Académique Documents

Professionnel Documents

Culture Documents

Lubrication

Transféré par

Abiodun IloriCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lubrication

Transféré par

Abiodun IloriDroits d'auteur :

Formats disponibles

,---tt.======:::::::!

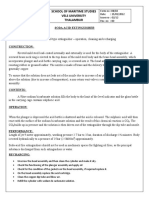

SECTION I : CHAPTER 14

....... 2

2 2 2 2 2 14.6.4 14.6.5

I

....-----...fl

MECHAN ICAL fr~GlNEERING

: LUBRICATION

.i , ~

14.1 Introduction. 14.2 Aim ofluhrication 143 Properties of lubricating oils and grease . 14.3 I Viscosity ... 14.3 2 r-Iash point 14.33 Pour and cloud points .. 14.34 Relative density 14 J 5 Carhon residue i 4 3 (, Rust-resistance 14 3 7 Neutralisation number 143 l( Dernulsification factor 14 3.9 Film strengh 14 J 10 Foaming characteristics 14 J It Anti-oxidation 14 1 12 Oiliness and Iubricuy

( "Galoobs")

2

2 3 3 3 3 3

1

I

.'"

1-1 J 13 Satonification number 1-1 3 14 ()d.:rgcncy 14 -1 Iypcs of lubrication i 44 I f Iydrodynamic lubrication 1442 Hydrostatic luhncation 144 3 Flastohydrodynamic lubncauon 14 4 4 Houndry lubrication 144 -; Solid-film lubrication 14 5 Mrxed-filrn lubricauon 1-1(, Functions of oil additives .. 14 6 I Detergents. 14.6.2 Dispersants 14.63 Oxidation inhibitors

J 3 3

3

3 4

4

4 4 4 4 4 4

Corrosion inhibitors .4 Oiliess agents, film-strength irnprovers and extreme pressure agents 4 14 6.6 Pour point depressants 5 14 6 7 Viscosity index improvers 5 14.68 Foam inhibitors. . 5 14.6.9 Emulsifiers. . . 5 14.6.10 Solid lubricants 5 14 6 I I Tackiness agents 5 147 Greases 5 14 7 I [Jail and roller bearings 5 1471 I Oil lubrication of ball and roller bearing .. . . 6 14 7 I 2 Grease lubrication of ball and roller beari ngs ..... .. .... .... 6 14 7 3 Internal combustion engines. . (, 14 7 4 Lubrication of compressors.... 6 14 7 5 Lubrication of stream turbines ... 6 14 7 (, Lubricating of reciprocarig steam engines. . .... 6 14 7 6 I Steam cylmdcrs.. . 6 14 7 6 2 Bearings and other moving parts .... ..... 7 14.8 Methods of gear lubncation .7 149 Foanung of lubricating oil 7 14.10 Test on oils ....... 8 Example I ... 8 Example 2 ........................ 8 Example 3 10

PREFACE

I~---...

that will encountopics, illustrative examples problems - a most irnpor-

The emphasis of this study material is to provide the user not only with material prepare him/her for the engineering examination, but also to depict realistic situations tered in engineering practice The book contains the development and explanation of specific and exercises designed to test the user's ability to apply the theory The emphasis IS placed on developing rant skill for any engineer. the student's ability to analyze

Notice must be taken that some of the chapters Please refer to the chapter's index for guidance

are only applicable to the mining regarding the above the scrutiny of the author

industry.

10

I apologize for any errors which may have escaped receive any corrections or constructive criticism.

I should be glad

D.l.

Author

Botes

AUGUST 2007

lst Edition

OBJECTIVE

I

types of belt drives .

With completion of this chapter the user will be able to:

chapter 14

LUBRICATION

Understand the basic working principles of belt drives. Solve practical problems on all types of belt drives. Know the advantages and disadvantages of the different

1--

L i

tIECHANlC.AL EflGINEERING : LUBRICATION

,-' '"

t'~~~-l

The purpose reduce: of lubrication

~,1.1 Introducti~

*,

is to

14.3 Properties of lubricating oils and grease

Three main classes of oil: unblended mineral oil. mineral oils, which are mixtures of two or more ~rieties. Compounded oils conrarrnng some animal or vegetable oil

Blended

The foUowing flash points are representative of a few types of lubricating oils: Light mineral oils Heavy mineral oils Cylinder oils 160C to 200C 200C to 260C 260C to 330C

g

~ of machine pans ~

rt

rIi

~i

,..

;~

Friction Wear

Heating

K

11

Straight

I

.

14.3.1

Viscosity

v

of a lubricant which denotes

11

This is the characteristic is relative fluidity. The heavier its viscosity.

14.3.3

Pour

and cloud

points

~Iolor...',M.~"!

.. ''::(:d.''~'..-::_~~''l':.o:':,'-'z.... ;;;;~~ ..... ~.; . .. ~.;.;.. ~..;.:.~~"'l.:.:....k,,?J

~ ;;

i

or less fluid an oil is, the higher will be

I!

~

d

I'he following applications require a'~c(' friction. wear and heating.

~f"":-:W . I.I.. ..,.;: . tf.l.

::::--.;~" -:::.....

::. r":::''Io(f.! r_''::'':'''"'''!~",~':~''::1t~;. .. !. . .:.::.-.~:~~~..l:t"'::Z.~

ij

lubrication

to re-

The rate of change temperature.

of viscosity varies inversely with

7..' , ._'" '~,-.. :'-..:~ ....... ,...., . 'It k .. ~:;. . ;. .. :..:io

nJ.,l

~

14.2 Aim of lubrication

Lubrication must maintain a film of the lubricant between two metallic surfaces which have relative motion If the film is squeezed away the surfaces ride directly one on the other with metallic contact which causes grinding, scouring, and eventual welding of one of the other which means a "seizure" The lubricant must therefore have sufficient to maintain the film, and is called viscosity. cohesion

~

"

In a sleeve bearing,

a shaft or

ij

~:

journal rotates or oscillates, and

S

::

" ~. '" ~ ~

the relative motion is sliding. In an antifriction bearing.

