:# . '.,

".

I .'

';...

!

!.

!I . !. I J-() 1111 d h). 'I"H! I) _. I (J :

Delete 11'( for splices only)."

f ) , :

"11"dlol!"",,"I,' If',,1 /l,d\''' I ,," "11.11,11 "/I IIh i c'

u,

110 f"f' :Hi f\R "d ro!If'" r' "

Clause-l,1.4 .1 1 s t l.i ne Page-12:

t:. i tu I,r:' t. he war'd wi t.h "cf\se.".

Clause-lL5.1.4. 4th line. Page-1"3:

Slibstitute the word "shal" ,.ri.th "shall".

C1 n u e - 1 1. fi 1. 6. Tab] e - 1. S 1. Na 7'. 8 & 9. Page - 1'1 :

"nuu" indicll-I..e<.l in the br"llcl<et Rltal] be substiLuf.elJ wi.f.h

Clause-l1.7.1. 1st line. Page-15:

The word '''verticaly'' shall be rend as "verti.cElI1Y."

i\PPENDIX-'e', Page-24:

.. Tfte !\pp('ndjx-C shall be the 1"rollowing:

APPENDIX I C'

P r' 0 per t. i eo g aft j 11 b r' 0 n 7. e .j n gal. sand

castings Extracts from

Chemical t.ion:

The. material when analysed either by the method

RPf'C i fi('d i II IS: 11027-1 nr,7+ n't. flllY ol.h('r .. I nnl.r:lIll1('nLnl/

C}l('111I clI.l 1Il('I.hod Rhnll ItIlV(-' Lite chemical comnoRitian

tn Table-5:

TABLE - 5:

CONSTITUENTS

PERCENT (castingR)

Till 9.5 - .10 e 5

Zi,w 1 !) . ()

*L(' n d. a x I . 5

Niclcel. 1 .0

Troll, Max. O. 15

i\1.t1minillrn. Max. 0.01

2

..

."..-.'

,

0,

CONSTITUENTS PERCENT

.. '

S iIi co iI, Hfl X 0; 02.

.: :.

..' .,.: ni S III II. t h'. . Mnx 0.03

To ttl.! . .i inj)u t' t. t iee,

i :'

O.fiO

(includes iron,' aluminium, .

. : antimony, silicon, bismuth)

' AI. ,,,." ,.

Copper Remainder

..:'" ,) ; i, .

.... .' ..'" .,

.. ' ( *P' . specifically by the purchaser,' the

.. 1.,"I*f)4 .. materIal may be supplIed with restricted,lead content .

..... .. 'l'h(' IIll\nufllcturer.' s111\J1. ",hen f'('(lIdred, free or

J ,L':' ' a copy of his works analysis of the material.

Pi The analysis is defined as the rdutine analysis

.'i carried out by the manufacturer in order to contrC?} the

. '. I

Quality of the material . ' I I

or' ;,.Hechanical propert i es:

ThemateriaJ. when tested in accordance :with IS: 2654 ,I

/- 1977++ shall Ilave tile nlechanicaJ properti"es as in

,I l' a b 1e - 6

'.; f,.

TABLE - 6: MECHANICAL PROPERTIES

HODE or TENSILE o. 2 PERCENT ELONGATION

:CAST TNn STHENr.TII PROOF STRESS PERCENT, ON

HPn, Min. Ml'a, Min. GAUGE, LENGTII

5.65 lA, Hin

.- .:

Sand 260 120 13

cast)

f '.

:' t ,. l Chill 210 120

'. 1\1

; i. '. !'. ;" ," Ii i

(Reparntely caRt)

Forms of test bars:

'ihc test bars shall be to one of the

appropriate tYnes described in

2.0 R_2_0 .

l_t-l_=w

.25

1...... 1&--- __

:. ")'

0"'

Hethods of chemicaL analysts of Q.ronzes.

.:'F

Hethods for tensile of copper and copper

alloys.

Hecommended pr'ocedllre for inspection of copper

hnse alloy Rllnd .

....: .. ,"

, ,- . .'

.. ' . I, <),' ; .

" .

1 "

. 1 '.

..... '.

. i . . ,t .

)

.

3

,

, .. '., {

',I

, . II'

. !.

.

f' :.( ..

(: APPENDIX -

t DI "

"'1' ':,f/{':' ,,'I!

Clause 0-2.1.1. last line,

Read "27mm of sand" in place of "27mm sand".

Clause 0-3.2,

2nd line and at the end 27.' ."

"IS:lRlfi-19fil"

shall be suhstituted with

!,

i" (' II 1!l !l 7

.

" <

, !

.

"J

. "

,

-{

"

,

!

-' '!it" '*'

:./.){

I

I ': j ,

,i t

,. ')',

i'

, ,. " : ,t"

I : .

!

,

.

," . r

4

I

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

TECHNICAL SPECIFICATION

\

FOH

...

F 1TT INGS FOR 25 kV <01. c. ClHE

~ " . J

SPECIFICATION No.ETI/QHE/49(9/9S)

RESEARCH DESIGNS & STANDARDS ORGAt.JlSATION

LUCKNOW'-226 01'1

'f

j,

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

RESEARCH DESIGNS & STANDARDS ORGANISATION

MANAK NAGAR, LUCKNOW 226.011

Specification No.ETI/OHE/49(9/95)

for Fittings for 25 kV,

50 Hz traction overnead :equipment

o. SCOPE

0.1 specification covers the requirements of the

fittings used on 25 kV a.c. 50 Hz traction equipment.

0.2 The fittings are made of copper, copper alloys,

malleable cast iron, aluminium al.loy, forged steel, fabricated/

welded steel and copper strip. The of fittings is

specified in the drawing nf the purchaser but the sampling and

the tests shall be done in with the relevent clauses

of this specification.

0.3 The fittings shall be grouped as tension joints/anchor

. non tension joints, suspension clamps and other fittings'

Osed'On the cantiLever assembly and'on OHE.

DEVIATION FROM SPECIFICATION.

-1.1 Any. d.eviation from this specification calculated to

improve performance. and utility of the eqUipment

proposed by the tenderer will be given due consideration prOVided

full particulars with thereof are furnished. In

such a case shall quote according to this

specification and indicate the deviation(s) separately in

"Statement of Dev tat ions ".

2. SERVICE CONDITIONS

2.1 The fittirigs shall outdoor use in moist

tropical climate and areas to heavy rainfall and severe

lightninl3 in -India. The limiting weather conditions which the

fittings have to in below:

Maximum temperature of air in shade

C

ii)Minimum temperature of air in shade o

(.

c

tJ,

iii) MaKimum temperature attainable 65.5 C

by an object exposed to Sun

iv)Maximum relative humidity

-1001.

v) Average annual rainfall Ran'3in9 frolTl

1750 mm to

6250 mm

1

!.r''':'' .' ':--:;:;,;:.J.n:u:11'l number .of ,thunder 85

"0 ';.,:n-'n, ciay s' p e' ri " -'

V:. :i.) 1"'1 a ;d ITI U. m f;jf dus t stor tTl 35

pe r - .' '"

viii)Number of rainy days per annum l20

. :;

2

ioK) c'wj.,n sure 200 kgf/m

.......

<)

,,}: .IHti .. Not exceeding 1000 m

: .

REFERENCE SPECIFICATIONS:' '

....;.

'be.en 'made! to following Indian,

International and RDSO in this

i )'IS: 3.06.,...1968, Tin bronze ingots and castings.

ii) IS:617-1975 ,and aluminium alloy and

.. ,:

castings engineering

iPurp.oses... '

i i1)' 15:737:-'1986 Specification for wrought aluminium and

"a141T!iniurri "alloyshe'et and strip for

",3e,t,:eral eng i heering pur poses.,

i Vi ),

IS ' '(e'c,hni lycondi t ionsfor,threaded

(P t Xl,r I ).-: ! steel fas tene rs .,j Pt. XI II Hot Dj p

.

castings'ln threaded fastners.

"

,,' !

v) IS: '1500-'1983 Method for Brine'li Hardness for

metallic materials.

"',' vi') ,Method for tensile testing of steel

. " prodUct$.

',', " , .: , .

, vi 1), ',Co p'pe.r st d p' for E!le,c:t r i,1:J9,1 '.

.. t :

viii) steel forging for general

en,,:} in e e r i h g ;purpos e s . ,

i:d Steel for' gen'er"al struc't,.(J.'f'al purposes.

:<> IS: 2108--1977 ITlal:leable,irqn castinlJs.

"',' .

:

>: 1> "IS: 2486 (P t . 1) Insulator fittings for overhead power

--1977 line witi-; .,( nciminal.'voltag'e )- than 1000 V

Genera] requirements and tests.

. . , .

'-.-' :,.

kii) 15:3091-1965 Aluminium bronze ingots and castings for

overhead fittings in electric traction.

xiii)BS:3288(Pt.I) Insulator and conductor fittings for

'1979 overhead power lines ( performance and

requirements).

2

xiv) 18:3658-1981

Code of practice for liquid penetrant

flaw detection.

xv) 18:5561-1970 Electric power connectors.

xvi) ROSD Specn

Hot dip zinc on gteel masts

No.ET1/OHE/ (rolled and fabricated), tubes and

'13(4/84)

fittings, used on 25 kv a.c. OHE.

):vii) ROSD Specn Steel and stainless steel bolts, nuts

j

No .,ETl/OHE/ and washers.

i

18(4/84)

1

-I

i

4. GENERAL REQUIREMENT

4.1 The fittings shall be free from defects which are

likely to be detrimental to their performance in service.

4.2 Aluminium bronze, tin bronze alloy cast

fittings shall preferably be made by pressure diecasting process.

