Académique Documents

Professionnel Documents

Culture Documents

McDonnell Douglas DC 10 40 Emergency Equipment

Transféré par

Ehsan Ul HaqueDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

McDonnell Douglas DC 10 40 Emergency Equipment

Transféré par

Ehsan Ul HaqueDroits d'auteur :

Formats disponibles

CHAPTER 7 EMERGENCY EQUIPMENT

Page TABLE OF CONTENTS 07-00-01/02

GENERAL

07-10-01

PASSENGER EVACUATION COMMAND SYSTEM Passenger Evacuation Command System Emergency Equipment Locations

07-10-01 07-10-02 07-10-03/04

OXYGEN SYSTEM Controls & Indicators Cockpit Oxygen System Oxygen Compartments .

07-20-01 07-20-03 07-20-05 07-20-06

EMERGENCY LIGHTING Emergency Lighting

07-30-01 07-30-02

EMERGENCY EXITS Cabin Doors - Interior Controls Cabin Doors - Manual Controls Cabin Doors - Exterior Controls Cabin Doors - Inadvertent Pneumatic Discharge Inflight Cockpit Door and Clearview Window .

07-40-01 07-40-02 07-40-04 07-40-05 07-40-06 07-40-08

JL Feb 1/76

07-00-01

Page ESCAPE SLIDE/RAFTS Escape Slide/Rafts Escape Slide/Rafts - Door to Door Movement 07-50-01 07-50-02 07-50-03

07-00-02

JL May 1/75

EMERGENCY

EQUIPMENT

GENERAL

The emergency equipment section describes and illustrates the systems and equipment which are essential to the safety of passengers and crew during adverse operational conditions. These include passenger evacuation command system, emergency equipment locations, passenger and crew oxygen systems, emergency lighting and escape slide/ rafts. The description for the emergency operation of the cabin doors, the cockpit door, and the clearview windows are also detailed in this chapter.

PASSENGER EVACUATION COMMAND SYSTEM The Passenger Evacuation Command System provides an aural means of alerting crew and passengers that an emergency evacuation is imminent. The system consists of an evacuation COMMAND switch, an EVAC horn, a HORN SHUTOFF button and an EVAC light on the overhead panel. In addition, an EVAC HORN, a horn off button, an evacuation switch and an EVAC light is installed at all cabin attendants' stations. The system is manually actuated by the COMMAND switch on the cockpit overhead panel, or the EVAC switch at the attendants stations, providing the pilot's switch is in ARM.

JL May 1/76

07-10-01

PASSENGER EVACUATION COMMAND SYSTEM Cabin Attendant's Evac switch (All stations) Normally in the off (switch guard closed) position. System is operated by opening the switch guard and actuating the Evac switch, when the Arming and Command switch is in the ARM position. Evac HORN OFF Button Evac horn off button silences individual horns at the attendant's stations.

EVAC HORN (CABIN ATTENDANT'S STATION - TYPICAL) EVAC FLASHING LIGHT

EVAC FLASHING LIGHT

EVAC HORN

(OVERHEAD PANEL)

Evac HORN OFF Button Evac horn off button silences individual horns at the pilot's stations.

EVACUATION COMMAND Switch ON Actuates warning horns and EVAC flashing lights at all applicable stations. ARM Provides power to actuate warning horns and EVAC flashing lights to all applicable stations when cabin attendant's Evac switch is placed in on position. OFF Evacuation Command System can not be actuated.

07-10-02

JL May 1/76

OXYGEN SYSTEM GENERAL Two independent emergency oxygen systems are provided: one for the flight crew, and one for the cabin attendants and passengers. The cockpit oxygen is supplied from a storage cylinder. The cabin and lavatory areas are supplied by individual, self-contained chemical oxygen generating/dispensing units. In addition, portable cylinders are located in the cockpit and cabin. DESCRIPTION Flight Crew Oxygen System The flight crew oxygen system is the pressure-breathing, diluter-demand type, and is provided for supplemental and emergency requirements. Oxygen from a high pressure storage cylinder is reduced to a regulated low pressure, then distributed to five flight crew stations. Individual quick-donning masks with mask-mounted regulators are provided at each flight crew station. Each mask is positioned for immediate use. Smoke goggles are also provided, and are stowed at each of the five flight crew stations. Passenger Oxygen System The oxygen generating/dispensing units supply supplemental oxygen to occupants of the cabin and lavatories. Each unit includes a chemical oxygen generator, oxygen mask(s) with reservoir bag(s), and hoses to convey oxygen from the generator to the mask(s). A two- or three-mask unit is installed in one seatback for each pair of seats in each row. Occupants of front row seats in each cabin section are supplied by two- or three-mask units in compartments in the ceiling, sidewall stowage compartments, or class dividers just forward of the seats.

A one-mask unit is installed in the oxygen compartment of each cabin attendant station console. A two-mask unit is installed in each lavatory ceiling. All oxygen compartment doors open automatically if the cabin altitude exceeds approximately 14,000 feet. Removing any one mask from a single- or multiple-mask unit compartment and pulling the mask toward the face so that the lanyard separates from the generator initiates the oxygen generating process and oxygen automatically flows through all masks in that compartment. The generators provide sufficient oxygen for at least 15 minutes continuous use. CAUTION; THE OXYGEN GENERATOR SURFACE TEMPERATURE MAY REACH 500F (260C) WHEN GENERATING OXYGEN. DO NOT TOUCH OR ATTEMPT TO REMOVE GENERATOR. BURN INJURY CAN RESULT. IF AN ACTIVE GENERATOR IS INADVERTENTLY REMOVED FROM COMPARTMENT, IT MUST BE PLACED IN METAL CONTAINER SUCH AS LAVATORY OR GALLEY SINK. HEAT WELL SCORCH OTHER MATERIALS OR FABRICS. NOTE; Odor similar to scorched cloth may be created by activation of generators. The odor does not affect the purity of the oxygen and there is no fire hazard.

Masks are continuous flow type. No shutoff valves are provided. Oxygen flow rates are low, so oxygen reservoir bags may not inflate fully between breathing cycles. Inflation rate is dependent on cabin altitude and elapsed time since generator activation. On some masks, an inflation indicator, small green compartment at the inlet end of mask reservoir bag, inflates providing evidence of oxygen flowAs a backup to the automatic system, the oxygen mask switch on the Flight

JL Nov 1/78

07-20-01

Engineer's Upper Panel provides a manual override for releasing the masks. Moving the switch to EJECT will open all oxygen compartment doors. If necessary, each individual oxygen compartment door also can be opened manually. Seatback-mounted compartment doors can be opened by inserting a finger or small diameter rod through the hole in the bottom of the compartment, and applying pressure to release the latch. Access to the hole in the bottom of the compartment is through the seatback tray compartment. The tray must be unlatched and pulled from the compartment to expose the hole. All other oxygen compartment doors can be opened by inserting a small diameter rod or pointed object into the slot in the door. Make contact with the latch opening mechanism, apply pressure 90 degrees to the direction of the slot and move the object to release the latch.

