Académique Documents

Professionnel Documents

Culture Documents

Instalatii

Transféré par

Florentina PaduraruCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

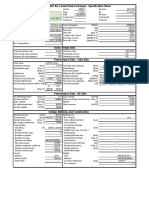

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Instalatii

Transféré par

Florentina PaduraruDroits d'auteur :

Formats disponibles

1.

Civilian and industrial buildings installations classification - Heating installations - Ventilation and air conditioning installations - Sanitary (plumbing) installations - Electrical installations - Natural gas feed installations - Refrigeration installations 2. Interior climate. Comfort parameters. Optimum comfort parameters values . COMFORT CONCEPT THERMAL COMFORT; CHEMICAL AIR COMPOSITION - GENUINE AIR; NOISE LEVEL; ESTHETICHAL DEMANDS - FURNITURE, INTERIOR DECORATIONS, COLOURS. THERMAL COMFORT PARAMETERS Indoor air temperature ti ( 0C); Air velocity vi ( m/s); Medium radiation temperature of space delimitation elements mr ( 0C); Air relative humidity oi ( %). Optimum values for thermal comfort parameters Indoor air temperature ti ( 0C); - SR 1907/2 -1997 - ti =20-22 0C; - Thermal gradient 2,5 0C/m Air velocity vi ( m/s); - Vi=0,1 0,15 m/s Medium radiation temperature of space delimitation elements mr ( 0C); - mr = ti - 6 0C Air relative humidity oi ( %) - Oi= 30- 70 ( %) Ooptimum= 60 ( %) . 3. Heating installations classification. Conventional classifications split heating systems into three groups as follows : LOCAL HEATING SYSTEMS; CENTRAL HEATING SYSTEMS; GLOBAL HEATING SYSTEMS . 4. Heating system classification . Local heating systems. LOCAL HEATING SYSTEMS represent heating systems in which thermal agent is generates in the same place where it is used, in other words, in the rooms that need to be heated. Stoves made of ceramic ware or metal parts. Fireplaces Electrical heaters.

5. Heating system classification . Central heating systems. CENTRAL HEATING SYSTEMS may also be classified as: Hot water heating systems; Steam heating systems; Air heating systems. 6. Heating system classification . Steam heating systems. Steam heating systems may be classified according with the following criteria: By steam pressure low pressure; medium pressure; high pressure. By distribution type superior distribution; inferior distribution. By steam circulation manner free condensation return; forced condensation return. By condensation pipes type dry condensation pipes; wet condensation pipes. 7. Heating system classification . Air heating systems. Air heating systems may be classified according with the following criteria: By the air circulation manner: normal circulation (gravitation) ; forced circulation (fans). By fresh air ratio : re-circulated; fresh; mixed.

8. Heating system classification . Global heating systems. Global heating systems thermal energy is obtained in the same time with electrical energy in high power stations and heat transportation is made using long distance transport networks. By their means: Urban; Industrial.

9. Central heating system components. A central heating system usually contains: - heating source; - distribution network; - indoor heating installation. Thermal energy necessary for a building, or a group of buildings it is obtained in a centralized manner, by a single heating boiler which represents the heating source. 10. Heat load calculation. Heat lost by transitions QT

m thermal mass multiplier for outdoor space delimitating elements; A the area of each space delimitating element, determined according with STAS 6472/3 [m2]; i indoor conventional temperature according with SR 1907 2 [0C]; e outdoor surfaces temperature, [oC], which can be one of the following : outdoor conventional temperature according with the appendix of the present standard; indoor conventional temperature for the adjoining rooms according SR 1907-2; R- corrected specific thermal resistance for the space delimitating element taken into consideration ,established according with STAS 6472/3, [m2 K/W]; Qs- thermal flow lost through ground [W]; CM- heat load correction coefficient, depending on specific construction weight. Thermal mass multiplier for outdoor space delimitating elements is given by the following formula: m = 1,225 0,05 D D thermal inertia coefficient for the space delimitating element according with STAS 6472/3. For the space delimitating elements with D>4.5, we shall consider m = 1 ; for outdoor joinery we shall consider D = 0,5; for the space delimitating elements in contact with the ground as well as the ceilings over not heated basements we shall consider m = 1 11. Heat load calculation. Additions (SA) Ao orientation additional coefficient, for the purpose of differentiating heat load for rooms with diversified exposure to solar radiations; Ac cold surfaces compensating additional coefficient, for the purpose of correcting thermal balance of human body in rooms where space delimitating elements have little specific resistance, it favors increased heat loss by radiation. Orientation additional coefficient, Ao, only affects on the thermal flow lost by space delimitating elements of rooms with underground walls and can have the following values: Cold surfaces effect compensation additional coefficient, Ac, only affects on the thermal flow trough space delimitating elements whose medium thermal resistance ,Rm, does not overrate 10 m2 K/W.