The castings made out of other processes like gravity die-casting

shell moulding/investment casting by lo.stway method shall also

be acceptable so long as the fittings/test\bars meet all the

necessary mechanical and electrical properties specified in

relevant specifications. Sand casting these cast fittings is

not acceptable. .'

4.3 Steel/Stainless steel bolts, nuts and washers shall

conform to ROSD Specification No.ET1/OHE/18(4/84). Non-ferrous

I

I

bolts/nuts shall not be used.

1

.'

4.4 All parts of the fittings shall be manufactured by the

in his works. Components such as washers

and split pins which form part of the fittings shall be obtained

from the approved manufacturers with the approval of

Cent ral Dr.;:}an i sat ion fo r Rai lway EI e ctr if ica:t ion. The supp li e r of

the assembly shall ensure that such bought out components conform

to the relevant specification.

4.5 Protection against corrosion:

4.5.1 All fittings shall be either inherently resistant to

the atmospheric corrosion or suitably protected against

corrosion, both during storage and in service. All ferrous metal

parts, except those of stainless steel,.hall be hot dip

galvanised in accordance with ROSO specification No.ETI/OHE/

..

13(4/84) .

4.5.2 Malleable cast iron fittings shall be shot or grit

blasted before and after heat treatment.

4.5.3 The threads of the tapped holesshall ,be cut after

and shall be adequately oiled or greased.

Female

threads shall be tapped after galvanisation and shall be o i1 ed.

3

male threads, galvanising process shall be so controlled that

galvanised fasteners can be assembled by hand with female

fasteners. Galvani'ied fasteners with male threads of . size M'12

only may be rolled facilitate assembly after

galvanising in accordance with (Pt.XIII)-1983. The thread

of all bolts and nuts shall be formed conforming' to their

relevant specification before galvanising.

4.5.4 bolts and nuts shall not be used.

Bolts andnuts.of 10 mm diameter and less shall be of stainless

steel unless stated .in the drawing.

4.6 Wherever not specified in the drawings,

furnished by the Purchaser, the following tolerances shall apply

for non mating surfaces:

Dimension Tolerance

including 35 mm

+/..;.. 0,.5 ITltT,

Dve r 35rrit'll

1.5 'Y.

" ;:.. . .

case of .mating surfaces, tolerances shall be +0.5 mm

-0.0

on 'the holes and +0.0 mmon shafts. The tolerance for wall

. -0.5

thickness shall be +1.0 mm

. -0.5

5.

5.1 The fittings shall be offered fer iri lots

either the whole or a part of the

ordered. A lot shall consist of the sarr.e,type, categl;Jry and

rating of fittihgsmanufac'f,ured from the same raIN material and

madeund.e,r identical conditions and from one. melt (in the case of

.. cast .F tin/as of di fferent type, and rat i ng may

be manufactured 'out of the same melt but shall constitute

separate and different lots. The manufacturer shall maintain the

records as to the raw materials used and temperature for every

cast/lot.

5.2 Castin9S

If the weight of the f'ittingis not more than one kg, a

lot shall consist of' pietes makingupto a afnot fuore than

200 kg. If each fitting weighs more than one kg, a lot shall_

consist or pieces making upto 500kg fof non-ferrous fittings and

1500 for fe'roul fittings.

5.3 Three test bars shall be made

for

'"

bea/

tensile and eloRgation tests. The test bars sh"'}ll

identification mark of the lot and date of melt.

4

5.4 Fofged

1

welded fittings:- The lot of forged. welded or

fabricated ferrous fittings shall consist of not more than 500

numbers of fittings.

5.5 Copper/aluminium alloy strip formed fitting:

The lot of such fittings weighin'3 e'ach upto 50 gmshall

not exceed 2500 numbers while for the fittin':Js weighing more than :,"' I

SO gmT the lot shall be restricted to -1000 numbers. :.'"

'";.

5.6 Sample size

5.6.1 The number of fittings to be selected from the

lot shall be in accotdance with column 1 and 20f table given

below. If' arlditionalnumber of fittings as in

column 3 of table given below shall be selected at' to

satisfy the criteria for conformity in accordinace with Clause

5.6.2 below.

SAMPLE SIZE AND CRITERION FOR CONFORMITY

Lot size First sample Second sample Acceptance Rejection

N size n1 size n2 criteriaC'1 Numbe r c2

'1-20 1 2 o 1

2-1-50

2 4 o '1

5-1-100 4 8 o 2

'10'1-500 5 '10 o 2

50'1-800 7 14 o 3

801-'1300 10 20 o 3

1301-3200 15 .30, 1 4

3201-8000 25 50 2 5

800'1 & above 35 70 2 7

5.6.2 Criterion iL conformity:

5.6.2.1 The lot shall be considered as conforming to the

requirements of the acceptance tests if the number of failures

found in the first sample n1 is less than or equal to c1. If the

number of failures is greater than or equal to c2, the lot shall

be considered as hot conforming to the of the

acceptance tests and shall be If .the number of failures

is between col and,c2. a s'ec'ond sample of n2 fittin':Js shall be

selected an.d subjected to acceptance tests. If the number of

failures in the two samples conbined is less than c2, the lnt

shall be considered as conforming to the reqUirements' of

acceptance tests, otherwise it shall be considered to have

failed

..

6.0 TESTS

6.1 Tests have been specified according to the material and

functional re1=1uirementof the fitting and are required to be

conducted to determine conformity to the material specification

and requirements of the fitting.

5

" ,

6.2 s s i fiea t ion 0 f t est and c ri t e ria 0 f ace e etanee:

The test are divide,d into three groups:.

i) Type tes ts

ii) Acceptance tests

iii) Routine tests

6.2.1 tests: Type test are intended to establish the

general qualities and design characteristics of the fittings and

to prove its conformity with the requirements of specification.

The type tests are to be conducted only after all the de5igns and

drawings have been approved and clearance given byRDSO/Purchaser

to this effect shall then take up the

manufacture of the prototype for ROSO/Purchaser inspection. It

is to be clearly understood that any change required to be done

in the prototype as required by ROSO/Purchaser shall be done

expeditiously. Each test shall be made on 3 samples. If the

sample fail,s in any of the tests the production of further

fittings shall be stopped till further investigation and

7

improvements in the manufacturing procedure done.

6.2.2 Acceptance tests: Acceptance tests are carried out to

verify the quality of material and workmanship for acceptance of

the lot.

6.2.3 Routine tests: Routine tests are carried out on each

fitting from the lot to check the which are likely to

vary during production. The defective ones are rejected. If 101

or more fittings fail to meet the requirement of the routine

the entire lot shall be rejected.

6.3 Bulk manufacture: Only after clear written approval of

the results of the test on the prototype communicated by ROSO/

Purchaser to the manufacturer. shall he take up bulk manufacture

of the fittings which shall be strictly with the same material

and, process as adopted for the prototype. In no

shall material other than those approved in -the design/drawin'3s

and/or the'prototype be used for bulk on the plea

that they obtained prior to the of the

prototype.

6.4 InsRection: Before giving the call to ROSO/Purchaser

for inspection and testing of the prototype of the system. , the

manufacturer shall submit a test schedule consistirig of

schematic circuit for each of the tests. nature qf the

test. venue of the test. duration of each test and the total

number of days required to complete the test at one stretch. Once

schedule is approved. the test shall invariably be done

However. during the process of type testing or even

later. RDSO/Purchaser's representatiVe the right to

conduct an-y addi tional tests besides, 'those speCified herein. on

any equipment/sub-system or system so as to test the system to

his satisfaction or for gaining additional inf9rmation and

6

" . :'. ,"",-,,, , , . .' ,.

know1edge :;:p r,'! .rii r:i: e be en the

man uf act ur e r . I:f ''!rhe,RlJmIDVPU e du n g the

".' _,; of, .. t.tS tl ngas the ty'pe ;tes-t':' and/n r the

typ,e test resul ts 1 it

s ha.11J retught1

i

t:o :i:;pe,o.f, i t,h J)'f,r:;e tori 'Gene ra l' (Trae t ion ' .;\

,Ins t.3:i lat'i on h""1 cbi\s e r . 'de G i,s,i Ol7t".,

shall be final and bindin.,;). n. .. 'i'. ;,.; ..

6 .: ins pet 6 f ' 9' c' r e 6 eon 5 i b i li MY 1. ;...' .

,',I..' .; ;, ,. if.' ;,'." of;, , '.:> ..

" J .. a proper )record "

of' of,erfi!4" .. the

number of fIt t 'i';'9sot'l J -Wh.l,th, s I .. 'antl." the,

indicating the number' of

, 'a_t;'d! 'r on51,; It heY'&l.,f'o;r. ; T,pJi!,se., r'B,Co r ds,o r co pi esthere of

to'it'he"

The'i'tls pect i n9 au-tJ,or,i'ty;' r fng 'hLs '

inspect'i'on chec:k:thet jpr.op,er tests

and prescrIbed . 'qua.lity assurance checks'" done at<,'the:

.. works are maintain'ed in the requil"ed l1"i"a.:nher ., ..

. " C"". ,.:1,'.;.: .. , --)<.; '.": ,),<.,' i '.:'.;":," ,j:,{,', ".;, .... :':.

7.

MA rE:'Rti!W:' 'S'PI!C'lf;J;0'-ATLONi n, L '?' r 1'1 ':""1 r.: .. ;., '.',

I ,. ,

7.1 Aluminium Bronze: Aluminium bronze alloy used for the

fittings shall conform to 18:3091-1965. The o'f

the specification are given in Appendix'A'. .

: ; , t 1" , .,. . ... ... .

