Académique Documents

Professionnel Documents

Culture Documents

Bondor Indonesia - Clean Room Flyer

Transféré par

cysautsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bondor Indonesia - Clean Room Flyer

Transféré par

cysautsDroits d'auteur :

Formats disponibles

Bondor Insulated Panel System application: CLEAN ROOM Application of Bondor Insulated Panel System in

TM

TM

CLEAN ROOM

To ensure the sanitation and hygiene needed inside a clean room are easily maintained, food processing facilities and pharmaceutical industries can benefit from using Bondor Insulated Panel Systems in order to get a room that is: ! able to ensure and preserve cleanliness and healthiness, ! easy in maintenance. ! able to preserve certain temperature to prevent materials damage inside the room, and ! capable to sustain air cleanliness.

BondorTM Insulated Panel Systems used in Clean Room in a pharmaceutical company

Advantage of using Bondor Insulated Panel Systems in Clean Room

As a superior quality product, the application of Bondor Insulated Panel Systems in Clean Room has many advantages such as: Slip Joint The Slip Joint system applied in Bondor panels has the ability to increase the strength and the bonding of the panels, which resulted in an increased capability as vapour barrier. Slip Joint also shortened panel installation time, reduced noise pollution and decreased the usage of support structure. Fire-Retardant or Fire-Resistant cores Fire retardant cores are self-extinguished Expanded Polystyrene (EPS), and Polyurethane (PU). For clean room, EPS with density of 15kg/m and 50 or 75mm thickness are usually used. PU with density 38-40kg/m is more popular to be used in commercial cold room between 4-36m while for industrial cold room or food processing plant more than 36m, EPS is more suitable due to the rigid construction. Fire resistant cores are Mineral Wool Fibreboard (known as Flameguard Panel in Bondor Insulated Panel Systems) and Polyisocyanurate (PIR). Mineral Wood Fibre is classed as non-combustible as a building material with an excellent fire performance and has a melting point above 1000C, while PIR Panels simply chars in an event of fire. Properly installed PIR Panels can significantly reduce the serious risk of property damage and loss of business due to fire. The PIR Panel used in Bondor Insulated Panel Systems has been FM Approved certified by FM Global Group.

The Slip Joint system used in EPS and PU Panels. Patent Reg. No. ID 0 010 442 - D

Four types of panels in Bondor Insulated Panel Systems: (1) EPS Panel, (2) PU Panel, TM (3) PIR Panel, (4) Flameguard Panel

TM

Bondor Insulated Panel System application: CLEAN ROOM

TM

No rivet expose for Clean Room applications

Steel Skin Bondor Insulated Panel Systems uses 0.6mm Food Grade off-white steel skin to make a strong and firm structure. The steel skin use weathering corrosion proof Galvanized Steel for superior life span against rusting to make a life-long maintenance free. For clean room or food processing applications, the surface of the panels will be plain surface with no profile. Wall to Ceiling / Floor Joints The connection between wall panels to ceilings and floors in clean room will use radius coving with 35 or 65mm diameter, or 90 angle and PVC/Polyacetal 3-way corners to meet clean rooms requirements for cleanliness and hygiene. All extrusions are made from off-white powdercoated Aluminum to make it esthetically matching with the steel skin colour. Doors Made with 50mm panels, extrusions with anti-corrosive component and no timber frame, doors are available in many different types either manually or electrically from single or double swing, horizontal or vertical to airtight doors with interlock systems. All doors are designed for heavy-duty usage, easy to operate and maintain. In airtight doors, such as for the ones used for access from public to production or grey to white area, P-setter will be used inside out to prevent air to get through to make sure the quality and condition wanted inside the room is sustained. Windows and Door Viewing Choices for extrusions used in windows and door viewing in clean room are rounded or 45 shaped. Depended on the needs and requirements of the customers, choices of glass to be used will be single, double or triple glass. Laminated glass is also available. Single glass is usually used in processing room; while double or triple glass is used in clean room to make sure there is flat surface between windows/viewing and the panels. Inside a triple glass there is dry air to prevent any fungi growth. Other Clean Room Attributes Lamp frame, man hole, supply air duct inside clean room will use the same extrusion used in windows and door viewing, while for return air wall flashing made from folded 0.6mm Food Grade off-white steel skin will be used. Fast, Easy, Clean Installation Bondor Insulated Panel Systems with Slip Joint provide a fast assembly erection and shorter construction time. The advantages of using Bondor Insulated Panel Systems from construction point of views are: ! panels are manufactured according to customer's need and order based on building structure, ! during installation, panels can be adjusted according to building structure, ! easy adjustment using the same panels if customers would like to change the design of the room, ! no rivet expose in doors or windows for clean room application, ! all gaps between extrusion, panel and glass will be sealed with sealant to structurally strengthen support structure, ! flexible during earth quake, ! able to be used for high-rise building, ! easy to transport and install, ! small construction load, start at 12 kg/m depended on the type of insulation material used, which resulted to ! less construction cost.