At Total room area (meaning the sum of all delimitating surfaces), [m2]; i, e ,CM i Qt have previous definitions . 12. Heat load calculation. Thermal load necessary for heating the cold infiltrated exterior air Qi Thermal charge for heating air infiltrated by leaky doors or windows, or by opening them, from outdoor to indoor temperature Qi, is determined as maximum value between thermal loads Qi1 and Qi2 [W], where: Qi1 Thermal load for heating, from outdoor to indoor conventional temperature, the air infiltrated by leaky doors and windows, or by opening them, calculated taking into consideration the number of air exchanges necessary to obtain physiological comfort. Qi2 - Thermal load for heating, from outdoor to indoor conventional temperature, the air infiltrated by leaky doors and windows, or by opening them, calculated taking into consideration the conventional wind velocity. Thermal load required for heating the air entered by opening exterior doors from outdoor to indoor conventional temperature,Qu, is given by the following formula: Qu = 0,36 Au n (i - e) CM, [W]; Au total exterior opening doors aria, [m2]; n number of openings per hour, based on particularities of the building; i, e ,CM have previous definitions. 13. Hot water heating systems. Hot water heating system may be classified according with the following criteria: By the manner the heat transfer towards rooms is made : by convection and radiation (static elements heating); by convection (air heating or convectors); by radiation (using radiant panels). By the manner in which the hot water circulation is made : natural (gravitation); forced (pumping). By the number of pipes that supply the heating equipments: double pipes; single pipe. By the type of heating equipments: radiators; floor convectors; registers (horizontal or vertical pipe radiators); curved pipes radiators;

radiant panels. By the manner of preparation, distribution and hot water supply : systems with centralized preparation, distribution and network adapters for apartments (in the case of multi-family house holds); systems with centralized preparation and distribution but individual network adapters using thermal modules for each apartment (in the case of multi-family house holds); systems with individual preparation, distribution and network adapters for apartments (in the case of multi and single family house holds). By the distribution of pipes manner: radiant; tree structure; circular. 14. Heating installation drawings bi-tubular, mixed distribution, open expansion tank and natural circulation

C heating boiler; B water exchanger with accumulation; VED opened expansion tank; CA air discharge pipe; CPP waste pipe; CC connection pipe; CSD safety inlet pipe; CSI safety outlet pipe; 1 distribution inlet pipe; 2 distribution outlet pipe; 3 inlet pipe; 4 outlet pipe ; 5 inlet valve; 6 outlet valve; 7 radiator valve; 8 - radiator; Ca- air discharge pipe.

15. Heating installation drawings bi-tubular, mixed distribution, open expansion tank and forced circulation

C heating boiler; P circulating pump; B water exchanger with accumulation; VED opened expansion tank; CA air discharge pipe; CPP waste pipe; CC connection pipe; CSD safety inlet pipe; CSI safety outlet pipe; 1 distribution inlet pipe; 2 distribution outlet pipe; 3 supply column;

4 return column; 5 connection inlet pipe; 6 connection outlet pipe; 7 radiator valve; 8 - radiator; Ca- air discharge pipe. 16. Heating installation drawings bi-tubular, inferior distribution, closed expansion tank and natural circulation

C - heating boiler; B - water exchanger with accumulation; VEI - closed expansion tank; VA - air separator; R - valve; SS - safety valve.

17. Heating installation drawings bi-tubular, inferior distribution, closed expansion tank and forced circulation

C heating boiler; P circulation pump;

B water exchanger with accumulation; VEI closed expansion tank; VA air separator; R - valve; SS safety valve; Ca air discharge pipe 18. Static heating elements dimensioning The number and size of heating elements is determined in such manner that the heat transferred equals the heat lost, Q, calculated at rated conditions (au pair). The calculation method has ,for all heating types, the same theoretical basis, but it differs by heating elements construction type as follows : Heating elements containing more than one body parts (pieces) (radiators, SP convectors, CRP panel convectors, etc.); Heating elements having as main feature length (curved pipes radiators, registers, plinth convectors etc.); Heating units heating elements with a single component (convectors). The heating element size, expressed as appropriate, in number of body parts n( meters of pipe, or a certain size type for the elements representing an undivided unit) is given by the formula : Qcorp = kSnDtmed, [ W ]; -k represents transfer heat total multiplier of heating elements, expressed in [W/m2 K]; - S is the surface where the heat transfer takes place ,expressed in m2/element, m2/m or m2/ piece; - Dtmed represents the average temperature difference between thermal agent and the room calculating temperature. - room temperature (thermal cell where the testing is made) ti = +20 0C; supply hot water temperature td = +90 0C; return hot water temperature tr = +70 0C; steam temperature ta = + 100 0C. 19. Radiators dimensioning. According with STAS 1797-79 we determine the number of components for a radiator , n, using the formula:

a represents the correction multiplier depending on the number of components of an element, taking into consideration that qn was established for a radiator with 10 components, and that in a bigger radiator, the unit flow decreases; the multiplier a is given by the following formula established experimentally: a = 0,94 + 0,6/n

