Académique Documents

Professionnel Documents

Culture Documents

Design and Implementation of Energy Management System With Fuzzy Control For DC Microgrid Systems

Transféré par

jaackson10Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Implementation of Energy Management System With Fuzzy Control For DC Microgrid Systems

Transféré par

jaackson10Droits d'auteur :

Formats disponibles

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 28, NO.

4, APRIL 2013 1563

Design and Implementation of Energy Management

System With Fuzzy Control for DC Microgrid

Systems

Yu-Kai Chen, Member, IEEE, Yung-Chun Wu, Chau-Chung Song, and Yu-Syun Chen

AbstractThis paper presents the design and implementation

of an energy management system (EMS) with fuzzy control for a

dc microgrid system. Modeling, analysis, and control of distributed

power sources and energy storage devices with MATLAB/Simulink

are proposed, and the integrated monitoring EMS is implemented

with LabVIEW. To improve the life cycle of the battery, fuzzy

control manages the desired state of charge. The RS-485/ZigBee

network has been designed to control the operating mode and to

monitor the values of all subsystems in the dc microgrid system.

Index TermsEnergy management system (EMS), fuzzy con-

trol, microgrid.

I. INTRODUCTION

W

ITH increased awareness of the depletion of traditional

energy sources and environmental damage caused by

increased carbon dioxide emissions from coal-red power gen-

eration, the use of renewable energy has become the goal for

energy development. Current green energy used in power gener-

ation includes: solar, wind, geothermal, biomass, and tidal [1].

Many countries have set a goal of increasing the usage of renew-

able energy above 20% of their total power consumption by the

year 2020. In addition, distributed power systems are subject to

the effects of environmental factors and restrictions of nature.

A general power system uses battery energy storage to avoid a

power outage or power surges caused by natural environmental

factors. The recent trend of renewable energy development is

a combination of distributed power sources and energy storage

subsystems to form a small microgrid [2], [3] that can reduce

loss of energy from power transmission lines over long dis-

tances. Renewable energy is converted into dc and buffered

with energy storage elements, and then it is inverted to ac and

fed into the utility grid. This approach can readily adapt to ex-

isting electrical facilities and expedite use of renewable energy.

However, existing high efciency and compact appliances and

equipment are powered by dc, which is converted by rectifying

Manuscript received March 31, 2012; revised May 17, 2012; accepted July

12, 2012. Date of current version October 26, 2012. This work was supported by

the National Science Council, Taiwan, under Project 101-3113-P-194-002 and

Project 101-2623-E-150-002ET. Recommended for publication by Associate

Editor Y.-K. Lo.

The authors are with the Department of Aeronautical Engineering, Na-

tional Formosa University, Yunlin 632, Taiwan (e-mail: ykchen@nfu.edu.tw;

jingballast@yahoo.com.tw; ccsong@nfu.edu.tw; gmezx@nfu.edu.tw).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TPEL.2012.2210446

Fig. 1. Conguration of the proposed dc microgrid system with EMS.

an ac source with power actor correction. To use renewable en-

ergy more efciently, dc electricity should be directly supplied

to these loads. Such a supply scheme is far different from that

of the conventional ac distribution and supply system. A con-

guration of the dc-distributed system with grid connection is

shown in Fig. 1, in which a bidirectional inverter is introduced

to regulate dc-grid voltage within a certain range.

DC-distributed systems were applied to data centers [4][14],

which reduced power loss by around 7%, saved 33% of space,

reduced facility investment by about 15% and increased reli-

ability by about 200% [1]. Additionally, low voltage (24 V)

ceiling-grid applications, especially for lighting, were also de-

veloped [15][19]. There are several research groups [20][33],

which have extended the high voltage (380 V) dc-distribution

system to drive home appliances, of which the elegant power

application research center (EPARC) has built a demonstra-

tion house for testing the overall system operation. In this pa-

per, the system conguration including green power generator,

energy storage element, dc appliance and equipment, and en-

ergy management system (EMS) with a fuzzy controller will be

introduced.

In the development of the green energy systems, a control

method is required to optimize energy distribution of a microgrid

system. Therefore, model construction is necessary for solar

energy, wind power, and storage devices, such as lithium-ion

0885-8993/$31.00 2012 IEEE

1564 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 28, NO. 4, APRIL 2013

batteries, to simulate dynamic changes of the renewable energy

for optimal energy distribution.

Fig. 1 shows the dc microgrid system in this study, composed

of solar power, wind power generation, lithium-ion battery, dc

load, and ac/dc converter. The proposed EMS was commanded

with RS-485/ZigBee [34], [35] network for data communica-

tion and delivery of energy distribution instructions. The design

concept of this study was to increase the useful life of lithium

batteries and to include charge and overdischarge protection

mechanisms.

As shown in Fig. 1, the system conguration includes ve

major blocks: power generator, energy storage equipment, dc-

bus regulator, dc load, and EMS. The power generator typically

includes PV panels, wind turbines, and fuel cells. The fuel cells

provide base power for the emergency loads when the system is

operated during a power failure. Maximum power point track-

ers are associated with PV panels and wind turbines to draw

maximum power, which is fed into the dc grid. The dc loads

are connected to the dc grid and supplied from the grid directly.

If there is power shortage, the bidirectional inverter will take

power from the ac grid and it is operated in rectication mode

with power factor correction to regulate the dc-grid voltage

within a range of 380 20 V.

If there is a power failure, the Li-ion battery will be rst

discharged to supply power for a short-time interval and if the

failure lasts longer (e.g., 2 min), the fuel cell will start supplying

power. Note that the battery discharger will be also responsible

for dc-grid voltage regulation if the bidirectional inverter is not

in operation. If the bidirectional inverter is in operation, the

battery can be charged.

If there is residual power on the dc grid, the battery can be

charged depending on its status, and/or the bidirectional inverter

can be operated in grid-connection mode to sell power and regu-

late dc-grid voltage to 380 20 V. The overall systemoperation

will be monitored and controlled by the EMS, so each module in

the system has to communicate with the EMS based on RS-485

or ZigBee communication protocol. The EMSwill command the

modules when to operate and collect operational status. How-

ever, in emergency situations, such as excessive current, voltage

or temperature, the modules will protect themselves without a

command from the EMS, but the modules still have to inform

the EMS of their current status.

The proposed fuzzy control is to optimize energy distribution

and to set up battery state of charge (SOC) parameters. The

control algorithm takes the priority of selling electricity as the

premise of energy distribution to allow remaining power gener-

ated by the renewable energy of the electrical grid sold through

the connected mains grid.

