Académique Documents

Professionnel Documents

Culture Documents

Introduction To Manufacturing Systems - Syllabus

Transféré par

CoursePinTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction To Manufacturing Systems - Syllabus

Transféré par

CoursePinDroits d'auteur :

Formats disponibles

Syllabus

Course Meeting Times

Lectures: 2 sessions / week, 1.5 hours / session

Course Objective

This course provides ways to analyze manufacturing systems in terms of material flow and storage, information flow, capacities, and times and durations of events. Fundamental topics include probability, inventory and queuing models, forecasting, optimization, process analysis, and linear and dynamic systems. Factory planning and scheduling topics include flow planning, bottleneck characterization, buffer and batch-size tactics, seasonal planning, and dynamic behavior of production systems.

Grading

The grading will be weighted as follows: ACTIVITIES Midterm Take-Home Assignment Final Take-Home Assignment PERCENTAGES 40% 60%

Notes

1. Problem sets: We will distribute problem sets related to each subject that we cover. These problem sets will not be graded, and you do not have to hand them in (posted "due" dates are only for helping you stay on track). However, you should try hard to solve all problems before looking at the answers as, like any other skill, the only way to really learn the material is by practicing

regularly (plus, working on the problems will help you do well on the take home assignments!). Detailed solutions will be provided a week later. 2. For students who end up being at the borderline between two grades, we will take into consideration evidence of diligence and effort, in the form of class participation, attendance to recitation and office hours, etc. This cannot hurt you, but it may tip the scale in your favor.

Calendar

This is an approximate schedule for the course topics, problem sets, and assignments. There may be some modifications of the class contents, and we may add a problem set or two. We'll give you some warning if we do. SES # TOPICS 1 2 3 4 Overview Probability I: introduction, discrete random variable Probability II: continuous random variable Queueing I: single-server queues HW 1 due 5 Queueing II: queuing networks HW 2 out HW 1 out ASSIGNMENTS

6 7 8

Inventory I: newsboy model, EOQ model, etc. Inventory II: base stock policy, periodic review inventory Optimization

SES # TOPICS

ASSIGNMENTS HW 2 due

Optimization (cont.)

HW 3 out

10 11 12

Optimization (cont.) Statistics: sampling, estimation, confidence intervals Regression: multivariate analysis of variance, etc. HW 3 due

13

Forecasting: time series model and forecasting

HW 4 out Mid-term take-home assignment out

14 15 16

Single-Part-Type Systems I Single-Part-Type Systems II Single-Part-Type Systems III HW 4 due Mid-term take-home assignment due

17

Multi-Part-Type Systems

HW 5 out

18 19 20

Material Requirements Planning Multi-Stage Control and Scheduling I Multi-Stage Control and Scheduling II HW 5 due

SES # TOPICS

ASSIGNMENTS HW 6 out

21 22

Simulation I Simulation II HW 6 due

23

Toyota Production System

Final take-home assignment

24 25

Quality/Quantity Guest Speaker Final take-home assignment due

Vous aimerez peut-être aussi

- c346 w15 Course OutlineDocument4 pagesc346 w15 Course OutlineAmine BadraouiPas encore d'évaluation

- Quantitative Methods SyllabusDocument12 pagesQuantitative Methods SyllabusIsraelllPas encore d'évaluation

- ENGR371 Course OutlineDocument4 pagesENGR371 Course OutlineCommissar CoproboPas encore d'évaluation

- Nachos LabsDocument33 pagesNachos LabsAdhar SurangePas encore d'évaluation

- SyllabusDocument3 pagesSyllabusNguyễn Hồng ĐăngPas encore d'évaluation

- L5 DS Assessment Handbook 2018-19Document15 pagesL5 DS Assessment Handbook 2018-19priti yadavPas encore d'évaluation

- Lean Six Sigma Pocket Toolbook, Maxey, Rowlands, and Price, 978-0470489536Document6 pagesLean Six Sigma Pocket Toolbook, Maxey, Rowlands, and Price, 978-0470489536rajakoppulaPas encore d'évaluation

- School: Business Course Number: ACCT605 Course Name: Cost Accounting Credit Hours: 3 Hours Length of Course: 8 Weeks Prerequisite: ACCT601Document10 pagesSchool: Business Course Number: ACCT605 Course Name: Cost Accounting Credit Hours: 3 Hours Length of Course: 8 Weeks Prerequisite: ACCT601Patrick VoicePas encore d'évaluation

- Syllab Yale MGT595 2018 FullDocument9 pagesSyllab Yale MGT595 2018 FulldavidinmexicoPas encore d'évaluation

- 4 Fall 2022, Mon, Wed 12:00-1:50 Pm. SOS-B44 Manochehr Rashidian, Personal Zoom ID # 594 296 5704Document6 pages4 Fall 2022, Mon, Wed 12:00-1:50 Pm. SOS-B44 Manochehr Rashidian, Personal Zoom ID # 594 296 5704PAWANKUMAR DASARIPas encore d'évaluation