When manually opening the door, care should be taken to avoid damaging the decorative appearance of the door. Portable Oxygen Cylinders One portable oxygen cylinder (with smoke mask attached) is located in the cockpit. Attendant's/First Aid portable oxygen cylinders and masks as required are located in the cabin. Refer to Emergency Equipment Location Diagram for locations of the cylinders. CONTROLS AND INDICATORS The controls, indicators, and components are located on the Flight Engineer's Upper Panel No. 1 and No. 2, the crew members stations, and throughout the cabin and lavatories. Illustrations of the major panels may be found by referring to Chapter 1. Locations of components and individual controls and indicators are illustrated and described in other sections of this chapter.

07-20-02

JL Nov 1/78

OXYGEN SYSTEMS - Controls and Indicators

OXY LINE PRESS Gage Indicates regulated (low) pressure in the distibution line. The broad white band indicates normal range. The narrow white band is the acceptable pressure range when oxygen is being used under maximum flow conditions. No electrical power is required for gage operation.

OXY QTY Gage Indicates quantity (pressure) in the supply cylinder. A fully charged cylinder will normally indicate about 1850 psi. A fully charged system will supply five persons under maximum (100% oxygen) demand conditions for approximately one hour, and under normal demand for four hours. Normal electrical power is required for gage operation. Pointer moves to zero if electrical power is lost.

FLIGHT ENGINEER'S UPPER PANEL NO. 2

OXY MASK Switch EJECT Momentary position used, as necessary, to open all oxygen compartment doors at any cabin altitude to assure mask presentation. NOTE of 5 seconds may cause damage to the oxygen compartment latches. NORM Door latches on all oxygen compartments will open automatically at any time cabin altitude reaches approximately 14,000 feet. Switch guard is normally closed. Holding switch in EJECT position in excess

FLIGHT ENGINEER'S UPPER PANEL NO. 1

JL Nov 1/78

07-20-03

OXYGEN SYSTEMS - Controls and Indicators

OXYGEN Quick-Disconnect Receptacle OXYGEN MASK MIC Jack Provides connection between oxygen supply and regulator hose.

100 Percent Lever (Detented) Press for 100 percent oxygen at all altitudes.

OXYGEN PANEL (Flight Crew/Observer Stations) DILUTE DETENT

MASK MOUNTED OXYGEN REGULATOR DILUTE Selector DILUTE-Regulates oxygen/cockpit air mixture in proportion to cockpit altitude up to approximately 28,000 feet, at which time oxygen flows at 100 percent.

EMERGENCY NORMAL NORMAL/EMERGENCY Selector NORMAL Regulator functions in demand mode at lower cockpit altitudes and in the pressure breathing mode at critically high cockpit altitudes. Selector normally set at NORMAL.

EMERGENCY- Overrides other positions. Regulator supplies 100 percent oxygen in positive pressure breathing mode.

07-20-04

JL Feb 1/75

COCKPIT OXYGEN SYSTEM

FLT. ENG. UPPER PANEL NO. 2

MASK AND BREATHING REGULATOR (TYPICAL) COPILOT

FLIGHT ENGINEER

MANUAL SHUTOFF VALVE NORMALLY OPEN

CAPTAIN

SECOND OBSERVER

FIRST OBSERVER LEGEND PRESSURE GAGE HIGH PRESSURE OXYGEN SUPPLY CYLINDER REGULATOR/ REFILL VALVE HIGH PRESSURE REGULATED PRESSURE OVERBOARD RELIEF ELECTRICALLY ACTUATED BREAKAWAY & SHUTOFF VALVE (5 PLACES) QUANTITY TRANSDUCER PRESSURE REGULATING VALVE FILL VALVE RELIEF VALVE

AVIONICS COMPARTMENT OVERBOARD RELIEF INDICATOR (BLOWOUT)

JL Nov

1/78

07-20-05

OXYGEN COMPARTMENTS Passenger Seats A. OPEN SEATBACK TRAY LATCH STEP 2 B. OPEN OXYGEN COMPARTMENT

STEP 1

STEP 1 DOOR

PASSENGER SEATS (TYPICAL) TRAY 1. ROTATE TRAY LATCH 2. LOWER FOOD TRAY

ACCESS HOLE

1. INSERT FINGER OR SMALL DIAMETER ROD IN ACCESS HOLE AND PUSH TO RELEASE DOOR LATCH.

C. MASKS AVAILABLE MASKS HEAT SHIELD LANYARDS GENERATOR LATCH HOSES

D. RESET LATCH SEE DOOR LATCH RESET ILLUSTRATION.

E.

CLOSE OXYGEN COMPARTMENT

STRIKE

1. CHECK THAT LANYARDS ARE STILL INSTALLED IN GENERATOR LANYARD GUIDES. NOTE: IF LANYARDS ARE SEPARATED FROM GENERATOR, THE GENERATOR IS EXPENDED AND M U S T BE REPLACED. 2. CHECK THAT NOTHING IS BETWEEN HEAT SHIELD AND DOOR. 3. CLOSE DOOR BY PRESSING ON DOOR UNTIL LATCH ENGAGES. 4. RAISE FOOD TRAY AND LATCH IN PLACE.

07-20-06

JL Nov 1/78

OXYGEN COMPARTMENTS Ceiling and Overhead Racks

LAVATORY CEILING (TYPICAL) OVERHEAD SIDEWALL STOWAGE RACK (TYPICAL) A. OPEN COMPARTMENT DOOR INSERT SMALL ROUND ROD IN LATCH RELEASE SLOT AND MOVE AT 90 DEGREES TO THE DIRECTION OF THE SLOT TO RELEASE LATCH. LATCH RELEASE SLOT CABIN CEILING (TYPICAL)

SMALL ROUND ROD

B. MASKS AVAILABLE (3-MASK UNIT SHOWN, 1-, 2- AND 4 MASK UNITS TYPICAL) GENERATOR LATCH

CUP LATCH

C. STOW MASKS 1. FOLD RESERVOIR BAGS AND STRAPS INTO MASK FACEPIECE. COIL HOSES INSIDE MASK, MAKING SURE HOSES ARE FREE OF KINKS. 2. INSERT MASK IN CUP. ENGAGE RETAINER CLIP IN CUP LATCH.

RETAINER CLIP HOSES LANYARDS D. RESET LATCH MASKS RESERVOIR BAGS

COIL AND STOW LANYARD UNDER RETAINER BEFORE ENGAGING CUP LATCH. SEE DOOR LATCH RELEASE AND RESET ILLUSTRATION.