II. MODELING OF GREEN ENERGY COMPONENTS

To verify the accuracy of the designed controller, a dynamic

model of the proposed microgrid system is necessary. The mod-

eling of dc microgrid distributed energy and energy storage com-

ponents was mainly built by MATLAB simulink mathematical

modules, based on equivalent circuits of the components. The

following describes the model of each subsystem in detail.

Fig. 2. Solar panel equivalent circuit.

A. Modeling of Solar Cell

Solar panel equivalent circuit is shown in Fig. 2.

Solar panel current equation can be expressed by (1)(3)

I

pv

= n

p

I

ph

n

p

I

rs

_

exp

_

q

kTA

V

pv

n

s

_

1

_

(1)

where V

pv

is output voltage of solar panels, I

pv

is output current

of solar panels, n

s

is number of solar panels in series, n

p

is

number of solar panels in parallel, k is the Boltzmann constant

(1.38 10

23

J/K), q is electron charge (1.6 10

19

C), A is

ideality factor (12), T is surface temperature of the solar panels

(K), and I

rs

is reverse saturation current.

In (1), the characteristic of reverse saturation current I

rs

varies with temperature, as expressed by (2)

I

rs

= I

rr

_

T

T

r

_

3

exp

_

qE

g

kA

_

1

T

r

1

T

__

(2)

where T

r

is the reference temperature of the solar panels (K), I

rr

is reverse saturation current of the solar panels at temperature T

r

(K), and E

g

is energy band gap of the semiconductor material

I

ph

= [I

scr

+ (T T

r

)]

S

100

(3)

where I

scr

is the short-circuit current at reference temperature

T

r

and illumination intensity 1 kW/m

2

, is the short-circuit

current temperature coefcient of the solar panels, and Sis the

illumination intensity (kW/m

2

).

This study used Sharp NUS0E3E solar modules, each with

a power rating of 180 W, as the photovoltaic device of the mi-

crogrid system. This study used a solar 5 kW power system,

generated by two photovoltaic arrays in parallel, where each ar-

ray was built with 14 solar panels in series. The simulated output

power versus output voltage of the solar cell is shown in Fig. 3.

This study used constant illumination intensity 1 kW/m

2

and

constant temperature with varying V

pv

for simulation

verication.

B. Wind Turbine Modeling [36], [37]

The power generated by wind turbine is expressed as

P

W

= 0.5AV

3

C

P

(,) (4)

where P

W

is power generated by the wind turbine W, P is

density of gas in the atmosphere (kg/m), A is cross-sectional

area of a wind turbine blade m

2

, V is wind velocity (m/sec), and

C

p

is the wind turbine energy conversion coefcient.

CHEN et al.: DESIGN AND IMPLEMENTATION OF ENERGY MANAGEMENT SYSTEM WITH FUZZY CONTROL FOR DC MICROGRID SYSTEMS 1565

Fig. 3. Simulated output power P

PV

versus output voltage V

PV

of the solar

cell with constant illumination intensity 1 kW/m

2

.

Fig. 4. Simulated output power P

W

with various wind speeds V.

The density of gas and energy conversion coefcient C

P

in

(4) is expressed by (5) and (6), respectively

=

_

353.05

T

_

exp

0.034(

Z

T

)

(5)

C

p

(, ) =

_

116

i

0.4 5

_

0.5 exp

1 6 . 5

i

(6)

where Z is the altitude, T is the atmospheric temperature,

i

is

the tip speed ratio, and is the blade tilt angle.

Equation (7) gives the expression of the tip speed ratio

i

in

(6) and (8) is the expression of the initial tip speed ratio in (7)

i

=

1

1/( + 0.089) 0.035/(

3

+ 1)

(7)

= r

V

. (8)

The wind turbine used in this study was AWV-1500 of Gallant

Precision Machining Company, Ltd. Wind speed is the most

critical factor in wind power generation. This simulated output

power P

W

of the wind turbine with various wind speeds V is

shown in Fig. 4.

C. Lithium-Ion Battery Modeling

Eq. (9) is the discharge equation and (10) the charge equation

of the lithium-ion battery

f

1

(it i

i) = E

0

K

Q

Qit

i

K

Q

Qit

it

+ A exp( B it) (9)

Fig. 5. Simulation results with constant discharge of 5 A.

f

2

(it i

i) = E

0

K

Q

it + 0.1 Q

i

K

Q

Qit

it

+ A exp( B it) (10)

where E

0

is initial voltage (V), K is polarization resistance (),

i

is low-frequency dynamic current (A), i is battery current (A),

itis the battery extraction capacity (Ah), Q is maximum battery

capacity (Ah), A is exponential voltage (V), B is exponential

capacity (Ah)

1

.

SOC of the battery is an important factor, which is calculated

by

SOC = 100

_

1

_

t

0

idt

Q

_

. (11)

This study simulated with constant discharge of 5 A for vali-

dation and observation of SOC variation. The results are shown

in Fig. 5. The battery voltage is easy to measure and implement

in the circuit. From the simulated results, we can see the nonlin-

earity between voltage and SOCof the Li-ion battery. Therefore,

the SOC parameter of batteries has been selected as the design

factor instead of battery voltage in this paper.

D. Fuel Cell Modeling

Fuel cells provide a high efciency clean alternative to todays

power generation technologies. The polymer electrolyte mem-

brane (PEM) fuel cell has gained some acceptance in medium

power commercial applications such as creating backup power,

grid tied distributed generation, and electric vehicles [1]. The

output voltage E of the PEM fuel cell is represented as

E = E

n

(V

act

+ V

ohm

+ V

con

) (12)

where E

n

is Nernst voltage, V

act

is the activation overpoten-

tial, V

ohm

is ohmic overpotential, and V

con

is concentration

overpotential

V

act

=[

1

+

2

T +

3

T ln(C

O

2

)+

4

T ln(i

f

)] (13)

V

ohm

= i

f

R

M

(14)

R

M

=

181.6

_

1+0.03(i

f

/A

f

)+0.062(T/303)

2

(i

f

/A

f

)

2.5

[

1

0.634 3(i

f

/A

f

)] exp [4.18((T 303)/T)]

l

1

A

f

(15)

1566 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 28, NO. 4, APRIL 2013

Fig. 6. Simulated voltage of the fuel cell with a constant discharge of 10 A.