7.,2 .- !.' .: ;.:' M'all eabl e cast iron: Th.e." I,Tla:\. 1 eabl e. cas t i ron fittings

shall. to Grad;-BM:3'40 o,f, e:<tracts

\ I ,} .. ..,. ' .. - .,.,. , '. ,'. .:' ". ;' .- _ : ,,' r,

o;f" i cat i on are g,iven .. "f:jt:<,) :'.

'. __. ,: ., . .:: ,.,;' :':) j: Ii: .:.' .. . / !..

7.,;3,' .." ":'rLn bronze: The tin 'c'onform to

".-", , .. t '-"1 ; .<,' - '.- '.- -. ;_).r !).,-,:: r r r'''' .., (

the IS:' 306-1968." : THe! 'r'e'l evant( i:< 'C'.

i: : i r:l _:', ,... . . : .... :.. i !: ;.; l' ') 't "':"";)'''' i' ""

7 4. "." '-"'AI umi n i urn alloy: The fit t ings shall

cOT)fQrm, to ,.Grade 4600 of . are given in

Ap pendi x '"tF {\i I:;':; ';<; m:.;. I ' .!

'<Jr,. l' f .. r ..; -;':". , r ," (' 1.,.. .. :.., _ . ' 'j',

. -F,orged steel: The fittIngs

to Clause 2 . other wise

spec i re 1ev;a,nll&i<t ra'ct s, i:<: 'E'

. ..' i;' .. ", :. >,

7.6

Fabricated steel: The mat.rial of fabricated steel

f i t ti n,gs

unless otherwise stated on confor,m.' ,to

iG,rade"A

'of 18:2062-1992. The extracts are given in

"\ F",;. ... " .: '-::"

{'. f: :: .

.. L., ;')'! t

7.7;" _ "'C'oDPer strip fttt.inqs: . ,The material of fi ttings formed

,by" epper" strip shall f;onform tel' '18:-'1897""1983. The relevant

given in i;,.d:

.. '.. ': ,,; i. I .: .-.'

" ii, c: .: ' . ...

7'.8 n Aluminium or aluminium li'lio;:l" st'i'ips/shee,ts: . The

material

18:737

,of: shall conform to Grade Condi ticn H2 of

19'86'. 'Tt',"e relevant .e)(tra;ct s <a(e, 9 i ven'i n'App.em:li x \ H:' ..

'. ," : .<.:: . ::.:. I '.

7

8.0 CONDUCTOR END CLAMPS',/MIO'8PAN TENSION JOINTS ANCHOR

FITTINGS AND TURN:":'BUCKLES(9-TONNE'

: " , . , : ' , .

8.1 Fittings for cleur;'pi;Ii,9, the 'conductor's, which are in'-

tension" at the ends and thei r"nii d-'s pan'-s'pl i cas ,al"ecal.l ed , ' end

clamps and tension joints respectively and 'a:ri:e,c::O'vered' in tftis

group.

8.2 Requirements: End tension jgints shall' be

manufactured so as to avoid sharp radius of

ridges whiah might lead, to localised

pressure"and damage to' the 'conduttor and fitting due to vibration

in service. They tests

. . . .

. l

8.3 The end clamps and may be of aluminium

all oy cast i ng, al umi n i um i ng,' ,me 11 ea.b 1e i rCln cas tinig

01" fOl"ged/fabri cated steel as', specified in tt'te purchase'r's

dl"awings,. The shall conform to

specifications.

8.4 The fitting may be bolted type, cone type, wedge

compression type, as specified in

8.5 Tests.,

. ,,'.\ ,j,

8.5.1 tests:

a), '" inspettiori' " (Se e C1 .1 '1 1 )

b) Dimensional verificatiotC 'C 1. 11.2)

c)

(8e'e C1 11 .3)

,,d'> ,'flnysj. c,aJ p,I".O pe I"t i as t est

'( e<c i . 11 .4)

,e'), '

;fai ({n.g, l!Jad test , ,;' -"i ".(8.e e' C1 11 .5)

f) Radi 0 g' f'a ph fc't'es t{'on'l

<

y fa

,

..,. c'astAr",;Jsl,,<,SeeCl.11 .. 6)

g) .resistance test

Hor spl i

'" . ( See C1 11 8 )

h)

Temperattire

", '.." ;' '.

(for splices only) (See C1.11.!:?)

i ).<

,Galvani$ing

:r t tin9$ 0 n1y') . ," ':

(See Cl.1"1.10)

" "!

j), ,Dye. penetr,atio'ri"'test ; .; ,(See Cl.11.12)

k) Hardnesstest (f"or MC!

.(8e'e . Cl.11. 14)

. '-. "

.. . .

Ac,tapt'ance tests :; "i

. a) Visual inspect'lon (8ee.Cl.11.1)

b) Dimensional verification"

(See

.2)

c) tist . ;':' (See C.1.11.3)

d) Physical propertias te.t

(See Cl. '11.4)

e) Failing lOad test ' <:i'>11.5)

f)

(for

fer'r-ous fi:ttings only) (See C1. -1-1.

9 )' Dye penetra\ion test

(SeeCl. '11'.12)

h) Hardness test fittings) (See L1"1.14)

8

8.5.3 Sam,les taken in accordance with Clause 5.6 shall be

subjected to all tests listed under 'Acceptance Tests' except for

chemical

should

composition test

be conducted in accordance

and physical

with

properties

Clause 11.3

test

and

which

11.4

8.5.4 Routine tests:

a) Visual inspection (See Cl.11.'l)

b)

Routine verification of dimension (See C1.1"1. '13)

c) Dye penetration test for fittings

listed in Appendix 'J' only. (See C1.11.12)

9.0 NON-TENSION JOINTS (PARALLEL GROOVE AND TERMINAL CLAMPS)

9.1 joints: The fittings used on the overhead

conductors for electrical continuity which are not subjected to

tension are classified as non-tension joints. Such fittings

include parallel groove clamps and terminal clamps of jumper

assemblies.

9.2 General requirements:

Non-tension joints shall be designed so that they meet

the requirements of the normal' service conditions. A rated

current shall be assigned to every joint which: shall be the

criterion for electrical type tests. Fittings intended to

connett conductors of two dis-similar materials shall be so

designed that harmful bimetallic corrosion when erected in

exposed atmospheric candition is minimised. Non-tension joints

are usually castings.

9.2.1

Fittings 'or non-tensions shall be manufactured and

finished

so as to avoid sharp of ridges which

may lead

to the localised pressure or damage to the conductor in

service.

9.3 Non-tension' joints are made of tin-bronze, aluminium

alloy or copper specified by the purchaser.

The material shall conform to relevant clauses of this

specification.

9.4 Non-tension joint fittings are bolted type,

though there may be some fittings of crimped type or soldered

type. All fittings are subjected to the tests as specified in

relevant paras of this specification.

9.5 Tests

9.5. '1 tests:

(See Cl.'l1.1)

a) Visual inspection

(See CI.11.2)

b) Dimensional verification

c) Chemical composition test

(See C1.11.3).

d) Physical properties test

(See C1.1"1.4)

9

Radiographic test (only

for castings)

(See CI.1'l.6)

f)

Slip test

(See C1. -1-1. 7)

g)

Electric resistance test

(for splices only)

(See Cl.'11.8)

h)

Temperature rise test

(for splices only)

(See C1.'l'l.9)

Dye penetration test

(See CI.'1"1.'12)

9.5.2

Acceptance test:

a)

Visual inspection

(See C1. -11 1 )

b)

Dimensional verification

(See CI.'11.2)

c)

Chemical composition test

(See CI. '11.3)

d)

Physical properties test

(Se e C1 '1 '1 .4)

e)

Dye penetration test

( S'e E! CI -11 . '12 )

9.5.2.1 Samples taken in accordance with Clause 5.6 shall be

subjected to all tests listed under 'Acceptance test' except for

chemical comoposition tests and physical properties test, which)

should be conducted in accordance with Clause 11.3 and 11.4

respectively.

9.5.3 Routine tests:

a) Visual inspection (See CI.11.1)

b) Routine verification of dimensions (See Cl.11.13)

10.

SUSPENSION CLAMPS AND OTHER CANTILEVER

ASSEMBLY FITTINGS.

10.1 Fittings which are used on the cantilever assembly and

the of conductors are covered in this group.

10.2 General requirementsi

The clamps and fittings shall be so designed and

manufactured that the effect of vibrations, both on the

conductors/cantilever assembly and fitting itself, are minimised.

The suspension clamps, additionally, shall be

manufactured and finished so as to avoid sharp radius of

curvature, ridges and excrescences which might lead to the

localised or damage to the conductor iri service. The

suspension clamps shall permit the conductor to slip before

failure of conductor occurs. The clamp shall have sufficient

contact surface to minimise damage by fault currents.

10.3 Tests

10.3. '1 .IY..J?e ,t est s :

a) . Visual inspection

(See Cl. -H. '1)

b) Dimensional verification

(Se e C1. -1 '1 .2)

c) Chemical composition test

(See C1. '1'1.3)

d)

P h:-:s i ca 1 pro pe I." t:: \.::,s,

(See Cl.11.4)

e) Fallin'J load test .

(See Cl.1'1.5)

,; : ; '" f,t

.Ra.di og,r tft9;t.o;nl;X"i, '.'

':' 1Y: rf . , '" " ';" .

(See Cl.11.6)

. ,;g):

Sl ,.folr, .....