11

the main relative motion is

rolling. l.--"" A follower may either roll or slide on the cam. Gear teeth mate with each other b~ ~ combination of rolling and

,1 .;~ . fj

~

In a bearing operating properly with a fluid film separating the surfaces, the viscosity of the oil at the operating temperature is the property which determines the friction in the bearing, the generation of heat and the rate of oil flow through the bearing under given conditions of load, speed and design of bearing.

These properties will determine the probable low temperature performance of a lubricating oil. When an oil is chilled at a specified rate. certain of the paraffinic hydrocarbons (in the form of wax) will begin to solidity and separate out in crystalline form. The temperature at which this occurs is called the cloud point. Further chilling until the oil just ceases to flow or pour, gives the pour point temperature. When an oil has to be handled and used under relatively cold conditions, it is essential to know the pour point. Both cloud and pour points will vary widely depending on the base and source of the oil and methods of refining and blending of the oil. Naphthenic-base oils will generally have a lower pour point for the same viscosity range than paraffin-base oils, unless the latter have been specially de-waxed in the refining process.

14.3.2

Flash

point by the Pensky-

i,j

;; li ~

The flash point is usually determined Martins Closed Tester.

sliding.

Pistons cylinders.

...

slide within their

i'

~

t.

d ~

~~

'_."""""""'~.d"''''''''''''''''~""",,",,'''''''~

Machinery with mechanical movement requires -quare lubrication for satisfactory performance. ad-

Although viscosity in itself is resistance to motion and leads to increase of temperature, it is necessary to have sufficient viscosity at the working temperature of the bearing. Oiliness means the quality of adherence to a metal surface, a kind of molecular attraction, and it is only of value if the viscosity is not sufficient to maintain a good film, a complete film in which case the oiliness reduces the grinding action of the two metallic surfaces and hence, postpones welding and seizure, and may prevent considerable damage.

The flash point is taken as the temperature read on the thermometer when a flash appears at any point on the surface of the oil. The flash point is important in the storage of oils and will indicate the existence of "light ends" which may be present as the result of oil blending and/or the dilution with a liquid of low boiling point. The test is also informative from crankcases of Le. Engines, dilution flash point. in analysing oils taken

14.3.4

Relative

density

,J

This is the ratio of the density of the oil to the density of pure water. Paraffinic oils range in RD from 0,863 9 to 0,878 3 while naphtenic oils range from 0,920 to 0,948 3.

~'o~ t machinery requires either mineral oils or mixture : of mineral oils with a lesser proportion of anim7.1 or vegetable oil; or certain parts may require grease, which is usually a mineral oil compounded . 'it)1 soap . :

14.3.5

Carbon

residue

by fuel, being indicated

by a reduced

Carbone residue is formed as a result of subjecting an oil to continued high temperatures in operation. The carbon is chiefly the result of the breaking down or decomposition of the lubricating oil and will reduce

POTCHEF~TR00t4

COLLEGE:

D,\WIE BOTES (copyrighted)

r1ECHA.rHCAL ENGttJEERING

: LUflRtCATlON

;1-; lubricating o.r valve seats

value

It can be particularly

as ceposits on piston heads, in combustion

or around and under i ~,ernal combustion engines.

harmful chambers, the piston rings in

14.3.9 Film strength

This is an indication of the load-carrying capacity of an oil showing the maximum load the oil will carry before the film breaks down.

14.3.14 Detergency

This refers to the property of an oil to prevent and reduce the formation of deposits on engine pistons and other working parts and in the crankcase, Detergent additives modify the process of oxidation of the oil and the type of products of oxidation so formed, so that these are less likely to separate from the oil as deposits. Instead, these tend to disperse and to become suspended in finely divided form in the oil. To a certain degree these detergent additives have a cleaning effect on an engine. Another feature of detergent-dispersive additives is that, in varying degree, they reduce corrosive wear on cylinder walls and rings of I C. engines They tend to neutralise the effect of acid materials which promote wear during the starting and warming-up period

The load on ajournal bearing is a function of velocity, temperature, bearing length and bearing clearance. It is desirable to obtain full film lubrication as soon after starting as possible. The following are requirements for obtaining an oil film or wedge:The lubricant must be capable of "wetting" the journal and bearing so that the oil will adhere to the revolvingjournal and be drawn into the pressure area. The journal and bearing must be free to assume a slight angle to permit the formation of a converging oil film, as it is not possible to obtain fluid film lubrication between two parallel flat surfaces where an oil wedge cannot be formed The clearance space between the bearing and journal must be kept full of oil, supplied in the low pressure area of the bearing. The viscosity of the oil must be high enough to permit the formation of a load-supporting oil film under the preva iling cond itions of load and speed. Rubbing speed must exceed the minimum which a full fluid oil film cannot be formed. below

Modern I C. engine oils are manufactured to have a righ chemical stability (fortified by additives) and "::VI: a carbon residue of only a fraction of one per C"II , generally varying directly with the viscosity

14.3.10 Foaming

These include when agitated the time taken to escape form the as for the

characteristics tendency for an oil to form foam in case of circulating systems and the foam to subside, i.e. for the air oil

