Académique Documents

Professionnel Documents

Culture Documents

Typical P&ID for Centrifugal Compressor Systems

Transféré par

msaroladanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Typical P&ID for Centrifugal Compressor Systems

Transféré par

msaroladanDroits d'auteur :

Formats disponibles

Typical P&ID arrangement for Centrifugal Compressor Systems

Figure 1 Typical P&ID for a centrifugal compressor system 1. Proper centrifugal compressor symbol should be selected first, as shown in figure1. Normally, a centrifugal compressor is accompanied by a Knock Out Drum (KOD) at the compressor suction and an aftercooler at the compressor discharge, as per a typical compressor PFD.SymbolsfortheseequipmentsshouldalsobeplacedontheP&ID

beforeproceedingahead.Alltheequipmentsymbolsshouldbeselected fromthelegendsheetsofaparticularproject. 2. Allthenozzlesonthecompressor,suctiondrumsandaftercoolershould thenbecorrectlyrepresentedwithsizeandflanges.Thisincludesinlet andoutletnozzlesandequipmentdrains/ventsasshowninthetypical P&IDinfigure1. 3. Centrifugal compressor suction KOD is intended for removing the entrainedliquidsbeforesendinggastothecompressor.Demister,mesh padetc.areusedintheknockoutdrumtoefficientlyremovetheliquid droplets. 4. Compressor aftercoolers are generally air coolers and the related fan, motor etc. should be clearly indicated on the P&ID. If cooling water is used,propersymbolforaheatexchangershouldbeused. 5. Inlet, outlet lines for each equipment, antisurge line, drain/vent lines, line to the relief valve etc. are the next to be drawn up. Line number, materialclass,sizeetc.istobecorrectlyassignedtoeachofthelines. 6. Isolation valves, spectacle blinds, spacers etc. to be used for maintenance should be drawn up next on various lines between the equipments. Requirement for isolation valves, spectacle blind, spaces etc. depend on the project standards, which should be followed while indicating these on the P&ID. Sometimes, to minimize the number of isolationvalvesbetweentheequipment,theycanbeplacedonlyatthe suction KOD inlet which is inlet of the centrifugal compressor system anddischargeoftheaftercoolerwhichturnsouttobetheoutletofthe centrifugalcompressorsystem.Spectacleblindsorspacerscanbeused for isolation between individual equipments for quick maintenance.

This is simply a guideline and project standards need to be followed whenindicatingtheisolationrequirements. 7. A check valve should be normally provided on the compressor dischargetoavoidreverseflowwhenthepumpisnotinoperation. 8. Pressurereliefvalvescanbeprovidedonthecompressordischargeline, downstreamtothecheckvalve,toprotecttheequipmentsdownstream ofcompressor. 9. Pressure gauges should be provided on suction and discharge of the compressor.Levelgaugesneedtobelocatedonthecompressorsuction knock out drum and temperature gauges on inlet, outlet lines for the aftercooler. 10. Pressuretransmittersshouldbeprovidedoncompressorsuction and discharge line. A flow transmitter should be provided on compressorsuctionline.Signalsfromthesetransmittersaresenttoan AntiSurgeController.Basedonthegasflowanddifferentialpressure head developed by the compressor, the antisurge controller operates theantisurgevalvestopreventcompressorsurgecondition. 11. An antisurge line from the aftercooler discharge to the suction KOD inlet should be provided for antisurge control. When the compressor approaches surge condition (low flow, high differential head), the antisurge valves open up to lower the pressure differential andcirculatehighergasflow. 12. Sometimes, a performance controller can be included in the centrifugal compressor system to control the rotating speed (RPM) of the compressor based on inlet pressure, flow etc. in order to achieve

optimumperformance.Performancecontrollerwilltypicallyadjustthe motor/turbinespeed. 13. Level transmitters provided on the suction knock out drum are responsible for liquid level control in the drum. Alarms are usually providedforhighandhighhighliquidlevelconditions. 14. Temperature transmitter can be provided on aftercooler for temperature control by sending a signal to adjust the fan speed of the aircooler. 15. Emergency Shutdown (ESD) valves can be provided on inlet / outletlinesofthecompressorssystemtoisolatewholesystemincaseof ashutdown.TheinletlineofthesuctionKODcorrespondstoinletofthe compressor system. Aftercooler discharge and liquid outlet of suction knock out drum correspond to the outlet lines of the compressor system. Shutdown valves can be located on these lines as shown in figure1. 16. Drainsandventstobeprovidedonthesuction/dischargelines, compressor casing, suction Knock Out Drum, air cooler body etc. for completely draining/venting compressor and associated piping, for maintenance. 17. line. 18. All the guidelines given here are very general and may be modifiedasperspecificrequirementsofanyparticularproject.