. j"',,;'

.. ,:,:.:i' ....., (See Cl.11.7>'

Cia 1 i n 9:t. eS. t., j) 0 f.,.: i'; ,.' . i..'

f,e.r; r:ous ,.f. Hit l.y, .' . ,.,.:; (See "e L 11.'10)

Assembly tes t (fo r contact'wi .;.: "

droper clip and swivel clips orti9>

j )

Dye . r;... "',.,, ,!, (See Cl.:'11.'12)

k)

Hardness test '(for' MClftttings)' ,.' '1'1.14)

. : ;, ;

.: .' ': ;", g' ;' I ' !:

:,.; .

/a)' vt sual,i ns pecti on. ('$ee Cl.n. 1 )

;b) D,irtlens-ionaJ.viu.ificat.ion ;'(See C1.11.2) .,

,C) Chem,ital test (See CL'1'L3)

i \

,d) ";. . . (See dl

" 'e)., '. Fai1:a. ng: to.aQ. .;. . .... " . (See'Cl +1\5) 'f

:; "

'f) 81 ip. tes t,:! f,o:r.: .claintd .::l (SeeC F. 1

j

1-i.,:n:

.i: 'g.),'. Ga,lv i:s,.i ng .t.e,s t '( fo r" f. erro!ls' :,: .

,.,!';

..... .fittings".onlY)., . . . '., ."',' '. '(See 'Cl.'1'1 >10)

h) Assembly test (forc:ontact' 'wire '.'".

" J

dropper c 1'i p 'andswi ve 1 cl on ly')'( See

i> Dye penetrationtes.t. . .... . , (See C1.11.12)

j ) Hardness test ({or 'MeT 'f-' it iings r:C-Se:e! C1. '1'1

. 10. .. ','in 1.3'as'e 5':'6 shall "be

!i'ubj e ctedto :<iiH 1 t e'$ ts.l is ti.'a tes'ts ' e pt f,o r

chemical composition test phsical. propeft'te's t'es't, which

should be conducted in accordance With Clause' :ij'L3' and 11.4

.\ r.,:,._ ni: '.' ': ':ic', .. "';:'

'.1 . ,- , ;: .. : . , ' ;.,_, " ' I . ,

- .1 .! ::.. -:-; I

.. ,"

'10.3.3 . ':

: I !:1 "';.;

!) ,".: .

. 'Jd .

Vis,ual (See Cl.-11.-1)

". : .b) , Rout,i'r.te.i . v,e,ri;f,i.catl'o"n .of 'dimen,sil,ln' '(See CI.1 hc13')

c) Dye penet rat i on test (fo'r' 'f i t,t i rliJs" .,: ", ,C,'

li.sted in Appendix 'J' only)';" .,,;.

:' ..: . .. :' " .

.TESmMSTH:QDS : .

. . , . r-" ..:' . '_;

: "'.:

V ua:l:: i . : :.' .' ..... ,-. / ;;.. . '" ..:' . ",... \i. .. ! .J

: .. ' :.:,.;. ".; ,... }"., .;.. ;:. : ;' . r, ..... :. " .. : t

., " ALI .. ;!:Ie for ,good wofk

manship and smoQ,tih,fin.i$.t', 'inciudin'g"mar,kb,'g' as" spec:if'ie-d, :in

PurC:haser's drawings andfeir f"r'o'n(def'eli:t'sstip'41ated. :,in

re 1e :sps cif i C.;lt i f t i shall be checked in

!accordafi'cewith. ROSO'SpecificAttion.' No.ETl/OHE/

'13l47B4) forvisUq! '<ina f'Tttlngsf-iaving "def-eat;s cmentiQ'1ed

in Appendix 'A' of that spetificaticin

11 .

11 n 2 verifica.ticm:'

All. dimensions of ritti'ri.js s'ha.'llbe;'verified with the

help of callipers and - check that they

conform l.I'.i ththe appro ed drawings. Th'read' gauges shall be used

to threads where er pro.... No-Go gauges

are used . for,. checking 0' dimeris ions . thed... r such gauges

shall be' '.;Jot approved by the"manufa'cturer beta-re use by the

inspecting ,

, . '", -/ .1, I

1'1.3

cal composi ti 0'1, n

...... ;

The chemical composition of the material

shall .be test.ed in accordance with the rele\Oil.nt spElcificati.on

mentioned inClause-1 In of castings, the tests shall be

done on the test bars as wall as on one sample'fittiTig of each

casting/melt. Material sha;llcoiif'orm to the requirements

specjfied in the rele.... ant spetificatioTl.ln case. of forged/

fabricated fittings, the be carried out on one

sampl,e:.each of raw materi.al and concerned fittin'3s:upto a lot of

200 nos and on. two samples_aeh '0' upto

a lot nos. In case of Coppe,rhduminium st.rip formed

fittings the test .snall. be carried out' on one fitting sample on

no,s ',0 r f ra c:t i on thereof a lot.

..... .

",.j

'

'11.4 ; "Physical prope.rties.test:

'11.4.1 In the cast of castings the' tests for mechanical

properties '.J:>e ccin'dutted on thetest'bars/pie.ces made, .j,n

accordance .w.itr\ .'t.herele.... antspecificatiCin (Clause. 7).(See

.rele.... Appendices .. '.," ';;;

.1 "

. . .l L" . .

If one test piece fails in any test,

pieces shall be tested. The samples shall be deemed. to.have

passed the if there is no failure

"11.4'.1.'1 In . case of malleable 'ca5t)'if'on (MCI) the

8.2) and (ref. 8.5)

alsoA tes"ted .. , ," .p., .. ;f' ';" .':":'-<.' .,'

, .

..

11.4.2 In case of forged/fabricated/welded 'fittings

properties tests shall bi conducted in with the

relevant specifications on one sampleupto"a lot of 100 nos and

on 3. samples for a lot. exceeding '100 'nos; 'Wb;ich sh9uld be selected

at random. ,If in any test, double the number of

test piece:s . shall :be deemed ,to have

passed the! te.sts. .if there is no' failure in the'retest. '"

In case formed';fittings

physical properties .. Qnone uptb a lot of 500cnos and

on three samples on 500ri6s shall be condqcted.

12

i.

11.5

test:

11.5.1 For clamps4 mid span tension joints and

,s pIt ces.

11.5.1.1 The fittings shall be assembled in accordance with the

standard drawings on the conductors 01 the size and type with

which it is meant to be used. The assembly shall ,be held in a

tensile testing machine and anchored in a manner as

nearly as possible, to the arrangement used in service'. The

compression end clamps shall be compressed on the specified

conductor. The precaution shall be taken to avoid bird caging of

the conductor. The length of the conductor between the fitting

under test and any other clamp or joint in the test assembly

shall not be less than 100 times the average overall diameter of

the conductor.

11.5.1.2 A tensile load of about 50% of the breaking load of the

conductor shall be applied and conductor shall be marked in such

J a manner in that movement relative to the fitting can be easily

detected. Without any subsequent adjustment of the fitting, the

load shall be steadily increased to 90% of the breaking load and

maintained for one' minute. There shall be no movement of the

conductor relative 'to the fitting due to slip during this period

of one minute.

11.5.1.3 The tensile load shall then be increased until

the

conductor either slips out of the fitting under test or snaps

or

one or more of the component(s), 01 the fitting fracture

or

deform.

11.5.1.4 The fitting shall not break, slip or deform till the

conductor breaks. Should the wire or conductor slip in the

fitting or any component of the fitting fractures or deforms

before the failure of conductor the fitting shal be deemed to

have failed in the load test. If the conductor breaks at a load

less than 95% 01 its specified breaking strength, the test shall

be repeated.

11.5.1.5 After the test it should be possible to dismantle the

fitting without difficulty and without recourse to any tools

other than those normally employed for assembling them.

11.5.1.6 The minimum failing load of the conductors are

indicated in Table-1.

'13

-----------------------------------------------------------------

TABLE-1: Ultimate tensile strength of conductors.

81 No. and diamter Ultimate ten

No. Type of conductors sile strength

(mm) (kgf)

...., "

1 Cadmium copper catenary 19/2.10 3920

2 Cadmium copper bridle wire 7/2.10 1443

3 Hard drawn grooved

contact wi re (107 mm 2,. ) 3905

4 Hard drawn 5475

contact wire (150

5 Hard drawn copper 37/2.25 6080

conductor ('150 mm 4 )

1

6 Hard drawn stranded cadmium 37/2.10 7650

copper conductor (130

7 Annealed copper stranded 19/1.80

jumper wire (50 mm )

8 Annealed copper stranded

jumper wire (105 mm '19/7/-1.016

9 Annealed copper stranded

jumper wire (160 mm ) '19/7/'1.25

10 Hard drawn copper wire for 5 825

droppers.

11 Hard drawn copper wire for 7 '1530

'droppers.

12 Earth wire - ACSR (RACCOON) 6/1/4.09 2746

13 Earth wire galvanisedsteel 19/2.,50 5'100

14 Return conductors (Spider) '19/3.99 3736

(All aluminium)

15 Aluminium large jumper

'133/1.40 3380

16 Stainless steel wire rope

34x7(6/1) 3800

17 Aluminium alloy conductor 19/2.79 33'10

'14

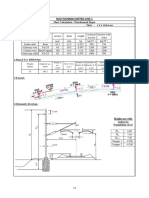

11.5.2 tlast anchor fittings, suspension ciamps

and-other fittinqs.

f1'.5.2,i"1 - Th'e fitting shall be held in a tensile testing machine

ina manner approximating, as nearly as possible, to the

to be used in service. The conductor shall be

replaced by a,suit,able rigid bar (see fig.1). Tensile load equal

to 50X of the specified failing load shall be applied and

thereafter at a steady rate. Fitting shall not fail or

deform below the minimum specified failing load maintained for a

period of one minute.

Note: The of the shall be specified

after actual tests.