E. CLOSE DOOR

2. PUSH ON DOOR UNTIL LATCH ENGAGES.

JL May 1 /80

07-20-07

OXYGEN COMPARTMENTS - Cabin Attendant Station A. OPEN COMPARTMENT SMALL ROUND ROD

CABIN ATTENDANT STATION (TYPICAL)

INSERT SMALL ROUND ROD IN LATCH RELEASE SLOT AND MOVE AT 90 DEGREES TO THE DIRECTION OF THE SLOT TO RELEASE LATCH.

LATCH RELEASE SLOT

B. MASK AVAILABLE LATCH

C. RESET LATCH SEE DOOR LATCH RELEASE AND RESET ILLUSTRATION.

GENERATOR D. CLOSE DOOR HEAT SHIELD LANYARD HOSE

MASK

1. ENGAGE DOOR SPRING HINGE AT BOTTOM OF COMPARTMENT. 2. MAKE CERTAIN THERE ARE NO KINKS IN HOSE AND MASK AND HOSE ARE NOT BETWEEN DOOR AND GENERATOR. 3. PUSH DOOR UNTIL LATCH ENGAGES.

07-20-08

JL Nov 1/78

OXYGEN COMPARTMENTS (Bayonet-Type Latch)

- Door Latch Release and Reset

NOTE: Latch installation will vary with different oxygen compartment installations. Installation and instructions for door release and latch reset are

typical for bayonet-type latches installed in overhead, console and vertical partition compartments.

1. INSERT SMALL DIAMETER ROD IN SLOT. 2. MOVE LEVER ARM TOWARD LATCH TO RELEASE.

LEVER ARM SMALL ROUND ROD

LEVER ARM LEVER CAP COIL LEVER CAP COIL

SLOT

Lever Arm locations may vary in seat back installations LATCHED (WITH DOOR CLOSED) OR RESET (WITH DOOR OPEN)

STRIKER (ON INSIDE FACE OF DOOR) TO OPEN DOOR

DOOR CUT AWAY FOR CLARITY

LEVER ARM

COIL

LEVER CAP LEVER CAP MOVE LEVER CAP TO COIL CORE COIL

MOVE LEVER ARM AWAY FROM LATCH TO RESET LATCH

JL Nov 1/78

07-20-09/10

EMERGENCY LIGHTING GENERAL The emergency lighting system consists of cabin ceiling lights, exit signs, galley lights, door lights, and cockpit dome lights. External emergency lighting is provided by electrical lighting as an integral part of the escape slides and ramps. DESCRIPTION Electrical power for emergency evacuation lighting system control and operation is supplied by the aircraft electrical system or from independent battery packs located in the cabin. These batteries are self-contained and continuously charged. Power is provided sequentially in the following priority: right emergency ac bus; left emergency dc bus; emergency battery packs. All packs are maintained at full charge by individual chargers powered from the aircraft electrical system. When fully charged,

the packs will provide sufficient power to operate the emergency lights for at least 10 minutes. Emergency lighting system control is either automatic or manual, as selected in the cockpit or at the left forward cabin attendant's control panel. In the automatic mode, a logic unit controls the system. In case of power interruption, the system will be switched automatically to the next available source of power. This provides power for emergency lighting without depleting battery pack power below the level required for dispatch. CONTROLS AND INDICATORS The controls, indicators, and annunciator lights are installed on the overhead panel in the cockpit and on the left forward cabin attendant's control panel. Illustrations of the major cockpit panel may be found by referring to Chapter 1. The individual controls and indicators are described in the following illustration.

JL Feb 1/75

07-30-01

EMERGENCY LIGHTING EMER LT Switch NORM-AM emergency evacuation lights are under control of the cockpit emergency Iights switch. Switch is guarded and lockwired in the NORM position. ON Placing switch in ON position will override cockpit switch OFF/ARM position and turn on all emergency lights. Placing the switch back to NORM will turn off the lights.

EMER LT TEST Button Button is pushed to test battery packs. Pushing TEST button will cause all emergency lights to come on for testing condition of batteries under load. The EMER LT TEST light will come on if all voltages are normal.

(FORWARD CABIN ATTENDANT'S STATION)

EMER LT Switch OFF Prevents lights from coming on. DISARMED light will come on. Connects battery packs to the continuous charging system when power is available to the airplane. The cockpit switch OFF position may be overridden by placing left forward Cabin Attendant's emergency lights switch in the ON position. ARM - Provides automatic sequential-power selection for emergency lighting. Also connects battery packs to the continuous charging system when power is available to airplane. Allows emergency lighting system to turn on automatically whenever normal airplane electrical power is interrupted. ON - Causes the emergency lignts and the DISARMED light to come on, These lights will remain on as long as sequential power is available. OVERHEAD PANEL

EMER LT TEST Light Comes on after the emergency lights test button is pushed and held for 3 to 5 seconds if all battery pack voltages are normal during emergency lighting test.

Emer Light DISARMED Light Comes on when the emergency lights switch is in ON or OFF position indicating the emergency lights are not armed for automatic operation.

07-30-02

JL Feb 1/76

EMERGENCY EXITS GENERAL Cabin doors will be used for emergency exits for both crew and passengers. All of the normal exits have backup systems to permit their operation during abnormal conditions. For the flight crew, alternate exit routes are provided through either the cockpit door blowout panel into the forward cabin or by opening the clearview windows. DESCRIPTION Cabin Doors There are eight main cabin doors, four on each side of the aircraft. From outside the aircraft all of the operating handles are identical and all are opened in the same manner in the event of an emergency. From inside the aircraft, the six aft doors have identical handles and identical emergency opening procedures. The two forward cabin door handles however, are not identical to the aft six and are operated differently. Power for the emergency opening of all cabin doors is pneumatic. An air reservoir and a pressure indicator are provided at each door. If the emergency door opening procedure is performed from inside the aircraft with emergency pneumatic power the associated escape slide will deploy automatically. When using emergency pneumatic power to open the doors from the inside, slide deployment is prevented by

holding the slide arming lever in the emergency interlock override position. A manual lift bar is installed on all cabin doors to provide a means for opening the doors from inside the aircraft when no emergency pneumatic power is available. The manual lift bar can only be used when the door handle in the emergency position. At least two people may be required to open a door by the manual lift method. Cockpit Door The cockpit door provides access to the main cabin from the cockpit. In the event the door is jammed, a blowout panel on the lower half can be unhinged or kicked open. This provides an adequate crawl-through opening to the main cabin and the normal evacuation routes. Clearview Windows Two sliding clearview windows provide an alternate emergency escape route for the flight crew. The clearview windows are adjacent to the windshields. Escape lines are provided to allow the crew to lower themselves to the ground. CONTROLS AND INDICATORS An emergency equipment location drawing, in another section of this chapter, locates the major emergency equipment and facilities. Individual controls and indicators are also illustrated and described.