V

con

= B

0

ln

_

1

J

J

max

_

(16)

where T is operating absolute temperature, Co

2

is concentra-

tion of oxygen, if is output current of the fuel cell,

1,2,3,4

are

reference coefcients, l

1

is effective thickness of membrane,

1

is adjustable coefcient, A

f

is effective area, B

0

is operating

constant, J is current density, and J

max

is maximum current

density.

The simulated output voltage with constant discharge of 10A

is shown in Fig. 6.

III. INTELLIGENT ENERGY MANAGEMENT SYSTEM

As shown in Fig. 1, the system conguration of the proposed

dc microgrid system includes ve major blocks. To design an

accurate controller of the proposed microsystem, the dynamic

mathematical models of the power sources (PV, wind turbine,

and fuel cell), dc/dc converters (buck-boost, buck, and phase-

shifted full-bridge converters), bidirectional converter (sym-

metrical full-bridge converter), and bidirectional inverter (full-

bridge inverter) of the integrated micro-system are necessary.

However, the modeling, analysis, and design of the proposed in-

tegrated dc microsystem are not simple. To maintain the battery

SOC with EMS, the fuzzy controller is needed to meet design

specications, because the control for EMS is a low response

component and the models of dc/dc converters, dc/ac converters

of the micro-dc microgrid systemare unnecessary. Additionally,

the dc microsystem is a nonlinear system and fuzzy logic can

offer a practical way for designing nonlinear control systems.

Fuzzy control theory is designed and implemented in EMS

for the dc microgrid system to achieve the optimization of the

system. The design criterion requires that both the photovoltaic

device and the wind turbine are supplied by a maximum power

point tracker to maintain the maximum operating point. The

difference between actual load and total generated power is

taken into account for Li-ion battery in charge and discharge

modes. The life cycle and SOC of the battery are in direct

proportion. To improve the life of the Li-ion battery, we can

control and maintain the SOC of battery with fuzzy control.

Fig. 7. Block diagram of fuzzy control to maintain the desired SOC of the

battery.

A. Fuzzy Control

Fuzzy theory was rst proposed in 1965 by Lot. A. Zadeh,

an American scholar of automatic control, as a tool of quanti-

tative expression for concepts that could not be clearly dened.

A fuzzy control system is based on fuzzy-logic thinking in the

design of how a controller works. The so-called fuzzy logic

is to establish a buffer zone between the traditional zero and

one, with logic segments of none-zero and none-one possible.

It allows a wider and more exible space in logic deduction

for the expression of conceptual ideas and experience. A fuzzy

controller differs from a traditional controller in that it em-

ploys a set of qualitative rules dened by semantic descriptions

[38][40].

The fuzzy controller is applied in the proposed microgrid

power supply system, as shown in Fig. 7. To obtain the desired

SOC value, the fuzzy controller is designed to be in charging

mode or discharging mode for the proposed microgrid system.

The input variables of the fuzzy control are SOC and P

and output variable is I. The denition of input and output

variables are listed as follows:

SOC = SOC

command

SOC

now

(17)

P = P

L

(P

wind

+ P

pv

). (18)

The power difference P is between required power for load

and the total generated power of the microgrid. The fuel cells

only provide base power for the emergency loads when the

system fails. Therefore, the fuel cell is not considered as power

source in (18). The generated power comes from solar power

P

pv,

wind turbine P

wind

and power load P

L

for the proposed

system. The input and output membership functions of fuzzy

control contain ve grades: NB (negative big), NS (negative

small), ZO (zero), PS (positive small), and PB (positive big),

as shown in Figs. 8 and 9. By input scaling factors K

1

and K

2

,

we can determine the membership grade and substitute it into

the fuzzy control rules to obtain the output current for charge

and discharge variance I of the Li-ion battery. If the P is

negative, it means that the renewable energy does not provide

enough energy to the load. Thus, the battery must operate in

charging mode; if the SOC is negative, it means that the SOC

of the battery is greater than the demand SOC. Thus, the battery

must operate in discharge mode.

CHEN et al.: DESIGN AND IMPLEMENTATION OF ENERGY MANAGEMENT SYSTEM WITH FUZZY CONTROL FOR DC MICROGRID SYSTEMS 1567

Fig. 8. Input membership functions of variables: (a) P and (b) SOC.

Fig. 9. Output membership function of variable I.

The control rules of this study prioritize selling additional

electricity generated by the renewable energy in response to the

present control strategy of microgrid development for selling

electricity and increasing the life of Li-ion batteries. Table I

shows the fuzzy rules of the proposed system. For example, the

output variable I is PB (the degree of discharging current is

large) when the input variable P is NB (the amount of elec-

tricity to sell is large) and input variable SOC is NS (greater

than the SOC command and the membership degree is small).

However, the output variable I is NS (the degree of charging

current is small) when the input variable P is NB (the amount

of electricity to sell is large) and input variable SOC is PS

(smaller than the SOC command and the membership degree is

small). The output variable is NS instead of NBwhen the system

is operated in the above conditions because selling electricity

is the rst priority in this case. Thus, the fuzzy control table of

the proposed dc microgrid system is not symmetrical. To extend

the life of storage batteries in the design of fuzzy control, the

fuzzy control rules are set to maintain battery SOC above 50%.

Moreover, in the fuzzy control rules the Li-ion battery is forced

to discharge as the control strategy when power demand at load

was greater than the power generated by the renewable energy.

B. Illustration Example

The dynamic model of the proposed dc microgrid system

using MATLAB simulink is shown in Fig. 10, where the system

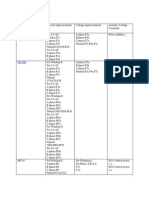

TABLE I

FUZZY CONTROL RULES

Fig. 10. Dynamic model of the microgrid system using MATLAB simulink.

Fig. 11. Simulation results with initial battery SOC at 10%.

consists of a 5 kW solar module, a 1.5 kWwind turbine module,

a 1.5 kW Li-ion battery module, and a 6.5 kW load.

This example veries the accuracy of the proposed system

with fuzzy controller that can maintain the SOC of the battery

at a certain level whether initial value of the SOC is low or high.

As shown in Fig. 11, the fuzzy controller Li-ion battery SOC is

maintained at 50% with an initial value of 10%. As shown in

Fig. 12, the fuzzy controller Li-ion battery SOC is maintained

at 50% with an initial value of 90%.