CON A

....... '-'-'_.1 .. ++-- T ..... :==@t---+

FI/<.O TO ""NE:. NON /-OADlffG

ENO 0;;- 111

FIG .. 1

'11.6 Ffad i 0 g raph i c t est:

Castings in each melt/heat shall be subjected to

radiographic examination - for Qetection of casting defects.

Applicable reference itandards for various alloys used on OHE

application alongwith the maximum permissible level of

discontinuity are given in Appendix-K.

Note: The radiographic test can be conducted by the outside

agencies till such time the facilities are established at

the premises of the manufacturer. In such situation the

sampling - be decided as agreed between the

manufacturer and purchaser. If the purchaser is satisfied

with the quality he may make this test optional.

11.7 Slip test!,

11.7.1 Slip strength for suspension clamps:

.

The suspension clamps shall be verticaly suspended by

means of a flexible attachment. A suitable length of the

conductor with which it is intended to be used shall be fixed in

the clamps with bolts and nuts tightened to the required torque.

A load shall then be applied gradually at one end of the

conductor (rate 0' increased being 0.5 kN-1.0 kN/second) and the

value of the load at which the conductor in the clamp begins to

slip shall be noted. The conductor shall not slip at a load of

25X or less of the breaking load of the conductor.

15

F I 2

Slip .1.gll for non-tension joints.

i

L-oOADtNG

1 L 7.2

, ,

11.7.2.1 The joint shall be assembled using cdnnector under

t-est on ionductors of the siz. with which it is to be used. The

/ assembly shall be mounted in a tensile testing machine and

anchored in such a way test ldadis applied in the

direction of conductor.

11.7.2.2 A tensile load of about 5 the breaking load

of the conductor, subject to a maximUm of 55 kgf. shall be

applied and the conductor shall be marked in such a way that

movement relative to the conductor be detected.

Without any subsequent adjustment of the conductor, the load

shall be steadily & slowly increased to 101. of the breaking load

of the conductor. subject to maximum of 110 load 'shall

be maintained for 1 minute. There shall be no movement of the

conductor relative to connector'due to one

minute period and no failure of " ,

11.8 Elettrical Resistante

11.8.1 The fittings which are required to carry current shall

be subjected to the resistance tests. The te$t"shali be done ....Jith

direct current. The polarity shall be reversed test

Average 0' two results shall be taken

11.8.2 The resistance measur'ements sh'all be m.ade by millivolt

drop_ an accurate

11.8.3 The actual. size of conductor whichwirl be used with

the connector or fitting shall be used during ,the tests.

EQL tension joints:

The fitting shall be assembled in with the

standard drawing on the conductors of the size and type with

which it is to be used. The electrical shall be

measured between two points on the conductorsone:i ther ,'S ide and

. 25mm clear of the fitting. The resistance of the conductor with

splice shall be of the same order as that of the equivalent

length of the conductor. The current connections snatl be crt a

distance of not less than 50 times of the diameter of the

conductor from the fitting and shall be made so that effective

contact is made with all those strands of conductor which would

be taken into account in calculating its equivalent resistance.

""':'_ 16_

1'1.8.5 f.Q..!:.. non-,tension joints:

,

resistance of 1.25 m Ot a conductor, inclUding one

connector, such a$ parallel groove connector shall not exceed the

resistance of 1.25 m of the identical conductor without

connector, by more than 10 percent. For terminal connectors, the

resistance measured shall be the sum of the resistance

measurement A and C to D as shown in figure 3. In

cases where the coriductor is a stranded cable, the strands shall

be sui tably bonded the. po i.rn:J.tthe measurement. at 0;

. ... ]

l' 1

lee

\ -

yo .:4 Sfr'l-I CE',..

- 2EJ

0

76

2 5 )7))01< 0 .' '"2.. 5 "YI.l-rr;.RM I N /'':-,L

.. FtG.it.. CNNcTOF<..S

11.9 Temperature test

11.9.1 The values of the currents to be used in temperature

rise test for the various -type of connectors/fittings shall be

rated current assigned to it. Where no rated current is assigned,

it shall be determined in accordance with the following:

(a) Equipment Connectors: The values of current shall be

selected on the basis of the rating of the equipment to

which the connector is cdnnected or on the of the

rated current of the conductor for which the

is intended whichever is lower.

(b) Junction Connectors: The value of current shall

be -,

selected on the basis of the conductor which has the

lower current carrying value.

( c ) 'T9 Connectors: The values of current shall be selected

on the basis of the full rated current in the tapped

conductor only.

11.9.2 The rise test for power connectors shall be

made with alternating current at an average frequency not below

951. of the rated frequency.

11.9.3 The connector shall be assembled indoors on conductors

of the size and type with which it is to be used. Air shall be

treely circulated around the assembly, but no draughts shall be

allowed.

11.9.4 Each test shall be made over a period of time

sufficient for the temperature to reach a constant value (for

practical the condition is attained when the variation

does not exceed 1 C/hour). Temperature measurement shall be made

using either themometer or thermocouple.

'17

11.9.5 The temperature-rise shall not exceed 40 degree C

above the reference ambient temperature of 45 degree C. If the

ambient temperature exceeds 45 degree C the permissible

temperature rise shall be reduced by an amount equal to excess

ambient temperature.

Galvanisation test:

The galvanised component of the fittings shall be

tested for mass of zinc coating (Clause 5.0 of specification

No.ETI/OHE/13(4/84). uniformity of coating. adherahce and other

defects (Clause 3.2 of specification No.ETII OHE/13(4/84).

11 '11 Assembly for contact dropper

tlll and swivel tlll ..:.

The dropper clip and swivel clip shall be assembled on

the contactwire of the standard and maximum profiles. The

distance between the hooks shall be within the limits as

prescribed in the relevant standard drawings.

11.12 Dye penetration test:

Dye penetration test shall be done either by ZygIa.

magnaflux or any other. approved method in accordance with

18:3658-1981 "Code of practice for liquid penetrant flaw

detection" (For list of fittings see Appendix - J).

11.13 Routine verification of dimensions:

Important dimensions of all fittings shall be checked

profile gauges grooves and suitable

gauges. For purpose of this. test, dimensions which effect the

assembly, which effett the of fitting such as

wall thickness and machined dimensions be taken as

important dimensions.

11. '14 Hardness test:

"

Hardness. of iron castings shall be measured

;

on the product by Brinell method as per 18:1500-1983. The

hardness of malleable iron castings shall not 150 HB.

12. MARKING:

12.1 For the purpose of identification, the following

marking shall invariably be made/cast on each fittings/castings.

i) Manufacturer's code number

ii) Railway Identifiation No. (R.I.No.)

18

.] ,

iii) The month and year of production shall invariably be

indicated on the fittings/castings.If it is not

possible to accommodate any particular marking on the

fittings/castings, the manu'acturer shall obtain prior

approval of the purchaser to delete the or to

make the marking by any other suitable means.

12.2 It is desirable that a code giving the lot or melt

number is also cast or engraved on each casting to facilitate the

identification 0' lot number of each fitting. Alternatively, the

month and year 0' production may be provided during casting.

12.3 In case 0' fabricated fittings marking shall be punched

on such fittings prior to the galvanisation so that not only the

markings are clearly visible after galvanisation, but also there

is no damage to the galvanised surface.

12.4 A lable indicating the inspectors code number and date,

shall be lixed indelibly on every fitting immediately after

te5ts and inspection.

13. DISPOSAL OF REJECTED FITTINGS.

The fittings shall destroyed in the

presence of the Inspector to prevent their in-advertent miXing

with the future supplies and shall advise RDSO/CORE with the

reasons 'or rejection.

14. PACKING:

For packing, wooden cases shall be employed. The

packing shall be fit to withstand rough handling, during transit

and storage at destination. The heads and threaded portions of

pins and the fitting shall be properly protected against damage.

The gross weight of the packing shall not normally exceed 50 kg.

Fittings of different types and rating shall be complete with

their minor accessories fitted in place. All nuts shall be hand

tightened the bolts and screwed upto the farthest point.

19

__c-.

!

"

APPENDIX A'

Properties of aluminium bronze castings

Extracts from 18:3091-1965.

A. '1

A.1.4 The material wh;h in accordance with 18=4027

1967* shall have the as given in table-2.

TABLE - 2 : CHEMICAL COMPOSITICJN'i OF ALVMINIUN

BRONZE INGO! AND CASTING8

CONSTITUENT \ PERCENT

Aluminium 9.0 to '1'1.9

Iron 4.0 to 5.0

Manganese O. '1 to 0.5

Copper balance

A.2The manufacturer shall supply free of charge a copy of

his works analysis of the material. Works may be

defined as the routine analysis conducted by the manufacturer in

order to control the quality of material.

A.3 Casting shall be clean. sound and free from harmful

inclusions. Any castings may subsequently be rejected due to

manufacturing defects. notwithstanding the fact that it had been

previously passed for chemical composition and mechanical

properties.

A.4 The material when tested in accordance with 1S:2654-64**

shall have the tensile properties given in Table-3.

TABLE - 3: TENSILg PROPERTIES OF ALUMIANIUM

BRONZE INGOTS BNR CASTINGS.

MODE OF CASTINGS TEST BAR PROPERTY VALUE

Chill cast or any other Tensile strength. 60 kgf/sqmm

casting process minimum

Elongation on 20 Yo

50 mm gauge

length minimum.

0.2'Y. permanent 25 kgf/mlTlsq

set stress

minimum.

------------------------------------------------------------.

* 18:4027-67: Method of chemical analysis of bronze.

** 1S:2654-64: Method of tensile testing of copper and

coppper alloys.

20

"' I. ..!!lber of tests.

'1 Three cast to shape test pieces (fig. 4) shall made for

e'ar: h lot. The test bar shall be lot and date of

i ..

