Académique Documents

Professionnel Documents

Culture Documents

Packers and Flowmeters

Transféré par

Sudeep SharmaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Packers and Flowmeters

Transféré par

Sudeep SharmaDroits d'auteur :

Formats disponibles

BIH

OCEAN DRILLING PROGRAM

w w w. o c e a n d r i l l i n g . o r g

Scientic Application

Packers A packer is an inatable rubber element that inates to seal the annular space between the drill string and the borehole wall. While there are different types of packers, ODP runs one, or two in tandem assemblies, on drill string into a

Reentry Cone

pre-existing ~9 in. hole (cored, drilled, or cased) and inates it with seawater to hydraulically isolate a borehole section from the annulus and tidal effects of the open ocean. Isolating the borehole from the open ocean allows measurement of pore pressure and in situ hydrological properties of the

formation. Formation uids may be sampled if the formation is permeable. It is possible to derive formation permeability and porosity in an isolated open-hole section using a straddle packer (i.e., two packers) by applying pump pressure with pulse, slug, or constant-rate injection tests.

Seafloor

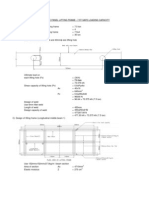

Casing Hangers 20 or 16 in. casing (Jet-In 60-80 mbsf) 9 in. Annulus 16 or 10 in. casing (cemented) Packer Control Sub Packer Go-Devil 3.89 in. w/ Press Recorder Straddle Interval 1-9+ m Packer Lower Test Interval Low Permeability Zone in. Packer Fill Line Fluid Sample & Injection Flowmeter Test Interval Logging Wireline

Go-Devil 3.99 in. w/ Press Recorders

Low Permeability Zone

Total Depth

SINGLE PACKER

STRADDLE PACKER

Schematic compares Straddle and Single Packers in a borehole. The Straddle Packer uses two packers to isolate a test interval between them, and the packers can be moved and reset. A second interval can be tested as well from the bottom packer to total depth. The Straddle Packer is used for hydrological testing as well as pulse and constant rate injection tests. The Single Packer uses one packer and tests the entire borehole below the packer. A owmeter is shown on the logging wireline in the Single Packer schematic.

Leg 118 Hole 735B Go-Devil #2

16 16

length. Pressure gages can be run to conrm the seal. A straddle packer incorporates two separate packers to span the test interval so it can be sampled or exposed to injection tests. The packers are separated by 1 to 9 m long drill pipe pup joint(s). The interval between the straddle packers and the interval from the bottom packer to the bottom of the hole can be tested separately. The straddle packer elements are connected by in. stainless steel tubing (strapped on the outside the drill pipe spacer) to ensure that neither element can be inated if there is a hydraulic failure. A pressure recorder can be hung below the lower Go-Devil to test for leakage from the straddled interval. Flowmeters A owmeter is run on the wireline to measure the ow rate of the uid pumped into the hole. The ow rate can be measured throughout the open hole. Within cased hole, the ow rate is 100%. Below the casing, ow rates decrease as a portion of the uid ows into the formation, providing information about permeability in the borehole (i.e., ow rate decreases below high permeability sections).

Packer at 389 mbsf

14

299 mbsf

233 mbsf

14

12

12

Slug test #8

Slug test #9

Pressure (MPa)

Hydrostatic

10

10

Slug test #10-#13

Move packer

Slug test #14-#15

Injection test #4

Hydrostatic

Move packer

Hydrostatic

Time (hr) Graph of a packer injection test taken during Leg 118 showing pressure at the recorder depth vs. time. The chart shows the hydrostatic pressure, the pressure buildup from pumping water into the formation, and the subsequent pressure decay (fall-off) after pumping ceases. The rate of pressure decay indicates the relative permeability of the exposed interval (with adjustments for interval height, viscosity, etc.). The packer was moved to test different intervals in this chart.