To control strategy of this study is to sell electricity as a

priority and to maintain battery SOC. Fig. 13 shows that the

fuzzy controller forced the Li-ion battery to discharge when P

was greater than 5 kW to keep the system in power equilibrium

without going over the power rating of the bidirectional inverter

subsystem. However, the SOC of the battery is not the rst

priority to achieve the safety when the inverter is over the power

rating.

1568 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 28, NO. 4, APRIL 2013

Fig. 12. Simulation result with initial battery SOC at 90%.

Fig. 13. Simulation results when the bidirectional inverter rating is over the

power rating.

Fig. 14. RS-485 half-duplex test signals.

Fig. 15. Intelligent EMS operating screen.

Fig. 16. Integrated testing of the dcmicrogrid system.

Fig. 17. Measured dc-bus voltage V

dc

and battery current I

b

waveforms of

the proposed dc microgrid system.

IV. IMPLEMENTATION OF EMS

The proposed fuzzy EMS using LabVIEW graphic software

was implemented to control and monitor the proposed dc micro-

grid system. The communication interface for each subsystem

includes wireless ZigBee and RS-485. When receiving system

commands from the fuzzy controller of EMS, each unit exe-

cuted corresponding actions and replied with signals to EMS.

The system converted the signals into monitoring data for dis-

play and database documentation in realization of an intelli-

gent EMS. The energy management system used RS-485 net-

work topology for half-duplex network communication. The

RS-485 network topology consists of RS-232 and UART of

each unit to formthe communication interface. Additionally, the

ZigBee wireless communication was implemented with XBee

module. Fig. 14 shows a data frame in which the EMS sends

commands to a subsystem and the subsystem replies to the

system. With three power sources: solar cell, wind turbine,

and fuel cell are connected, and implemented in DC micro-

grid system with fuzzy control using LabVIEW, as shown in

Fig. 15. Fig. 16 shows the integrated testing of the proposed dc

microgrid system. Fig. 17 shows the measured transient

CHEN et al.: DESIGN AND IMPLEMENTATION OF ENERGY MANAGEMENT SYSTEM WITH FUZZY CONTROL FOR DC MICROGRID SYSTEMS 1569

waveforms of dc-bus voltage V

dc

and battery current I

b

of the

dc microgrid system with fuzzy control. From the measured

results, we can see that the battery current is regulated by the

fuzzy controller and the dc bus is regulated to 380 20 V.

V. CONCLUSION

This paper presents the modeling, analysis, and design of

fuzzy control to achieve optimization of an energy manage-

ment system for a dc microgrid system. From the simulation

results, the system achieves power equilibrium, and the battery

SOC maintains the desired value for extension of battery life

by using the control rules for a dc microgrid. Additionally, the

optimization rules can be included in the intelligent microgrid

management system, and the system can conduct data com-

munication and control operating status of subsystems via the

RS-485/ZigBee network. The management system takes advan-

tage of the design to control microgrid with power equilibrium,

and achieves optimal control of the dc microgrid system.

REFERENCES

[1] H. Rongxian, L. Zhiwen, C. Yaoming, W. Fu, and R. Guoguang, DC

micro-grid simulation test platform, in Proc. 9thTaiwan Power Electron.

Conf., 2010, pp. 13611366.

[2] S. Morozumi, Micro-grid demonstration projects in Japan, in Proc.

IEEE Power Convers. Conf., Apr. 2007, pp. 635642.

[3] Y. Uno, G. Fujita, R. Yokoyama, M. Matubara, T. Toyoshima, and

T. Tsukui, Evaluation of micro-grid supply and demand stability for

different interconnections, in Proc. Power Energy Conf., 2006, pp. 611

616.

[4] Experience in Developing and Promoting 400 V DC Datacenter Power,

T. V. Aldridge, Director, Energy Systems Research Lab, Intel Corporate

Technology Group, Green Building Power Forum, Jun. 2009.

[5] Maximizing Overall Energy Efciency in Data Centres, S. Lidstrom, CTO,

Netpower Labs AB, Green Building Power Forum, Jun. 2009.

[6] Renewable Energy & Data Centers, J. Pouchet, Director Energy Initia-

tives, Emerson Network Power., Green Building Power Forum, Jun. 2009.

[7] Development of Higher Voltage Direct Current Power Feeding System

in Data Centers, K. Asakura, NTT Energy/Environment, Green Building

Power Forum, Dec. 2010.

[8] Specications for 400 V DC Power Supplies and Facility Equipment,

D. Symanski, Sr. Program Manager, Electric Power Research Institute,

Keiichi Hirose, NTT Facilities, and Brian Fortenberry, Program Manager,

Electric Power Research Institute, Green Building Power Forum, Jan.

2010.

[9] Development of a DC Power Inlet Connector for 400 V DC IT Equipment,

B. Davies, Director of Engineering, Anderson Power Products, Inc. Green

Building Power Forum, Jan. 2010.

[10] Development of Socket-outlet Bar and Power Plug for 400 V Direct Cur-

rent Feeding System, T. Yuba, R&D Manager, Fujitsu Components Ltd.

Green Building Power Forum, Jan. 2010.

[11] Power Inlet Connector for 380 V DC Data Center, B. Davies, Anderson

Power Products, Green Building Power Forum, Dec. 2010.

[12] Intel Labs New Mexico Energy System Research Center 380 V DC Mi-

crogrid Testbed, G. Allee, Intel Labs, Green Building Power Forum, Dec.

2010.

[13] International Standardization of DC Power, K. Hirose, NTT Facilities,

Green Building Power Forum, Dec. 2010.

[14] R. Simanjorang, H. Yamaguchi, H. Ohashi, K. Nakao, T. Ninomiya,

S. Abe, M. Kaga, and A. Fukui, High-efciency high-power DC-DC

converter for energy and space saving of power-supply system in a data

center, in ProcAppl. PowerElectron. Conf., 2011, pp. 600605.

[15] Direct Powered DC Lighting Technologies, J. Busch, Commerical Engi-

neer, Osram Sylvania Inc. Green Building Power Forum, Jun. 2009.

[16] An Exploration of the Technical and Economic Feasibility of a Low-

Powered DC Voltage Mains Power Supply in the Domestic Arena, M. C.

Kinn, University of Manchester, Green Building Power Forum, Jun. 2009.

[17] DC Input Dimmable Fluorescent Ballast, T. Ribarich, Vice President,

International Rectier, Green Building Power Forum, Jun. 2009.