JL Nov 1/78

07-40-01

CABIN DOORS - Interior Controls Emergency Operation With Slide Deployment GUARD Slide Arming Lever Arms and disarms the associated escape slide. Lever is normally in the SLIDE ARMED position for emergency operation. Door Emergency Control Handle (Red) When slide is armed for emergency operation, rotating control handle to emergency open position will activate the emergency pneumatic power to open the door and deploy the escape slide. NOTE Door control handle will stay in the emergency open position. Green Band indicates normal pressure in psi. SLIDE ARMING LEVER EMERGENCY OPEN POSITION ARMED POSITION PRESSURE GAGE VIEWING PORT, TYPICAL (Aft and Above Each Door - Interior) POSITIVE STOP IF SLIDE IS DISARMED DOOR EMERGENCY CONTROL HANDLE STOWED POSITION DOOR CONTROLS (AFT SIX) (Side View)

EMERGENCY OPEN POSITION

POSITIVE STOP IF SLIDE IS DISARMED

CABIN DOOR INTERIOR CONTROLS (FWD TWO) (View Looking Forward, Left Side; Right Side Opposite)

Slide Mode Window Indicates whether the escape slide is armed or disarmed. Door Emergency Control Handle (Red) When slide is armed for emergency operation, pulling the control handle to emergency open position will activate the emergency pneumatic power to open the door and deploy the escape slide. NOTE Door control handle will return to stowed position when released.

Slide Arming Lever A r m s and d i s a r m s the associated escape slide. Lever is normally in the SLIDE ARMED position for emergency operation. CABIN DOOR INTERIOR CONTROLS (AFT SIX) (View Looking Forward Left Side, Right Side Opposite)

07-40-02

JL Nov 1/78

CABIN DOORS - Interior Controls Emergency Operation Without Slide Deployment GUARD Slide Arming Lever A r m s and d i s a r m s the associated escape slide. Also provides the capability for opening the associated door pneumatically without deploying the escape slide, by holding to emergency interlock override position. SLIDE ARMED POSITION EMERGENCY OPEN POSITION

Door Emergency Control Handle (Red) While holding slide arming lever in the emergency interlock override position, rotating the control handle to the emergency open position will activate the emergency pneumatic power to open the door. NOTE Door control handle will stay in the emergency open position.

SLIDE DISARMED POSITION

EMERGENCY INTERLOCK OVERRIDE POSITION POSITIVE STOP IF SLIDE IS DISARMED CABIN DOOR INTERIOR CONTROLS (FWD TWO) (View Looking Forward, Left Side; Right Side Opposite)

EMERGENCY OPEN POSITION

Green Band indicates normal pressure in psi.

ARMED POSITION DOOR EMERGENCY CONTROL HANDLE

SLIDE ARMING LEVER EMERGENCY INTERLOCK OVERRIDE POSITION DISARMED POSITION

STOWED POSITION PRESSURE GAGE VIEWING PORT, TYPICAL (Aft and Above Each Door - Interior) Door Emergency Control Handle (Red) While holding slide arming lever in the emergency interlock override position, rotating the control handle to the emergency open position will activate the emergency pneumatic power to open the door. NOTE Door control handle will return to stowed position when released.

DOOR CONTROLS (AFT SIX) (Side View) Slide Mode Window Indicates whether the escape slide is armed or disarmed.

GUARD

Slide Arming Lever Arms and disarms the associated escape slide. Also provides the capability for opening the associated door pneumatically without deploying the escape slide.

CABIN DOOR INTERIOR CONTROLS (AFT SIX) (View Looking Outboard Left Side, Right Side Opposite)

JL Nov 1/78

07-40-03

CABIN DOORS - Manual Controls

Manual Lift Bar Provides the means for manually lifting door when no emergency pneumatic power is available.

GIRT BAR CABIN INTERIOR DOOR (AFT SIX) (Right Side Shown, Left Side Opposite) Slide Mode Verification Indicator (Two Each Door) Verifies actual condition of escape slide. An ARMED placard is visible when door is closed and slide is armed. Green Band indicates pressure in psi. Pressure Gage Viewing Port, Typical (Aft Side and A b o v e Each Door-Interior) normal CABIN INTERIOR DOOR (FWD TWO) (Left Side Shown. Right Side Opposite)

If door can not be opened using pneumatic power, pull door inboard at approximately a 45 degree angle and lift upward. NOTE Door controls must be set for emergency operation.

Release manual lift bar and push door upward to full open position.

07-40-04

JL May 1/75

CABIN DOORS - Exterior Controls TYPICAL (Left Side Shown, Right Side Opposite)

EMERGENCY OVERRIDE LEVER FILLER (Installed on forward doors only) DOOR CONTROL HANDLE

DOOR CONTROL HANDLE

JL Aug 1/82

07-40-05

CABIN DOORS - Inadvertent Pneumatic Discharge In Flight

(SHEET 1)

Refer to Sheet 2 for procedures. NOTE Inadvertent actuation of a cabin door control handle, to Emergency (pneumatic) Open position, inflight will discharge the corresponding door pneumatic bottle. Discharging the bottle will not open the door inflight unless cabin differential pressure is less than approximately 0.55 psi. Cabin differential pressure above approximately 0.55 psi will keep door closed. With door closed, pneumatic bottle pressure will bleed off within a few seconds, leaving no residual pressure that could force door open even if cabin differential pressure is relieved. CAUTION When operating with cabin differential pressure of less than 1 psi, crew should caution cabin attendants to ensure that unauthorized personnel remain clear of doors. Procedures which may result in prolonged periods of operation at low differential pressure are:

DECOMPRESSION AND EMERGENCY DESCENT COCKPIT SMOKE REMOVAL UNPRESSURIZED RAM AIR VENTILATION OPERATION CABIN OR COCKPIT SMOKE OR FUMES COCKPIT PREPARATION FOR PASSENGER EVACUATION NOTE

Immediately following inadvertent discharge of a cabin door pneumatic bottle, reset door control handle from emergency (pneumatic) to neutral position. This locks door in closed position until ready for subsequent operation.

07-40-06

JL Feb 1/76

CABIN DOORS - Inadvertent Pneumatic Discharge In Flight (Sheet 2]

REFER TO NOTES AND CAUTION ON SHEET 1.

RESET LEVER (LOCKING PAWL)

DOOR EMERGENCY CONTROL HANDLE

SLIDE ARMING LEVER GUARD

DOOR EMERGENCY CONTROL HANDLE (Moves in direction of arrow) CAM

SLIDE ARMING LEVER

RESET LEVER (LOCKING PAWL) EMERGENCY OPEN POSITION

NEUTRAL DETENT CABIN DOOR INTERIOR CONTROLS (FWD TWO) (View Looking Forward Left Side; Right Side Opposite) TO RESET DOOR EMERGENCY CONTROL HANDLE 1. Hold control handle in emergency open position and rotate reset lever upward. 2. While holding reset lever up, return handle to neutral position. 3. Release reset lever. 4. Make certain slide arming lever is in SLIDE ARMED position. 5. After landing use normal operating procedures to open door. CABIN DOOR INTERIOR CONTROLS (AFT SIX) (View Looking Outboard Left Side; Right Side Opposite) TO RESET DOOR EMERGENCY CONTROL HANDLE NOTE A cam held in a rotated up position by a reset lever is visible when control handle is in the emergency open position. 1. Hold control handle in emergency open position and press bottom or pull top of reset lever to permit reset lever to clear cam. 2. While holding reset lever clear of cam, squeeze handle trigger and move handle toward neutral position, releasing reset lever when clear of cam. 3. When neutral position is reached, release handle and stow. 4. Make certain slide arming lever is in SLIDE ARMED position. 5. After landing use normal operating procedures to open door.

