Académique Documents

Professionnel Documents

Culture Documents

Ucs 56

Transféré par

enemesio_85Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ucs 56

Transféré par

enemesio_85Droits d'auteur :

Formats disponibles

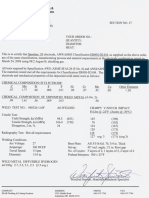

2010 SECTION VIII DIVISION 1

TABLE UCS-56

POSTWELD HEAT TREATMENT REQUIREMENTS FOR CARBON AND LOW ALLOY STEELS

Minimum Holding Time at Normal Temperature

Normal Holding

for Nominal Thickness [See UW-40(f)]

Temperature,

F (C), Up to 2 in. Over 2 in. to 5 in. Over 5 in.

Material Minimum (50 mm) (50 mm to 125 mm) (125 mm)

P-No. 1 1,100 (595) 1 hr/in. (25 mm), 2 hr plus 15 min for 2 hr plus 15 min

Gr. Nos. 1, 2, 3 15 min minimum each additional inch for each addi-

(25 mm) over 2 in. tional inch (25

(50 mm) mm) over 2 in.

(50 mm)

Gr. No. 4 NA None None None

NOTES:

(1) When it is impractical to postweld heat treat at the temperature speci ed in this Table, it is permissible to carry out the postweld heat treatment

at lower temperatures for longer periods of time in accordance with Table UCS-56.1.

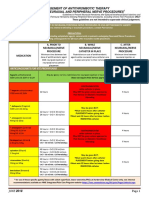

(2) Postweld heat treatment is mandatory under the following conditions:

(a) for welded joints over 1

1

2

in. (38 mm) nominal thickness;

(b) for welded joints over 1

1

4

in. (32 mm) nominal thickness through 1

1

2

in. (38 mm) nominal thickness unless preheat is applied at a

minimum temperature of 200 F (95 C) during welding;

(c) forweldedjoints of all thicknesses if requiredbyUW-2, except postweldheat treatment is not mandatoryunderthe conditions speci edbelow:

(1) for groove welds not over

1

2

in. (13 mm) size and llet welds with a throat not over

1

2

in. (13 mm) that attach nozzle connections

that have a nished inside diameter not greater than 2 in. (50 mm), provided the connections do not form ligaments that require

an increase in shell or head thickness, and preheat to a minimum temperature of 200 F (95 C) is applied;

(2) for groove welds not over

1

2

in. (13 mm) in size or llet welds with a throat thickness of

1

2

in. (13 mm) or less that attach tubes

to a tubesheet when the tube diameter does not exceed 2 in. (50 mm). A preheat of 200 F (95 C) minimum must be applied when

the carbon content of the tubesheet exceeds 0.22 .

(3) for groove welds not over

1

2

in. (13 mm) in size or llet welds with a throat thickness of

1

2

in. (13 mm) or less used for attaching

nonpressure parts to pressure parts provided preheat to a minimum temperature of 200 F (95 C) is applied when the thickness of

the pressure part exceeds 1

1

4

in. (32 mm);

(4) for studs welded to pressure parts provided preheat to a minimum temperature of 200 F (95 C) is applied when the thickness of

the pressure part exceeds 1

1

4

in. (32 mm);

(5) for corrosion resistant weld metal overlay cladding or for welds attaching corrosion resistant applied lining (see UCL-34) provided

preheat to a minimum temperature of 200 F (95 C) is maintained during application of the rst layer when the thickness of the

pressure part exceeds 1

1

4

in. (32 mm).

NA p not applicable

169

Copyright ASME International

Provided by IHS underlicens e with ASME Licensee Lloyds Regis ter Group Services/5975710001, User Luo, Wu

Not forResale, 07/21/2010 05:52:34 MDT No reproduction ornetworking permitted without license from IHS

-

-

,,,,,,,,,,,,,,,,-

-

,,,,,,,-

-

-

Vous aimerez peut-être aussi

- Ibr RegDocument6 pagesIbr RegSitaram Jha100% (1)

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawarePas encore d'évaluation

- Ug-116 - RT4Document3 pagesUg-116 - RT4miteshpatel191Pas encore d'évaluation

- Cathodic Protection BOMDocument4 pagesCathodic Protection BOManonymous542Pas encore d'évaluation

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaPas encore d'évaluation

- Straddle Principle For FlangesDocument1 pageStraddle Principle For Flangesameybarve67% (3)

- Sa 672Document7 pagesSa 672lalitaliPas encore d'évaluation

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- Tema StandardsDocument1 pageTema Standardsjose_alberto2Pas encore d'évaluation