[18] Low-Voltage DC Interconnection, J. Akins, Director of Business Devel-

opment, Tyco Electronics, Green Building Power Forum, Jan. 2010.

[19] Advantages of Low-Voltage DC Power in Commercial Building Interi-

ors, B. Graham, President, Projects/Design & Construction Division of

Johnson Control, Green Building Power Forum, Jan. 2010.

[20] DC Distribution and the Home of the Future, B. Fortenbery, Program

Manager, Electric Power Research Institute, Green Building Power Forum,

Jun. 2009.

[21] DC Nanogrid for Sustainable Building, D. Boroyevich, F. Wang, F. C.

Lee, I. Cvetkovi c, D. Jiang, T. Thacker, and D. Dong, Center for Power

Electronics Systems, The Bradley Department of Electrical and Computer

Engineering, Virginia Polytechnic Institute and State University, Green

Building Power Forum, Jun. 2009.

[22] Optimizing Efciency and Reliability of DC Branch Circuits in Build-

ings, D. Mulvey, Executive VP, Roal Electronics USASession 2 Emerge

Alliance Activities, Green Building Power Forum, Jan. 2010.

[23] M. B. Camara, B. Dakyo, and H. Gualous, Polynomial control method of

DC/DCconverters for DC/DCconverters for DC-Bus voltage and currents

management-battery and supercapacitors, IEEE Trans. Power Electron.,

vol. 27, no. 3, pp. 14551467, Mar. 2012.

[24] B. Liu, S. Duan, and T. Cai, Photovoltaic DC-building-module-based

BIPV system-concept and design considerations, IEEE Trans. Power

Electron., vol. 26, no. 5, pp. 14181429, May 2011.

[25] DC Power Systems for Sustainable Buildings, I. Cvetkovic, Virginia Poly-

technic University, Green Building Power Forum, Dec. 2010.

[26] Concept of Fukuoka Smart House - Achievement of Hybrid System in

Renewable Energy and Grid, Y. Nakamura, Smart Energy Laboratory,

Green Building Power Forum, Dec. 2010.

[27] A Modication Guideline for Electrical Appliances Compatible with DC

Distribution Systems, K. Choi, Seoul National University, Korea, Green

Building Power Forum, Dec. 2010.

[28] H. Kakigano, A. Nishino, Y. Miura, and T. Ise, Distribution voltage

control for DC microgrid by converters of energy storages considering

the stored energy, in Proc. Energy Conv. Congr. Expo., 2010, pp. 2851

2856.

[29] L. Zhang, T. Wu, Y. Xing, K. Sun, and J. M. Gurrero, Power control of

DC microgrid using DC bus signaling, in Proc. Appl. Power Electron.

Conf., 2011, pp. 19261932.

[30] T.-F. Wu, K.-H. Sun, C.-L. Kuo, and G.-R. Yu, Current distortion im-

provement and DC-link voltage regulation for bi-directional inverter in

DC-microgrid applications, in Proc. Appl. Power Electron. Conf., 2011,

pp. 15821587.

[31] D. Dong, F. Luo, W. Zhang, D. Boroyevich, P. Mattavelli, I. Cvetkovic,

L. Jiang, and P. Kong, Passive lter topology study of single-phase AC-

DC converters for DC nanogrid applications, in Proc. Appl.Power Elec-

tron. Conf., 2011, pp. 287294.

[32] A. Stupar, T. Friedli, J. Minib ock, M. Schweizer, and J. W. Kolar, To-

wards a 99% efcient three-phase buck-type PFC rectier for 400 V DC

distribution systems, in Proc. Appl.Power Electron. Conf., 2011, pp. 505

512.

[33] I. Cvetkovic, D. Boroyevich, P. Mattavelli, F. C. Lee, and D. Dong, Non-

linear, Hybrid Terminal Behavioral Modeling of a DC-based Nanogrid

System, in Proc. Appl. Power Electron. Conf., 2011, pp. 12511258.

[34] Y. F. Wang, W. Mao, J. Li, P. Zhang, and X. Wang, A distributed rectier

testing system based on RS-485, in Proc. IEEE Int. Conf. Ind. Electron.

Appl., Jun., 2010, no. 5, pp. 779781.

[35] W. Baosheng, Acontrollable rectier wind and solar hybrid power system

based on digital signal processor developed, M.S. thesis in electrical en-

gineering, National Taiwan University of Science and Technology, Taipei,

Taiwan, 2009.

[36] L. Zhengmin and C. Mingzong, Small stand-alone wind turbine device

characteristics analysis, M.S. thesis in electrical engineering, Southern

Taiwan University of Science and Technology,Tainan, Taiwan, vol. 35,

May 2010.

[37] R. Bharanikumar and A. N. Kumar, Analysis of wind turbine driven PM

generator with power converter, Int. J. Comput. Electr. Eng., vol. 2, no. 4,

pp. 766769, Aug. 2010.

[38] R.-J. Wai and L.-C. Shih, Adaptive fuzzy-neural-network design for

voltage tracking control of a DCDC boost converter, IEEE Trans.

Power Electron., vol. 27, no. 4, pp. 21042115, Apr. 2012.

[39] M. F. Naguib and L. Lopes, Harmonics reduction in current source con-

verters using fuzzy logic, IEEE Trans. Power Electron., vol. 25, no. 1,

pp. 158167, Jan. 2010.

[40] F.-J. Lin, M.-S. Huang, P.-Y. Yeh, H.-C. Tsai, and C.-H. Kuan, DSP-based

probabilistic fuzzy neural network control for li-ion battery charger,

IEEE Trans. Power Electron., vol. 27, no. 8, pp. 37823794, Aug. 2012.

1570 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 28, NO. 4, APRIL 2013

Yu-Kai Chen (S98M99) was born in Chiayi,

Taiwan, in 1967. He received the B.S. degree in

electronic engineering from Feng Chia University,

Taichung, Taiwan, in 1990, the M.S. degree in in-

formation and electronics engineering from National

Central University, Chungli, Taiwan, in 1994, and the

Ph.D. degree in electrical engineering from National

Chung Cheng University, Chiayi, in 1999.

From 1994 to 1999, he was a Lecturer with the

Department of Electronic Engineering, Wu Feng In-

stitute of Technology, Chiayi. He was an Associate

Professor with the Department of Electrical Engineering, Chien kuo Institute of

Technology, Changhua, Taiwan, from 1999 to 2003. Since 2003, he has been

with the Department of Aeronautical Engineering, National Formosa Univer-

sity, Huwei, Taiwan, where he is currently a Professor. His research interests

include modeling and control of dc/dc converters, design of solar panel-supplied

inverters for grid connection, and DSP- and microprocessor-based application

systems with fuzzy and robust control.