I Ld>.::: 5-0 ' I I

1 '

I 40 " =t1 Pj

A.5.2 pieces shall be tested at the expense of the

manufacturer in the presence of the Inspector.

A.5.3 One test piece shall ,be tested. If the mechanical

properties are met by this one test, the lot shall be accepted.

If the first test piece fails to t6 the specified

the two remaining test pieces shall be tested, and

if' 'either of them fails to meet the specified requirements, the

whole lot shall be rejected

.

-- -

The test

)

;

APPENDIX'S

Properties of black heart malleable cast

iron castings -Extracts from 15:2108-1977.

composition.

The Phosphorus content 0' dif'erent grades of malleable

iron, when tested in accordance with 15:228-1959* shall be as

follows:

GRADE DESIGNATION PHOSPHORUS,

(See IS:4843-1968) PERCENT MAX.

BM 340 O. 12

BM 310 O. 15

SM 290 0.18

B.2 Micro-structure.

B.2.1 The material shall be 'ree from primary graphite and

shall not contain 'ree cementite or pearlite in a form or amount

detrimental to the physical properties 0' machinability of the

casting.

B.3 .Dlll bars.

B.3.1 Provision of test bars- All test bars shall be cast

separately. They shall be suitably so that the castings

they represent could be identified.

B.3.2 Test bars Shall be cast in green or dry sand moulds of

the same material as the moulds used for the castings they

represent. They shall be cast in the same time and 'rom" the same

melt as the casting they represent.

B.3.3 Test bars shall in all cases undergo the melleabilizing

heat treatment being together with the castings they represent.

S.3.4 In the event of any 'urther heat treatment being given

to the castings, to meet the requirements provided under B-4. the

test bars shall be suitably heat treated alongwith the castings

they represent.

B.3.5 Tensile test bars shall be cast to the dimensions

specirfied in 'igure-5. The dimensions of the shanks may be

modified to suit the jaws 0' the testing machine .

15

1

-.-----'1

I!: i" liI

F

,

' G.5

22

B.3.6The cast tensile test bars may be dressed or cleaned and

:;; h':';\ :'.:i bet ! s t din the. unma chi ned con d i t ion.

B.4 Mechanical tests:

8.4.1 Tensile test: A t.nsile test bar, as for as

practicable to the dimensions shown in figure-5 shall when tested

in accor-dance with IS:1608-1972** without machining the gauge

length, give results not less than those in table-4.

Since the test bars are in unmachined state, they may not be quite

circular, in which case the tensile strength shall be calculated

on. the mean diameter at the midale of the gauge length by taking

two measurements at right angles. one of which shall be maximum

diameter.

TABLE-4: TENSILE PROPERTIES OF BLACK HEART

MALLEABLE IRON CASTINGS.

GRADE DESIG- SECTIONAL . DIAMETER TENSILE 0.5PERCENT ELONGATI

NATION THICKNESS OF TEST STRENGTH PROOF STRESS (Lo=3D)

(See 18:4843 REPRESENTED BAR(mm) N/mm N/mm (mi n. )

-'1968 )+ (mm) (D) (kgf/mm) (h1f /mm) . percent

.._._-._---

BM 340 All sizes 15 340(35) 2QO( 2-1) -12

BM 3-10 All sizes -15 319(32) 190 ( 19) 10

BM 290 All sizes 15 290(30) 6

B-5 Hardness test:

8-5.1 Casting of grade BM-340 produced according to t.his

standard shall not have hardness more than 150 HB.

* IS:228-1959: Methods for chemical analysis of the steel.

** 18:1608-1972: Methods for tensile testir\9 of steel products.

+ IS:4843-1968: Code for designation of ferrous castings.

\.

23

-----------------------------------------------

-----------------------------------------------

----------------------------------------------------------

APPENDIX - tC'

Properties .Q..f. tine bronze inqots and

gstinqs =E:<tracts from 18:306-'1968.

Chemical composition.

'. ,

C-'l.1 The material when analysed in accordance with IS:4027-67+

shall have the chemical composition as given in Table-5.

TABLE - 5: CHEMICAL COMPOSITION

CONSTITUENTS PERCENT

Tin

7.5 to 8.5

Zinc 3.5 to 4.5

Lead ma)<.

'1.5 '*

Total of the elements other

than copper plus incidental 0.20

nickel, tin and zinc and those

set out above, maximum copper

plus incidental nickel balance

Impurities

Aluminium maximum 0.0-1

Silicon maNimulTl 0.02

8i slTluth ma:<imum 0.03

* If specially required by the purchaser, the material may

supplied with restricted lead content.

C-1.2 The manufacturer shall, when required, supply free of

a copy of his works analysis of the material. The work

analysis is defined as the analysis carried out by the

manufacturer in order to control the quality of the material.

C-2 Physical properties:

C-2.1 The material when tested in accordance with 18:2654

1964++ sMall have the tensile properties as given in Table-6.

TABLE -6: TENSILE PROPERTIES

MODE OF CASTING MINIMUM LIMIT FOR

Tensile strength Elon .;)ation

kgf/sqmm percent Min.

on t.;)au'Je

length 5.65_/A

Sand cast (cast on) 22 8

Sand cast (separately cast) 23 -12

Chill cast 25

24

(-3.1 The test bars shall be according to one of the

.;lppropriate types described in 1S:1408-1959.*

'? 2.5,'.' 1.0 .

'en Ft-,j

__

CAST?O .5/I/-IR4

I

*18=1408-1959 - Recommended procedure for inspection of copper

base alloy sand castings.

+18:4027-1967 - Method of chemical analysis of bronze.

++18:2654-1964 - Method of tensile testing of copper and copper

alloys.

\

25

.:s:-.

APPENDIX - 0

,j.

Aluminium and aluminium alloy castinqs .::'

. ."" Ext ra. ct s.f..!::..!;trr! i 8: 617-1975 !

ctalco,mpos l\i on and me't:hanical pro pe rt les

The .compo,sitio,nand. mechanicjal propertie.s of I'

aluminium and.alt.indnium, alloy are given in Table-7:. The mechanical

g{ven' in apply to cast test . piece.

The chemical composition aluminium alloy fittings Itest bars

shall 'betestedin ac.cord,ance, wi th'lS=504:"'1963.*

, ; - ,-. ,l, :.. . . -.

TABLE - 7: (gravity 'or

die cisting alloy) .

Alloy designation, '

Chemical composition; percent

(values given

shown as a .range

Copper 0.1

, 8il1con 10.0 - '13.0

Magnesium o. '10

Iron

. 0.60

Man'3anes e

0 .5

Nickel' 0.1

Zinc 0.1

Lead 0.1

Tin 0.05

Titanium 0.2

Aluminium Remainder

_ M

::' ;'.

-----------------------.-----,.-:-------_....:_------------

Me.chan i calprope rt-i es.

Tensile strength

N/sqmm .( ko3f Isqmm) "165 (-16.5,)

Chill cast, N/sqmm(kgf/sqmm) 190(19.0)

Elongation (percent)(on 5.65 180 or 50 mm gauge length

Sand cast 5

Chill cast 7

*18:504-1963: Methods of analysis of aluminium and its alloys.

26

D-2

'-,f. ';-" .' -', ; ". (';'t., - -: _ ...... _ t'" '.'-,,' ..','.,' ", ,;.

D-2.1 The "'metal, fo,.r:"t,he",'test 'shal"ii, be taken from the

crucible or ladle fro,,,,,,,\.ihich, the"ca5'tings are poured and shall

not besu,bjected ,to any tr,e;atmentother than adjustment of

the t'em'perat u re; t,o,'t hat: ''su'i t a.b1 e 'fo:r." poU'r'ih g;.i" ..,.,:,' '"

iO:''2;.'1 >r' ,,:: Skn'dCast fn''ij= 'Th'e cas,t in dry

'" sarid mou'ld"s 'shall'hav'e .:(s" 'shdwn' in

':, :'I. r : ( ". ..,'; ,,: - I " ; I _. "" _. -. \ ,', ",. '. :.. ; ,.. . I . '. , ,_. _ _ ': _. ,

figure-10r2 of 18:'617.' The lTloLildsshall be 'iTl'cl the

ve'rti'c'al pour ifj,ijian'd:!lt'h,:l:! ":sha"l1' be

poured into th'e!' top elf 'thl,{ ITIQulds iTiay be

rammed into any convenient container <such as steel tubej,

provided that the portion'o'f theba'r" tapering; fr'olTi, 2S"to 24 mm i':5

separated from the contai ne,r waTI s b'yno't less than 27 mm sand..

D-3 Tests for physical

D-3.'1 Tensile test: Test pieCes, froITI 'test samples

cast as specified in D-2' shall be;' 'tha'chinedto' the' 'di'mensions of

the standard round test piece fig.7 and "thbse from chill

moulds as per fig.6 of 18:617.

y -;:., 2-D, ;' (; '/11 /YI

..... -1'--- II' 22> l' x=:;::: ----=, .

----+.-I-----.- I ===r= I .. ', ----

L - . \..D" % )'Ynl'! --..-l ----L':"':': 'j :",

CH() 5 S S i.eT I t.. ARE-A S" =- OQ;Y;l1-',''''?

7

D-3.2 The testing. procedure for carryin9 out;'tt-fe' tensi Ie test

shall be as laid down in IS='-1'816":"'19'61*:'"

D-3.3 Should a test piece break' outs:ide,themi'dd'te,:, half of

the gauge length, test may at the option of the supplier be

di s carded and anot he r test made.'" ' , ",;, c: :

*IS: 1816- '1961':" Me t hdd for tensile te:stf /1 i:glTt.t.nle taLs: 'an'I!l,-,lhe i r

Cl,lloys.