AFTER LANDING, IF IT IS NECESSARY TO DEPLOY SLIDE. 1. Make certain slide arming lever is in SLIDE ARMED position. 2. Move control handle to emergency open position. 3. Using manual lift bar, manually raise door to full open position. As door moves upward, slide will drop

out of container and automatically deploy. CAUTION The two forward doors weigh approximately 350 pounds (159 kg) each and the six aft doors weigh approximately 440 pounds (200 kg) each until the slide drops out.

JL Nov 1/78

07-40-07

COCKPIT DOOR AND CLEARVIEW WINDOW BLOWOUT PANEL HINGE

BLOWOUT PANEL BLOWOUT PANEL

Hinge Release Pin Move pin in direction shown to release blowout panel.

LATCH BLOWOUT PANEL RELEASE LATCH

COCKPIT DOOR View Looking Aft Clearview Window Locking Handle Locks the window in the closed position. ESCAPE ROPE

Clearview Window Crank Push in to engage, then rotate handle to open clearview window.

SLIDING CLEARVIEW WINDOW View Looking Fwd (Typical both sides)

JL

ESCAPE SLIDE/RAFTS

An inflatable escape slide/raft (combination escape slide and life raft) is installed in a slide stowage container, mounted on the inside of each cabin door. Opening the door will automatically inflate and deploy the slide when the arming lever adjacent to the door is in the SLIDE ARMED configuration. Should a door, other than the overwing doors, become jammed and cannot be opened, the slide/raft may be moved to a usable door for deployment and use as a raft. A step-by-step procedure to remove the slide/raft from the jammed door and move it to another door for deployment is illustrated in this section. A manual inflation handle is installed in the slide/raft assembly and becomes visible when the slide/raft is deployed. If the automatic inflation mechanism malfunctions the manual handle must be pulled to inflate the slide/raft. The cabin doors are equipped with doubletrack slide/rafts so that two persons can exit the airplane simultaneously. The overwing slide/rafts are fitted with integral ramps and deploy over the leading edge of the wing, outboard of the engine pylon. When the overwing slide/rafts are deployed and ready for use, slide position indicators will be visible on the upper end of the slide/rafts. Each slide/raft and ramp is equipped with self-powered, battery operated electric

lights as an integral part of the slide/raft and the ramp. The lights illuminate the evacuation route from the passenger compartment to the ground/water. Side handles are provided at the lower portion of the slide so that the first evacuees to exit during a ground evacuation can help hold the slide in position, if necessary. Also attached to each slide/raft is a re-entry/mooring line to be used as an aid to re-enter the airplane, if necessary, or to moor the slide to the airplane when used as a raft during evacuation and ditching. Each slide can be released quickly from the airplane and used as a life raft. A slide disengagement cable with an attached fabric handle is located at the top of the slide. The cable and handle are protected by a fabric flap. The slide/raft may be disengaged by lifting the protective flap and pulling the handle placarded PULL. The slide/raft may be released from the airplane by unfastening/cutting the re-entry/mooring line. An integrally lighted slide inflation cylinder low pressure light is installed on the door, directly over each slide/raft stowage container. The light will automatically come on when the inflation cylinder has insufficient pressure to inflate the slide/raft. The integrity of the indicator light and electrical circuit may be tested by pressing the light. A faulty circuit is indicated when the light does not come on when pressed.

JL Feb 1/76

07-50-01

ESCAPE SLIDE/RAFTS (Sheet 1) SLIDE INFLATION CYLINDER LOW PRESSURE SWITCH/LIGHT Light comes on automatically when the inflation cylinder has insufficient pressure to inflate slide/raft Switch is also used to test integrity of light electrical circuit. MANUAL SLIDE/RAFT INFLATION HANDLE (Visible when slide/raft is deployed) If the automatic inflation mechanism malfunctions, the handle may be pulled to inflate slide/ raft. VELCRO RETAINERS (UNFASTENED)

TO INFLATE PROTECTIVE FLAP

RE-ENTRY/MOORING LINE FASTENER (TYPICAL)

ESCAPE SLIDE/RAFT (STOWED)

CABIN DOOR (8 TYPICAL)

SLIDE/RAFT DISENGAGE HANDLE - FOR DITCHING ONLY (Visible when slide/ raft is deployed and protective flap lifted) To use as a life raft, pull handle to disengage slide/ raft from girt bar. Use same procedure to disengage overwing slide from ramp. NOTE Slide/raft is still attached to the airplane by the re-entry/mooring line.

SLIDE/RAFT DEPLOYED

GIRT BAR RE-ENTRY/MOORING LINE Used as an aid for re-entering airplane. Also used to moor slide/raft to airplane after being disengaged from airplane. Line must be cut/disconnected to free slide/raft from airplane completely. Line is attached to slide/raft and to girt bar flap assembly at Fwd,Mid, and Aft doors. Overwing line is attached to ramp and to slide/raft at the leading edge of wing.

SLIDE/RAFT (4) INFLATABLE RAMP (2)

Slide Position Indicator (Overwing only) A luminescent patch on the end of the slide (left and right side) visible when slide is properly deployed and ready for use.

SLIDE/RAFT WITH SPONSONS (4)

DISENGAGE HERE TO USE SLIDE AS A LIFE RAFT ( EACH SIDE )

07-50-02

JL Aug 1/79

ESCAPE SLIDE/RAFTS-Door to Door Movement (Sheet 1)

LOWER LINER MANUAL LIFT BAR

LOWER LINER MANUAL LIFT BAR

FORWARD DOORS (2)

ARM (Raised position)

MID AND AFT DOORS (4)

MANUAL LIFT BAR

BAR ARM

QUICK-DISCONNECT PIN (One each side)

SLIDE/RAFT MOVEMENT PLACARD (Inside of liner)

LOWER LINER (Typical Fwd,Mid, and Aft doors) FASTENER (One each side)

JL Aug 1/79

07-50-03

ESCAPE SLIDE RAFTS-Door to Door Movement (Sheet 2)

LOCKING PAWL RESET LEVER

SNAP (4 PLACES) DOOR CONTROL HANDLE

GIRT BAR GIRT RELEASE FLAP RE-ENTRY-STATIC LINE GIRT RELEASE LACING

SLIDE ARMING LEVER TRIGGER

NEUTRAL POSITION

EMERGENCY DOOR OPEN POSITION

EMERGENCY DOOR OPEN POSITION DOOR CONTROL HANDLE

CAM

GIRT BAR

SLIDE ARMING LEVER DISARMED POSITION

GIRT DITCHING RELEASE HANDLE (WHITE)