qn unit nominal thermal power for cast iron radiators 600/200/2 152 W/piece 624/4 - 128 W/piece 218/9 - 124 W/piece ct- correction multiplier for using the radiator for another average temperature difference Dtm than the one established in nominal conditions Cc- correction multiplier for another heat loss of the thermal agent, different by the nominal heat loss; For usual installations, cc = 1 same as for steam installations ; cr correction multiplier based on the connection manner for hot water supplied radiators, a manner which influences thermal agent circulation. Cm- correction multiplier based on the mounting manner of the radiator, which influences the heat transfer by convection by favoring or inhibiting the gravitational air circulation and inhibiting heat transfer by radiation due to screen effect; Ch altitude correction multiplier Cv- correction multiplier based on the paint nature which influences the heat transfer by. It has the value 0,95 for light oil paints, 1 for dark oil paint and 0,9 for metallic pigment paints. The use of aluminum bronze paints is not recommended. The number of components for a radiator resulted from a calculation formula is rounded to an integer. 20. Centralized individual heating. Drawings. Components. Centralized individual heating represents a new concept in heating installations which combines the advantages of individual heating with the performances of collective (centralized) heating. Components: 1. heating source represented by boiler together with the thermal agent preparation and distribution equipment. 2. primary distribution network containing the distribution network placed at the boilers level and the supply column for the thermal-hydraulic modules. 3. thermal-hydraulic module containing measuring, distribution and metering equipments placed in a niche related with each apartment. 4. secondary distribution network or, the so called, individual apartment knot to which heating elements are connected.

I-boiler; II-primary distribution; III-thermal-hydraulic modules; IV-apartment knot I boiler, II primary distribution; III hydraulic module; IV secondary distribution network (apartment knot); 1 - boiler; 2 - thermal agent circulating pump; 3 - distributor; 4 - collector; 5 - supply pipe for primary; 6 - return pipe for primary distribution; 7 - hydraulic module; 8 - inlet; 9 - outlet; 10 - radiator valve; 11 - air valve; 12 - radiator; 13 - supply distribution pipe for secondary network; 14 - return distribution pipe for secondary;

21. Factors that influence on the choice of central heating boilers. total thermal power, respectively necessary heat of the source; type and power of boiler; type of fuel; location of the boiler; automation level. Due to the fact that a boiler must ensure heating, as well as warming the water, based on necessary of heat one can choose one or two boilers. For thermal capacities bigger than 100 KW one will appreciate the need for more that one boiler, even one will take into consideration the need for a spare boiler. Based on the fuel type used, the efficiency of boilers differ, varying between 90% for liquid or gas fuel down to 80% for solid fuel. Location of boiler in a building is decided based on functional and economical criteria, taking into consideration also the gas exhaust (evacuation) and fuel supply. 22. Central heating boilers. Classification. Central heating boiler have the role of transforming fuels chemical energy in thermal energy sing a burner and also transmitting that energy to a thermal agent. Based on the nature of thermal agent: Water boilers; Hot water boiler; Steam boilers. Based on the material they are executed: Cast iron boilers; Steel boilers; Stainless steel boilers. Based on the fuel used: Solid fuel boilers; Liquid fuel boilers; Gas boilers. Based on construction manner: Horizontal boilers; Vertical boilers; Fire-tub boiler; Water tub boiler, etc. By pressure drive: Low pressure; Medium pressure; High pressure. By usage domain: Central heating boilers; Industrial boilers.

23. Central heating boilers. Cast iron boilers. Cast iron sectioned boilers are made from elements assembled by nipples that compose the furnace and the boiler. The material the boiler element is made of is a special type of cast iron ,eutectic, that ensures a homogenous heat transfer, avoiding cracking due to thermal pressure and condensation. 24. Central heating boilers. Steel boilers. Steel sectioned boilers are made of steel seamlesspipes that form convective thermal transfer surfaces. At modern models these surfaces are composed from one seamless pipe pressed in the interior of another one, thus resulting a better thermal connectivity. Through longitudinal ribs of the interior pipe the thermal transfer surface increases 2.5 times comparing with that given by a smooth surfaced pipe. The contact points between the two pipes are proportioned in a manner that, at the posterior part of the boiler, where burned gas temperature is no longer high, heat transfer towards the boiler water decreases, avoiding gas temperature loss below dew point of the vapors contained. 25. Central heating boilers. Condensation boilers. Condensation boilers are in part of the stainless steel boilers category. These type of boilers with heat recovery components, represent a new concept in what concerns the usage of classical fuel types. Thermal efficiency of these boilers is determined based on inferior calorific power of the fuel, which doesnt take account of the latent heat of vapours in the burned gas. If this calculation is applied, for condensation boilers, one can obtain a thermal efficiency bigger than one unit. This aspect might be avoided if thermal efficiency of all boilers should be calculated based on superior calorific power. 26. Modern solutions for boilers- walls integrated units. The apartment boiler is an assembly that includes : the system of producing thermal agent for heating, the system of hot water preparation, pumping system, expansion system, safety system. Apartment boiler are mounted on the wall and can be classified as follows: - based on the burning room type: with open burning room; with closed burning room; - based on burned gas exhausting mode: with natural exhaust gas; with forces exhaust gas; - by hot water hater type: with instant preparation these are made in two variants