The 8 to 8 in. outer diameter (OD) packer element can be expanded to as much as twice the uninated diameter (~16 in.); however, full ination produces a weaker hydraulic seal that withstands less differential test pressure. Effective formation testing in an open hole requires that all packers be positioned in low-permeability borehole sections that are relatively in-gage and have smooth bores. Wireline logs such as caliper, borehole televiewer, resistivity, density, and sonic logs are typically run before packer tests to identify permeable test intervals and good seal sections. The logging information allows the bottom-hole assembly (BHA) and packer(s) to be spaced out accordingly. Logs and experiments

can be run through an uninated packer; however, wireline operations through an inated packer require special safety measures because the packer grips the borehole wall. The packer immobilizes the BHA, but the top of the pipe at the rig oor can still move up and down, requiring drill string heave compensation to avoid tearing the packer loose. The drill string packer can be run in several combinations: A single-element packer is used to isolate the interval below the packer to the bottom of the hole. Two packers can be run together, acting as a single packer to increase the seal

Tool Operation

Packer Operation The packers typically used by ODP are made by TAM International, Inc., of Houston, Texas. The 8 in. TAM packer assembly consists of an internal steel strength member, an expandable internal rubber bladder, and an 8 to 8 in. OD outer rubber cover. A Go-Devil

The seawater presses the rubber bladder outward to grip and seal against the borehole wall. The bladder cover has an embedded expandable (woven stainless steel) strength member. Drill string packer(s) are run on the drill string as part of the BHA and are positioned over the desired interval based on logging depths. When the drill string is freely suspended without heave compensation (running in and out of the hole), the packer element(s) remain uninated. When the packer is in position, a wireline retrievable Go-Devil with two GRC (vendor) pressure recorders (covered with a special core barrel and retaining catcher) is free-fall deployed and pumped down the drill string at ~200-250 gpm to increase the speed. The Go-Devil lands in a seating nipple at the packer, and a hydrostatic pressure baseline is recorded for 10-15 min. The rig pumps are typically used to inate the packer element(s) with seawater to ~1200 to 1500 psi maximum. When the packer elements inate and start to grip the borehole wall, air is bled off the heave compensator, which lowers the drill string to set down ~15,000 lb weight on the packer (~12,000 lb of weight/1000 psi of test pressure) to prevent packer movement from the piston effect of test pressures. To inate and deate a packer, a Packer Control Sub is used. It also provides a way to run a pressure instrument in the hole. The Packer Control Sub has an internal control tube that connects two or more packers hydraulically. Lowering the drill string ~20 cm (8 in.) shifts the packer control sleeve

down, isolates the inated packer element, and opens the bore to the interval below the upper packer. The heave compensator is positioned at mid-stroke, and ~1520 min is required for the pressure pulse to decay. A typical set-down weight of 15,000 lb requires a BHA of approximately six 8 in. drill collars above the packer. ODP recommends running several drill collars below the packer to help set it. The packer elements are not designed to support much more than ~15,000 lb weight. Formation uids may be sampled before pump tests if the formation is permeable enough. Go-Devils can be used to activate multiple packers and open or close valves for formation testing. The GoDevil and pressure recorders are retrieved with the coring wireline. After formation testing is completed, the packer(s) are deated by using the heave compensator to pull the drill string upward and open the deation ports. The straddle packer element deates passively in ~30 min, and it can be moved and reset (~2-3 times) if the element is not damaged. When straddle packers are used, pulse, slug, or constant-rate injection tests may be run to determine the formation transmissivity (from which permeability can be derived) and (less accurately) storage coefcient. Storage coefcient is directly related to formation porosity. The cementing-unit pump is typically used to apply pressure (~500 to 1500 psi) to the isolated open-hole section. Test pressures typically do not exceed 1500 psi (unless formation hydro-fracture is attempted), and pump rates typically do not exceed 3-5 bbl/min. All pumped

Single Packer

Straddle Packer

Figure shows examples of a straddle and single TAM packer. A straddle packer assembly consists of two single packers separated by a 1-9 in. perforated spacer.

plug is dropped down the drill pipe and lands in a seating nipple in the pipe (see Packer Control Sub gure). The Go-Devil seals the drill pipe so pump pressure can inate the packer bladder with seawater pumped down the drill string.

(injection) volumes should be measured using a standpipe meter or the volume tanks on the cementing unit. Pressure pulses may require up to 30 min to decay, and multiple tests (2 to 4) may be run. Flowmeter Operation A owmeter/sinker bar/Go-Devil assembly can be run on the logging wireline. After inating the packer, the logging line is sheared off the Go-Devil by pressuring up to 2000 psi. The owmeter is lowered below the packer (~50 m) and calibrated by pumping at several rates. Flowmeter readings typically are taken at 10 m intervals (to total depth [TD]) for ~10-20 min at each interval. The owmeter/ Go-Devil assembly is retrieved by wireline.