LOCKING PAWL ARMED POSITION HANDLES

SLIDE/RAFT PACK GIRT BAR

PACK RELEASE PINS

FLOOR FITTING

LOWER VELCRO DEPLOYMENT STRAPS

07-50-04

JL Aug 1/79

ESCAPE SLIDE/RAFTS-Door to Door Movement (Sheet 3 for Slide/Rafts with Center Valise Release Lacing)

SHORT VELCRO STRAPS

COVER

CENTER RELEASE STRAP

RE-ENTRY-STATIC LINE

GIRT BAR CENTER VALISE RELEASE LACING

CENTER VALISE RELEASE PIN

MANUAL INFLATION HANDLE

JL Feb 1/75

07-50-05/06

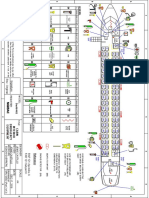

EMERGENCY EQUIPMENT LOCATIONS ESCAPE SLIDE/RAFT/RAMP COMBINATION STOWED ON DOOR (2)

SLIDE/RAFT

NOTE LIFE VESTS MAY BE STOWED UNDER EACH PASSENGER SEAT AND AT EACH CABIN ATTENDANT STATION. IN ADDITION SPARE LIFE VESTS MAY BE STOWED IN THE COATROOM AREAS,

RAMP ESCAPE SLIDE/RAFT STOWED ON DOOR (2) INSTALLED ON SOME AIRPLANES

CLEARVIEW WINDOWS

LEGEND CREW PORTABLE OXYGEN CYLINDER WITH SMOKE MASK (1) ATTENDANT'S/FIRST AID PORTABLE OXYGEN CYLINDERS (19) FIRST AID KITS (4) EXITS (10) ESCAPE LINES (2) WATER FIRE EXTINGUISHERS (4) C02 FIRE EXTINGUISHER (1) DRY CHEMICAL FIRE EXTINGUISHERS (3) CRASH AXE (1) PORTABLE MEGAPHONES (3) SMOKE GOGGLES (5) EMERGENCY RADIO BEACON TRANSMITTER (2) SIGNAL KIT

ESCAPE SLIDE/RAFT WITH SPONSONSSTOWED ON DOOR (4)

C02 fire extinguisher is replaced with a HALON 1211 fire extinguisher on aircraft reworked per AOL 10-1723.

JL Feb 1/84

07-10-03/04

Vous aimerez peut-être aussi

- McDonnell Douglas DC 10 40 ElectricalDocument24 pagesMcDonnell Douglas DC 10 40 ElectricalEhsan Ul HaquePas encore d'évaluation

- Military Low-Level Flying From F-4 Phantom to F-35 Lightning II: A Pictorial Display of Low Flying in Cumbria and BeyondD'EverandMilitary Low-Level Flying From F-4 Phantom to F-35 Lightning II: A Pictorial Display of Low Flying in Cumbria and BeyondPas encore d'évaluation

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 Hydraulic PowerDocument8 pagesMcDonnell Douglas DC 10 40 Hydraulic PowerEhsan Ul Haque100% (1)

- Use of Rudder On A300-600 & A310Document4 pagesUse of Rudder On A300-600 & A310fakernevernoPas encore d'évaluation

- B727-Air Cond and PressDocument13 pagesB727-Air Cond and PressmacvsogchingaPas encore d'évaluation

- Ac A300-600 20091201Document192 pagesAc A300-600 20091201Mahmoud Elbolkini100% (1)

- Ahm 560 A340-300 Dow DoiDocument10 pagesAhm 560 A340-300 Dow DoiFilip SkultetyPas encore d'évaluation

- Airbus A310 FCOM Vol 1 AIC Rev 39 Oct 2007 - 1228527939Document8 pagesAirbus A310 FCOM Vol 1 AIC Rev 39 Oct 2007 - 1228527939TomeuPas encore d'évaluation

- PDF N Ccom Fia TF N Eu 20170613 01Document20 pagesPDF N Ccom Fia TF N Eu 20170613 01Ion ciocaPas encore d'évaluation

- McDonnell Douglas DC 10 40 Flight InstrumentsDocument13 pagesMcDonnell Douglas DC 10 40 Flight InstrumentsEhsan Ul Haque100% (1)

- 3 00 - 09.08.10 - QRH 95004Document322 pages3 00 - 09.08.10 - QRH 95004svyat_kPas encore d'évaluation

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemAlly GuiaoPas encore d'évaluation

- Chapter 16 - Landing Gear: REV 3, May 03/05Document34 pagesChapter 16 - Landing Gear: REV 3, May 03/05Anish ShakyaPas encore d'évaluation

- Flight International - 3-9 December 2013 PDFDocument48 pagesFlight International - 3-9 December 2013 PDFsanderribeiroPas encore d'évaluation

- Shannon Control: Vateir Training Department Enr 1.XDocument9 pagesShannon Control: Vateir Training Department Enr 1.XAnonymous CmnGxnUPas encore d'évaluation

- Airbus Commercial Aircraft ARFC A300 600 Jun 2007Document17 pagesAirbus Commercial Aircraft ARFC A300 600 Jun 2007Ekta pujaraPas encore d'évaluation

- HYDRO B737 Equipment-CatalogueDocument138 pagesHYDRO B737 Equipment-CatalogueSauli Waziri SimkondaPas encore d'évaluation

- McDonnell Douglas DC 10 40 Landing GearDocument21 pagesMcDonnell Douglas DC 10 40 Landing GearEhsan Ul HaquePas encore d'évaluation

- Final Report Sukhoi Superjet 100 Accident, Released On Dec 18, 2012Document91 pagesFinal Report Sukhoi Superjet 100 Accident, Released On Dec 18, 2012REZA FAHLEFIPas encore d'évaluation

- Aircraft Tow Bar X PD FDocument12 pagesAircraft Tow Bar X PD FMohammad Azam100% (1)

- FCTM 20171123-084713 LeduDocument52 pagesFCTM 20171123-084713 Leducaptmon351Pas encore d'évaluation

- B 737 DraftDocument98 pagesB 737 DraftAlrino Dwi PrasetyoPas encore d'évaluation

- Air New Zealand's DC8 Era Part 1Document31 pagesAir New Zealand's DC8 Era Part 1Leonard G Mills100% (1)

- Structure-Basico B-727Document103 pagesStructure-Basico B-727Nicolas PrietoPas encore d'évaluation

- Control Pitch, Roll and Yaw Axis of AircraftDocument49 pagesControl Pitch, Roll and Yaw Axis of AircraftRavi PansheriyaPas encore d'évaluation

- Boeing 747Document9 pagesBoeing 747dave abad80% (5)