:with plate heat exchanger and bi-thermal heat exchanger; with water heater exchanger with accumulation. 27. Heating elements. Classification. Heating elements are those components of a heating installation with the role of transmitting in the room to be heated the heat released be the thermal agent. Heating elements transfer heat in two manners: by convection, trough the air that comes incontact with its surface and by radiation. Based on the main characteristic of the two components, a heating element will be named convector or radiant. Heating elements can be grouped as : static heating elements, where the convective air circulation is natural. This group contains radiators, convector-radiators, and convectors. dynamic heating elements, where the air circulation is activated by mechanical means. This group contains unit heaters, fan coil units and air heater batteries (heating coils) of mechanical ventilation systems. 28. Heating elements. Cast iron radiators. Cast iron radiators are the classical heating elements that use as thermal agent water heated at maximum 115 degrees and maximum pressure 6 bars or steam at up to 0.7bar pressure. 29. Heating elements. Aluminium radiators. Aluminum radiators have particular properties due to material they are made of and to improve fabrication technology. The main qualitative characteristics are design, high thermal efficiency due to increased thermal conductivity of aluminum, reduced water content which diminishes thermal inertia as well as smaller weight and surface occupied comparing to thermal power developed. Constructive, aluminum radiators are available in the range 350, 500, 600, 700, 800 mm which represents the distance between axis. There are models especially designed to solve the heating problem in rooms where the surfaces available for radiators mounting are narrow. The respective radiators heights vary between 900 up to 2000 mm and thermal powertakes value from 235 to 437 W / element . 30. Heating elements. Steel radiators. Steel radiators are made from special iron plates with good properties for coldembossing, with high thermal power. They are produced in two constructive models : a)panel radiators and b) elements radiators. Most used are panel radiators characterized by their high thermal power according to the overall size surface. One radiator contains 1,2 or 3 interior convectors. One panel is formed from two parallel embossed iron sheets, where there are created one distributor and one collector united by vertical channels for thermal agent circulation. Radiators are made by combining these panels and convectors.

31. Heating elements. Fan coils. Heating and air-conditioning were treated as separate systems. The connection element is nowadays the fan coil unit (fan coil) which changes the manner of studying heating and airconditioning as a unit. Fan coil is a terminal element of a heating and/or air conditioning installation which has two basic components: one heating battery (coil) and a fan. Working principle is simple : the outgoing air trough fan is supplied by heating coil in the room. Generally the fan coils are mounted under windows and use the re-circulated air, but there are models that allow interference of fresh air, or exclusive fresh air supply. There are many constructive types: vertical, horizontal, as well as models designed for hidden (masked) mounting in walls or false ceilings, especially in large rooms or if they serve for more than one room . Fan coils with masked mounting in false ceiling previously presented can be used for larger or more than one room. These models come very close as far as functionality and size as the inferior limit of one piece air handling units. Just like these, fan coils use supply and exhaust ducts, air intakes, air diffusers and exhaust air holes. Based on thermal agent used, fan coils allow heating or cooling the air in a room. We must stress that fan coil can function for heating as well as for cooling with the same battery (two pipes fan coils), or can use two separate batteries (four pipes fan coils) , leaving the option of choice to the designing engineer. As construction features, fan coils can haveaccessories as follows: speed adjustment (air flow) fan : in steps (at least 2 + stop) or continuous; water flow adjustment with two or three way tap. Control of air velocity or water flow can be made manually, from the switch, or tap or automatically. Automatic control supposes the existence of an thermostat which allows setting the fan on/off and/or shutting the tap. Evolved systems impose fitting fan coils with a control device that act on the tap of each battery and on the fan. 32. Heating installations pumps. Thermal agents circulation inside heating installations is ensured by circulation pumps. Their role is to overcome linear and local hydraulic resistance in the most unprivileged circuit of the heating installation. For small and medium capacities there are usually used pipe mounted pumps (in-line pumps) with variable speed, low electrical energy consumption, silent and very reliable. The main characteristics of a pump are: fluid flow rate G, expressed in m3 / h and pressure difference between supply and exhaust expressed in N /m2 or in bars. In some cases one uses the notion of : pumping height H as the equivalent of pump pressure expressed in liquid column height. It is also important to know the shaft motors power P, in kw, speed n, supply voltage and electric power frequency. Circulation pumps must always be chosen in such manner that the functioning point places on the characteristic Q/H corresponding to maximum motor speed, in its point ,or closest to maximum efficiency.

