Académique Documents

Professionnel Documents

Culture Documents

Comparison Table

Transféré par

rayscrubberDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Comparison Table

Transféré par

rayscrubberDroits d'auteur :

Formats disponibles

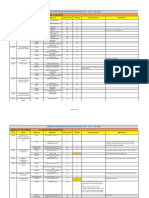

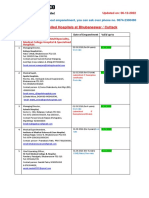

COMPARISON TABLE - VOLUTE and Other Equipments Volute Dewatering Press Screw Press Centrifuge Belt Press Overall

Image

Model

(Throughput 100 kgDS/h max.)

ES-301

The main body is composed of accumulated Rings and Screw. The accumulated Rings work as filter. The solids and the liquid are separated by the pressure caused by the Screw. The Screw pushes the edge of the Moving Rings (diameter smaller than the Screw) so that they move continuously in the gaps between the

Inner Diameter: 500mm

The main body composed of the punching metal or wedge wire and screw. The punching metal or wedge wire works as filter. The solids and the liquid are separated by the pressure caused by the Screw. The gravity dehydration and the pressuring dehydration are done to the floc made by the coagulant.

Inner Diameter: 800mm

The screw is built in the closure body. It separates by the specific gravity difference of liquid and solids. The sludge is introduced into a bowl rotaing at high speed. Centrifugal force causes liquid-solid separation.

Belt: 1m wide

The main body is composed of filter cloth. After gravity dewatering, the sludge is sandwiched between two filter cloths. Dewatering is carried out by compression and application of pressure, using rollers and belts.

Principle

Dewatering Performance

sludge cake solids content on waste activated sludge

205

205

205

155

Footprint Installation

3260mm 940mm

(Including a control panel and a flocculation tank)

3182mm 630mm

(Excluding a control panel and a flocculation tank)

2910mm 1485mm

(Excluding a control panel and a flocculation tank)

3150mm 1950mm

(Excluding a control panel and a flocculation tank)

Dry Weight

840kg

(Including a control panel and a flocculation tank)

550kg

(Excluding a control panel)

1900kg

(Excluding a control panel and a flocculation tank)

3000kg

(Excluding a control panel and a flocculation tank)

Vibration and Noise Suitability for Oily Sludge Daily Maintenance Initinal Cost *Power Consumption *Water Consumption Total Costs

0.8kWh 1,752/year 0.04/h 876 /year

63dB

0.8kWh 1,752/year 0.5/h 10,950/year

67dB

11kWh 24,090/year 2.5/h 54,750/year

83dB

1.20kWh 2,628/year 4.6/h 100,740/year

74dB

2,628/year

12,702/year

78,840/year

103,368/year

*Electricity cost is 0.3/kWh and water cost is 3/m3. Operation cycle of dewatering equipment used for the above calculation is 20 h/day, 365 days/year. *Above data is an example based on a specific operational condition. Please understand that it varies depending on target sludge and operational condition.

Vous aimerez peut-être aussi

- Material Handling Equipment World Summary: Market Values & Financials by CountryD'EverandMaterial Handling Equipment World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Brochure Horizon - Sdi Series Catalog 201310Document12 pagesBrochure Horizon - Sdi Series Catalog 201310fahim khattakPas encore d'évaluation

- ZLD Presentation 3 PDFDocument24 pagesZLD Presentation 3 PDFramkeshmit_413125668100% (1)

- Importance of ZLD SYSYTEMDocument15 pagesImportance of ZLD SYSYTEMAVINASH THAKURPas encore d'évaluation

- Week8 Shell&TubeHEPart2Document56 pagesWeek8 Shell&TubeHEPart2Mochammad ReshaPas encore d'évaluation

- Quotation Request For Irrigation Automation Work in PalaceDocument4 pagesQuotation Request For Irrigation Automation Work in PalaceMathew YoyakkyPas encore d'évaluation