14..1.6 Rust-resistance

TI'i~ characteristic is important in steam-turbine oils vhi.:h operate in the presence of water The property ::, tor the oil to prevent the rusting of ferrous parts should water become mixed with the oil

14.3.11 Anti-oxidation

characteristics

14.'1. 7 Neutralisation ~l.;~, is an indication

o~ t'ie oil.

number of the organic or mineral acidity

These are the resistance properties of an oil to oxidation in the presence of air at high temperatures, which result in the formation of acids and sludge's

14.3.12 Oiliness

and

lubricity

(" Galoobs')

14.4 Types of IUbriC~M. n

~ f ...::-~<r-+--.~l't.~.:.::~~n~'~"k:.!,:arL~~:Z:'X1~"TI

Five distinct forms of lubrication may be identified: ~ ~

iiOl

~A!neral acids are corrosive and it is necessary to watch the neutralisation number of oils in use carefulI:' Oxidation and sludge formation tend to increase oil acidiry.

Oiliness is the property possessed by certain oil molecules of attaching themselves to metal surfaces These again attach themselves to other oil molecules to form an oil film on the metal surface called the boundary film This oil film only comes into action if the supply of lubrication fails or conditions are such that a thick film cannot be built up.

~.

, ~

1'~.J.8 Demulsification

l'h is is the ability

factor

t,i n

"

""~ter mixed if ;di standing.

of an oil to separate completely from with it, with no emulsion at the surface,

Hydrostatic Elastohydrodynamic Boundary scua- film

....:.~u,fAIW+"*a

Hydrodynamic

ii

~

TIll> property is important in all cases where oil is expe rted to operate in the presence of water. steam engine cylinders 111" reciprocating air compressor cylinders ernulsifica,iO,1 )f the oil is desirable to prevent washing away of the lubricant.

Ll

t:-C'"-:.xtr:rf""!!tYS:e"X

Hydrodynamic lubrication does not depend upon the introduction of the lubricant under pressure, though that may occur, but it does require the existence of an adequate supply at all times. The film pressure is created by the moving surface itself pulling the lubricant into a wedge-shaped zone at a velocity sufficient high to create the pressure necessary to separate the surfaces against the load on the bearing,

14.3.13 Safonification

number

luoricating of reciprocating

This indicates the tendency of an oil to form soapy deposits with acids and hence harmful sludge's. It will also increase the foaming tendencies of oils in presence of water.

14.4.1 Hydrodynamic

lubrication

14.4.2 Hydrostatic

lubrication

The load-carrying surfaces of the bearing are separated by a relatively thick film of lubricant, so as to prevent metal-to-metal contact.

The lubricant, which is sometimes air or water, is introduced into the load-bearing area at a pressure high enough to separate the surfaces with a relatively thick

rOTCHEfSTRoor-1

COLLEGE:

DAWIE OOTES (copvnqnted)

r~ECHANlCAL ENGtNEFRtNG : l.UBRtCAnON

'rlrr of lubricant. This method can be considered -,\here the velocities are small or zero and where the fr icional resistance is to be an absolute minimum

1-1.4.3

Elastohydrodynamic

lubrication

r~z~-=-u

~ ~ ~ ~ ~, etable fats: Stearic acid Palmitic acid Oleic acid

molecules bind themselves to the journal and bearing surfaces with such great strength that the metallic asperities of the rubbing metals do not weld or shear.

addition to occurring with a scarcity of lubricant, mixed-film conditions may be present when:

and usually have some dispersant

properties,

It occurs when a lubricant is introduced between suraces which are in rolling contact, such as mating ;;~d -s or rolling bearings.

The following are known fatty acids that occuc in animal and veg-

r~

'1 :1

14.6.2 Dispersants

is toO'I:~-=--'

The Vi::~

11

i.

1

g,

';

14.4.4 Boundary lubrication

','::len two surfaces slide relative to each other with 0:11:, a partial lubricant film between them, boundary lubrication is said to exist. Boundary or thin-film lubnr.uion occurs in hydrodynamically lubricated bear" gs when:

'"1;..,

);:U.-.i~

1J ~ I . ~ .. -;:.,:,~-r';;'~J/I":.~" 6"-~l',o.;~,~c:t-e..:-.'!.:.~r~~~"JJi::~

~ ~ ~

E

The bearing speed is too low The bearing is overloaded The clearance is too tight Journal and bearing are not properly aligned,

i

~ jI

They keep deposits in suspension, thereby preventing the blockage of oil passages and orifices, They work by surface effect and are commonly used with detergents.

!I

. ~ . a::~~

14.6.3 Oxidation inhibitors

They prevent breakdown of oil and formation of deposits caused by oxidation (through contact with air). They become more important as the working temperatures are increased Their action may be by sacrificial oxidation or by reacting with the causes of deposit formation.

~t~Li<~~~'r:~"""

':..': .. .l~t:~!f"..:n~~'

b. . ,:.:_v..:.tL: .~\L

.:JU:t'"~"',":;'4~":..:.~\""':=.:l;; " ..... ~;3;1

~l . They

~ ~' ~ ~

;1

11

...

"

~ .. ..Jf~~"'''';:~

are starting or stopping The load increases The supply of lubricant decreases' Other operanng changes happen to occur,

:~;~4,,41i...._~ .;L::~ ~,

(j

1I )'

Fatty acids will break down at temperatures of 120C or more, causing the extreme pressure In such cases the extreme pressure lubricants may be mixed with the fatty-acid lubricant There are composed of chemicals such as chlorinated esters or tricresyl phosphate. which form an organic film between the rubbing surfaces.