Thermal agent flow resulted from calculations can be varied with more pumps in parallel connection. Parallel mounting is currently used for the purpose of achieving a flexible functionality, as well as increased safe exploitation. In the case of two identical pumps parallel mounted in the same network, the common characteristic curve of the two will be obtained by doubling characteristic flows for a certain pumping height. It is also possible the parallel mounting for two pumps with different characteristics, on the condition that maximum pumping height will be the same. Functioning point for the two pumps parallel connected is the intersection point of pumps common characteristic curve with network characteristic curve. Pumps must be chosen in the manner that the functioning point be positioned in the maximum efficiency aria. 33. Opened expansion tanks. In any water heating installation may occur dangerous overpressure situation up to explosion, as consequence of exceeding vaporization temperature. Standard 7132 / 1986 classifies water heating installations with maximum temperature up to 115 0C into two categories: Installations directly related with the atmosphere, provided with opened expansion tank; Installation not related with the atmosphere, provided with safety valves and closed expansion tank. A safety system with opened expansion tank has the following functions : overtaking water volume variations, due to normal temperature variations heating-cooling and ensuring a water reserve which covers for reasonable period of time the small, inevitable loss; exhausting in atmosphere the steam resulted as less supervising the boiler, errors, malpractice, negligence, automation breakdown, etc. maintaining the installation filled, once filled up, up to a level that exceeds higher consumers level, in an inferior distribution installation, respectively, pipe network level, in case of a superior distribution installation; exhausting air during filling up the installation, as well as supplying it during emptying it, in the manner that no air nor water sacs are formed. 34. Closed expansion tanks. For the choice of ensuring heating installations with safety valves and closed expansion tank, safety systems functions are satisfied as follows : overtaking volume variations and the small water reserve by the closed expansion tank; maintaining at full capacity the water in installation by the pressure exerted by the air cushion over the water from the closed expansion tank , which, in this case may be mounted at the inferior part of the installation, close to the boiler; upper limitation of installation pressure using safety valves mounted on the boiler before every shutting element; exhausting air at filling and supplying it at emptying the installation trough ducts, tanks and air valves. Closed expansion tank is provided with an elastic membrane between eater cushion and water

A closed expansion tank is mounted at the inferior part of the installation, close to the boiler. Upper limitation of pressure is made using safety valves mounted on the boiler previous every shutting element. Exhausting air at during filling and supplying air at exhaustion is made with manual or automatic air valves. Constructively, closed expansion tanks can be rectangular, disk, or cylinder type, and their volume vary between 6 up to 5000 liters. 35. Heat exchangers with accumulation. Heat exchangers are units used for hot water preparation for the option of accumulation installation (water heater) as well as without accumulation.Likewise, heat exchangers are used in heating systems for the superior parts of high buildings or for heating buildings part of centralized heating systems that use hot water or stem as primary agent. Water heaters are heat exchangers with water accumulation used for hot water preparation and they are constructed in two shape types: horizontal and vertical. The heat exchange surface, respectively, the coil, will be dimensioned in a manner that will ensure warm water flow in accordance with the temperature difference from the secondary circuit (+10 0C cold water temperature, +60 0C warm water temperature ) and with the temperature difference from the primary circuit. Water heater capacity varies from 80 up to 1000 liters. Water heater body is made from anticorrosive protected steel, and for supplementary cathode protection a magnesium anode is used, or, optionally an anode fed from an external source. Heat losses are diminished by completely covering the heater with a thermal insulated layer.As a construction option, water heaters can performed as bivalent water heaters in systems with solar panels combined with boilers. Heat supplied by the solar panel is transferred in the heater trough the inferior coil. As an option some heaters can be provided with an electrical heating system. Besides the types presented above, there is another constructive model called Tank in Tank, meaning, stainless steel heaters, with high resistance to extremely corrosive water without temperature (fig. 3.26). Stainless steel used is a chrome-molybdenum alloy itch give resistance to all temperatures and corrosive waters up to 2000 mg chlorides/liter. These types of heaters are used for direct sea water heating, for therapy water, residual water in regions with extremely corrosive waters, and they are recommended in industrial applications that use corrosive waters. 36. Heat exchangers without accumulation. Heat exchangers without accumulation. The most common in this range are plate heat exchangers. They are simple devices used for thermal energy transfer between two fluids, made of a pack of identical stainless steel plates, with sealing, aligned at the both superior and inferior part of two supporting pipes between two pressure plates, one of them fixed and another mobile. The pack is sealed withsealing guys. Between the plates a free space is left for fluid circulation; they are kept equidistant from humps, scratches or dimples. Each plate has two walls, one representing the front, the other one the back of the plate.