- GSR 34 (E) 35 (E) 36 (E) 37 (E) 38 (E)Document6 pagesGSR 34 (E) 35 (E) 36 (E) 37 (E) 38 (E)Nsp ReddyPas encore d'évaluation

- Sports High MastDocument2 pagesSports High MastmaxtamPas encore d'évaluation

- Rod BaffelsDocument2 pagesRod BaffelsVenkatesh SivarchanaPas encore d'évaluation

- Hamim Enterprise: A Life Safety CompanyDocument13 pagesHamim Enterprise: A Life Safety CompanyTaher AzadPas encore d'évaluation

- WTP - Opeation Engineer - GulfDocument2 pagesWTP - Opeation Engineer - GulfmaniyarasanPas encore d'évaluation

- SCS - Vendor ListDocument1 pageSCS - Vendor ListAnonymPas encore d'évaluation

- Swecs External 22072013 - Product - v1Document20 pagesSwecs External 22072013 - Product - v1Amir Asyraf SuhailiPas encore d'évaluation

- Water Champ - FX Series (Jul'14)Document47 pagesWater Champ - FX Series (Jul'14)PATRICIA GALINDO100% (1)

- r0 Proposal of Gree Tophill Lars - Ehi Rev1Document45 pagesr0 Proposal of Gree Tophill Lars - Ehi Rev1Anonymous fS6Znc9Pas encore d'évaluation

- SPX Johnson Pump OverviewDocument8 pagesSPX Johnson Pump OverviewSLNSG - 李玟福Pas encore d'évaluation

- Force Ksb-Omega-Pump Sarcina Pe Flanse PDFDocument19 pagesForce Ksb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaPas encore d'évaluation

- HSC Series: - Rotary Screw Air CompressorsDocument4 pagesHSC Series: - Rotary Screw Air CompressorsMAZENPas encore d'évaluation

- Car Parking LP SystemDocument4 pagesCar Parking LP SystemIorga Andrei EmilPas encore d'évaluation

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocument5 pagesDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaPas encore d'évaluation

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniPas encore d'évaluation

- Magnetrol O&gDocument100 pagesMagnetrol O&gesakkiraj1590Pas encore d'évaluation

- Material Material Description Mat Typ X-Plant Statx-Plant Date MFR Id MFR Name CountryDocument2 pagesMaterial Material Description Mat Typ X-Plant Statx-Plant Date MFR Id MFR Name CountryZain Abidi100% (1)

- Baili Hydraulic Hose 4SP-4SHDocument2 pagesBaili Hydraulic Hose 4SP-4SHJane ZhangPas encore d'évaluation

- Redico ProjectDocument94 pagesRedico ProjectAbhishek AgarwalPas encore d'évaluation

- 2015 Foster HVAC Selection GuideDocument2 pages2015 Foster HVAC Selection Guidesiva_nagesh_2Pas encore d'évaluation

- ApprovedMFRlistbyPG PDFDocument129 pagesApprovedMFRlistbyPG PDFMorgan PalmaPas encore d'évaluation

- LX325 (New Hi-Cyclic Low-ResDocument24 pagesLX325 (New Hi-Cyclic Low-ResGianna FrolaPas encore d'évaluation

- HVAC System Vendor and Subcontactor List: Technical Finance Product Manufactures Country Subcontractor Offer RemarkDocument1 pageHVAC System Vendor and Subcontactor List: Technical Finance Product Manufactures Country Subcontractor Offer RemarkMuhammad ElbarbaryPas encore d'évaluation

- Hexamide Agrotech CatalogueDocument13 pagesHexamide Agrotech CatalogueHexamide Agrotech Inc100% (3)

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDocument20 pagesUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SPas encore d'évaluation

- Express Water - June 2018Document60 pagesExpress Water - June 2018mayur_259100% (1)