- CS Lecture 1Document6 pagesCS Lecture 1sadaf asmaPas encore d'évaluation

- Usf 320 01 Syl s17Document3 pagesUsf 320 01 Syl s17api-282211401Pas encore d'évaluation

- Cit 752Document124 pagesCit 752Onaga NnaemekaPas encore d'évaluation

- DADM Syllabus - Pinter, Spring 2023Document7 pagesDADM Syllabus - Pinter, Spring 2023Dhwanik ShethPas encore d'évaluation

- Residency In-Service Training Examination (RITE) - Neurology Boards Study GuideDocument20 pagesResidency In-Service Training Examination (RITE) - Neurology Boards Study GuideMcRee Learning Center0% (2)

- SYLLABUSDocument16 pagesSYLLABUSvix130Pas encore d'évaluation

- Ms&e 213 / CS 269oDocument3 pagesMs&e 213 / CS 269oCPas encore d'évaluation

- 36106-02/03: Managerial Decision Modeling Spring 2015 SyllabusDocument8 pages36106-02/03: Managerial Decision Modeling Spring 2015 Syllabussina giahkarPas encore d'évaluation

- How To Prepare For Quantitative AptitudeDocument5 pagesHow To Prepare For Quantitative AptitudeGaurav JayantPas encore d'évaluation

- HCM540 StaffingAndScheduling IIDocument38 pagesHCM540 StaffingAndScheduling IIDonna Christine DotarotPas encore d'évaluation

- MBA133 Courseplan LDocument7 pagesMBA133 Courseplan LSoham SamantaPas encore d'évaluation

- Personal Learning System 1.0 (PLS 1.0) Study Guide: February 2007Document6 pagesPersonal Learning System 1.0 (PLS 1.0) Study Guide: February 2007kingtinPas encore d'évaluation

- Algorithms and Data Sctructures 2Document3 pagesAlgorithms and Data Sctructures 2Laila HassanPas encore d'évaluation

- CIA P2 Plan A4Document8 pagesCIA P2 Plan A4Vasil TraykovPas encore d'évaluation

- National Council of Architectural Registration Board (NCARB) Architect Registration Examination (ARE) Study GuideDocument20 pagesNational Council of Architectural Registration Board (NCARB) Architect Registration Examination (ARE) Study GuideMcRee Learning CenterPas encore d'évaluation

- HCM540 StaffingAndScheduling IIDocument38 pagesHCM540 StaffingAndScheduling IImterwerPas encore d'évaluation

- Construction Health & Safety Technician (CHST) Exam Study GuideDocument20 pagesConstruction Health & Safety Technician (CHST) Exam Study GuideMcRee Learning Center50% (4)

- Reading Instruction Competence Assessment (RICA) Test Study GuideDocument20 pagesReading Instruction Competence Assessment (RICA) Test Study GuideMcRee Learning Center0% (2)

- Study Plan (2022) : Csir-Net Part-ADocument10 pagesStudy Plan (2022) : Csir-Net Part-APushkar BoraPas encore d'évaluation

- BOOK David Miller - Measurement by The Physical Educator - Why and How (2010, McGraw-Hill Education) - Libgen - lc-81-94Document14 pagesBOOK David Miller - Measurement by The Physical Educator - Why and How (2010, McGraw-Hill Education) - Libgen - lc-81-94R DarmawanPas encore d'évaluation

- MGMT 372 Operations Management IDocument5 pagesMGMT 372 Operations Management IolemissgirlPas encore d'évaluation

- PdcaDocument14 pagesPdcamydotcom100% (1)

- Information Resource ManagementDocument2 pagesInformation Resource ManagementMansour BalindongPas encore d'évaluation

- 294 Managerial Accounting - COURSE OUTLINEDocument5 pages294 Managerial Accounting - COURSE OUTLINEsilenteyes100% (1)

- Miller Analogies Test (MAT) Study GuideDocument20 pagesMiller Analogies Test (MAT) Study GuideMcRee Learning Center100% (1)

- Syllabus For IEE 572 Fall 2011Document5 pagesSyllabus For IEE 572 Fall 2011zazaidiPas encore d'évaluation

- Yale ECON136 Tartari Syllabus Spring2013 PDFDocument6 pagesYale ECON136 Tartari Syllabus Spring2013 PDFcothom_3192Pas encore d'évaluation

- ASE A2 Automatic Transmission/Transaxle Study GuideDocument20 pagesASE A2 Automatic Transmission/Transaxle Study GuideMcRee Learning CenterPas encore d'évaluation

- S No. Topic Page NoDocument30 pagesS No. Topic Page NoNidhi GuptaPas encore d'évaluation