Fluid 1 flows all along the front of the plat e and bathes it and fluid 2 flows along the back of the same plate, in counter-flow with fluid 1: in this manner the heat is transfer along the entire surface of the plate, while the gaskets tighten the border of the plate and in the same time separate the fluids. Plate heat exchangers are used in heating for thermal points modernization, for heating or preparing heated water, in the heating and cooling processes, in heat recovery, for thermal tests on fluids (e.g. pasteurization) and in situations were working fluids are corrosives( using plates executed from austenitic stainless steel, resistant to corrosives environments). Stainless steel plates are 0,5 0,6 mm thick, which allows achieving a very good transmission coefficient as well as a reduced thermal emission, but also lead the fluid in the heat exchanger. They are made of rubber resistant at up to 150 0C temperature (propyl-ethylene), silicon rubber or food industry rubber . 37. Low temperature radiation heating systems. Classification Radiant floor heating by including heating elements inside the floor ; Radiant ceiling heating - by including heating elements inside the ceiling; Radiant wall heating by including heating elements or radiant panels (opened or closed radiant panels ) inside the walls. Using delimitating elements of a surface as radiant elements imposes, from physiological reasons, the limitation of surface temperatures as follows : 40 0 C for ceiling heating; 29 0 C for floor heating; 70 0 C for walls heating. 38. Low temperature radiation heating systems. Radiant floor heating. Radiant floor heating installations have the following components: the heating floor panel; distributors-collectors (which are the common element of more heating circuits); adjustment equipment ; thermal energy source. A radiant floor panel contains: the insulation layer (for thermal and acoustic insulation); the insulation protection layer ; heating pipes ; thermal flow allotment and emission slab (heating slab); final floor ; other elements, such as : diffusion layer, marginal insulation, etc. The temperature at the floor level is limited, from physiological reasons at up to +30 0C, based on the destination of the room. 39. Low temperature radiation heating systems. Radiant ceiling heating. This type of heating system allows achieving a more homogenous air temperature, as well as a

more reduces air circulation, which are considered important advantages as far as thermal comfort is concerned. For the heating surface the hole ceiling is available ,except for the cases where there are large windows (glass surface) when supplementary heating surfaces will be added (for example inside the exterior walls). Main advantage is given by elimination of exterior heating elements, thus obtaining more free space, more architectural freedom. The space gained, for social buildings, can be considered an important space saving. Another advantage is given by the option of cooling the ceiling during summer, thus a reversible ceiling. This system is very reliable in museums, showrooms or commercial places. Due to hygienic advantages, the system is preferred in hospitals, nursing homes, medical centers. The possibility of reversing ceiling heating, meaning cooling during summer represents a big gain for choosing this system in administrative and office buildings. 40. Low temperature radiation heating systems. Radiant walls heating. Transforming walls into heating surfaces by integrating a curved pipes system, is possible taking into consideration the following aspects: exterior walls require supplementary thermal insulation; there is always the chance of piercing the pipe , specially in apartment buildings (e.g. with paintings supports); placement of furniture will rest rict the radiant thermal flow of the walls. Radiant wall heating can be used in different variants : individually; in combination with radiant floor heating system; in combination with radiators heating system. 41. Low temperature radiation heating systems. Curved pipes used for radiant panels construction. The mounting rails system ensures rising the pipe up to 5mm, and thus a minimum height for the cement layer. Sustaining clamps and clips guarantee a solid fixing of the pipe. Border insulation Before the slab, along the walls, an insulating strap will be laid, around frames and pillars. Insulation will be laid from the base floor (sub floor) till the final floor, allowing a maximum displacement of 5 mm. 42. Ventilation and air conditioning installations.Classification. VENTILATION SYSTEMS NORMAL VENTILATION MECHANICAL VENTILATION

43. Normal ventilation. Classification Unorganized normal ventilation systems ventilation is accomplished by opening doors and windows, by leaky rooms, offices, warehouses, working places, etc. Organized normal ventilation systems ventilation is made through gaps or special constructions, windows, scuttles, ventilation chimneys in kitchens, bathrooms, industrial buildings,etc. 44. Mechanical ventilation. Classification General mechanical ventilation systems uses fans for air circulation that serve the entire building and make the circulation for the entire air volume in industrial buildings, social, cultural, commercial, administrative, etc. Local mechanical ventilation systems act on the air supply source, sweeps the air around the source, absorbs the harmful substances before the air comes back in the room (industrial furnaces, weld tables, industrial zinc bathing, varnish removals, grinders, wood processing etc.) . Mixed mechanical ventilation systems apply both general and local ventilation. 45. Basic drawings for a mechanical ventilation installation.

46. Basic drawings for a general ventilation installation.

47. Basic drawings for a cooling ventilation installation.

48. Drawings of a ventilation installation with dehumidification.

49. Drawings of a ventilation installation with dehumidification without fresh air supply.

50. Drawings of Installation with air handling unit.

51.Components of a ventilation installation. General information. A ventilation installation contains: air ventilation unit ; duct (pipe) network; ventilation grids ; regulating devices; 52. Components of a ventilation installation. Air handling units. Air ventilation units Air ventilation units are placed in specially designed places, in the interior or exterior of buildings Air ventilation units introduce fresh air. They contain modules in which equipments are mounted. Casing Dampers Filters Heat exchangers (coils) Heat recovery devices Humidifiers Fans and Motors Casing Aluminum frame with rounded corners