14.6 Functions of oil additives

-:~~~~ ,T_....,Ji.U~tU.L;..~~:)~~~."..:'.M.1.~!J

'J

1

~

Main functions

of oil additives of the oil

I!

r.

It

~ ;1

~ Fi '

IH

~

1

14.6.4 Corrosion inhibitors

They protect ferrous and other metals from corrosive attack. generally by the formation of a protective film

To prevent deterioration

!1

~

This lubrication is used when bearings must be operated at extreme temperatures Graphite or molybdenum disulfide must be used because the ordinary mineral oils are not satisfactory.

14.4.5 Solid-film lubrication

,,_.,:''':.J~(j'!::..,,:,l

in service (e.g. oxidation) To inhibit harmful effects of the oil or contamination of the i surroundings (e.g. corrosion) To improve certain limiting features of the oil. (e.g. pour

~ 1'1 ~ ~

.1

i'here are a large number of cases in design in which ooundary-lubricared bearings must be used because of the type of application or the competitive situation. TIe coefficient of friction for boundary-lubricated surt ices may be greatly decreased by the use of aninal or vegetable oils mixed with the mineral oil or i;t'!2se, Oiliness agents are fatty acids which appear to reduce ;-'C'ion, either because of their strong affinity for cerI; II' surfaces by a chemical reaction, The fatty-acid

1;

depressants) To Introduce

totally new features ~

14.6.5 Oiliness agents, film-strength imp rovers and extreme pressure agents

The first improve the physical absorption boundary lubrication. of oils for

of oil (e.g. emulsifiers)

14.5 Mixed-film lubrication

This type of lubrication exists when a bearing operates partly under hydrodynamic conditions and partly under dry or thin-film conditions. If the lubricant is supplied by hand oiling, by drop or mechanical feed, or by wick feed, for example. the bearing is operating under mixed- film conditions. In

~=~~""..,-,...:;,-=.. ~ .. =;.>:.=.~

Principal low: additives used for modern oils are as fol-

The latter form a chemical bond with the metal under high temperature with a resulting film which can be easily sheared, yet prevents metal-to-metal contact. They are used for boundary and extreme pressure applications and allow for higher bearing and gear loading without seizure, pitting and scuffing,

14.6.1 Detergents

They prevent formation of deposits in I.C, engines. Work by reacting with the causes of deposit forming

POTCHFFSTROOM COLLE(;E ' OAWIE IlOTES (c-opyrightro)

r~f.CHAt~ICAI.

ENGttlFERING

: LUBRtCAr[ON

III 6.6 Pour

point

depressants

14.7 Greases

They are essentially thickened oils and are the result of inclusion of mineral oil in a metallic soap. The properties of the grease depend on the nature of the base mineral oil and the soap, the latter having a profound effect on the character of the grease as shown below: rUool'-!.:r'~"'~'!~~=""'Il*~:,",.II'l-"\~~'-';"'~

tive motion that is both rolling and sliding. If the relative velocity of the sliding surfaces is high enough. then the lubricant action is hydrodynamic. Elastohydrodynamic lubrication (EHO) is the phenomenon that occurs when a lubricant is introduced between surfaces that are in pure rolling contact. The contact and-follower of gear teeth, rolling bearings, surfaces are typical examples. and cam~ The main duties of lubricants ball and roller bearings are: To reduce friction between the for

The lower the usable temperature of the oil by modit)'ing the wax crystals in the oil to prevent the formarion of a rigid sr-ucture.

!

ill

Tney are used only on paraffinic

oils

~.! t

. .~

;:~:~

rolling

P'''' of the

14 0.7 Viscosity

index

imp rovers

i'he Y minimise changes of viscosity with temperature i'ld may be visualised as coiled springs which uncurl as the oil is heated. taking up more space and prevent'(;1; now of the surrounding liquid.

ii

~

Lime

base (calcium)

grease

~ ~ ~ ~

r~

~ ~ fJ

'" :~

This is a soft, buttery grease, insoluble in water and limited to moderate operating temperatures.

When a lubricant is trapped between two surfaces in rolling contact, a tremendous increase in the pressure within the lubricant film occurs. But viscosity is exponentially related to pressure and so a very large increase in viscosity occurs in the lubricant that is trapped between the surfaces. The change in viscosity in and out of contact pressure is equivalent to the difference between cold asphalt and light sewing machine oil.

I

~

~_..

To assist in dissipating the heat generated within the bearing. To protect the highly polished working surfaces of the bearing from corrosion and rusting. To assist in sealing the bearing against the entry of contaminants such as dust and moistu re.

~ Ii

i4.,s.8

Foam

inhibitors the formation of stable foam by lowertension of the oil molecules

T'ie y prevent Ing interfacial

J

~

Sodium base grease This grease has a fibrous structure, emulsifies in the presence of water and can be used at much higher temperatures than lime base grease .

~ ~ ~

ij

r ~

~

I

... ~

r $;.:::A,"~.~.t:,..;".!'1t"r.4o:;'.c,,"!.:.~a.. . z:.:.~.:s

~ ~

..~:

:..:b,D.&J'"~

~ ~ ~

4.6.9 Emulsifiers

Tnr-y allow of the mixing of oil and water. thus combining the lubricating properties of oil to be coupled v/ith the cooling properties of water

:j !;

~ ~ ~ ~ ~ ~ ~

Either oil or grease may be employed as a lubricant The following rules may help in deciding between them.