" " .' l . :'

..;' j.:..

;',- ",\ "..'

.. - -_.._-...

.

_

::".1'::

27

APPENDIX 'E9

,. ':j .

: '-:,

E-1 Chemical composition.

.. . ....,.".." , , . I .

E"';-1 -1

.. -The analysis of the' steel shall conform

to the requl rements given .. in Table-8.. The methods of, chemical

be prescribed ,in the relevant IS:228.0I

: . :",

CHEMICAL COMPOSITION

. DESIGNATION . CONSTITUENT, .

CLASS

-1974* Carbon Silicon Manganese Sulphur Phosphorus

Max.

..

1 14 C6 0.10 to O. '15 to 0.40 to 0.040 0.040

0.18 . 0.35 0.70

1A -15 C8 0.10 to 0.15 to 0.60 to 0.040 0.040

0.20 0.35 0.90

20 C8 0.15 to 0.15 to 0.60 to 0.040 0.040

0.25 0.35 0.90

2A 25 C8 0 . 20 .to 0.15 to 0.60 to 0.040 0.040

.0.30 0.35 0.90 .

3 30 C8 0.25 to .0.15 to 0.60 tQ 0.040. 0.040

0.35 0.35 0.90

3A. 35 C8 (': :', 0.30 to 0.15 1.,0, ' . to 0.040 . 0040

0.40 0.90

" ;" ".

4 45 C8 0.40 to O. -15 to 0 ..60 to.,Q.040. 0.040

0.50 0.35 0.90

..

5 55 CB 0.50.

0.15 to 0.60 taQ,040 0.040

0.60. 0.35 0.90

6 65 C6 O. 60

O. '15 to 0.5Q ,.to

0.040

0.70,(, 0.35 0.80

,

Note(1): When the steel is aluminium killed or.killed with both

aluminium and silicon, the requirement of minimum

silicon content shall not apply. For aluminium killed

steel the total aluminium content shall

to 0.05 percent.. j

, '. .:

\ ,'.,1

*IS:1762CPt.!)-1974=Code for designation of Steels - based. on the

letter symbols.

iil1S:22B= "Method for chemical analysis of ;st,eel.

28

:, ;:::,.. ;;, Check analysis:

The purchaser may specify check

analysis on finished The number of samples on which the

,3.na 1ys :i s ied:out

shall be; at: ether-ate of one sample

per cast per section.

E-1.2:1 The permissible deviation in from the

corrfposition li"i'nits, $'hal1', be 'as gi'yen' berow:

", ','; , .; __:.......:. L_.... _.;;. ...:.. .:.. !.::. .;;...:.: ,__::..:.. ._

., "Va;"'fation' froiTt;'the

percent ", , ,.Pmits, percent

. :;l'..... _.1......'... __ __ . _

Carbon

;-,.

, I'

.

upto, 0.?5

, +/-6.02

ave r 0\.25 and upto +/-0.03

and 0.50

over 0.50 04;

8i lican ' +/-:'0.03

! ..'

Manganese +/-0.04

", ,.,', ,"",

,', '.

Sulphur +/-0.005

+/":'0.005

Note: Variations shall over .. under the

'linhts in'sevedd deter

lTl

in'ations'in a. he-a.-t._

E-1.3 Elements not specified in table 8 shall not be added to

the steel , "except "c.ilhen ag;eed to;. 'other than f,orthe purpose of

finishing the heat and"shall not' exceed 'the' following:

"! I.

Canst i tuer{t ' ,; Percent

,', :"

'Nickel'" 0 .. 30'

Chromium

0.30"--:' .,

Copper ,

0.25

" Mo l'ybydenurn '<

Vanadium "

0.05" ,

Tin 0.05

Boron 0.0003

" ,

'. r ( "; r T .....

tal

. \

.'; ,j ::-',': . ';: J; '....

E-2.1 Tensile tests: The out in

accordance with 18:1608-1972*. The test pieces shall be machined"

ffbm!each properti.s shall

conform to the requirements table 9.

*Note: See e:<tract (jf attached after..:,Appendi'F'

.,.-............

29

\

-----------------------------------------------------------------

-

TABLE 9 -TENSILE PROPERTIES AND HARDNESS

TENSILE YIELD ELONGATION HARDNESS NORMALIZING

CLASS STRENGTH STRENGTH PERCENT TEMPERATURE

Min(MPa) Min(MPa) Min. Min. DEGREE c

( length (HB)

5.65

-

ISo

-1

370 200 26 '100 880-910

'1A 4'10 220 25 110 880-910

2 430 230 24 '120 880-910

2A 460 250 22 -130 880-910

3 490 270 21 140 860-890

3A 540 280 20 155 850-880

4 620 320 15 175 830-860

5 7-10 350 13 200 8-10-840

6 740 370 10 210 800-830

- ., -----------------------------------------------_._------------

*IS:1608-1972: Methods foY tensile testing of steel pYoducts

.. /

30

APPENDIX 'F'

Steel =Extracts from 15:2062-1992.

Chemical Composition:

F.1.1 The chemical composition be determined on the

samples of finished product from the standard position. The

specified contents are as under:

Grade Desiqnation

LaddIe analysis. Percent,

.!; Mn E Si

A Fe410W A

0.23 '1.5 0.050 0.050

B Fe410W B 0.22 '1.5 0.045 0.045 0.4

C Fe4'10W C

0.20 1.5 0.040 0.040 0.4

F.2

Mechanical 1ests:

F. 2.1 Tensile tests:

F.2.-1.1 The tensile strength. yield strength and percentage

elongation of steel shall be oetermined from standard test pieces

cut length-wise or crosswise from plates and lengthwise from

sections, flats and bars. The test shall be carried

standard test pieces prepared in accordance with 18:1608-197a.

F.2.i.2 .As a rule only proportional test complying with

the requirements Lo=5.65 ISo should be used for tensile test.

where La is the gauge length and 50' is the l;:ross sectional area

of the test piece.

,

F.2.1.3 The gau'3elengths other than 5.65,;.../So may also be used

in which case the elongations shall be read from 18:3803 (Pt.1)

1989 .... '#;

F .2.1.4 The tensile stren'1th; yield strength and; percentage

elongation determined in accordance with IS:1608-1972 shall be as

given in Table-i0.

F.2.1.5 In case of sections the thickness of which is not

uniform throughout the profile. the limits of sizes given in

Table-10 shall be applied according to the actual maximum

thickness of the piece adopted for testing.

*15: 1608-1972 - Method for tensile of steel products.

**I5:3803(Pt.1)-1989 - Steel conversion of elongation values:

Carbon and low alloy steels.

31

TABLE-10: MECHANICAL PROPERTIES

Tensile Yield Elongation Bend test

CJrad.e> Desi9na. strength strength percent Min (Internal

tion Min. Min.MPa (In gauge DIA) Min.

(Kgf Immz' ) length)

MPa 2 <20 20-40 >40 5.65_/50

(kgf/mm ) mm mm mm

410 250 240 230

A Fe4-10W A (42) (25.5) (24.5) (23.5) 23 3t

4'10 250 240 230

B Fe4-1()W B (42) (25.5) (24.5) (23.5) 23 2t for less

than or equal

to 25mm thic

kness.

3t for more

than 25mlTl

thick

products. '-.,.

410 250 240 230 2t

.i

C Fe410W C (42) (25.5) (24.5) (23.5) 23

't' is the thickness of the material.

F.2.2 Bend Test:

F.2.2.1 Bend test piece:

Test pieces shall be cut lengthwise or crosswise from

plates and strips and lengthwise from flats and bars.

When sections permit, these shall not be less than 40 mm wide. ,

In all bend test pieces

7

the rough edge or arris

resulting from shearing may be removed by filling or grinding or

machining but the test pieces shall receive no other preparation.

The test pieces shall not be annealed or otherwise subjected to

heat treatments unless the material from which these are taken is

similarly treated. In such cases

7

the test pieces shall be

similarly treated in the same furnace with the material before

.testing.

F.2.2.2 Bend test shall be conducted in accordance with 15:1599

'1985.

F.2.2.3 For bend test, the test piece at room temperature shall

withstand bending through 180 Deg. to an internal diameter not

greater than that given in Table-10.

32

--, ..._-. .. ..'.:::::::::'

.::- '.... : ;, .'.. ";". . . ,'i .. '. '. .' :. ... :' . '. - ."

. :

:!: .,

F.3

Re 1e t' 'e:< t'r'a'c C fr om"! S.:'160;8:"'1972:

, l' , :,: ,:.,'

- GRi P'P.E. D

,'<: ,,1-- EI'JDS

Fl',. 8

.'. -_.,

--'- l .

Test

Circular

Note - The formlof end . of" test' piece' 1sonly "irlted ed

a 3 a guide.

J j

..'[' F.3. "1'

.

',t.'.:;,:...

) .. ;.; ,; i (! "

F.3.1.1 The of the test may be circular,

square, .'re:ctan.gLi.lar.,or::i::'n 'specia.l' . of ,0-t.he:f':d'o.r'l1h for test

pi. e c e s of r e c tan.] u 1a rse cti on it d,s r,e d;'qiat . :t, here:\ t i 0 of

the width to thickness of' 8:'1shoul'd Ol)t

F.3. '1. '1'.:1 Tes;t . climl;1.,nsion

given .in Table--'1'1 and '12. Sect.'ions,;. bar's etc. : may be

tested' wi thou'tbein.;J machined., There should -be a._ .tr.:arlsi tion

radius be t ..... e en the 'dripped '.;\;nd the paraUel The

dimension of thi.s transition are important and.,.I,1,nless

stated, shall c:'onform to the requirements 9iven.,in Table--l,;.,.nd 2.