- COSC 2336, 01W, Data Structures and Algorithms: Instructor InformationDocument8 pagesCOSC 2336, 01W, Data Structures and Algorithms: Instructor InformationTetteh SamuelPas encore d'évaluation

- ASE A6 Electrical/Electronic Systems Study GuideDocument20 pagesASE A6 Electrical/Electronic Systems Study GuideMcRee Learning Center50% (2)

- Course Packet: 95-710 A1/C1 - ECONOMIC ANALYSIS (Remote Course)Document13 pagesCourse Packet: 95-710 A1/C1 - ECONOMIC ANALYSIS (Remote Course)ro paPas encore d'évaluation

- Study Plan (2022) : Csir-Net Part-ADocument10 pagesStudy Plan (2022) : Csir-Net Part-A彡RIP彡īlī GAMERZPas encore d'évaluation

- DBMS SyllabusDocument4 pagesDBMS SyllabusRishabh PatelPas encore d'évaluation

- Certified Clinical Hemodialysis Technician (CCHT) Exam Study GuideDocument20 pagesCertified Clinical Hemodialysis Technician (CCHT) Exam Study GuideMcRee Learning Center50% (2)

- Cpa f2.1 - Management Accounting - Revision GuideDocument90 pagesCpa f2.1 - Management Accounting - Revision Guidepaul saguda100% (1)

- Course Syllabus: Psychology (6Document7 pagesCourse Syllabus: Psychology (6jesusPas encore d'évaluation

- Test of Essential Academic Skills (TEAS) Study GuideDocument20 pagesTest of Essential Academic Skills (TEAS) Study GuideMcRee Learning CenterPas encore d'évaluation

- Management of Operations: OM 711 - Winter 2007 Course InformationDocument3 pagesManagement of Operations: OM 711 - Winter 2007 Course InformationhyanandPas encore d'évaluation

- Problem Solving ToolsDocument9 pagesProblem Solving ToolsBrady_tomPas encore d'évaluation

- Syllabus For Chem 255 - Winter Quarter 2014: Instructor InformationDocument8 pagesSyllabus For Chem 255 - Winter Quarter 2014: Instructor InformationthemusicalaznPas encore d'évaluation

- BUSS244Document4 pagesBUSS244yugrig01Pas encore d'évaluation

- MGMT 306 SyllabusDocument4 pagesMGMT 306 SyllabusLucChuPas encore d'évaluation

- ACCT 3310 - Syllabus - Fall 2017 - OlsenDocument7 pagesACCT 3310 - Syllabus - Fall 2017 - OlsenStevenkyPas encore d'évaluation

- Syllabus EC3303Document4 pagesSyllabus EC3303flylikethestarsPas encore d'évaluation

- How ACCA Can Ce CrackedDocument4 pagesHow ACCA Can Ce CrackedSyed AhmadPas encore d'évaluation

- Course Information: ChronousDocument8 pagesCourse Information: ChronousEdward WongPas encore d'évaluation

- AQA Psychology BRILLIANT MODEL ANSWERS: Memory: AS and A-levelD'EverandAQA Psychology BRILLIANT MODEL ANSWERS: Memory: AS and A-levelÉvaluation : 2 sur 5 étoiles2/5 (1)

- Thinking About Equations: A Practical Guide for Developing Mathematical Intuition in the Physical Sciences and EngineeringD'EverandThinking About Equations: A Practical Guide for Developing Mathematical Intuition in the Physical Sciences and EngineeringPas encore d'évaluation

- Calendar: Lec # Topics Key DatesDocument3 pagesCalendar: Lec # Topics Key DatesCoursePinPas encore d'évaluation

- Lecture Notes: Lec # TopicsDocument2 pagesLecture Notes: Lec # TopicsCoursePinPas encore d'évaluation

- AssignmentsDocument1 pageAssignmentsCoursePinPas encore d'évaluation

- New Century Cities Real Estate, Digital Technology, and Design - CalendarDocument2 pagesNew Century Cities Real Estate, Digital Technology, and Design - CalendarCoursePinPas encore d'évaluation

- Research Seminar On Urban Information Systems - SyllabusDocument2 pagesResearch Seminar On Urban Information Systems - SyllabusCoursePinPas encore d'évaluation

- Problem Sets ProblemsDocument3 pagesProblem Sets ProblemsCoursePinPas encore d'évaluation

- Tools: Ses # Topics Overviews Matlab® Help Section ReadingsDocument2 pagesTools: Ses # Topics Overviews Matlab® Help Section ReadingsCoursePinPas encore d'évaluation

- Projects: The Lawrence ProjectDocument10 pagesProjects: The Lawrence ProjectCoursePinPas encore d'évaluation