Yung-Chun Wu was born in Kaohsiung, Taiwan,

in 1971. He received the Ph.D. degree in electrical

engineering from National Chung Cheng University,

Chiayi, Taiwan, in 2000.

From 2000 to 2001, he was an Assistant Professor

with the Department of Electrical Engineering, Chien

kuo Institute of Technology, Changhua, Taiwan. He

was an Assistant Professor with the Department of

Electrical Engineering, I-Shou University, Kaohsi-

ung, from 2001 to 2007. Since 2007, he has been

with the Department of Aeronautical Engineering,

National Formosa University, Huwei, Taiwan, where he is currently an Assis-

tant Professor. His research interests include developing and designing converter

topologies, electronic ballasts, and high-efciency converter.

Chau-Chung Song received the M.S. degree in

control engineering, in 1994, and the Ph.D. degree

in electrical and control engineering from National

Chiao Tung University, Taiwan, in 2001.

He has been with the Department of Aeronauti-

cal Engineering, Institute of Aviation and Electronic

Technology, National Formosa University, Huwei,

Taiwan, since 2006, where he is currently an As-

sociate Professor. His research interests include the

analysis and control of nonlinear systems, the power

electronics and energy applications, the networking

integration of information and communication technology, the embedded mi-

croprocessor systems and the automotive networking communication, and elec-

tronic control systems for electric vehicle.

Yu-Syun Chen was born in Taipei, Taiwan, in 1987.

He received the B.S. degree in aeronautical engineer-

ing from National Formosa University, Huwei, Tai-

wan, in 2009, where he is currently working toward

the Masters degree.

His research interests include the power electron-

ics and energy applications, the maximum power

point tracking for PV system, and microprocessor-

based application systems.

Vous aimerez peut-être aussi

- Grid Connected Converters: Modeling, Stability and ControlD'EverandGrid Connected Converters: Modeling, Stability and ControlPas encore d'évaluation

- Renewable Energy Sources - Combined Notes For The Lecture SeriesDocument231 pagesRenewable Energy Sources - Combined Notes For The Lecture Seriesravith88100% (1)

- Energy Output Estimation For Small-Scale WindDocument15 pagesEnergy Output Estimation For Small-Scale WindWangi Pandan SariPas encore d'évaluation

- Soon Ching ChunDocument45 pagesSoon Ching ChunDivyabharathi Janakiraman100% (1)

- Relyay Test ReportsDocument209 pagesRelyay Test Reportsjaackson10Pas encore d'évaluation

- Integration of Green and Renewable Energy in Electric Power SystemsD'EverandIntegration of Green and Renewable Energy in Electric Power SystemsPas encore d'évaluation

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977D'EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Pas encore d'évaluation

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Converter-Based Dynamics and Control of Modern Power SystemsD'EverandConverter-Based Dynamics and Control of Modern Power SystemsÉvaluation : 2 sur 5 étoiles2/5 (1)

- Final Year Project 30 AprilDocument25 pagesFinal Year Project 30 AprilTobaPas encore d'évaluation

- Report On Solar PV TechnologiesDocument16 pagesReport On Solar PV Technologiessagar paneliyaPas encore d'évaluation

- Seminar ShajeeDocument27 pagesSeminar ShajeeMohammad Shajee Quasmi0% (1)

- Energy Harvesting Tree ReportDocument14 pagesEnergy Harvesting Tree ReportAnonymous R3xiiFkXN8100% (1)

- Energy Conversion PDFDocument20 pagesEnergy Conversion PDFpushpendra singhPas encore d'évaluation

- Solar Power Plant DesignDocument28 pagesSolar Power Plant DesignKarthik SengodanPas encore d'évaluation

- Chapter 2Document14 pagesChapter 2Harsha VardhanPas encore d'évaluation

- MHD Power GenerationDocument15 pagesMHD Power GenerationMANN BATTISEPas encore d'évaluation

- Under Water WindmillDocument23 pagesUnder Water Windmillapi-343773957100% (2)

- Tese Grid Connected PV 2001Document124 pagesTese Grid Connected PV 2001chauhan303Pas encore d'évaluation

- Grid-Connected PV System Case StudyDocument7 pagesGrid-Connected PV System Case StudyHayan JanakatPas encore d'évaluation

- Unit 4 Smart GridDocument21 pagesUnit 4 Smart GridMutharasu SPas encore d'évaluation

- V S DDocument17 pagesV S DveguruprasadPas encore d'évaluation

- Transient Stability Analysis of Hybrid Power System: ElectricalDocument15 pagesTransient Stability Analysis of Hybrid Power System: ElectricalSumit DubeyPas encore d'évaluation

- Cost-Effective Design of A Hybrid Solar PV-Genset Power Supply System For A Small Rural Community (Zuro-Kpumi) Using HOMERDocument6 pagesCost-Effective Design of A Hybrid Solar PV-Genset Power Supply System For A Small Rural Community (Zuro-Kpumi) Using HOMERInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- RE Grid Integration and Distributed Generation Specialization Syllabus - 100916Document8 pagesRE Grid Integration and Distributed Generation Specialization Syllabus - 100916malini72Pas encore d'évaluation

- Solar Micro ControllerDocument18 pagesSolar Micro ControllerElangovanPas encore d'évaluation

- Example 3: A 7.5-hp 120-V Series DC Motor Has An Armature Resistance of 0.2 Ohm and ADocument3 pagesExample 3: A 7.5-hp 120-V Series DC Motor Has An Armature Resistance of 0.2 Ohm and Ahakkı_aPas encore d'évaluation

- Electrical Drives NotesDocument6 pagesElectrical Drives Noteskaushik9595Pas encore d'évaluation

- Utilization of Electrical Energy (1-100) 11Document100 pagesUtilization of Electrical Energy (1-100) 11Gopala Krishna YadavPas encore d'évaluation

- Experiment 10Document3 pagesExperiment 10toshi12Pas encore d'évaluation

- PV System AnalysisDocument5 pagesPV System AnalysisklguuPas encore d'évaluation

- Radial Feeder ProtectionDocument6 pagesRadial Feeder ProtectionSrivalli ReddyPas encore d'évaluation