- List of Acceptable Manufacturers / Suppliers Elevators Equipment Manufacturer / SupplierDocument11 pagesList of Acceptable Manufacturers / Suppliers Elevators Equipment Manufacturer / SuppliertharazainPas encore d'évaluation

- Sajid HussainDocument48 pagesSajid HussainTimothy GarciaPas encore d'évaluation

- 18-06 27 Presentation VTS Roediger Version 02 enDocument33 pages18-06 27 Presentation VTS Roediger Version 02 enmunjaPas encore d'évaluation

- Vendors - List 01-15Document7 pagesVendors - List 01-15Saif MohammedPas encore d'évaluation

- Company Profile - Kandy Constructions - SoftDocument36 pagesCompany Profile - Kandy Constructions - SoftUpali KarunarathnePas encore d'évaluation

- Agile Process Chemicals LLPDocument12 pagesAgile Process Chemicals LLPProduction SHVPMPas encore d'évaluation

- Frost & Sullivan Report On WTPDocument2 pagesFrost & Sullivan Report On WTPSameer PiklePas encore d'évaluation

- New Company ProfileDocument34 pagesNew Company ProfileSubhra JyotiPas encore d'évaluation

- General Specification For Electric Actuators - Integral Motor ControlDocument4 pagesGeneral Specification For Electric Actuators - Integral Motor ControlschgirlPas encore d'évaluation

- Oil and Gas 2016Document3 pagesOil and Gas 2016Mykel VelasquezPas encore d'évaluation

- Exodura CatalogDocument20 pagesExodura CatalogChad SoribelloPas encore d'évaluation

- Global Care Enviro System Tamil Nadu IndiaDocument10 pagesGlobal Care Enviro System Tamil Nadu IndiaGlobal Care Enviro SystemPas encore d'évaluation

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1Document198 pagesMetering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1kambiadoPas encore d'évaluation

- Common Ingress Protection (IP) Ratings For Electric MotorsDocument2 pagesCommon Ingress Protection (IP) Ratings For Electric Motorsavandetq15Pas encore d'évaluation

- MasterVarioR2C Product DataDocument5 pagesMasterVarioR2C Product DatanicolauscopernicPas encore d'évaluation

- Big Bolt Nut Brochure PDFDocument4 pagesBig Bolt Nut Brochure PDFanon_932866951Pas encore d'évaluation

- Consumer Guide Steelbars PDFDocument2 pagesConsumer Guide Steelbars PDFEdwin Ramos Policarpio100% (1)

- AQ - Solar - Presentation - Mar 2019 PDFDocument23 pagesAQ - Solar - Presentation - Mar 2019 PDFAhmadHussain09Pas encore d'évaluation

- Division Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)Document51 pagesDivision Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)insafaPas encore d'évaluation

- Container OfficeDocument1 pageContainer OfficeBANGGAPas encore d'évaluation

- Iwater Ion ExchangeDocument9 pagesIwater Ion ExchangeYogesh BadhePas encore d'évaluation

- Oil Separator DimensionDocument2 pagesOil Separator DimensionislamakthamPas encore d'évaluation

- ProcessIndustriesandDrives - Introduction - Slide - SetDocument26 pagesProcessIndustriesandDrives - Introduction - Slide - Setmfonseca31Pas encore d'évaluation

- STP BioshaftDocument54 pagesSTP BioshaftImran KhanPas encore d'évaluation

- BMG-BEL23042009 Idlers and RollersDocument16 pagesBMG-BEL23042009 Idlers and Rollersstevens75788Pas encore d'évaluation

- 1200-Palfinger Grijpers 2Document4 pages1200-Palfinger Grijpers 2ZoebairPas encore d'évaluation

- Glassmate Brochure 0Document2 pagesGlassmate Brochure 0Julie DicksonPas encore d'évaluation

- Katalog 2Document19 pagesKatalog 2Avazagha HuseynovPas encore d'évaluation

- Chapter 24 - The Solar SystemDocument36 pagesChapter 24 - The Solar SystemHeather Blackwell100% (1)

