Académique Documents

Professionnel Documents

Culture Documents

Jaw & Jaw Turnbuckles

Transféré par

Boby ThomasDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jaw & Jaw Turnbuckles

Transféré par

Boby ThomasDroits d'auteur :

Formats disponibles

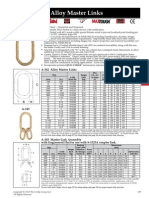

Jaw & Jaw Turnbuckles

End fittings are Quenched and Tempered or Normalized, bodies heat treated by normalizing.

Hot Dip galvanized steel.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Forged jaw ends are fitted with bolts and nuts for 6 mm through 16 mm, and pins and cotters

on

19 mm through 70 mm sizes.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design

factor, proof load and temperature requirements. Importantly, these turnbuckles meet other

critical performance requirements including fatigue life, impact properties and material

traceability, not addressed by ASME B30.26.

Lock Nuts available for all sizes (see page 178).

Comprehensive end fitting data provided on page 176.

Fatigue Rated.

Rigging

Accessories

HG-228

Meets the performance requirements

of Federal Specifications FF-T791b,Type 1, Form 1 - CLASS 7,

and ASTM F-1145, except for those

provisions required of the contractor.

For additional information,

see page 450.

HG-228

Jaw & Jaw

Thread

Working

Diameter &

Load

Weight

Take Up

HG-228

Limit

Each

E

(mm)

Stock No.

(t)*

(kg)

A

B

Closed

G

6.35 x 102

1032493

.23

.17

6.35

11.4

42.0

16.1

7.94 x 114

1032518

.36

.25

7.94

12.7

51.2

22.0

9.53 x 152

1032536

.54

.39

9.53

13.5

53.5

21.5

12.7 x 152

1032554

1.00

.83

12.7

16.3

81.8

27.1

12.7 x 229

1032572

1.00

1.04

12.7

16.3

81.3

27.1

12.7 x 305

1032590

1.00

1.23

12.7

16.3

81.3

27.1

15.9 x 152

1032616

1.59

1.46

15.9

20.1

99.1

33.5

15.9 x 229

1032634

1.59

1.79

15.9

20.1

98.8

33.5

15.9 x 305

1032652

1.59

2.08

15.9

20.1

98.8

33.5

19.1 x 152

1032670

2.36

2.18

19.1

24.6

120

38.5

19.1 x 229

1032698

2.36

2.65

19.1

24.6

119

38.5

19.1 x 305

1032714

2.36

3.05

19.1

24.6

119

38.5

19.1 x 457

1032732

2.36

3.83

19.1

24.6

120

38.5

22.2 x 305

1032750

3.27

4.25

22.2

29.5

140

44.8

22.2 x 457

1032778

3.27

5.34

22.2

29.5

140

44.8

25.4 x 152

1032796

4.54

4.74

25.4

34.0

155

52.1

25.4 x 305

1032812

4.54

6.25

25.4

34.0

155

52.1

25.4 x 457

1032830

4.54

7.77

25.4

34.0

155

52.1

25.4 x 610

1032858

4.54

9.51

25.4

34.0

154

52.1

31.8 x 305

1032876

6.89

9.94

31.8

46.7

205

71.5

31.8 x 457

1032894

6.89

11.7

31.8

46.7

205

71.5

31.8 x 610

1032910

6.89

13.5

31.8

46.7

205

71.5

38.1 x 305

1032938

9.71

14.8

38.1

52.3

227

71.4

38.1 x 457

1032956

9.71

17.2

38.1

52.3

227

71.4

38.1 x 610

1032974

9.71

19.7

38.1

52.3

227

71.4

44.5 x 457

1033018

12.7

24.3

44.5

66.0

238

85.0

44.5 x 610

1033036

12.7

27.7

44.5

66.0

238

85.0

51.0 x 610

1033054

16.8

43.7

50.8

66.5

300

95.0

63.5 x 610

1033072

27.2

75.9

63.5

77.7

337

113

70.0 x 610

1033090

34.0

90.1

69.9

93.7

379

106

Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

Copyright 2011 The Crosby Group LLC

All Rights Reserved

Dimensions

(mm)