Packer Inflation Mode

Inflation Differential Pressure Inflation Equalization Port Port

TSP Inflation Element

Go-Devil

Seating Nipple

Seals

Circulation Port

Circulation Mode (with drill pipe slacked off)

Schematic of the Packer Control Sub on the TAM Straddle Packer (TSP) showing ination and circulation ow paths.

eter (ID), connection 5 in. IF box up and pin down Minimum ID: Single packer 3.94 in., Straddle nonrotating packer 3.84 in., and rotating packer 3.84 in. Packer Ination Pressure: typically ~500 to 1000 psi (~half of planned test pressure), 1500 psi maximum Set down weight on packer: ~12,000 lb weight/1000 psi test pressure, 15,000 lb maximum Drill string movement to shift control tube: ~20 cm (8 in.) Typical Packer BHA: 9 to 9 in. bit, crossover, 1 joint 5 in. drill pipe, 8 in. packer, crossover, ~5 each 8 in. OD drill collars, tapered drill collar, crossover to 5 in. drill pipe. BHA length ~70 m, weight ~18,000 lb Pressure Recorders GRC Pressure Recorders The GRC pressure recorder is typically set for 10,000 measurements per day. It is run below

the Go-Devil in a special core barrel tube with a retaining catcher. Kuster Pressure Recorders (for backup) Kuster model K-3 mechanical self-contained pressure recorders are available in three pressure ranges (0-9925, 0-11900, and 0-15275 psi) and can record for 9, 18, or 36 hours. For a single packer, two K-3 recorders are free-fall deployed inside a 12 ft long inner core barrel tube attached to the Go-Devil. For straddle packers, one K-3 recorder is attached to the lower Go-Devil and one or two to the upper Go-Devil. Surface Pressure Recorder A Gould PG3000 pressure transmitter (0-5000 psi) is installed at the standpipe to provide a realtime pressure record.

Design Features

1) Compatibility The drill string packer BHA is compatible with wireline logging tools. Benet: It may be possible to accomplish both logging and packer measurements during a single pipe trip. 2) Multiple Tests A packer can be set, moved, and reset (up to three times) if the element is not damaged. Benet: Multiple tests can be attempted during one trip in the hole.

Specications

Packer TAM International, Inc., model TAMJAY Packer, 8 in. OD element, stroked out length 3.12 m (10.2 ft), 3.97 in. internal diam-

Typical Operating Range

Temperature Packer elements and seals are rated to ~100C. Special high-

temperature elastomers (i.e., packer elements and inner seals) rated to 120C were used (Leg 111 Hole 504B) at temperatures of 120-145C, but lasted for only one setting. Depth Limit: None

Limitations

Packer Damage The rubber elements on packers are made of elastomers that can be damaged by contact with jagged formations. Moving a set packer before it has relaxed back to normal size may damage the element.

Hole Damage from Packers The packer expands with hydraulic force to rmly contact the formation; however, over-ination can fracture the formation or burst the packer element. Packers can also reduce the hydrostatic pressure, causing a formation to ow or cave-in, resulting in stuck pipe. Temperature The packer elements are made of an elastomer that has an operating temperature range of 100-120C.

TAM Nonrotating Packer The TAM drill string straddle packers are a nonrotating design that is deployed with the drill string. They should be kept in tension and are not compatible with a coring and rotating BHA; therefore, a separate trip is required to run the packer. TAM Rotatable Packer The TAM rotatable packer was designed for use as a single packer for testing and drilling ahead; however, tests (Legs 110, 123, and 130) indicate that it may be more suitable for tests in unstable pre-drilled reentry holes that may require some reaming or cleanout.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- NBS Q10 - 110 Proprietary Precast Concrete Kerb - Edges - ChannelDocument8 pagesNBS Q10 - 110 Proprietary Precast Concrete Kerb - Edges - ChannelSudeep SharmaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 20 Words That Describes Emotions We Can Feel But Just Can't Explain - Expanded ConsciousnessDocument3 pages20 Words That Describes Emotions We Can Feel But Just Can't Explain - Expanded ConsciousnessSudeep SharmaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- All Along - Idioms - by The Free Dictionary, Thesaurus and EncyclopediaDocument2 pagesAll Along - Idioms - by The Free Dictionary, Thesaurus and EncyclopediaSudeep SharmaPas encore d'évaluation

- STABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsDocument4 pagesSTABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsSudeep SharmaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Strike and Dip: Jaime Marso 11/1/2004Document17 pagesStrike and Dip: Jaime Marso 11/1/2004Putri Rafika DewiPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Underground Railway TunnelingDocument38 pagesUnderground Railway TunnelingSudeep SharmaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Patanjali Yoga Sutras - Knowledge Sheet 58 - Meditation Beats Boredom.Document5 pagesPatanjali Yoga Sutras - Knowledge Sheet 58 - Meditation Beats Boredom.Sudeep SharmaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Pressuremeter TestDocument39 pagesPressuremeter TestSudeep SharmaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Geotechnical Research TopicsDocument1 pageGeotechnical Research TopicslearnafrenPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- ChineseDocument1 pageChineseSudeep SharmaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Prophet (Book)Document54 pagesThe Prophet (Book)Sudeep SharmaPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- MM4455US PartsandAccessories2013Document32 pagesMM4455US PartsandAccessories2013Edgar HuimanPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Engines Teaching ManualDocument151 pagesEngines Teaching ManualSenthil Muthu Kumar TPas encore d'évaluation

- User Manual Whirlpool AWO - D 41115 (English - 14 Pages)Document3 pagesUser Manual Whirlpool AWO - D 41115 (English - 14 Pages)Bojan TorbicaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Morgan CatalogueDocument114 pagesMorgan CatalogueGurcharan SinghPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- 177232D1Document6 pages177232D1Muhammad Usman SindhuPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Pump SelectionDocument4 pagesPump SelectionmhmdjdgmailcomPas encore d'évaluation

- Siemens Contactor - Fuse CombinationDocument42 pagesSiemens Contactor - Fuse CombinationBill CaiPas encore d'évaluation

- Research Report - Land PollutionDocument9 pagesResearch Report - Land PollutionMisbah GroupPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Barbieri.a New Environmentally Friendly Process For The Recovery of Gold From Electronic WasteDocument8 pagesBarbieri.a New Environmentally Friendly Process For The Recovery of Gold From Electronic Wastep3lu_Pas encore d'évaluation

- Overview of Liquid Metal MHD Power SystemsDocument6 pagesOverview of Liquid Metal MHD Power SystemsdenisekrsePas encore d'évaluation

- An Experimental Study On The Use of Eggshell Powder As A PH Modifier: Production of Lime From EggshellsDocument3 pagesAn Experimental Study On The Use of Eggshell Powder As A PH Modifier: Production of Lime From EggshellsAnonymous lAfk9gNPPas encore d'évaluation

- Graseby® MS26 Syringe DriverDocument60 pagesGraseby® MS26 Syringe DriverMarcel GhidusulPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- Alfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureDocument6 pagesAlfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureEmmaPas encore d'évaluation

- Chemistry Project FileDocument12 pagesChemistry Project FileSahil MohammedPas encore d'évaluation

- Lifting FrameDocument8 pagesLifting FrameSaravanan SKPas encore d'évaluation

- Method Statement For Site Handling of Concrete Made With GGBSDocument2 pagesMethod Statement For Site Handling of Concrete Made With GGBSabobeedoPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Elements of Water Distribution SystemDocument1 pageElements of Water Distribution SystemjocelPas encore d'évaluation

- Link 8Document6 pagesLink 8Diego MtzPas encore d'évaluation

- GCM 79-Introduction PDFDocument8 pagesGCM 79-Introduction PDFGunk SuryoPas encore d'évaluation

- (M) B (M) T (M) (M) (Ton) (Ton)Document5 pages(M) B (M) T (M) (M) (Ton) (Ton)Maniac VolleyballPas encore d'évaluation

- Hattersley CatalogDocument64 pagesHattersley CatalogMaaz Junaidi100% (1)

- Solid Shell Connection in Finite Element AnalysisDocument21 pagesSolid Shell Connection in Finite Element AnalysisvilukPas encore d'évaluation

- FMC Elevator BucketsDocument11 pagesFMC Elevator BucketscesarPas encore d'évaluation

- Zephyr 20S Spare Parts ManualDocument42 pagesZephyr 20S Spare Parts Manualmircomirco100% (1)

- Technical Specification PaintingDocument10 pagesTechnical Specification PaintingSandip ShahPas encore d'évaluation

- PSHJ0009-01 HcoDocument26 pagesPSHJ0009-01 Hcogustavo arayaPas encore d'évaluation

- 8 Chemical Effects of Electric CurrentDocument5 pages8 Chemical Effects of Electric Currentandrew andrewPas encore d'évaluation

- PQT LG Lk-0525ccDocument229 pagesPQT LG Lk-0525ccGerardo Zamorano100% (2)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Bioethanol Technology PDFDocument16 pagesBioethanol Technology PDFMd. Saimon IslamPas encore d'évaluation