- Saab340 Ata 25 PDFDocument19 pagesSaab340 Ata 25 PDFKarlPas encore d'évaluation

- BAe146 Fuelling Procedures 2008Document25 pagesBAe146 Fuelling Procedures 2008Antonio Correia C100% (1)

- ATA 5-12 Ground Handling & ServicingDocument70 pagesATA 5-12 Ground Handling & Servicingامیر شعاعیPas encore d'évaluation

- RAM 747-200/7Q: Distribution ListDocument20 pagesRAM 747-200/7Q: Distribution ListStiliyana BakalovaPas encore d'évaluation

- 757 Oil FlapsDocument52 pages757 Oil FlapsDede HidajatPas encore d'évaluation

- Section 3 - Emergency Procedures: Z 242 L Flight ManualDocument18 pagesSection 3 - Emergency Procedures: Z 242 L Flight ManualJuan Carlos Sanchez MaldonadoPas encore d'évaluation

- Ea 767 31-002 Eicas Upgrade Ops6 PDFDocument5 pagesEa 767 31-002 Eicas Upgrade Ops6 PDFjuanf490Pas encore d'évaluation

- Jeppesen Expands Products and Markets: Preparing Ramp Operations For The 787-8Document32 pagesJeppesen Expands Products and Markets: Preparing Ramp Operations For The 787-8AHMET DERVISOGLUPas encore d'évaluation

- MM Comments To Aselsan - Challenger 605 Special Mission Stress & Dadt ApproachDocument18 pagesMM Comments To Aselsan - Challenger 605 Special Mission Stress & Dadt ApproachbarracudacemPas encore d'évaluation

- 1 Ata 00Document32 pages1 Ata 00Andy Pamelita DiegoPas encore d'évaluation

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument333 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationMartin FeigePas encore d'évaluation

- Aom 145 1114 05 Sec 1 07Document48 pagesAom 145 1114 05 Sec 1 07bnolasco100% (1)

- EASA TCDS A.110 Airbus A380Document17 pagesEASA TCDS A.110 Airbus A380kiecard33% (3)

- Iee - N689ac Lopa PDFDocument1 pageIee - N689ac Lopa PDFLuis HernandezPas encore d'évaluation

- Boeing 767 Reading LightsDocument1 pageBoeing 767 Reading Lightsjuanf490Pas encore d'évaluation

- 00 ContentsDocument14 pages00 Contentsali4957270Pas encore d'évaluation

- Manchester, Uk Egcc/Man: 1.1. Atis 1. GeneralDocument45 pagesManchester, Uk Egcc/Man: 1.1. Atis 1. GeneralTweed3APas encore d'évaluation

- 4Document17 pages4Jai DeepPas encore d'évaluation

- B727-Hydraulics SystemDocument0 pageB727-Hydraulics SystemSander GolsteynPas encore d'évaluation

- CPCP e PDFDocument263 pagesCPCP e PDFKarina Flores100% (1)

- Cao 20.7.1BDocument16 pagesCao 20.7.1BChris BarryPas encore d'évaluation

- A330 MRTT ATA 21 L1 - TM - Issue 2Document18 pagesA330 MRTT ATA 21 L1 - TM - Issue 2RaulPas encore d'évaluation

- DA20 Katana Flight ManualDocument136 pagesDA20 Katana Flight Manual韩超Pas encore d'évaluation

- Embraer E175 v1.0 Fms ManualDocument38 pagesEmbraer E175 v1.0 Fms ManualEvgeny ZoomPas encore d'évaluation

- ETOPS Maintenance, Planning and StoresDocument69 pagesETOPS Maintenance, Planning and StoresEduardo RuizPas encore d'évaluation

- 26-2018 TUI Airways Operational Notice - Standard Loading Instructions With Pre-Pack-AMENDEDDocument2 pages26-2018 TUI Airways Operational Notice - Standard Loading Instructions With Pre-Pack-AMENDEDblechasapo.cvPas encore d'évaluation

- Enr 6 en - Route ChartsDocument2 pagesEnr 6 en - Route ChartsladienpkikPas encore d'évaluation

- Vnav Not Complying With Altitude Constraint During ApproachDocument4 pagesVnav Not Complying With Altitude Constraint During ApproachtangautaPas encore d'évaluation

- C-141C Dash 1 016 3 - 1-50 EPDocument50 pagesC-141C Dash 1 016 3 - 1-50 EPbkaplan452Pas encore d'évaluation

- Lgciu Ts GuideDocument34 pagesLgciu Ts GuidePankaj KhondgePas encore d'évaluation

- A 380Document23 pagesA 380darkmenschPas encore d'évaluation

- WMKK-Charts Related To KL International Sepang Airport PDFDocument69 pagesWMKK-Charts Related To KL International Sepang Airport PDFFiqri ProductionPas encore d'évaluation

- McDonnell Douglas DC 10 40 Navigation SystemDocument22 pagesMcDonnell Douglas DC 10 40 Navigation SystemEhsan Ul Haque100% (1)

- McDonnell Douglas DC-10-40-Ice and Rain ProtectionDocument8 pagesMcDonnell Douglas DC-10-40-Ice and Rain ProtectionEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 Landing GearDocument21 pagesMcDonnell Douglas DC 10 40 Landing GearEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 Flight InstrumentsDocument13 pagesMcDonnell Douglas DC 10 40 Flight InstrumentsEhsan Ul Haque100% (1)

- McDonnell Douglas DC 10 40 Flight ControlsDocument19 pagesMcDonnell Douglas DC 10 40 Flight ControlsEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 APUDocument9 pagesMcDonnell Douglas DC 10 40 APUEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC-10 Flight Crew Operating ManualDocument68 pagesMcDonnell Douglas DC-10 Flight Crew Operating ManualTamás Varga100% (4)

- Atr 72 CommunicationsDocument29 pagesAtr 72 CommunicationsEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 Fire ProtectionDocument8 pagesMcDonnell Douglas DC 10 40 Fire ProtectionEhsan Ul HaquePas encore d'évaluation

- McDonnell Douglas DC 10 40 Emergency EquipmentDocument29 pagesMcDonnell Douglas DC 10 40 Emergency EquipmentEhsan Ul HaquePas encore d'évaluation

- Atr72 AfcsDocument29 pagesAtr72 AfcsEhsan Ul HaquePas encore d'évaluation

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaquePas encore d'évaluation

- MKT Management AssainmentDocument11 pagesMKT Management AssainmentEhsan Ul HaquePas encore d'évaluation

- Kaplan Design Marko KogovsekDocument10 pagesKaplan Design Marko KogovsekIvan Batistic BeloPas encore d'évaluation

- A Survey of Air-to-Ground Propagation Channel Modeling For Unmanned Aerial VehiclesDocument31 pagesA Survey of Air-to-Ground Propagation Channel Modeling For Unmanned Aerial Vehicleskasun prabhathPas encore d'évaluation

