Académique Documents

Professionnel Documents

Culture Documents

Aea8 780095 0213

Transféré par

emnm30Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aea8 780095 0213

Transféré par

emnm30Droits d'auteur :

Formats disponibles

TM

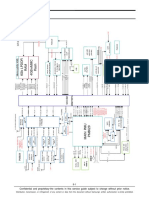

Controls for Resistance Welding

EN6041

Single Phase AC Cascade Constant Current Controls

Cascade Firing of up to 8 Contactors

Part of the EN6000 Series family with common hardware and programming 300 Amp air-cooled and 1200, 1800, 2200 & 3200 Amp water-cooled Contactors available Shorted contactor detection on all contactors Extremely flexible Heat Control allows 2 welds for every schedule programmed to Constant Current or Phase Shift Current on any contactor individually selectable 8 independent Valve Outputs control relay protected and monitored Standard I/O features provide additional 16 inputs and 8 outputs as compared to EN6021 Controls Similar in programming and operation to EN1000 Series Controls Only one Primary or Seconday Coil required

Constant Current

Control adjusts current output every cycle. No setup necessary for constant current operation. When optional secondary or primary coil is used, secondary amps are directly displayed. Current High, Low and Pre limits. Results of last weld available immediately. Pulse Width Monitor

PLC Compatible

PLC compatible via EtherNet/IP or MODBUS Function Code 04, 16 and 43 through low-cost serial (RS232 and RS485) or ethernet interfaces Design custom operator interface Actuate Weld Control Inputs from PLC, minimal interconnecting wires required Use weld control I/O for remote PLC I/O

Standard with every control !

Communication software provides PC interface for USB or Ethernet interfaces.

Features

USB B interface for ENLINK programming USB A Memory Stick Jack for Schedule backup USB A Memory Stick Jack for Weld Log and Error Log storage Spot or Pulsation Sequence Programmable options: Slope, Preheat, Quench, Temper, Postheat Linked Programs External Schedule Select Event Outputs Advanced Error Outputs 100 Programs Non-Repeat Water Saver Timer Programming in phase shift or kA 24 VDC flexible I/O (40 in/24 out); some mapable between weld functions, events and simple I/O sequences (32 in/ 24 out available for sequencer) with output protection I/O Sequencer/Programmer Stepper with Force and Current Presets Diverse schedule capabilities provide maximum application versatility 2) 4-20 mA / 0-10V analog input & output provided for pressure sensing & control Program Select Weld Log (57,600 entries) and Error Log (1,000 entries) with real time clock Shorted contactor detection

Options

Detachable 128 x 64 dots graphic (8 lines) LCD Program Pendant (RPP2) with data backup and 10N cable Primary or Secondary coils Program Lockout Operation Mode Switch (OMS) Program Lockout & Weld/No Weld Pressure Sense & Proportional Valve Isolation Contactor GFI for portable guns Water Flow Switch RS232/485/Ethernet communication card USB Memory stick for backup

Exclusive ENTRON two year warranty

Available Contactor Sizes:

300, 1200, 1800, 2200, 3200 Amp

8000 6000 5000 4000 3000 3200 Amp SCR Contactor 2200 Amp SCR Contactor 1800 Amp SCR Contactor 1200 Amp SCR Contactor

AMPERES DEMAND CURRENT RMS

2000

1000 800 600 500 400 300 200

300 Amp SCR Contactor

4 Cascade Control in G Cabinet

DEMAND CURRENT vs. PERCENT DUTY CYCLE for 30 Cycle Conduction Time

1 2 3 4 5 6 7 8 9 10 20 30 40 50 60 80 100

100

PERCENT DUTY CYCLE

Options (Expanded Capabilities require additional software and/or hardware)

TO PROGRAM, YOU WILL NEED: Program Pendant (RPP2) (P/N 730014-001) Detachable, hand-held pendant accesses all programmable variables and displays current and status. OR ENLINK 6041

(P/N 730015-001)

Pressure Sense and Control Hardware Using provided analog I/O or additional hardware: Differential sensors (P/N 730005-008) Single-ended sensors (P/N 730005-005) Proportional valves: 2O port (P/N 730005-007) 13O port (P/N 730005-006)

Communication Cards

(P/N 730014-007 & 730014-013)

Provides ability to network multiple controls using ENLINK 6041.