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyPas encore d'évaluation

- Problems With B16.5 and B16.47 Flange StandardsDocument1 pageProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamPas encore d'évaluation

- Is 210Document16 pagesIs 210Debopriyo GhoshPas encore d'évaluation

- 32 Samss 031 PDFDocument9 pages32 Samss 031 PDFFlorin Daniel AnghelPas encore d'évaluation

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanPas encore d'évaluation

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiPas encore d'évaluation

- GIC Pressure GaugeDocument2 pagesGIC Pressure GaugeSUSOVAN BISWASPas encore d'évaluation

- E1 Technical Data Sheet - ShortDocument2 pagesE1 Technical Data Sheet - ShortOmaiyio M. SaginiPas encore d'évaluation

- TDC 1150Document3 pagesTDC 1150shazanPas encore d'évaluation

- Dished Heads - Head TypesDocument7 pagesDished Heads - Head Typesnaveenbaskaran1989100% (1)

- Codes StandardsDocument61 pagesCodes Standardshrk100Pas encore d'évaluation

- 32 Samss 036Document33 pages32 Samss 036naruto256Pas encore d'évaluation

- API Specification 6D 24th Edition Errata 10 20210803Document1 pageAPI Specification 6D 24th Edition Errata 10 20210803ANANDPas encore d'évaluation

- DCP Nde DV 297 HLT 01Document7 pagesDCP Nde DV 297 HLT 01Chandrasekhar mishraPas encore d'évaluation

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 pagesLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- P17-1TS-KBR Bolting Types Carbon & Alloy SteelDocument2 pagesP17-1TS-KBR Bolting Types Carbon & Alloy Steelyulianus_sr100% (1)

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xPas encore d'évaluation

- 32 Samss 004Document44 pages32 Samss 004ayubali009Pas encore d'évaluation

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivPas encore d'évaluation

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAOPas encore d'évaluation

- 7-12-0017 Rev 5Document2 pages7-12-0017 Rev 5cynidePas encore d'évaluation

- CuNi NUFITDocument16 pagesCuNi NUFIT9823458877Pas encore d'évaluation

- Mesc 76-210Document3 pagesMesc 76-210vtsusr fv100% (1)

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranPas encore d'évaluation

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinPas encore d'évaluation

- General Specification FOR Pressure VesselsDocument13 pagesGeneral Specification FOR Pressure Vesselssumit kumarPas encore d'évaluation

- Epilux 200 Polyamide Cured Coaltar EpoxyDocument3 pagesEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsPas encore d'évaluation

- ASME UM Audit Preparation ListDocument2 pagesASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- UG-100 Pneumatic TestDocument2 pagesUG-100 Pneumatic TestInaamPas encore d'évaluation

- IBR - 1950 - Reg282 p1Document2 pagesIBR - 1950 - Reg282 p1ganesh82100% (1)

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchPas encore d'évaluation

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyPas encore d'évaluation

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILPas encore d'évaluation

- Asme Section Ii A-2 Sa-961Document12 pagesAsme Section Ii A-2 Sa-961Anonymous GhPzn1xPas encore d'évaluation

- Buried Pipes and Fittings Painting SpecDocument5 pagesBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Toaz - Info Lifting Lug Calculation On Dish End PRDocument156 pagesToaz - Info Lifting Lug Calculation On Dish End PRandry4jcPas encore d'évaluation

- PVG PDFDocument40 pagesPVG PDFArindam DasPas encore d'évaluation

- Astm A216Document3 pagesAstm A216Ruth Sarai YañezPas encore d'évaluation

- Car ParkingDocument18 pagesCar ParkingYash SinghPas encore d'évaluation

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoPas encore d'évaluation

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pages6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarPas encore d'évaluation

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Document4 pagesTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalPas encore d'évaluation

- Asme Viii 1 - PWHT PDFDocument1 pageAsme Viii 1 - PWHT PDFGANGADHAR SAHUPas encore d'évaluation

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document1 pageTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3CITRIXPas encore d'évaluation

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDocument6 pagesTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalPas encore d'évaluation

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDocument6 pagesTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalPas encore d'évaluation

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDocument3 pagesTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalPas encore d'évaluation

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDocument4 pagesTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalPas encore d'évaluation

- Ultrasonido Por Arreglo de FasesDocument12 pagesUltrasonido Por Arreglo de Fasesenemesio_85Pas encore d'évaluation

- Large Structure Inspection (LSI™) System: Pipelines Ship Hulls Storage Tanks Pressure VesselsDocument2 pagesLarge Structure Inspection (LSI™) System: Pipelines Ship Hulls Storage Tanks Pressure Vesselsenemesio_85Pas encore d'évaluation