The gripped erids may be of any shape to suit the holders the

testing machine.

!

dimensions of. the pieces

be"in:acCO'f;"da.nce with those

" '" I",

f.3.1.2 In general, the pos{i'ion' of

Hie :; m'8.'c h 1. ned' 'cy1 i ode ri . tes,t pieces' ho.u;4 d be . than

'4. Om'rt, V,:::: "'" . " .,.: ,. ,':','\,':.' ': .

. \ n' : ... '-, ,.

F.3.1.3 As a rule, only proportion test pieces

complying ,..Ji,th

ireqi.d. rerhen t 65...../,So'shoul d 'be used.. <:,; ',J ....

,'i 1 ': .'

..:.

F.3.1.4 It is recommended that the parallel length (Lc) of the

test pieces of circular cross-section should be between Lo+2d and

lo+d/2 and. of test pieces of rectangular cross-section between

Lo+ '1. 5_/ So an d Lo+2. 5_/80.

F.3.1.4.1 Provided there is sufficient material, the parallel

length <Lc) used for arbitrAtion purpose should be Lo+2d for test

pieces of circular crosssection and Lo+2_/So for test pieces at

rectangular cross-section.

33

------------------------------------------------------------

TABLE-11: DIMENSIONS OF CIRCULAR SECTION TEST PIECES.

<Clause 5.1.1)

Gauge length Lo=5.65 ISo

..R.' ._ - . - \ _

Di.i\111 e r Gauge Minimum Minimum

'; ':< c: t :i. ona 1

d length' . par-aile I transition

1"

diameter' length radius

sqmm mm Lo mm Lc=5.5 d r mm

'j ""',.

/l-OO

28.56 '1'13 124 23.5

200 15.96 80 88 '15

'150 '13 69 76 10

'100 . : 11.28

",

1'56 ....

62 10

50 7.89 40 44 8

25 5.84 28 31 5

2 3.99 20 22 '4

. . . .. . . . . . . ..

Note--'l : length is given to the nearest 1 mm and the

parallel is

Note-2: Test pieces wi th diameters otn.erthan. these given in

this table may be used provided the gauge Lo=5.65_/So,

:... 1

TABLE-12=- DIMENSIONS OF RECTANGULAR SECTION TEST PIECES

;( NON--PROPORTlONAL ).< C1 aus;e 5. '1 1 ) .

All dimensions in.!mm.

.

WIDTH GAUGE'LENGTH MINIMUM TRANSITION APPROXIMATE TOTAL

b Lo RADIUS r LENGTHLt

.... -.__.

40

,'200

25 450

20 '200 25 375

2s '100" 25 300

'12.5 50 25 200 . ,

6 24 -12 '100

3 12 6 50

,

Note-1: NotWithstanding the above. test ,pieces having a

. gauge length equal to 5.65 So are permitted.

Note-2:' . width from 3 to 25 mma lengJh Df

50mm may be used. the total .length being adjusted

accordingly.

Note-3: A straight. parallel test pi1:!ce.without

ends is permissible for any size.

34

II !

TABLE-13: TOLERANCE ON DIMENSIONS OF CIRCULAR CROSS-SECTION

TEST PIECES (Clause 5.1.2)

(All dimensions in mm.)

.........- -.

: rn ",t 1 Machining tolerance* Tolerance

c'.irnensions on nominal dimensions on form

......... -.11 __._--:.....--- _

f.!

to 6 +/- 0.06 0 ..03

over" 6 to '10 +/- 0.075 0.04

C"" e r '10 to 18 +/- 0.09 0.04

over -18 to 30 +/- 0.105 0.05

*The machining tolerance applies when it is desired to use

the nominal cross-section without measurement or calculation.

_._.... _----------------------"':'""--------------------------------

TOLERANCE ON DIMENSIONS OF RECTANGULAR

SECTION TEST PIECES MACHINED ON TWO

OPPOSITE FACES. (Clauses 5.1.2)

(All dimensions are in mm)

NOMINAL DIMENSION TOLERANCE ON

EQBl:1

VALUES

3 to 6 0.18

6 to 10 0.'22

10 to -18 0.27

18 to 30 0.33

30 to 50 0.39

Note-1: Dimensions of the ends of the section of test

pieces should not differ in width by more than O.imm.

Note-2: For rectangular section te5t pieces machined pn the four

faces. same tolerances as for diameter Qf circular test

pieces shall apply.

--- - --- ._.

35

.... .'

, ...

'.' ;"

.,' .. '

=""

--"O..,....;, __ -... __ ...__

APPENDIX -'G'

Copper strip Tor electrical purposes

(Extracts from 15=1897-1983)

ChemicaL Composition.

G.1.1 The chemical composition shall be determined either by

the method specified in IS:440-64* or any other established

instrumental/chemical method. In case of dispute the procedure

specified in latest edition of IS:440-1964*for chemical analysis

shall be the reference method. The material shal; conform to

grade ETP or FRHC of IS:191 (Pt.I to X)-1980.**

G.2 Physical Properties.

G. 2. -1 The material when tested in accordance with 18:3260

1965#

given

and IS:2654-1977+shall have the

in Clause 7.2 & 7.3 respectively.

physical properties as

G.3 Bend test.

G.3.1 Where possible. the strip shall be subjected to a

transverse bend test made on test pieces cut with their major

axes at right angles to the direction of rolling (see Fig.9);

where this is not possible it shall be subjected to a

longitudinal bend test made on test pieces cut with their major

axes parallel to the direction of rolling. (see figure-9). Both

surfaces of the pieces shall be tested.

Test spec imen

Loneitud mal bend test .

- Spec :trnen ---- ...... --:1'

H of bend -..

of rolling on drawing .

9 - __ ..

G.3.2 The test pieces shall not crack when bent once through

the appropriate angle as specified below:

BEND TEST

Bend test

Thickness Condition

Tran s ve r ...!_.Lon.9...tt ud i lJ.

a

1:.

Angle in radius

degree

Upto and Annealed (0) 180 Close

including Half hard (HB) -180 t

10 mm Hard (HD) 90 t

t=thickness of material

36

G.3.3 The test pieces shall be of conventent length and the

width shall be follows:

Upto and including 6.0mm 15mm other

wise full width.

Over 6.0 mm 2'times the thickness of

material.

G.3.4 The longer edges shall be carefully rounded and

smoothened longitUdinally so that section has

approximately semi-circular edges.

G.4 Tensile Test.

G.4.1 Material of thickness O.50mm and upto and inclUding

10mm shall comply with the requirements of tensile test given in

Table-15. Material below O.50mm thick shall not be subjected

tensile test.

G.4.2 Test pieces of full thickness of the with a

gauge length 4 IArea or 50mm shall be used. The longitudinal

axis of the test piece shall be in the direction of rolling.

TABLE-1S: TENSILE PROPERTIES OF STRIP

UPt 0 and i n L: III d ] Tl '] Over- :300wm upto

300 mm v,'i dth , and inc 1ud i I'll;:)

Thickness Tempe r '1000 mm '/Jidth

. ..... _...- ..... _--_ .. _

Over, Upto & Tensile Tensile Elon')ation

mm includinlJ percent on stroength on

..

mm kgf/sqmm 4_iArea kqf /sqrrlfTI 1.1

0

_1 (1 ..

(Min. ) or 50mm (Mi ) 'Ja.Ul;J E'

']'3.U'J e

lenqth

len,]th<t1in) Uiin. :'

i ) 0.50 2.50 Annealed (0 ) 2-1.0 35.0 21.0 -...l::>.u

Ho'O\lf h<:1.rd (HB) 25.0 10.0 0 "10.0

Hard <HD) 3'1.5 29.0

.' i i ) 2.50 '10.0 Annealed (0 ) 2-1.0 35.0 2'1.0 0

Ha.lf hard<HB) 25.0 -15.0 2:'i-. () 15.0

Hard (HD) .30.0 28.0

* IS:440-1964: Methods of chemical analysis of copper.

** IS:191(Pt.i to x)-1980 : Specification for copper.

# IS:3260-1965: Method for bend test for copper and

copper

+ 18:2654-1977 : Method of tensile testing of copper and

copper alloys.

37

G.5 Electrical resistivity test.

('

G.5.1 The standard values at 20 C for the electrical

resistivity at aDnealed high conductivity copper shall be taken

as 0.01724 ohm mm/m. The electrical resistivity Ot strip shall be

measured in accordance with IS:3635-1966*. The electrical

resistivity values are given in Table-16.

, TABLE-16: ELECTRICAL RESISTIVITY

Resistiyity Conductivity

Condition (Ohm mm" /rrd ( pe r c en t 1'1 in. )

o

at 20 C ( Ma x. )

- - - - - - - - - - - - - - - - ~ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Annealed (0) 0.01737 99.25

Half hard(HB) 0.01777 97.00

Hard (HD) 0.01777 97.00

Note: Conductivity percent is expressed as percentage of the

standard value for standard annealed copper of 100%

conductivity as laid down by the International

Electrotechnical Commission.

*IS=3635 Methods of test for resistance of metallic

electrical resistance material

..

. 1

38

'. :"

,

.....

APPENDIX 'K'

., Maximum permissible level of discontinuity

in radiographic examination

. .

Sl . Alloy

Specification for stndard Discontinuity level

No. reference rediographs. permissible

(2) (3) (4)

1 specification

bronze 18:3091 General conditions

castings for radiograph as per ASTM

-272 (Standard).

a) Sensitivity of

radiographs - 21.

b) IGI must be used

" in all cases

';:'

c. . Tin Material specification