Communication software provides PC interface for remote programming and monitoring of control. TO MEASURE CURRENT IN AMPS, YOU WILL NEED: Secondary Rogowski Coils Available in 5O or 8O diameters. Provides actual secondary amperage measurements. OR Coil as part of Weld Transformer. OR Primary Coil

(P/N 313022) (S5 P/N 730014-005; S8 P/N 730014-006)

External USB & Ethernet Connectors

(P/N 730014-002)

Operation Mode Switch (OMS)

(P/N 730014-004)

Program Lockout (PLS)

(P/N 730014-009)

RS232 Printer

(P/N 730014-011)

Distributed by:

Data storage on USB memory stick

(P/N 730014-003)

TM

Water Flow Switch

(P/N 730005-009)

ENTRON Controls, LLC. 601 High Tech Court Greer, SC 29650 (864) 416-0190 FAX (864) 416-0195 www.entroncontrols.com e-mail: info@entroncontrols.com

7

MEMBER

780095-0213

Vous aimerez peut-être aussi

- Rhino - Inside.Revit Live Online Training Course - Simply RhinoDocument5 pagesRhino - Inside.Revit Live Online Training Course - Simply Rhinoemnm30Pas encore d'évaluation

- Rhino - Inside.Revit Essentials CourseDocument2 pagesRhino - Inside.Revit Essentials Courseemnm30Pas encore d'évaluation

- Rhino 3D Level 1 Certified Training From The UK Rhino Experts - Simply RhinoDocument5 pagesRhino 3D Level 1 Certified Training From The UK Rhino Experts - Simply Rhinoemnm30Pas encore d'évaluation

- Advancing parametric knowledge with Grasshopper Level 2Document7 pagesAdvancing parametric knowledge with Grasshopper Level 2emnm30Pas encore d'évaluation

- Simply Rhino Level 2 Course OutlineDocument8 pagesSimply Rhino Level 2 Course Outlineemnm30Pas encore d'évaluation

- RhinoCam Horizontal Roughing : Recommended Feeds & SpeedsDocument8 pagesRhinoCam Horizontal Roughing : Recommended Feeds & Speedsemnm30Pas encore d'évaluation

- Rhino 3D Level 2 Certified Training From The UK Rhino Experts - Simply RhinoDocument4 pagesRhino 3D Level 2 Certified Training From The UK Rhino Experts - Simply Rhinoemnm30Pas encore d'évaluation

- Rhino Level 1 Online Outline and ObjectivesDocument5 pagesRhino Level 1 Online Outline and Objectivesemnm30Pas encore d'évaluation

- Simply Rhino Level 1 Jewellery Design 2020Document3 pagesSimply Rhino Level 1 Jewellery Design 2020emnm30Pas encore d'évaluation

- Rhino 3D Level 1 Certified Training For Jewellers - Simply RhinoDocument4 pagesRhino 3D Level 1 Certified Training For Jewellers - Simply Rhinoemnm30Pas encore d'évaluation

- Grasshopper Training - Level 1 - Start Your Parametric Journey - Simply RhinoDocument5 pagesGrasshopper Training - Level 1 - Start Your Parametric Journey - Simply Rhinoemnm30Pas encore d'évaluation

- Grasshopper Training - Level 2 - Advance Your Parametric Knowledge - Simply RhinoDocument5 pagesGrasshopper Training - Level 2 - Advance Your Parametric Knowledge - Simply Rhinoemnm30Pas encore d'évaluation