Panels slotting directly into the frame No fixing screws Panels 50 mm sandwich panels injected polyurethane insulation (42 kg/m3 foam density) or mineral wool (40 kg/m3 or 100 kg/m3) Special executions for fan section extra noise Reduction SYNTHETIC PREFILTERS: G2 metallic (eff. 75%, EU2) G3 (efficiency 85%, EU3) G4 (efficiency 90%, EU4) BAG FILTERS Rigid or soft bags Class F7 Class F9 Available Filters: Absolute filters Roll filters Carbon filters Electrostatic filters UV lamps Heat exchangers (coils, batteries): Water coils DX coils Steam coils Electric coils Plate Heat Exchangers: Efficiency: 50-70% G4 prefilter (fresh air) as standard Drain Pan Recirculation damper By-Pass damper Adiabatic Humidification: PVC wet deck with/without recirculating pump Paper wet deck with/without

recirculating pump Water+Compressed Air High Pressured Air Air Washer Steam Humidification steam manifold in stainless steel AISI 304 with or without steam producer Plug fans: Backward-curved blades Direct-driven fans Very easy to clean 53. Components of a ventilation installation. Fans. Fans contain : -chassis with two connection pieces :for air inlet and outlet -rotor with blades depending on fan type -electric engine for rotor actuation Fans can be : - centrifugal (radiant ) - axial flow 54. Components of a ventilation installation. Air filters. Filters know different types: - Filters with air filter cells .One cell contains a metallic case filled with metallic perforated foils impregnated with mineral oil, overlapped. Cells are placed in a rack. - Dry band filters .At superior part a coil with synthetic fiber filter is attached .At the inferior part there is the coil that rolls the dirty. The material ,which creates a screen through which the dusty air passes, rolls between the two coils. - Self-cleaning filters .Filter is made of cells cleaned in an oil bath. 55. Components of a ventilation installation. Heating coils. Are made of a wings pipes fascicle in an iron case with flanges to which ducts are connected. Trough ducts steam or hot water flow and between them circulates the air that heats due to heat transfer by ducts contact. 56. Components of a ventilation installation. Heat recovery. a) Wheel heat recovery The most used is wheel recuperator. At the case the ducts for cold and warm air are connected.

Rotor contains a heat accumulation surface with the looks of a honeycomb with small channels parallel with the rotation axis. At small speed, the rotor offers the two air flows ,warm and cold, a heat exchange surface. Rotor accumulates heat in contact with hot air which the transmits it to the cold air, after rotating. At the edge of the two flows there is a purification sector, with clean air for cleaning ducts where noxious air flows. In order to increase the heat exchange, the rotors surface is covered in a solution containing lithium chlorate, which is an excellent absorber. Due to this substance rotor also absorbs vapors from the warm air which it transfers to cold air. Due to lithium chlorate and the fact that heat accumulation mass comes alternatively in contact with both air flows, wheel recuperator achieves a total heat transfer, thus resulting in a high thermal efficiency. In order to be mounted in the ventilation systems, wheel recuperators require a meeting point for the cold and warm air ducts, where heat exchanger should be mounted. b) Intermediate fluid heat recovery system c) Plate heat recovery The device is made of parallel plates installed in a case. Plates are mounted at small distances, forming narrow, parallel channels for cold and warm air circulation. Plates are mounted in manner that allows cold and warm air an alternative circulation. Heat transfer is made through plates surfaces. 57. Components of a ventilation installation. Ventilation ducts. Ventilation pipes contain : straight ducts special pieces : bends, branches, level change pieces, diffusers ,confusers, etc. Used materials : - black or galvanized sheets; plastic materials , mineral fibers plates , etc. Ducts shape : circular or rectangular . Ducts dimensions ( diameters , sides ) are standard. 58. Components of a ventilation installation. Air grids. This category includes : discharge openings,intakes, air intakes, exhaust air grids. Discharge openings are posed in openings executed in walls, or ahead of supply air ducts. 59. Components of a ventilation installation. Regulating devices. Regulating devices are mounted inside the ducts , or in the discharge openings. - wings dumpers , mounted inside ducts , made from a rigid plate sheet which rotates around a central fixed axis; -branch dumpers , mounted inside branch pieces, made from a rigid plate sheet which rotates around an axis fixed at one border; -shut off dumpers , mounted inside ducts or at discharge openings; -adjustable blinds .