~ ~

Lithium base grease This grease is both resistant to water and suitable for high temperatures. Its low-temperature characteristics are also good. Aluminium soap grease Th is g~ease is resistant to water and acids and has therefore a

8

~ ~

"~~'r:-~~~~:-~:~l.'iC-~~~~'"-!.;.;;J;;."...z"".::r.;

I~

~

"

U

The purposes of bearing lubricant: an antifriction-

.t

Use grease when

Use oil when

11

tj

14.6.10 Solid

lubricants

I'.g Graphite, molybdenum disulphite. They act as lubricants in their own right by reason of their crystall.ue structure.

11.6.11 Tackiness

They prevent chinery.

agents

from fast moving ma-

I k.~:=:==:~:: .

14.7.1 Ball and roller

The contacting surfaces bearings in rolling bearings have a relaPOT(HFFs-moor,

J

l:l ~

~

;~ To provide a film of lubricant between the sliding and rolling surfaces To help distribute and dissipate corrosion of the

~

1'1

1

~

l~ .1

n

~

'I,

!.! "

~

_L

A

~~a;revent

f~

bearing surfaces To protect the parts from the entrance of foreign matter

I~

~

The temperature is not over 200F The speed is low Unusual protection is required from the entrance of foreing matter Simple bearing enclosures are desired Operation for long periods without attention is desired