J

Open

284

332

413

474

633

786

501

662

815

536

698

851

1155

880

1197

605

910

1215

1535

1000

1305

1624

1035

1340

1661

1355

1660

1769

1853

1899

K

Closed

183

218

260

321

405

481

349

434

510

383

470

546

698

575

740

453

605

757

925

695

848

1014

731

883

1051

898

1050

1159

1244

1289

M

Open

309

359

445

512

671

824

554

715

868

601

764

916

1221

956

1272

690

995

1300

1620

1107

1412

1731

1160

1465

1786

1503

1807

1949

2087

2172

N

Closed

208

244

292

359

443

519

402

487

563

449

535

612

764

651

815

538

690

843

1010

802

955

1121

855

1008

1176

1045

1198

1339

1478

1562

BB

103

116

155

153

238

314

153

239

315

156

244

320

471

309

473

157

309

462

631

306

459

625

313

465

633

467

619

622

625

626

173

Vous aimerez peut-être aussi

- Employee Code of Conduct Company Policy PDFDocument4 pagesEmployee Code of Conduct Company Policy PDFBrandon Beach100% (2)

- Pickling and Passivation ProcedureDocument5 pagesPickling and Passivation ProcedureBoby Thomas100% (5)

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Water-Soluble Salts On Substrate - Bresle MethodDocument5 pagesWater-Soluble Salts On Substrate - Bresle Methodjasminnee100% (1)

- Load Test Procedure For Lifting TacklesDocument4 pagesLoad Test Procedure For Lifting TacklesBoby ThomasPas encore d'évaluation

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- A449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseDocument7 pagesA449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseislamakthamPas encore d'évaluation

- 0106-7 Section C-DDocument129 pages0106-7 Section C-DPartsGopher.comPas encore d'évaluation

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Procedure For Tubing & ExpansionDocument6 pagesProcedure For Tubing & ExpansionBoby ThomasPas encore d'évaluation

- MSS SP 97 PDFDocument15 pagesMSS SP 97 PDFgowtham_venkat_4100% (1)

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Cotton Web ReportDocument30 pagesCotton Web ReportHumaRiaz33% (3)

- Sandvik Bantlı KonveyörlerDocument71 pagesSandvik Bantlı KonveyörlerEmin KorkmazPas encore d'évaluation

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimPas encore d'évaluation

- Crosby® TurnbucklesDocument11 pagesCrosby® TurnbucklesMidfiild CosminPas encore d'évaluation

- VideoDocument1 pageVideopothirajkalyanPas encore d'évaluation

- Crosby G2140 ShackleDocument1 pageCrosby G2140 Shacklepgarrett775814233Pas encore d'évaluation

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Pas encore d'évaluation

- Bolts & Nuts SpecificationDocument7 pagesBolts & Nuts Specificationpattanaik_munaPas encore d'évaluation

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1Pas encore d'évaluation

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Document1 pageCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupPas encore d'évaluation

- ASTMF436Document6 pagesASTMF436Zara DholkawalaPas encore d'évaluation

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13Pas encore d'évaluation

- BAP Choke CatalogDocument26 pagesBAP Choke Catalogkutts76Pas encore d'évaluation

- Astm A 563 2014Document9 pagesAstm A 563 2014Marlonnog100% (2)

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaPas encore d'évaluation

- Astm A182Document6 pagesAstm A182Rayan AlfredPas encore d'évaluation

- Structural SteelDocument30 pagesStructural Steelnandi_scr100% (1)

- Asme Section II A Sa-354Document8 pagesAsme Section II A Sa-354Anonymous GhPzn1xPas encore d'évaluation

- Adaptable TIGEAR Right Angle Speed Reducers: For More Information About ..Document44 pagesAdaptable TIGEAR Right Angle Speed Reducers: For More Information About ..Ryusuke IshikawaPas encore d'évaluation

- Metric TubeDocument6 pagesMetric TubePartsGopher.comPas encore d'évaluation

- CATALOGO FGS Internet-Katalog-EngDocument106 pagesCATALOGO FGS Internet-Katalog-Engjunico76Pas encore d'évaluation

- Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded FastenersDocument6 pagesQuenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded FastenersJennifer TurnerPas encore d'évaluation

- Zero Quality PDFDocument6 pagesZero Quality PDFDia Putranto HarmayPas encore d'évaluation

- A 449 - 00 - Qtq0os1sruqDocument8 pagesA 449 - 00 - Qtq0os1sruqAnderson VelandiaPas encore d'évaluation

- Weld Pipe FittingsDocument21 pagesWeld Pipe FittingsRanjit SinghPas encore d'évaluation

- Drilling StabilizersDocument2 pagesDrilling StabilizersWei ShangPas encore d'évaluation

- A354 PDFDocument7 pagesA354 PDFDeen ewPas encore d'évaluation

- FL OriginalLineDocument134 pagesFL OriginalLinebrooklynsnowPas encore d'évaluation

- Parker Series 2A Air CylinderDocument36 pagesParker Series 2A Air Cylindersdey26Pas encore d'évaluation