- Application of Solar EnergyDocument202 pagesApplication of Solar EnergyAbdou BouzianePas encore d'évaluation

- 2-Stability and Reliability Improvement in Solar Wind Hybrid Power System With Battery Energy Storage StationDocument9 pages2-Stability and Reliability Improvement in Solar Wind Hybrid Power System With Battery Energy Storage StationEngrImranKhanPas encore d'évaluation

- Syncronous DQ PV Grid ControlDocument95 pagesSyncronous DQ PV Grid ControlAlex RochaPas encore d'évaluation

- PV-Wind Hybrid SystemsDocument24 pagesPV-Wind Hybrid SystemssahitPas encore d'évaluation

- Power Quality Improvement in Transmission Line Using DPFCDocument7 pagesPower Quality Improvement in Transmission Line Using DPFCVIVA-TECH IJRIPas encore d'évaluation

- Chapter 2 Solar SystemDocument8 pagesChapter 2 Solar SystemavocadocolorPas encore d'évaluation

- A Review of Renewable Energy Systems For Industrial ApplicationsDocument8 pagesA Review of Renewable Energy Systems For Industrial ApplicationsIJRASETPublicationsPas encore d'évaluation

- Question Bank For Module 1 and 2Document2 pagesQuestion Bank For Module 1 and 2Apoorva v Hejjaji100% (1)

- Wind EnergyDocument49 pagesWind Energyanand upadhyayPas encore d'évaluation

- Models For A Stand-Alone PV SystemDocument78 pagesModels For A Stand-Alone PV Systemcristian2388Pas encore d'évaluation

- Optimal PlacementDocument21 pagesOptimal PlacementSunnyJoelPas encore d'évaluation

- Power Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFDocument4 pagesPower Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFRevati KalalPas encore d'évaluation

- MPPT Based PV System For Partial ShadingDocument70 pagesMPPT Based PV System For Partial ShadingSwarnav Majumder100% (1)

- DC GeneratorDocument38 pagesDC GeneratorAshwini ChaurasiaPas encore d'évaluation

- Standalone Solar PVDocument17 pagesStandalone Solar PVGetie Tesfaye ZeliePas encore d'évaluation

- Presentation On Design & Installation of 2.5KVA Solar PV System (Group2)Document12 pagesPresentation On Design & Installation of 2.5KVA Solar PV System (Group2)Metro BazPas encore d'évaluation

- Desai Harshad Suresh B050254EEDocument37 pagesDesai Harshad Suresh B050254EEvikkyymsnbPas encore d'évaluation

- MPPT Based PV System For Partial ShadingDocument73 pagesMPPT Based PV System For Partial ShadingSwarnav MajumderPas encore d'évaluation

- Economic Dispatch ControlDocument31 pagesEconomic Dispatch ControlTirumalesh ReddyPas encore d'évaluation

- PS7008 Smart GridDocument2 pagesPS7008 Smart GridLakshmi Zahara100% (1)

- Energy Storage Systems-NotesDocument23 pagesEnergy Storage Systems-NotesJaivirPas encore d'évaluation

- Lab Manual Power Plants PDFDocument46 pagesLab Manual Power Plants PDFKhushnoodPas encore d'évaluation

- Basic Structure of A Power SystemDocument9 pagesBasic Structure of A Power Systembiruke6Pas encore d'évaluation

- Gogte Institute of Technology: Dr.V.N.SatwikDocument16 pagesGogte Institute of Technology: Dr.V.N.Satwikaditya thakkarPas encore d'évaluation

- Ps2113 Distributed Generation and Microgrid 2013 14Document2 pagesPs2113 Distributed Generation and Microgrid 2013 14Eric Hernandez0% (1)

- Simulation Model of Hydro Power PlantDocument7 pagesSimulation Model of Hydro Power Plantwoldemariam workuPas encore d'évaluation

- Microgrid Lecture 1Document15 pagesMicrogrid Lecture 1JitendraTandekarPas encore d'évaluation

- Ch7 Smart Metering&DSI SDocument49 pagesCh7 Smart Metering&DSI SksajjPas encore d'évaluation

- Hybrid Power Generation by Solar - WindDocument27 pagesHybrid Power Generation by Solar - WindUday Wankar100% (1)

- Castrol IndiaDocument10 pagesCastrol Indiajaackson10Pas encore d'évaluation

- Wrestling MindDocument41 pagesWrestling Mindjaackson10Pas encore d'évaluation

- AdvertisementDocument7 pagesAdvertisementjaackson10Pas encore d'évaluation

- Relay Selection Guide R0 81105Document27 pagesRelay Selection Guide R0 81105padmawarPas encore d'évaluation

- BSPHCL1Document2 pagesBSPHCL1jaackson10Pas encore d'évaluation

- It Is The That Is Meant For Free of ItDocument1 pageIt Is The That Is Meant For Free of Itjaackson10Pas encore d'évaluation

- Lessons Learned Document Library-LL20130701 Current Transformer Ground RelayDocument3 pagesLessons Learned Document Library-LL20130701 Current Transformer Ground Relayjaackson10Pas encore d'évaluation

- Advance Application Fro Ground Fault Protection PDFDocument26 pagesAdvance Application Fro Ground Fault Protection PDFalfredohdnPas encore d'évaluation

- Challan FormDocument1 pageChallan Formjaackson10Pas encore d'évaluation

- Lessons Learned Document Library-LL20130703 Use Loading Resistors When Applying Solid State ContactsDocument2 pagesLessons Learned Document Library-LL20130703 Use Loading Resistors When Applying Solid State Contactsjaackson10Pas encore d'évaluation

- Lessons Learned Document Library-LL20130702 Transmission Relaying Backup Ground ProtectionDocument3 pagesLessons Learned Document Library-LL20130702 Transmission Relaying Backup Ground Protectionjaackson10Pas encore d'évaluation

- Blocking of Distance Relays Zone3 Under Load Encroachment Conditions - A New Approach Using Phasor Measurements TechniqueDocument6 pagesBlocking of Distance Relays Zone3 Under Load Encroachment Conditions - A New Approach Using Phasor Measurements TechniqueconstellanaPas encore d'évaluation

- Lessons Learned Document Library-LL 20130401 Transmission Relaying Undesired BlockingDocument2 pagesLessons Learned Document Library-LL 20130401 Transmission Relaying Undesired Blockingjaackson10Pas encore d'évaluation