oil being thrown

~~~~~~~J

Speeds are high Temperatures are high Oiltight seals are readily employed Bearing type is not suitable for grease lubrication. The bearing is lubricated from a central supply which is also used for other machine parts

COt.t.EGE : O/IVJIE nOTES (copyrighted)

i:'

t1ECHANlCAL

ENGtNFERING

: LUBRtCAHON

1':.'l.I.1

Oil lubrication

of ball and roller bearings than grease, exist. provided

pitch line speeds are not so high as to cause excessive churning. The main functions of a gear lubricant are to reduce friction and wear by providing a lubricating film between the teeth and, in the case of enclosed gears, to transmit heat to the gear casing and so act as a coolant. Where service conditions are not abnormally severe, a mineral oil with a viscosity as low as is consistent with proper lubrication of the teeth, is used, often with oiliness agents and film strength improvers as additives. With severe operating conditions, such as hypoid gears, extreme pressure additives are used with in addition, corrosion inhibitors, pour point depressants and foam inhibitors

Oil is generally more effective ae.equate sealing arrangements Application hf.1t speed in particular

for high

temperature

and

LC engine oils are accordingly of the most complex type, and are commonly fortified by the following additives. Detergent and dispersant additives, oxygen and corrosion inhibitors, oiliness and film-strength improvers, pour point depressant, viscosity index improvers as well as foam inhibitors.

Additives include these for reciprocating compressors, except for foam inhibitors and usually requires detergent-dispersant additionally.

',"s"osiry depends on the design and duty of the bear!(lg Oil bath and splash systems of application are use.I for slow and medium speeds; circulating sys,e:1'5 for medium speeds and spray or mist application f0~ high speeds.

14.8.4 Lubrication

of compressors

Turbo-compressors These are commonly steam- turbine driven and have a common lubricating system.

~

~

r:"'=00,=:-1

Cylinder and crankcase oil are generally common and, except where very moist air is compressed, compounded oils are not favoured.

rl

~

11 ~

.4 7.1.2

Grease lubrication bearings

of ball and roller

Ijrease is employed as a lubricant where temperatures are not excessive and the sealrng arrangements do not at.cw for satisfactory oil lubrication ~"'.'].2 Gear lubricant

.! ~!

ti

14.8.5 Lubrication

of steam

turbines

14.8.3 Internal

combustion

engines

'.

14..'1.2.1 Open gears These are generally of the spur and bevel type and t~le lubricant is often applied by hand. It should have good adhesive properties to prevent it being flung off the teeth. Solid lubricants are often included in the iricant.

The generally used system for lubrication comprises of a pressure circulating system for the main and bigend bearings with a bypass to the cam-shafts and other components. Cylinders are lubricated by oil thrown from the big-ends Gudgeon pins are lubricated by means of oil leads taken form the big-ends or by oil throwers. The reciprocating movement of the piston in the cylinder, during which it is momentary stationary at the top and bottom of the stroke, together with the high pressure and temperature in the combustion chamber and the presence of extremely corrosive products of combustion, give rise to highly unfavourable conditions in which to provide and maintain an oil film between the piston rings and the walls of the cylinder. Effective running of the engine depends on the effective sealing of the combustion chamber by the oil film and proper functioning of the rings and valves.

Oil of high oxidation stability is required to prevent the formation of gummy deposits in contact with air at high temperatures. Generally napbthenic base o;lsare preferred as the hard, brittle carbon formed by paraffinic oils may be deposited on the valve seats, interfering with valve operation. Low viscosity oils are preferred. Oil additives include oxidation and corrosion inhibitors, oiliness and film strength improvers, pour point depressants and foam inhibitors,

I

~ r. ~ ~

~1"

Steam turbines are provided with pressure-circulating systems. The oil must not only provide adequate and dependable lubrication but also serves as a coolant and must protect the turbine parts against rust. In addition the oil is used as a hydraulic medium in governor relay and control gear and, where reduction gearing is used without separate lubrication, it is used as a gear oil as well. Intimate mixing of the oil with air and water takes place and the oil furthermore gets in contact with oxidation catalysts such as copper Iron oxide, brass etc. Low viscosity oil of high stability is required and common additives include oxidation and corrosion inhibitors, oiliness and film strength improvers, pour point depressants, inhibitors and demulsifier agents.

1#.'.1.2.1 Enclosed This case level oi.;

gears

type may either be splash lubricated, in which the oil in the gear box is maintained at such a that the teeth of the lower gear just dip in the or a pressure circulating system may be used in -vhich the oil is sprayed on the teeth close to the point of engagement. The first system is employed where

Rotary compressors Heavier oils are normally partly improve the seal. .m"tW"s:;y"'nr~ used to

14.8.6 Lubricating

engines 14.8.6.1

of reciprocating

steam

Steam cylinders

POTCHEFSTROOM

COLLEGE:

DAWtE

BaTES

(copyrighted)

r~ECHANICAL ENGIIJEE'mJG

. l.UBRlCATlON

') It function

of a steam cylinder lubricant is to form n oil film which will reduce friction and wear of sliding surfaces and prevent leakage of steam past valves. ~j;t:ms and glands

C"S1'S"e'.'

Spray or brush With this method a thin film of lubricant is put on the meshing gear faces by either automatic spray equipment or brush or dip pan. This method of lubrication is normally for large open gears such as found on rod or ball mill drives or cement kilns. Splash Any churning of oil in the presence of air will encourage frothing or foaming. The mechanism of foamingresemble in some respect to that of emulsification..Both emulsion and foam consists of one phase dispersed within another. in foam. air is dispersed and oil the continuous-phase. Both emulsions and foams are capable of being stabilized through the pressure of substances that tend towards the interface. between the one phase and the other Excessive foaming can cause over spilling of foam through vents or filters.

1'~~ normal method of introducing the oil is to feed it to an atomiser in the steam line where the oil is broken up in a fine mist and deposited by the steam on rhe working surfaces

1 'Ii~ IS VI

supplemented

hy direct feed to piston rod and

v-: rod glands

Tle oil must atomise efficiently and spread read,:,. ever the working surfaces and must be capable of mamtaining a film at the temperature inside the cyl-