- Standard Specification For Corrugated Aluminum Pipe For Sewers and DrainsDocument15 pagesStandard Specification For Corrugated Aluminum Pipe For Sewers and Drainsjun floresPas encore d'évaluation

- Norma Astm A194Document11 pagesNorma Astm A194EstefaníaPas encore d'évaluation

- Turnbuckle Hook To EyeDocument1 pageTurnbuckle Hook To EyeeraswastaPas encore d'évaluation

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- A 354 - 03 - Qtm1nc1sruqDocument11 pagesA 354 - 03 - Qtm1nc1sruqJc DimayugaPas encore d'évaluation

- Wheatstone Project LNG PlantDocument1 pageWheatstone Project LNG PlantLegend AnbuPas encore d'évaluation

- Metric Tube - ParkerDocument6 pagesMetric Tube - ParkerJenny Cecilia Ureña ZuriPas encore d'évaluation

- FastenersDocument46 pagesFastenerser_lalitgargPas encore d'évaluation

- GHGGFHJDocument13 pagesGHGGFHJAllswell EllePas encore d'évaluation

- High-Strength Bolts For Structural Steel Joints (Metric)Document5 pagesHigh-Strength Bolts For Structural Steel Joints (Metric)carlokandiPas encore d'évaluation

- A 563 - 00 - Qtu2my1sruqDocument10 pagesA 563 - 00 - Qtu2my1sruqAnderson VelandiaPas encore d'évaluation

- Rolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelDocument1 pageRolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelbollidPas encore d'évaluation

- DM Water Tank SpecificationDocument9 pagesDM Water Tank SpecificationManish PatelPas encore d'évaluation

- 19.sec.1900 (Structural Steel)Document31 pages19.sec.1900 (Structural Steel)aalignup arc & const. pvt ltdPas encore d'évaluation

- Astm A193/a 193MDocument13 pagesAstm A193/a 193MCLEMENTPas encore d'évaluation

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- Catalog ParkerDocument230 pagesCatalog Parkeringerash_mic9067% (3)

- MSS Type 14 Fig332Document1 pageMSS Type 14 Fig332Brandon SmithPas encore d'évaluation

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99Pas encore d'évaluation

- 53 - Butt-Weld Pipe FittingsDocument13 pages53 - Butt-Weld Pipe Fittingsjoni_capelletoPas encore d'évaluation

- Din 1615Document5 pagesDin 1615David FonsecaPas encore d'évaluation

- Cone Roof Tank Erection ProcedureDocument8 pagesCone Roof Tank Erection ProcedureBoby Thomas100% (1)

- VPCL Application and Removal ProcedudreDocument3 pagesVPCL Application and Removal ProcedudreBoby Thomas100% (1)

- Welding Machine Calibration ProcedureDocument3 pagesWelding Machine Calibration ProcedureBoby Thomas100% (1)

- DIN-7972 - Self Tapping ScrewDocument2 pagesDIN-7972 - Self Tapping ScrewBoby ThomasPas encore d'évaluation

- AWS C5.10 - Sheilding Gas PDFDocument6 pagesAWS C5.10 - Sheilding Gas PDFBoby ThomasPas encore d'évaluation

- Asme 36.10MDocument26 pagesAsme 36.10MAlberto darian100% (1)

- Enviornment Impact Aspect Register MatrixDocument1 pageEnviornment Impact Aspect Register MatrixBoby ThomasPas encore d'évaluation

- RA-001a Rev 00 Risk Assessment Matrix PDFDocument24 pagesRA-001a Rev 00 Risk Assessment Matrix PDFBoby ThomasPas encore d'évaluation

- VesselDocument66 pagesVesselG100% (3)

- Fracture Testing According EN 9017Document3 pagesFracture Testing According EN 9017Anil100% (1)

- DEWA Vendor Guidelines Issue-4Document5 pagesDEWA Vendor Guidelines Issue-4Boby ThomasPas encore d'évaluation

- BSPT R ThreadDocument2 pagesBSPT R ThreadBoby ThomasPas encore d'évaluation

- PoothapatDocument4 pagesPoothapatBoby ThomasPas encore d'évaluation

- Bolt Tightening SequenceDocument1 pageBolt Tightening SequenceBoby ThomasPas encore d'évaluation

- BSPT R Thread PDFDocument1 pageBSPT R Thread PDFBoby ThomasPas encore d'évaluation

- PSG Teflon PtfeDocument1 pagePSG Teflon PtfeKanagala Raj ChowdaryPas encore d'évaluation

- Waste Management ProcedureDocument3 pagesWaste Management ProcedureBoby ThomasPas encore d'évaluation