- A History of Fatigue - Walter SchuetzDocument38 pagesA History of Fatigue - Walter Schuetzstem86100% (2)

- Accumulator ManualDocument4 pagesAccumulator ManualFernandoMartínIranzoPas encore d'évaluation

- Module 17.2 - B1 - Rev 00 PDFDocument13 pagesModule 17.2 - B1 - Rev 00 PDFAhmed Nasir MalikPas encore d'évaluation

- Orion ExploreFarther-mediakit PDFDocument37 pagesOrion ExploreFarther-mediakit PDFajrespinaPas encore d'évaluation

- Branch Name B.E. Aeronautical Engineering: Semes Ter Subject Name Subject Code Exam Date SessionDocument3 pagesBranch Name B.E. Aeronautical Engineering: Semes Ter Subject Name Subject Code Exam Date SessionPRAKASH MPas encore d'évaluation

- Influence of Weak and Strong GyroscopicDocument10 pagesInfluence of Weak and Strong GyroscopicMATEUS RODOVALHO EDINGERPas encore d'évaluation

- FRA AF432/23 MAR/LGW-CDG: - Not For Real World NavigationDocument49 pagesFRA AF432/23 MAR/LGW-CDG: - Not For Real World NavigationSLADE GRAPHICPas encore d'évaluation

- The Drone Technology ResearchDocument9 pagesThe Drone Technology ResearchSibusiso MkhizePas encore d'évaluation

- Duncan Flett Safety ResumeDocument3 pagesDuncan Flett Safety ResumeOsyn KhPas encore d'évaluation

- ASTM For Bend TestingDocument16 pagesASTM For Bend TestingMaha LingamPas encore d'évaluation

- Pannon B2 ANGOL GyakorlofeladatsorokDocument79 pagesPannon B2 ANGOL Gyakorlofeladatsorokruz_agnes100% (1)

- Dear Khun PAWIKA,: Further DetailDocument2 pagesDear Khun PAWIKA,: Further DetailPearwika JansamakaoPas encore d'évaluation

- V-N DiagramDocument3 pagesV-N Diagram2jraj100% (1)

- Air India Express LimitedDocument11 pagesAir India Express LimitedM.ShahnamPas encore d'évaluation

- Preditor Program Cost and Contract OverviewDocument22 pagesPreditor Program Cost and Contract OverviewTom HananPas encore d'évaluation

- Fluid Sloshing in Diaphragm TanksDocument11 pagesFluid Sloshing in Diaphragm TanksrenatobellarosaPas encore d'évaluation

- CSP SPM I0r17tr10002pDocument292 pagesCSP SPM I0r17tr10002probinyPas encore d'évaluation

- 102MEC241Document7 pages102MEC241Syihabuddin Abdul RahmanPas encore d'évaluation

- Learjet 20/30 Series Structural Repair ManualDocument66 pagesLearjet 20/30 Series Structural Repair ManualAlonso Herrera Aguilar100% (1)

- Hydraulics Learning ManualDocument8 pagesHydraulics Learning ManualJebone Stein Web JuarbalPas encore d'évaluation

- HSBA MIC Open Source Review 2014Document11 pagesHSBA MIC Open Source Review 2014Aly VerjeePas encore d'évaluation

- Chualar Plane CrashDocument3 pagesChualar Plane CrashAmy LarsonPas encore d'évaluation

- AN603 - Thruster MountingDocument6 pagesAN603 - Thruster MountingAhmad NazriPas encore d'évaluation

- Boeing 787 - RMDocument15 pagesBoeing 787 - RMKARTIKEYA MISRAPas encore d'évaluation

- Airbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be AssimilatedDocument128 pagesAirbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be Assimilatedejt01Pas encore d'évaluation

- 1696 DroneDocument118 pages1696 DroneEri Dya FadliPas encore d'évaluation

- DD HEL IST BP 21 NovDocument1 pageDD HEL IST BP 21 NovAilincai GeorgePas encore d'évaluation

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterD'EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterÉvaluation : 4 sur 5 étoiles4/5 (468)

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- Simplified Organization: Learn to Love What Must Be DoneD'EverandSimplified Organization: Learn to Love What Must Be DonePas encore d'évaluation

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeD'EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeÉvaluation : 5 sur 5 étoiles5/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingD'EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingÉvaluation : 4.5 sur 5 étoiles4.5/5 (847)

- It's All Too Much: An Easy Plan for Living a Richer Life with Less StuffD'EverandIt's All Too Much: An Easy Plan for Living a Richer Life with Less StuffÉvaluation : 4 sur 5 étoiles4/5 (232)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyD'EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyÉvaluation : 4 sur 5 étoiles4/5 (278)

- Summary of KC Davis's How to Keep House While DrowningD'EverandSummary of KC Davis's How to Keep House While DrowningÉvaluation : 5 sur 5 étoiles5/5 (1)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeD'EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (164)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiD'EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsD'EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsPas encore d'évaluation

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.D'EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Évaluation : 4 sur 5 étoiles4/5 (17)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffD'EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffÉvaluation : 4.5 sur 5 étoiles4.5/5 (578)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsD'EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsÉvaluation : 5 sur 5 étoiles5/5 (339)

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlD'EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlÉvaluation : 4.5 sur 5 étoiles4.5/5 (205)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingD'EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingÉvaluation : 4 sur 5 étoiles4/5 (2997)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeD'EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (67)

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideD'EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideÉvaluation : 5 sur 5 étoiles5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingD'EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingÉvaluation : 4.5 sur 5 étoiles4.5/5 (79)

- Organization Tips That Work: Declutter Your Home In Just 15 Minutes Now!D'EverandOrganization Tips That Work: Declutter Your Home In Just 15 Minutes Now!Évaluation : 4 sur 5 étoiles4/5 (5)

- How to Build a House: A Practical, Common-Sense Guide to Residential ConstructionD'EverandHow to Build a House: A Practical, Common-Sense Guide to Residential ConstructionÉvaluation : 4 sur 5 étoiles4/5 (5)

- The Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeD'EverandThe Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeÉvaluation : 3 sur 5 étoiles3/5 (1)

- Home Decor Cheat Sheets: Need-to-Know Stuff for Stylish LivingD'EverandHome Decor Cheat Sheets: Need-to-Know Stuff for Stylish LivingÉvaluation : 5 sur 5 étoiles5/5 (5)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyD'EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyÉvaluation : 4 sur 5 étoiles4/5 (40)

- Tortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringD'EverandTortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringÉvaluation : 4.5 sur 5 étoiles4.5/5 (52)

- Simply Clean: The Proven Method for Keeping Your Home Organized, Clean, and Beautiful in Just 10 Minutes a DayD'EverandSimply Clean: The Proven Method for Keeping Your Home Organized, Clean, and Beautiful in Just 10 Minutes a DayÉvaluation : 4 sur 5 étoiles4/5 (87)