No rivet expose in doors and windows

Single or Double Doors with viewing windows

Ceilings with in-bowed lamp and Supply Air Diffuser

Return Air Grill in the corner and pipe installed in panel

PVC / Polyacetal 3-way corners

Pass Box from inside a Clean Room. Inset: from outside

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 05 Automotive Catalog 10Document26 pages05 Automotive Catalog 10vava raamdhanaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 03 Airpressured UpdateDocument12 pages03 Airpressured UpdateRamadhan FebriPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Minimum Construction Requirement Water Bore-AUSDocument97 pagesMinimum Construction Requirement Water Bore-AUScysauts100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- 02 Agriculture Catalog10 Update PDFDocument6 pages02 Agriculture Catalog10 Update PDFNonikhudiaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 01 Adhesive and Selant Product Catalog10Document2 pages01 Adhesive and Selant Product Catalog10abdul muslimPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 04 Air Tool UpdateDocument6 pages04 Air Tool UpdateAliSyariefPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Isolab 2020-2022 English CatalogDocument226 pagesIsolab 2020-2022 English CatalogSilvia GratiiPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Variable Speed DrivesDocument546 pagesVariable Speed DrivescysautsPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Addresses Chambers of Commerce (Alamat Kamar Dagang) : WWW - Iccc.or - IdDocument2 pagesAddresses Chambers of Commerce (Alamat Kamar Dagang) : WWW - Iccc.or - IdcysautsPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Safety: Public Health Significance of Foodborne IllnessesDocument16 pagesSafety: Public Health Significance of Foodborne IllnessescysautsPas encore d'évaluation

- Tesys - Motor Stater Solution - 2006Document880 pagesTesys - Motor Stater Solution - 2006cysautsPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Law of The Republic of Indonesia Number 19 Year 2002 RegardingDocument26 pagesLaw of The Republic of Indonesia Number 19 Year 2002 RegardingcysautsPas encore d'évaluation

- Tesys - Motor Stater Solution - 2006Document880 pagesTesys - Motor Stater Solution - 2006cysautsPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- WHO Global Strategy For Food SafetyDocument27 pagesWHO Global Strategy For Food SafetycysautsPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

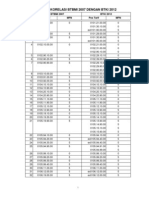

- Tabel KorelasiDocument244 pagesTabel Korelasiboma_sudiroPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- HACCP Training GuidelineDocument55 pagesHACCP Training Guidelinecysauts100% (1)

- Risk Assessment of Salmonella in Eggs and Brioler ChickenDocument70 pagesRisk Assessment of Salmonella in Eggs and Brioler ChickencysautsPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- TQA-HACCP Manual For Clam Production and ProcessingDocument49 pagesTQA-HACCP Manual For Clam Production and ProcessingcysautsPas encore d'évaluation

- Sss GuideDocument26 pagesSss GuideAsif HameedPas encore d'évaluation

- Hazard Characterization For Pathogens in Food and WaterDocument76 pagesHazard Characterization For Pathogens in Food and WatercysautsPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- WHO Risk Asessmentmarch1995Document43 pagesWHO Risk Asessmentmarch1995cysautsPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

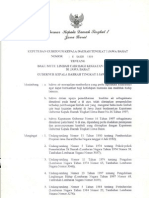

- SK MenhumkamDocument2 pagesSK MenhumkamcysautsPas encore d'évaluation

- A Guide To HACCP System in The Seafood IndustryDocument146 pagesA Guide To HACCP System in The Seafood IndustrycysautsPas encore d'évaluation

- SK Gub No.6 TH 1999Document55 pagesSK Gub No.6 TH 1999Dede Andryan100% (4)

- Buffer Tank Design FaanesDocument11 pagesBuffer Tank Design FaanescysautsPas encore d'évaluation

- Water Quality in Streams and Rivers Is The End Product of All Processes in The BasinDocument89 pagesWater Quality in Streams and Rivers Is The End Product of All Processes in The BasinVivek GolchhaPas encore d'évaluation

- HSE. Chloride Stress Corrosion Cracking in Austenitic Stainless SteelDocument62 pagesHSE. Chloride Stress Corrosion Cracking in Austenitic Stainless Steelfallalovaldes100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- F94026-Corrosion of MetalsDocument60 pagesF94026-Corrosion of MetalscysautsPas encore d'évaluation

- Buffer Tank Design FaanesDocument11 pagesBuffer Tank Design FaanescysautsPas encore d'évaluation

- InTech-Corrosive Effects of Chlorides On MetalsDocument41 pagesInTech-Corrosive Effects of Chlorides On MetalsAndrey756Pas encore d'évaluation

- Bulk Carrier InspectionsDocument3 pagesBulk Carrier InspectionsmetallourgosPas encore d'évaluation

- Evaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentDocument4 pagesEvaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Carl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiDocument1 pageCarl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiA GHAILANE EL HASSANI RABII SOUMAYAPas encore d'évaluation

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Emissivity TableDocument13 pagesEmissivity TableUtubesPas encore d'évaluation

- Four Stroke Diesel EngineDocument17 pagesFour Stroke Diesel Engineamirsyawal87Pas encore d'évaluation

- What Is The Role of Zinc Oxide in Rubber Formulations - Nanjing Union Rubber ChemicalsDocument3 pagesWhat Is The Role of Zinc Oxide in Rubber Formulations - Nanjing Union Rubber ChemicalsShukri FaezPas encore d'évaluation

- 2006 - Solar-Driven Refrigeration Systems With Focus On The Ejector CycleDocument286 pages2006 - Solar-Driven Refrigeration Systems With Focus On The Ejector CycleFernandoMartínIranzoPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Geography Form 3 Week 2 Lesson 1 Study PackDocument8 pagesGeography Form 3 Week 2 Lesson 1 Study PackIss MePas encore d'évaluation

- Air Permeability Test ResultDocument4 pagesAir Permeability Test Resultritesh0raj-2Pas encore d'évaluation

- Spargers - For Reaction Vessels: New From ACE..Document2 pagesSpargers - For Reaction Vessels: New From ACE..parykoochakPas encore d'évaluation

- Borgianni, de Filippis - Gasification Process of Wastes Containing PVCDocument7 pagesBorgianni, de Filippis - Gasification Process of Wastes Containing PVCJorge VeraPas encore d'évaluation

- 2-1-2 - General Specification of Main Laying Materials For Waterworks LatestDocument112 pages2-1-2 - General Specification of Main Laying Materials For Waterworks LatestRaulSaavedra0% (1)

- Datasheet SKHI 22A PDFDocument12 pagesDatasheet SKHI 22A PDFGlauber GoncalvesPas encore d'évaluation

- NCSE 2006 Integrated ScienceDocument19 pagesNCSE 2006 Integrated ScienceChristian PatricePas encore d'évaluation

- Tolerances Tables PDFDocument16 pagesTolerances Tables PDFPramod SaljoshiPas encore d'évaluation

- TMB 60Document2 pagesTMB 60oac08Pas encore d'évaluation

- Wisner Case 13Document8 pagesWisner Case 13Nabaneeta SahanaPas encore d'évaluation

- Aluminium Alloy 6061Document3 pagesAluminium Alloy 6061choobyPas encore d'évaluation

- Método EPA 3010ADocument5 pagesMétodo EPA 3010APaulina Armella RojasPas encore d'évaluation

- CatalogDocument482 pagesCatalogAnonymous 6EW2MsFbkPas encore d'évaluation

- VDO Commercal Product CatalogueDocument40 pagesVDO Commercal Product CataloguejasminbijedicPas encore d'évaluation

- MOS For Bituminous Protective Coating Water ProofingDocument5 pagesMOS For Bituminous Protective Coating Water ProofingHussam WaleedPas encore d'évaluation

- Development of Filament Winding Machine For Producing Round Shapes With Different Fiber ReinforcementsDocument7 pagesDevelopment of Filament Winding Machine For Producing Round Shapes With Different Fiber ReinforcementsŞafak ÖzdenPas encore d'évaluation

- LA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsDocument2 pagesLA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsNordson Adhesive Dispensing SystemsPas encore d'évaluation

- Product Range: Typical ValuesDocument32 pagesProduct Range: Typical ValuesRodrigoMachadoPas encore d'évaluation

- Chapter 8: Failure: How Do Materials Break?Document40 pagesChapter 8: Failure: How Do Materials Break?Leann FarleyPas encore d'évaluation

- PEI-QHSE-002-Hazards Identification and Risk Management ProcedureDocument16 pagesPEI-QHSE-002-Hazards Identification and Risk Management ProcedureJacob Keemink100% (1)

- Swan Teasmade Instructions 14140Document8 pagesSwan Teasmade Instructions 14140Roy RussellPas encore d'évaluation

- Danfoss - Compressor Case StudiesDocument5 pagesDanfoss - Compressor Case Studiesgpax42Pas encore d'évaluation

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingD'EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingÉvaluation : 4.5 sur 5 étoiles4.5/5 (845)

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterD'EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterÉvaluation : 4 sur 5 étoiles4/5 (467)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyD'EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyÉvaluation : 4 sur 5 étoiles4/5 (277)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.D'EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Évaluation : 4 sur 5 étoiles4/5 (17)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeD'EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeÉvaluation : 5 sur 5 étoiles5/5 (2)

- Simplified Organization: Learn to Love What Must Be DoneD'EverandSimplified Organization: Learn to Love What Must Be DonePas encore d'évaluation

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyD'EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyÉvaluation : 4 sur 5 étoiles4/5 (40)