1:,1er

In a-tdirion, the film must be capable of withstandrng Ih? scounng acuon of the steam and the washing acnrn of the water formed by cylinder condensation Compounded oils suit these requirements except und, r rond itions of high superheat where the fatty (natura l) oils volatilise and very little advantage shown over straight mineral oils Tackiness agents are used -s an additive. lI.~ .6.2 Bearings and other moving parts. ~

The gear teeth dip into a bath of lubricant. and the lubricant adhering to the tooth face provides the lubricating film. It is normally used for small gear boxes of relatively low transmission power or speed and motor gearbox sets. Pressure feed

,'::~:~:=~'=~~~I

~.

To counteract the effects of foaming the procedure is to prevent foaming by certain oil additives. The greater the viscosity of the oil the greater the tendency 10 foam.

JI ,.

,. ;{ r.

Air leaks in pump connections joints of the oil pipes. Contamination of oil. Pump suction not completely merged in oil.

or

9

~

~ ,.

sub

Foaming can be overcome by the addition of minute quannties of a silicone The most effective being the polyrnethyl siloxanes used in concentrations of less than 0.001% Antifoams function by reducing the surface tension of the oil, thus facilitating release of cxtrained air.

Oil is sprayed in copious quantities to provide lubrication as well as cool-

li

bearings and sliding surfaces are used. In the crankcase the oil is splashed and subject to oxi.l.u iou , which rvquuv oil of hi~h oxidation stability Anti-foaming properties are required and. being in contact with steam and water. the oil must have good ..!clTIJlsibility and corrosion and oxidation inhibitors a: ~ desirable.

Bu!'1 journal

i1

f,:l ,! ~

ing. It is normally used in large gear sets where high powers or speeds are required.

i

~

i!!r:

The system is bad designed and does not permit air to escape., When dip or splash lubrication is used when high pitch line velocities are encountered. Oil must be circulated by pump with high pitch lines or velocities.

~

t' ;j

~ i * ~

~:.:f

~

~", .. r._",.. -~",,_~~-.::::.,_-~.., > "";,;:=,....... =e...r.r...::l.::-=:~~ Methods of recovery used oils: by steam and/or ~

Distillation

_ ~ Effects caused by foaming:

lk~=~

14.10 Foaming of lubricating oil

~

M. ~ !;i ~ Excessive wear of the gear teeth as a result of the entrained air pre venting the lubricant from lubrieating the gear teeth correctly. Exposure of oil to large amounts of air. promotes oxidation of oil.

1.J.9 Methods of gear lubrication:

All oils foam to some degree. but excessive foaming should not be permitted. foaming is a surface tension effect.

II I

I

S

~

'. i~.

L~~~

vacuum. Heating Filtering Settling for long periods in tanks and decanting Centrifugal separators to remove water and ash . Treatment by sulphuric acid followed by neutralising and decolouring by Fullers earth

-.--=:::=unds;u._~

POTCHEFSTRoor'l

COLLEGE: Of,VlIE BOTES (copyrighted)

,',

'; '~'i

r~ECHANICAL

ENGINEE~ING

: LUBRICATION

14.11 Tests on oils

Contribution of additives

Oil film strength can be increased. Oiliness increases, with other words should the oil film break down the additive prevents or delays metal seizure. Reduces the viscosity index. Small percentage of silicones prevents foaming and 011 corrosion. Viscosity tests Flash point test to detect if there is contamination by inflarnmable impurities having low boiling points. Setting point or solidifying point test which should be lower than the lowest temperature of the service conditions required. The coking test, to indicate the tendency to form carbon deposits in engine cylinders. Acidity and demulsibility tests. Acidity and saporification test for presence of animal or vegetable oil.

Q=Px60xT]

=

1000

60

0,85

= 51 kJ tmin ~

Mass of oil used:

m Cp.M

51 = m x 1,47 x 6 m = 5,78 kg Zmin=-s

The volume of oil required in tlmin:

"'_-' le-engines carbon deposits on pistons, rings and v lives are washed ofT and keeps the working parts in c'ean conduions

Volume

mass + density 5,78 0,82

= 7,08 et mill ~

000000000

r-

~ ~

Example 1

In the bearing of an engine I kW is absorbed by friction and all of this power is converted into heat of which 85% is carried away by the oil supply. The specific heat capacity of the oil is 1,47 k1/kgK and the rise in temperature density of the oil is 0,82, calculate the required supply of oil in tlmin. SOLUTION: Heat carried away by oil:

000000000

Example 2

i

I

!

1

:1

I:

I j

I I rL

I

The thrust of a shaft is taken up by a thrust bearing. The bearing is fitted with a forced lubrication system which maintains a film of oil of constant thickness 0,3 mm between the surface of the collar and the surface of the bearing. The outer and inner diameters of the collar are 156 mm and 120 mm respectively. The coefficient of viscosity of the oil is 0,2 N 5/m'. Determine the power lost in friction of the thrust bearing when the shaft rotates at 500 r/min.

~

POTCHEFSTROOM

COLLEGE:

DAWIE BOTES

(copyrighted)

r~f(HANICAI..

fNGINfERHlG

: LUHRICA'110N

AIea of side contact: 7t d2

A=----

1t D2

= ~

(0,1562 - 0,122)

X

= 7,804

10-3 m2

The tangential force on thrust bearing: SOLUTION: If two contacting surfaces are separated by a film of oil the force required to provide relative velocity varies as the product of area of contacting surface and velocity or power varies as A.v. The mean diameter of the collar:

v F=f.lxAxt

= 0,2

7,804

10-3 X

-...:........--

3,613 0,3 X 10-3

=---

D +d

= 18,8 N ~

I

2

=

=

0,156

+ 0,12

Power loss in friction of the thrust bearing:

2 0,138 rn---).

P=Fxv

=

18,8

3,613

Mean velocity at 500 r/rnin: 1tdmN

67,924 W ~

v=

=

60

1t X

0,138

500

L_---'-

60 3,6l3 rnls ~

-..I

000000000

POTCHEF5TROO~l

COI.LECE : DNNlE

IlOTES (copyrighted)

'

t~ECHANI(,AL ENGINEERING:

LUBRICATION

le

Example 3

~

F=JlxAxA shaft having a diameter of 50 mm rotates concentrically in a bush baving a length of 100 mm, The radial clearance being 0,075 mm, The annular space between the shaft and bush is filled with oil having a viscosity of 0,09 kg/rns. Determine: (a) Define coefficient of viscosity. (b) Determine the power lost in bearing friction when the speed of rotation is 10 rls. SOLUTION: Heat energy lost:

v

t

I

I ,

I

= 0,09 x 15,71 x

io"

x __ 1.=....,5_7_1_

0,075

10-3

= 29,62 N ~

P=Fxv

=

29,62

1,571

=46,53

W ~

Area of contact:

A=7tdxi

=

7t x 0,05 x 0,1

X

= 15,71

Relative velocity:

10-] m2

=s

n dn

= 7t X 0,05 X 10 = 1,571 m/s ~

Friction resistance on surface:

POTCtiEF~"ROOM COLLEGE: DAWIE BOTES (copyrighted)

Vous aimerez peut-être aussi

- SANS Number Edition Title XDocument1 pageSANS Number Edition Title XAbiodun IloriPas encore d'évaluation