- Chloride SalinityDocument9 pagesChloride SalinityBoby ThomasPas encore d'évaluation

- 8 8 and A325 ComparisonDocument1 page8 8 and A325 ComparisonBoby ThomasPas encore d'évaluation

- Physical Properties of Heavy Hex Structural Bolts ASTM A325 TYPE-1Document2 pagesPhysical Properties of Heavy Hex Structural Bolts ASTM A325 TYPE-1jhony0294km5Pas encore d'évaluation

- BPVC Viii-1 U-1 PDFDocument3 pagesBPVC Viii-1 U-1 PDFBoby ThomasPas encore d'évaluation

- TMCP Plates - Preheat RequirementsDocument2 pagesTMCP Plates - Preheat RequirementsSridharan ChandranPas encore d'évaluation

- IoclDocument25 pagesIoclShubham JainPas encore d'évaluation

- PETg Data SheetDocument4 pagesPETg Data SheetVikram BorkhediyaPas encore d'évaluation

- Aci 10 - 08Document62 pagesAci 10 - 08maPas encore d'évaluation

- Webers Least Cost TheoryDocument4 pagesWebers Least Cost Theoryapi-314084641Pas encore d'évaluation

- Slim Pom PG Pom PPC-4Document11 pagesSlim Pom PG Pom PPC-4Bhawin DondaPas encore d'évaluation

- Ankerlig Additional Storage TanksDocument48 pagesAnkerlig Additional Storage Tanksmarina890416Pas encore d'évaluation

- Mahindra & Mahindra Thrives On SAP - Enterprise Software in India - Express Computer IndiaDocument3 pagesMahindra & Mahindra Thrives On SAP - Enterprise Software in India - Express Computer IndiaSahil AnejaPas encore d'évaluation

- Furniture ManualDocument21 pagesFurniture ManualHabibie Akbar100% (1)

- En 19Document3 pagesEn 19Sanjay GorePas encore d'évaluation

- Milling Machine SpecificationsDocument17 pagesMilling Machine SpecificationsParas GoelPas encore d'évaluation

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsPas encore d'évaluation

- MdsDocument124 pagesMdsAnonymous GE8mQqxPas encore d'évaluation

- ASTM A510 03-Astm-Standardspecivication-1 PDFDocument7 pagesASTM A510 03-Astm-Standardspecivication-1 PDFNina LazuardiPas encore d'évaluation

- OECD Tourism Innovation GrowthDocument150 pagesOECD Tourism Innovation GrowthInês Rodrigues100% (1)

- Lession 1 Materials and Sanitary Features of The Dairy EquipmentDocument77 pagesLession 1 Materials and Sanitary Features of The Dairy EquipmentRajat Jain100% (1)

- A. Civil Engineering and ArchitectureDocument11 pagesA. Civil Engineering and ArchitectureMARIO HUAMANPas encore d'évaluation

- Course Material TwoDay Workshop Sheetemetal DHIO GTTCDocument132 pagesCourse Material TwoDay Workshop Sheetemetal DHIO GTTChsvjvv100% (1)

- iCON SB150 Professional Plant PDFDocument18 pagesiCON SB150 Professional Plant PDFmurci2929Pas encore d'évaluation

- CoatingPro July2012 - Adhesion Test Methods - Making Sure The Result StickDocument4 pagesCoatingPro July2012 - Adhesion Test Methods - Making Sure The Result StickUgoRibeiro100% (1)

- Internal Auditing As ISO 1900:2000Document74 pagesInternal Auditing As ISO 1900:2000mwlwaji100% (2)

- Lean ManufacturingDocument5 pagesLean ManufacturingruturrajPas encore d'évaluation

- Toyota Motors Manufacturing Usa Inc.: Weekly Assignement CaseDocument7 pagesToyota Motors Manufacturing Usa Inc.: Weekly Assignement CaseAyesha TahirPas encore d'évaluation

- AD0011-0511 ToughMet 3 at Temper Rod and TubeDocument2 pagesAD0011-0511 ToughMet 3 at Temper Rod and TubeBuchan65Pas encore d'évaluation

- BS en - 14532 2 2004 PDFDocument26 pagesBS en - 14532 2 2004 PDFPacoPas encore d'évaluation

- Extrusion Blow Molding Process PDFDocument2 pagesExtrusion Blow Molding Process PDFPetePas encore d'évaluation

- Improvement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesDocument9 pagesImprovement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesTavo MuñizPas encore d'évaluation

- Material HandlingDocument55 pagesMaterial HandlingNishaThakuri100% (2)

- CIP CycleDocument43 pagesCIP Cyclepatel9090% (1)