- AlloyDocument1 pageAlloyenemesio_85Pas encore d'évaluation

- TALRUT InspectionDocument1 pageTALRUT Inspectionenemesio_85Pas encore d'évaluation

- Ultrasonic Testing: Weld Inspection Using AWS D1.1Document65 pagesUltrasonic Testing: Weld Inspection Using AWS D1.1CLIFFORDPAPas encore d'évaluation

- ANSI B31.3 Tratamiento TermicoDocument6 pagesANSI B31.3 Tratamiento Termicoenemesio_85Pas encore d'évaluation

- Panchakanya Structural SteelDocument5 pagesPanchakanya Structural Steelkabira12Pas encore d'évaluation

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDocument1 pageESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987Pas encore d'évaluation

- Eiffic/Efuf (T:, RFRDT (FrrtfuDocument17 pagesEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuPas encore d'évaluation

- Chemistry Kerja Kursus PPSIMP Sem1. (BHG 2)Document18 pagesChemistry Kerja Kursus PPSIMP Sem1. (BHG 2)Ayisy HarizPas encore d'évaluation

- Sodium Metabisulphite RPTDocument51 pagesSodium Metabisulphite RPTGodolias WoldemariamPas encore d'évaluation

- Chemistry March 2008 EngDocument7 pagesChemistry March 2008 EngPrasad C M0% (2)

- 11.drug StudyDocument1 page11.drug StudyFreisanChenMandumotanPas encore d'évaluation

- MorphologyDocument5 pagesMorphologyJimi LeePas encore d'évaluation

- Stop Anticoagulation Neuraxial AnesthesiaDocument3 pagesStop Anticoagulation Neuraxial AnesthesiaGihan NakhlehPas encore d'évaluation

- Minimum VentilationDocument4 pagesMinimum VentilationNathan Smith100% (1)

- Tugas 1 PPADocument29 pagesTugas 1 PPAlulalalaPas encore d'évaluation

- Identification of CarbohydratesDocument2 pagesIdentification of CarbohydratesChristine Pearl Po0% (2)

- PerforatingDocument65 pagesPerforatingdriller22100% (1)

- ColaMulse EZDocument2 pagesColaMulse EZmndmattPas encore d'évaluation

- FDA-356h 508 (6.14)Document3 pagesFDA-356h 508 (6.14)sailaja_493968487Pas encore d'évaluation

- Kami Export - Hanna Huff - Amoeba Sisters - DNA Vs RNA 1Document1 pageKami Export - Hanna Huff - Amoeba Sisters - DNA Vs RNA 1hannakhuffPas encore d'évaluation

- Spiral Wound GasketsDocument7 pagesSpiral Wound GasketssadatPas encore d'évaluation

- Experimental Detemination of Crystal StructureDocument40 pagesExperimental Detemination of Crystal StructureAASHIR AHMAD JASKANIPas encore d'évaluation

- Experiment No. 2 Classes of Chemical Reactions BackgroundDocument5 pagesExperiment No. 2 Classes of Chemical Reactions BackgroundjonastolentinoPas encore d'évaluation

- Astm G200 - 09Document4 pagesAstm G200 - 09Sofia YuliPas encore d'évaluation

- Influence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloyDocument8 pagesInfluence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloywicaksonoPas encore d'évaluation

- Hydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCDocument18 pagesHydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCmoorpvrPas encore d'évaluation

- Is 8224Document16 pagesIs 8224Ankit YadavPas encore d'évaluation

- NESC Diploma - MillwrightDocument2 pagesNESC Diploma - MillwrightjamesPas encore d'évaluation

- Anatomi Dan Fisiologi Tumbuhan: Ihsan Tria Pramanda, M.SDocument19 pagesAnatomi Dan Fisiologi Tumbuhan: Ihsan Tria Pramanda, M.SReva RahmafitriPas encore d'évaluation

- E Grout Mc050Document2 pagesE Grout Mc050Tori SmallPas encore d'évaluation

- DNA-protein Interactions: Methods For Detection and AnalysisDocument31 pagesDNA-protein Interactions: Methods For Detection and AnalysisAhsan Arshad BSIT-F16-LC-008Pas encore d'évaluation

- Inconel 625Document5 pagesInconel 625koushkiPas encore d'évaluation

- 5MF 10MFDocument8 pages5MF 10MFRodrigo Pessoa VespaPas encore d'évaluation

- DapusDocument4 pagesDapuslisa ariantiPas encore d'évaluation