- National Skills Development Management System (NSDMS) Skills Development Provider: User Manual 2019Document15 pagesNational Skills Development Management System (NSDMS) Skills Development Provider: User Manual 2019Abiodun IloriPas encore d'évaluation

- WebCTRL - Brochure - April 2016Document8 pagesWebCTRL - Brochure - April 2016Abiodun IloriPas encore d'évaluation

- t870 - Industrial Orientation n3 Aug Memo 2019 Signed OffDocument5 pagest870 - Industrial Orientation n3 Aug Memo 2019 Signed OffAbiodun IloriPas encore d'évaluation

- Centrifugal Pumps 2Document25 pagesCentrifugal Pumps 2Abiodun IloriPas encore d'évaluation

- Centrifugal Pumps 1Document9 pagesCentrifugal Pumps 1Abiodun IloriPas encore d'évaluation

- General Use, Care and Maintenance Manual For Steel Roller Shutter DoorsDocument3 pagesGeneral Use, Care and Maintenance Manual For Steel Roller Shutter DoorsAbiodun IloriPas encore d'évaluation

- Roller Shurter Door Maintenance 2021Document28 pagesRoller Shurter Door Maintenance 2021Abiodun IloriPas encore d'évaluation

- Operation and Maintenance For Electrically OperatedDocument15 pagesOperation and Maintenance For Electrically OperatedAbiodun IloriPas encore d'évaluation

- Industrial Door Operation: Operating & Maintenance InstructionsDocument11 pagesIndustrial Door Operation: Operating & Maintenance InstructionsAbiodun IloriPas encore d'évaluation

- Industrial Door - Operating Manual Insert Address HereDocument12 pagesIndustrial Door - Operating Manual Insert Address HereAbiodun Ilori0% (1)

- Power Supply System For 5G Micro Base Station: Lifepo4Document4 pagesPower Supply System For 5G Micro Base Station: Lifepo4Abiodun IloriPas encore d'évaluation

- Eskom Rotek Engineering Roller Shurter Door Technical ReportDocument4 pagesEskom Rotek Engineering Roller Shurter Door Technical ReportAbiodun IloriPas encore d'évaluation

- Resource Library: The Industry's Most Authoritative Collection of Technical Resources For TechniciansDocument2 pagesResource Library: The Industry's Most Authoritative Collection of Technical Resources For TechniciansAbiodun IloriPas encore d'évaluation

- Profile - For - 3ruby Projects and Technical ServicesDocument6 pagesProfile - For - 3ruby Projects and Technical ServicesAbiodun IloriPas encore d'évaluation

- Operating Manual: Roller Garage DoorsDocument16 pagesOperating Manual: Roller Garage DoorsAbiodun IloriPas encore d'évaluation

- Profile - For - Ndou Technical ServicesDocument5 pagesProfile - For - Ndou Technical ServicesAbiodun IloriPas encore d'évaluation

- Ee6404 Measurements and InstrumentationDocument69 pagesEe6404 Measurements and InstrumentationAbiodun IloriPas encore d'évaluation

- Manual ABT SYSTEMDocument72 pagesManual ABT SYSTEMAbiodun IloriPas encore d'évaluation

- DS4 Trainingssysteme Katalog en FinalDocument158 pagesDS4 Trainingssysteme Katalog en FinalAbiodun IloriPas encore d'évaluation

- Motor WindingsDocument12 pagesMotor WindingsAbiodun IloriPas encore d'évaluation

- Pressure Vessels Act 2012Document35 pagesPressure Vessels Act 2012Abiodun IloriPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- IMO55 2021 T2 Problems EngDocument15 pagesIMO55 2021 T2 Problems EngTrần Phạm Gia BảoPas encore d'évaluation

- Analysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesDocument33 pagesAnalysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesaviantaraPas encore d'évaluation

- Determination of Total Carbohydrates by Anthrone MethodDocument2 pagesDetermination of Total Carbohydrates by Anthrone MethodGuru Raj PNPas encore d'évaluation

- SMC EIA Final Report - Baseline ReportDocument54 pagesSMC EIA Final Report - Baseline ReportGary JopsonPas encore d'évaluation

- Autoclave Aerated ConcreteDocument3 pagesAutoclave Aerated ConcreteFireSwarmPas encore d'évaluation

- Code For Electrical Installations at Oil and Gas Facilities-2015 4edDocument58 pagesCode For Electrical Installations at Oil and Gas Facilities-2015 4edMarijan Utroša100% (1)

- Lab 8Document4 pagesLab 8SHEILA HADIDPas encore d'évaluation

- PT - PhytoAct Golden Sericin - B2 - Customer VersionDocument11 pagesPT - PhytoAct Golden Sericin - B2 - Customer VersionNishikino MakiryPas encore d'évaluation

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Processraulpalma93Pas encore d'évaluation

- ConcreteDocument11 pagesConcretesiddhi gangwalPas encore d'évaluation

- States of Matter Solids and LiquidsDocument27 pagesStates of Matter Solids and LiquidsAtharva SatputePas encore d'évaluation

- Cryogenic GrindingDocument21 pagesCryogenic GrindingRahul Yadav100% (1)

- A716-08 (2014) Standard Specification For Ductile Iron Culvert PipeDocument5 pagesA716-08 (2014) Standard Specification For Ductile Iron Culvert PipejuegyiPas encore d'évaluation

- SpECcell Fibre TDSDocument2 pagesSpECcell Fibre TDSNgọc Đức ĐoànPas encore d'évaluation

- Kinetics of The Iodination of Acetone PDFDocument6 pagesKinetics of The Iodination of Acetone PDFsamPas encore d'évaluation

- Carbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Document5 pagesCarbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Matias Riera LópezPas encore d'évaluation

- School of Maritime Studies Vels University Thalambur: Soda Acid Extinguisher AimDocument2 pagesSchool of Maritime Studies Vels University Thalambur: Soda Acid Extinguisher AimAayush AgrawalPas encore d'évaluation

- Compact First - EnglishDocument45 pagesCompact First - EnglishLilianaOliveiraPas encore d'évaluation

- Solid Waste Management For HouseholdDocument70 pagesSolid Waste Management For HouseholdsonPas encore d'évaluation

- Brochure EN Ver - Thai Parkerizing Company ProfileDocument4 pagesBrochure EN Ver - Thai Parkerizing Company ProfileTAEWARAT RAKRUANGPas encore d'évaluation

- Dose The Right Amount of ChemicalsDocument3 pagesDose The Right Amount of ChemicalsrajachemPas encore d'évaluation

- Anchor Bolt For Brick MasonryDocument11 pagesAnchor Bolt For Brick MasonryEdmond Chow100% (1)

- Scientific Paper On Exercise 5 OsmosisDocument12 pagesScientific Paper On Exercise 5 OsmosisJustin BeltranPas encore d'évaluation

- DNV-RP-O501 Erosive Wear in Piping SystemsDocument43 pagesDNV-RP-O501 Erosive Wear in Piping SystemsTroyPas encore d'évaluation

- Lecture-2-Fluid Statics - UsmDocument32 pagesLecture-2-Fluid Statics - UsmSyed Naveed AhmedPas encore d'évaluation

- BOQ Fountain Water Body (1) .XLSXBDocument6 pagesBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- Chapter-6 Tissues-Full NotesDocument12 pagesChapter-6 Tissues-Full NotesAdithya VinodPas encore d'évaluation

- Topic 12 - Acid-Base Equilibria MCQsDocument11 pagesTopic 12 - Acid-Base Equilibria MCQsmegaordinaryday0% (1)

- 1100 XC Airless SprayerDocument28 pages1100 XC Airless SprayerR Fonseca GomezPas encore d'évaluation

- Origin and Evolution of LifeDocument40 pagesOrigin and Evolution of LifeMary Grace BesinPas encore d'évaluation