- RecitationsDocument1 pageRecitationsCoursePinPas encore d'évaluation

- Lecture Notes: Ses # Topics I. Motion of A Single ParticleDocument2 pagesLecture Notes: Ses # Topics I. Motion of A Single ParticleCoursePinPas encore d'évaluation

- Calendar: Ses # Topics Key Dates I. Motion of A Single ParticleDocument5 pagesCalendar: Ses # Topics Key Dates I. Motion of A Single ParticleCoursePinPas encore d'évaluation

- List of Topics: Ses # Topics I. Motion of A Single ParticleDocument3 pagesList of Topics: Ses # Topics I. Motion of A Single ParticleCoursePinPas encore d'évaluation

- ToolsDocument1 pageToolsCoursePinPas encore d'évaluation

- ReadingsDocument2 pagesReadingsCoursePinPas encore d'évaluation

- A Workshop On Geographic Information Systems - CalendarDocument3 pagesA Workshop On Geographic Information Systems - CalendarCoursePinPas encore d'évaluation

- Project Appraisal in Developing Countries - ReadingsDocument6 pagesProject Appraisal in Developing Countries - ReadingsCoursePinPas encore d'évaluation

- Property Rights in Transition - CalendarDocument2 pagesProperty Rights in Transition - CalendarCoursePinPas encore d'évaluation

- Genil v. Rivera DigestDocument3 pagesGenil v. Rivera DigestCharmila SiplonPas encore d'évaluation

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDocument17 pagesApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamPas encore d'évaluation

- Nantai Catalog NewDocument30 pagesNantai Catalog Newspalomos100% (1)

- World War II D-Day Invasion by SlidesgoDocument55 pagesWorld War II D-Day Invasion by SlidesgoPreston SandsPas encore d'évaluation

- ST Arduino Labs CombinedDocument80 pagesST Arduino Labs CombineddevProPas encore d'évaluation

- Arithmetic QuestionsDocument2 pagesArithmetic QuestionsAmir KhanPas encore d'évaluation

- Tuma Research ManualDocument57 pagesTuma Research ManualKashinde Learner Centered Mandari100% (1)

- Gis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaDocument9 pagesGis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaGrantPas encore d'évaluation

- J.K. Brimacombe - Design of Continuous Casting MachinesDocument13 pagesJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezPas encore d'évaluation

- Carnegie Mellon Thesis RepositoryDocument4 pagesCarnegie Mellon Thesis Repositoryalisonreedphoenix100% (2)

- Johnson & Johnson Equity Research ReportDocument13 pagesJohnson & Johnson Equity Research ReportPraveen R V100% (3)

- Practice Problems - Electrochemical CellDocument5 pagesPractice Problems - Electrochemical CellYehia IbrahimPas encore d'évaluation

- Grade 7 Nap MayDocument6 pagesGrade 7 Nap Mayesivaks2000Pas encore d'évaluation

- APA Vs Harvard Referencing - PDFDocument4 pagesAPA Vs Harvard Referencing - PDFTalo Contajazz Chileshe50% (2)

- Mission and VisionDocument5 pagesMission and VisionsanjedPas encore d'évaluation

- СV Nestor RodriguezDocument28 pagesСV Nestor RodriguezKate BrownPas encore d'évaluation

- Diogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFDocument54 pagesDiogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFAndres Felipe Pineda JaimesPas encore d'évaluation

- Modular Q1 WK3-4Document3 pagesModular Q1 WK3-4JENIFFER DE LEONPas encore d'évaluation

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 pagesToh736 - 84000 The Dharani of Parnasavari PDFJames LeePas encore d'évaluation

- Importance of Skill Based Education-2994Document5 pagesImportance of Skill Based Education-2994João Neto0% (1)

- MFE Module 1 .Document15 pagesMFE Module 1 .Adarsh KPas encore d'évaluation

- Conducting Focus GroupsDocument4 pagesConducting Focus GroupsOxfam100% (1)

- 220245-MSBTE-22412-Java (Unit 1)Document40 pages220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhPas encore d'évaluation

- Tese Beatbox - Florida PDFDocument110 pagesTese Beatbox - Florida PDFSaraSilvaPas encore d'évaluation

- Based On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial StatementsDocument12 pagesBased On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial Statementsbobo kaPas encore d'évaluation

- Mecha World Compendium Playbooks BWDocument12 pagesMecha World Compendium Playbooks BWRobson Alves MacielPas encore d'évaluation

- Origin ManualDocument186 pagesOrigin ManualmariaPas encore d'évaluation

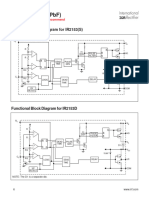

- IR2153 Parte6Document1 pageIR2153 Parte6FRANK NIELE DE OLIVEIRAPas encore d'évaluation

- Existentialism in CinemaDocument25 pagesExistentialism in CinemanormatthewPas encore d'évaluation