Vous aimerez peut-être aussi

- "Gheorghe Asachi" Technical University of Iasi Faculty of Civil Engineering and Building ServicesDocument19 pages"Gheorghe Asachi" Technical University of Iasi Faculty of Civil Engineering and Building ServicesFlorentina PaduraruPas encore d'évaluation

- Building Services Installations CourseDocument286 pagesBuilding Services Installations CourseFlorentina PaduraruPas encore d'évaluation

- DR Youngs Complete Whole Body Alkalizing Program PromoDocument20 pagesDR Youngs Complete Whole Body Alkalizing Program PromoSteven J DeaversPas encore d'évaluation

- There Are No Incurable DiseasesDocument25 pagesThere Are No Incurable DiseasesRajesh Kumar100% (2)

- RuraleDocument2 pagesRuraleFlorentina PaduraruPas encore d'évaluation

- Building Services Installations CourseDocument286 pagesBuilding Services Installations CourseFlorentina PaduraruPas encore d'évaluation

- Grinda Precomprimata Flo-ModelDocument1 pageGrinda Precomprimata Flo-ModelFlorentina PaduraruPas encore d'évaluation

- Column StrengtheningDocument1 pageColumn StrengtheningFlorentina PaduraruPas encore d'évaluation

- Composites As High Performance Building SolutionsDocument5 pagesComposites As High Performance Building SolutionsFlorentina PaduraruPas encore d'évaluation

- FermaDocument1 pageFermaFlorentina PaduraruPas encore d'évaluation

- Column StrengtheningDocument1 pageColumn StrengtheningFlorentina PaduraruPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 210928-Beierde-CO2 Water Filling PlantDocument21 pages210928-Beierde-CO2 Water Filling PlantHuong NguyenPas encore d'évaluation

- Direct and Indirect Evaporative CoolingDocument10 pagesDirect and Indirect Evaporative CoolingSloba H TD-VR-BG-MOSPas encore d'évaluation

- Alfa Laval Fresh Water GeneratorDocument131 pagesAlfa Laval Fresh Water GeneratorOvidiu Petcu80% (5)

- VRF DVM S Troubleshooting GL en 2016 Ver1 14Document190 pagesVRF DVM S Troubleshooting GL en 2016 Ver1 14El Manú ManúPas encore d'évaluation

- Heat Exchanger EfficiencyDocument10 pagesHeat Exchanger EfficiencyFrancois BornmanPas encore d'évaluation

- Heat Exchangers: Applications & Classifications Applications of Heat ExchangersDocument5 pagesHeat Exchangers: Applications & Classifications Applications of Heat Exchangersmz_haqPas encore d'évaluation

- Blow DownDocument94 pagesBlow DownManit Siriworasilp100% (1)

- 20160969Document7 pages20160969Dr.AhmedPas encore d'évaluation

- Tirupati Pipe and Allied Industries PVTDocument4 pagesTirupati Pipe and Allied Industries PVTpareshwaniPas encore d'évaluation

- FX Dryer BrochureDocument8 pagesFX Dryer Brochureblacx_rzkyPas encore d'évaluation

- Double Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDDocument31 pagesDouble Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDBashir AliPas encore d'évaluation

- Thermodynamic Modeling of Absorption Heat PumpDocument99 pagesThermodynamic Modeling of Absorption Heat PumpvidmantasPas encore d'évaluation

- Informacoes de ProdutoDocument196 pagesInformacoes de ProdutoGustavo CâmaraPas encore d'évaluation

- York Chiller YcivDocument80 pagesYork Chiller Ycivatiq100% (1)

- TECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame ExchangerDocument4 pagesTECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame Exchangerdilip matalPas encore d'évaluation

- Aqua Cooler Industrial Process Chiller Brochure 2009Document8 pagesAqua Cooler Industrial Process Chiller Brochure 2009Nitin NarendranPas encore d'évaluation

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryPas encore d'évaluation

- Design Operation of Full-Scale Anaerobic Dairy Manure Digester 1979Document85 pagesDesign Operation of Full-Scale Anaerobic Dairy Manure Digester 1979MrWolf23Pas encore d'évaluation

- Minor Project ppt-1Document27 pagesMinor Project ppt-1Ankit ChandelkarPas encore d'évaluation

- Condenser Maintenance and OperationDocument340 pagesCondenser Maintenance and Operationkalyan1967100% (3)

- Heat Transfer DR - JamalDocument11 pagesHeat Transfer DR - JamalJuan David FlórezPas encore d'évaluation

- AT-05197 - HYSYS - Study Guide - 2 PDFDocument8 pagesAT-05197 - HYSYS - Study Guide - 2 PDFahmedPas encore d'évaluation

- EjectorsDocument7 pagesEjectorsashirwad shetty50% (2)

- REFFIPLANT Training CourseDocument76 pagesREFFIPLANT Training CourseKESAVARAPU UMA SAI MAHESHPas encore d'évaluation

- Chapter 3 Vapour Compression Refrigeration Systems L1Document22 pagesChapter 3 Vapour Compression Refrigeration Systems L1Toke BekelePas encore d'évaluation

- Flow Induced Vibration in Heat ExChangersDocument7 pagesFlow Induced Vibration in Heat ExChangersamrandconanPas encore d'évaluation

- Jun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan XuDocument10 pagesJun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan Xunarendar.1Pas encore d'évaluation

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- 02 Semi Continuous DeodorizingDocument8 pages02 Semi Continuous DeodorizingMaicon Espindola Dos SantosPas encore d'évaluation

- Thermoeconomic Analysis of Organic RankineDocument14 pagesThermoeconomic Analysis of Organic RankinePower Power100% (1)