- Manual 2Document0 pageManual 2Rafat ThongPas encore d'évaluation

- DC GeneratorsDocument1 pageDC Generatorsjaackson10Pas encore d'évaluation

- Ge T60Document622 pagesGe T60jaackson10Pas encore d'évaluation

- Chapter 21 Multiple Choice Questions (Answers)Document26 pagesChapter 21 Multiple Choice Questions (Answers)jaackson10Pas encore d'évaluation

- Mit 161Document24 pagesMit 161Santosh Gairhe100% (1)

- Grid enDocument81 pagesGrid enwppwegPas encore d'évaluation

- Grid enDocument81 pagesGrid enwppwegPas encore d'évaluation

- Chapter 21 Multiple Choice Questions (Answers)Document26 pagesChapter 21 Multiple Choice Questions (Answers)jaackson10Pas encore d'évaluation

- 3gdatayuva 01102012to29122012Document1 page3gdatayuva 01102012to29122012jaackson10Pas encore d'évaluation

- DC GeneratorsDocument1 pageDC Generatorsjaackson10Pas encore d'évaluation

- Extratalkvalue 01102012to07102012Document1 pageExtratalkvalue 01102012to07102012jaackson10Pas encore d'évaluation

- CDMA Prepaid Services: Unlimited Local / Unlimited STD CallDocument1 pageCDMA Prepaid Services: Unlimited Local / Unlimited STD Calljaackson10Pas encore d'évaluation

- Reserve Bank of India: Test I: ReasoningDocument5 pagesReserve Bank of India: Test I: Reasoningjaackson10Pas encore d'évaluation

- TextDocument99 pagesTextjaackson10Pas encore d'évaluation

- Relay TerminalsDocument8 pagesRelay Terminalsjaackson10Pas encore d'évaluation

- SAIL Placement Paper Question Paper 40615 - Sample Placement PapersDocument14 pagesSAIL Placement Paper Question Paper 40615 - Sample Placement Papersjaackson10Pas encore d'évaluation

- Solar Project REPORTDocument15 pagesSolar Project REPORTismailPas encore d'évaluation

- Determining The Best Site and Sizing For A Wind Power Plant in Romblon IslandDocument4 pagesDetermining The Best Site and Sizing For A Wind Power Plant in Romblon IslandANGEL JOY RABAGOPas encore d'évaluation

- Commercial Circular No.333Document1 pageCommercial Circular No.333Sanjay NirmalPas encore d'évaluation

- Ererer PDFDocument24 pagesErerer PDFkishorPas encore d'évaluation

- Presentation About Environmental Pollution: Air, Soil and Water PollutionDocument5 pagesPresentation About Environmental Pollution: Air, Soil and Water PollutionThanh Vân AnPas encore d'évaluation

- Off - Grid & Grid Benchmark Cost 2018 19 PDFDocument2 pagesOff - Grid & Grid Benchmark Cost 2018 19 PDFAnant energyPas encore d'évaluation

- An Assessment of The Renewable Energy Sector of The Philippines Through SWOT AnalysisDocument14 pagesAn Assessment of The Renewable Energy Sector of The Philippines Through SWOT AnalysisAndrea MercadoPas encore d'évaluation

- 2022 Civil Nuclear Cyber Security StrategyDocument47 pages2022 Civil Nuclear Cyber Security StrategyEric MertzPas encore d'évaluation

- MechanicalDocument2 pagesMechanicaljvc_84Pas encore d'évaluation

- DRRG Equipmentlist 78Document24 pagesDRRG Equipmentlist 78Barun BiswasPas encore d'évaluation

- Panasonic HIT 240S Data SheetDocument2 pagesPanasonic HIT 240S Data Sheetcrd1990Pas encore d'évaluation

- REPowerEU - A PlanDocument5 pagesREPowerEU - A PlansamPas encore d'évaluation

- Indirect Solar GainDocument3 pagesIndirect Solar Gainbamboozed2011Pas encore d'évaluation

- Energy Effecient Build - Solar KitchenDocument6 pagesEnergy Effecient Build - Solar KitchenyuvarajPas encore d'évaluation

- Grey Wolf Optimization Algorithm Based MPPT Technology For Solar PV SystemDocument2 pagesGrey Wolf Optimization Algorithm Based MPPT Technology For Solar PV SystemNexgen TechnologyPas encore d'évaluation

- Renewable Energy Technology: Dr. Md. Rifat HazariDocument26 pagesRenewable Energy Technology: Dr. Md. Rifat HazariAlamin KhanPas encore d'évaluation

- HSETS 11 Horizon Solar Energy Training SetDocument4 pagesHSETS 11 Horizon Solar Energy Training SetDoménica Pinargote MoránPas encore d'évaluation

- Mnre Resco 1.0Document2 pagesMnre Resco 1.0anjes1Pas encore d'évaluation

- Renewable Capacity Highlights: Headline FiguresDocument2 pagesRenewable Capacity Highlights: Headline FiguresMuhammadFazrinPas encore d'évaluation

- Res UNIT 4Document4 pagesRes UNIT 4VinAyPas encore d'évaluation

- Hybrid Renewable Energy System For Island Electrification: Final Year Project 1 PresentationDocument13 pagesHybrid Renewable Energy System For Island Electrification: Final Year Project 1 PresentationAwlia KhanPas encore d'évaluation

- ChapsDocument2 pagesChapsAhmad Murtaza ErshadPas encore d'évaluation

- Cleaning PhotoVoltaic Solar Panels by Drone AerodynamicDocument5 pagesCleaning PhotoVoltaic Solar Panels by Drone AerodynamicDennis WamaePas encore d'évaluation

- Comed Sample BillDocument1 pageComed Sample BillAlberto CayetanoPas encore d'évaluation

- Duke Letter Opposing The Suniva/SolarWorld Trade CaseDocument2 pagesDuke Letter Opposing The Suniva/SolarWorld Trade CaseFrank AndorkaPas encore d'évaluation

- HydropowerDocument11 pagesHydropowerBinod ShresthaPas encore d'évaluation

- Renewable Energy (Solar Energy)Document18 pagesRenewable Energy (Solar Energy)nabouPas encore d'évaluation

- GHHJJJJ HJJKKDocument6 pagesGHHJJJJ HJJKKSheelaPas encore d'évaluation

- Memorandum 222Document4 pagesMemorandum 222api-316846678Pas encore d'évaluation

- PID5733223Document6 pagesPID5733223eogollaPas encore d'évaluation