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Document19 pagesEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uPas encore d'évaluation

- What Is Denim? Why It's Called Denim?: Properties of Denim FabricDocument21 pagesWhat Is Denim? Why It's Called Denim?: Properties of Denim Fabricrahmanshanto623100% (1)

- Rocker ScientificDocument10 pagesRocker ScientificRody JHPas encore d'évaluation

- Essay Final ProjectDocument7 pagesEssay Final Projectapi-740591437Pas encore d'évaluation

- What Are Some of The Best Books On Computer ScienceDocument9 pagesWhat Are Some of The Best Books On Computer ScienceSarthak ShahPas encore d'évaluation

- Jurnal 1 Ieevee LPF PDFDocument4 pagesJurnal 1 Ieevee LPF PDFNanda SalsabilaPas encore d'évaluation

- ANS145 - Beef Cattle ProductionDocument52 pagesANS145 - Beef Cattle ProductionEgie BulawinPas encore d'évaluation

- Principles To Action (Short)Document6 pagesPrinciples To Action (Short)nsadie34276Pas encore d'évaluation

- 2.1 DRH Literary Translation-An IntroductionDocument21 pages2.1 DRH Literary Translation-An IntroductionHassane DarirPas encore d'évaluation

- BluePrint & High Pressure Pascalization (HPP)Document3 pagesBluePrint & High Pressure Pascalization (HPP)Prof C.S.PurushothamanPas encore d'évaluation

- Mangement of Shipping CompaniesDocument20 pagesMangement of Shipping CompaniesSatyam MishraPas encore d'évaluation

- Furnace Temperature & PCE ConesDocument3 pagesFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Risha Hannah I. NazarethDocument4 pagesRisha Hannah I. NazarethAlpaccino IslesPas encore d'évaluation

- Astm D 1196 PDFDocument3 pagesAstm D 1196 PDFSetyawan Chill Gates0% (1)

- 2001 Ford F150 ManualDocument296 pages2001 Ford F150 Manualerjenkins1100% (2)

- Corporate Restructuring Short NotesDocument31 pagesCorporate Restructuring Short NotesSatwik Jain57% (7)

- Ice 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisDocument15 pagesIce 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisBipin KrishnaPas encore d'évaluation

- Auditory Evoked Potentials - AEPs - Underlying PrinciplesDocument19 pagesAuditory Evoked Potentials - AEPs - Underlying PrinciplesMansi SinghPas encore d'évaluation

- Inspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsDocument13 pagesInspection Report For Apartment Building at 1080 93rd St. in Bay Harbor IslandsAmanda RojasPas encore d'évaluation

- Profibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/SpDocument3 pagesProfibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/Spmelad yousefPas encore d'évaluation

- Flip The Coin - EbookDocument306 pagesFlip The Coin - EbookAjesh Shah100% (1)

- UBMM1011 Unit Plan 201501Document12 pagesUBMM1011 Unit Plan 201501摩羯座Pas encore d'évaluation

- Mother Tongue K To 12 Curriculum GuideDocument18 pagesMother Tongue K To 12 Curriculum GuideBlogWatch100% (5)

- FDD Spindle Motor Driver: BA6477FSDocument12 pagesFDD Spindle Motor Driver: BA6477FSismyorulmazPas encore d'évaluation

- 3g Node B On Ip MediaDocument79 pages3g Node B On Ip MediaBsskkd KkdPas encore d'évaluation

- Assessment 4 PDFDocument10 pagesAssessment 4 PDFAboud Hawrechz MacalilayPas encore d'évaluation

- CH 15Document58 pagesCH 15Chala1989Pas encore d'évaluation

- FHHR 013 Red Tag Procedure PDFDocument5 pagesFHHR 013 Red Tag Procedure PDFN3N5YPas encore d'évaluation

- T688 Series Instructions ManualDocument14 pagesT688 Series Instructions ManualKittiwat WongsuwanPas encore d'évaluation