- Simply Rhino Grasshopper Level 1 Online Evening ClassDocument7 pagesSimply Rhino Grasshopper Level 1 Online Evening Classemnm30Pas encore d'évaluation

- Simply Rhino Grasshopper Level 1 Online Evening ClassDocument7 pagesSimply Rhino Grasshopper Level 1 Online Evening Classemnm30Pas encore d'évaluation

- Advancing parametric knowledge with Grasshopper Level 2Document7 pagesAdvancing parametric knowledge with Grasshopper Level 2emnm30Pas encore d'évaluation

- Simply Rhino Grasshopper Level 1 Online Evening ClassDocument7 pagesSimply Rhino Grasshopper Level 1 Online Evening Classemnm30Pas encore d'évaluation

- Advancing parametric knowledge with Grasshopper Level 2Document7 pagesAdvancing parametric knowledge with Grasshopper Level 2emnm30Pas encore d'évaluation

- Advancing parametric knowledge with Grasshopper Level 2Document7 pagesAdvancing parametric knowledge with Grasshopper Level 2emnm30Pas encore d'évaluation

- Microsoft Word - Word Processing Software - Office PDFDocument7 pagesMicrosoft Word - Word Processing Software - Office PDFemnm30Pas encore d'évaluation

- Microsoft Word - Word Processing Software - Office PDFDocument7 pagesMicrosoft Word - Word Processing Software - Office PDFemnm30Pas encore d'évaluation

- Resurrect Your Whimsy - The Adventures of Baron MunchausenDocument16 pagesResurrect Your Whimsy - The Adventures of Baron Munchausenemnm30Pas encore d'évaluation

- Microsoft Word On The App Store PDFDocument3 pagesMicrosoft Word On The App Store PDFemnm30Pas encore d'évaluation

- Milling Machine Patterns and SetupDocument7 pagesMilling Machine Patterns and Setupemnm30Pas encore d'évaluation

- Microsoft Word - Work Together On Word Documents PDFDocument1 pageMicrosoft Word - Work Together On Word Documents PDFemnm30Pas encore d'évaluation

- The Adventures of Baron Munchausen - WikipediaDocument10 pagesThe Adventures of Baron Munchausen - Wikipediaemnm30Pas encore d'évaluation

- Plastic Snap Fit Design PDFDocument26 pagesPlastic Snap Fit Design PDFemnm30Pas encore d'évaluation

- Wren - Sky Garden Planter Light - WarmlyDocument13 pagesWren - Sky Garden Planter Light - Warmlyemnm30Pas encore d'évaluation

- Whats NewDocument224 pagesWhats NewHeard AmberPas encore d'évaluation

- Archery Bow Vibration Dampener Device Reduces ShockDocument10 pagesArchery Bow Vibration Dampener Device Reduces Shockemnm30Pas encore d'évaluation

- The Future CeoDocument20 pagesThe Future Ceoemnm30Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Digital Logic Test Questions For InterviewDocument53 pagesDigital Logic Test Questions For InterviewDwaraka OrugantiPas encore d'évaluation

- Illustrated Parts Catalogue BK117 C-1 Battery InstallationDocument5 pagesIllustrated Parts Catalogue BK117 C-1 Battery Installationjmam1992Pas encore d'évaluation

- Synchronous Step-Down11Document57 pagesSynchronous Step-Down11ed251Pas encore d'évaluation

- Week 3 Assignment SolutionDocument3 pagesWeek 3 Assignment Solutionlibin babyPas encore d'évaluation

- 4.5.4 Pulse Code Modulation PDFDocument40 pages4.5.4 Pulse Code Modulation PDFFirdausPas encore d'évaluation

- Fully Supported PRO Audio (And Video) Hardware Interfaces For The AV LinuxDocument26 pagesFully Supported PRO Audio (And Video) Hardware Interfaces For The AV LinuxvgkkctndPas encore d'évaluation

- Interfacing of Flame Sensor With ArduinoDocument14 pagesInterfacing of Flame Sensor With Arduinotech agentPas encore d'évaluation

- Operation: USB Interface U1, U2, U3 and U4Document5 pagesOperation: USB Interface U1, U2, U3 and U4Mohammed MostefaiPas encore d'évaluation

- Analog Circuits Versus Digital CircuitsDocument2 pagesAnalog Circuits Versus Digital CircuitsTalha MaqsoodPas encore d'évaluation

- Dynamic Microphone Order # 406.910: Eatures Echnical PecificationsDocument2 pagesDynamic Microphone Order # 406.910: Eatures Echnical PecificationsgbPas encore d'évaluation

- User Manual of DCH-4000P-Ver DDocument17 pagesUser Manual of DCH-4000P-Ver DRobertPas encore d'évaluation

- 07 - LTE Mobility ManagementDocument59 pages07 - LTE Mobility ManagementAnonymous Bqwv6CdPas encore d'évaluation

- MEEN 364 Lecture 4 Examples on Sampling and Aliasing PhenomenaDocument5 pagesMEEN 364 Lecture 4 Examples on Sampling and Aliasing PhenomenaHiren MewadaPas encore d'évaluation

- LEOXFER LEOMATIcDocument3 pagesLEOXFER LEOMATIcJosué T SilveiraPas encore d'évaluation

- WAGO 750 461 DatasheetDocument1 pageWAGO 750 461 DatasheetJoako ArandaPas encore d'évaluation

- Neptune Power Analyzer ManualDocument2 pagesNeptune Power Analyzer ManualsanjayPas encore d'évaluation

- Prog Controller Wiring SystemsDocument208 pagesProg Controller Wiring SystemsKyle StackPas encore d'évaluation

- Curriculum 2005Document67 pagesCurriculum 2005simardeepsingh3Pas encore d'évaluation

- Rx 1575.42MHz AGPS Supported MSM_ADocument58 pagesRx 1575.42MHz AGPS Supported MSM_ASalvadorRodriguesPas encore d'évaluation

- Using The Operational AmplifierDocument6 pagesUsing The Operational AmplifierYanPas encore d'évaluation

- Pro-Ject Essential/Phono USB: Instructions For UseDocument8 pagesPro-Ject Essential/Phono USB: Instructions For UseAleksandar KeracPas encore d'évaluation

- Lumped-Element System Dynamics: Joel Voldman Massachusetts Institute of Technology (With Thanks To SDS)Document69 pagesLumped-Element System Dynamics: Joel Voldman Massachusetts Institute of Technology (With Thanks To SDS)Nguyen Thanh KhuongPas encore d'évaluation

- IGBT Intelligent PwrMods SerbanDocument18 pagesIGBT Intelligent PwrMods SerbanjaphlmsPas encore d'évaluation

- Input Output InterfacingDocument48 pagesInput Output InterfacingLokesh Kumar ChoudharyPas encore d'évaluation

- Efficient SNR Estimation in OFDM SystemDocument3 pagesEfficient SNR Estimation in OFDM SystemkrishnaPas encore d'évaluation

- DsPIC Elmer 166 en USDocument78 pagesDsPIC Elmer 166 en USnawzat100% (2)

- MK 231 ADocument4 pagesMK 231 AAli AhmadPas encore d'évaluation

- Fast Audio Peak Limiter CircuitDocument4 pagesFast Audio Peak Limiter CircuitLuiz Clemente PimentaPas encore d'évaluation

- 80 Watt KU Band BUC ManualDocument53 pages80 Watt KU Band BUC ManualspeedyeduPas encore d'évaluation

- Sams ComputerFacts - Apple II, II PlusDocument66 pagesSams ComputerFacts - Apple II, II PlusOscar Arthur KoepkePas encore d'évaluation