Forpurgingthecompressorsystem,anitrogenconnectioncanbe

provided right after the first isolation valve on the suction KOD inlet

Typical PFD for Centrifugal Compressor Systems

19. Thefollowingfigure1 representsatypicalprocessflow diagram

(PFD) for a compressor system. Common equipments included in such systemsarecompressors,drivermotorsorturbines,suctionknockout drums (KOD) to remove traces of liquid from the gas going into the compressor and aftercoolers which help lower the temperature of the dischargegasfromcompressor.Oftenantisurgecontrollersalongwith antisurge valves are also part of this system to avoid operating the compressoratsurgeconditions.

20. 21. 22. Figure1TypicalPFDforacentrifugalcompressorsystem Centrifugalcompressorsaretypicallydrivenbyanelectricmotor

or a steam turbine. The sample PFD in figure1 indicates use of an electric motor. The driver motor or turbine is connected to the

compressorbyashaftwhichcanrotateatdifferentspeedsforwhichthe motor or turbine is designed. Compressor manufacturer creates a compressor map which is essentially a graph of compressor curves plottedatdifferentrotationalspeed(RPM)values.Foragivenvalueof gasflowthoughthecompressor,dischargepressureofcanbecontrolled by controlling the rotational speed of the driver. Hence a pressure controllerinstalledonthecompressordischargestream,sendsasignal to the driver motor or turbine to control the rotational speed. Sometimes a compressor performance controller can be used which takes into account a lot of other parameters than just the discharge pressure,toeffectivelymaintaintherotationalspeed. 23. Presence of small liquid droplets in the gas compressor can be damaging to the compressor. Hence Knock Out Drums (KOD) at compressorsuctionaredesirabletoremoveevensmalltracesofliquid droplets from gas going to the compressor. These compressor suction drumsmaybeequippedwithdemisterpadsandwiremeshtoimprove theefficiencyofliquiddropletremoval. 24. Whengasiscompressedthegastemperaturealsorisesalongwith its pressure, since there is not enough time to vent the heat to atmosphere. Often high temperatures of the compressed gas are not desirablehenceaircoolerscanbeinstalledatthecompressordischarge toenabletemperaturecontrolofthedischargegas.Theseareknownas compressoraftercoolers. 25. Compressor surge is seen as a very dangerous and detrimental phenomenonforcompressorsystems,becauseitcausesthecompressor tovibrateanddamagesthecompressorparts.Compressorsurgeoccurs

due to high back pressure on the compressor discharge so that very smallgasflowcanbepushedthrough.Thisisindicatedbyasurgeline onanycompressormap.Toavoidcompressorsurgethebackpressure atcompressorhastobeloweredsothatmoregasflowcanbecirculated through the compressors. This can be accomplished by an antisurge controller which opens the antisurge valves so that excess pressure from the compressor discharge is vented to the compressor suction KOD. The antisurge valves also enable more gas flow to be circulated through the system, avoiding prolonged compressor operation in the surgeconditions.

Vous aimerez peut-être aussi

- Centrifugal Compressor Piping Layout GuideDocument5 pagesCentrifugal Compressor Piping Layout GuideFaizal KhanPas encore d'évaluation

- Reciprocating Compressor Cooloing ConsoleDocument22 pagesReciprocating Compressor Cooloing ConsolerutujaPas encore d'évaluation

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalPas encore d'évaluation

- REBOILER CALCULATION GUIDEDocument12 pagesREBOILER CALCULATION GUIDESabba CabbaPas encore d'évaluation

- Considerations For Centrifugal Compressor Piping LayoutDocument6 pagesConsiderations For Centrifugal Compressor Piping LayoutRakesh RanjanPas encore d'évaluation

- Characteristics of Thermosiphon Reboilers: Stephan Arneth, Johann StichlmairDocument7 pagesCharacteristics of Thermosiphon Reboilers: Stephan Arneth, Johann StichlmairKiril AckovskiPas encore d'évaluation

- Process Design Engineering Test-1Document6 pagesProcess Design Engineering Test-1Vague FruitsPas encore d'évaluation

- NGL SeparationDocument6 pagesNGL SeparationhoustonmathPas encore d'évaluation

- Designing Biogas Systems: A Technical GuideDocument7 pagesDesigning Biogas Systems: A Technical GuideMunish VashisthaPas encore d'évaluation

- Acfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-CogswellDocument9 pagesAcfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-Cogswellegsg50100% (1)

- DR - Reciprocating Compressor Table of Contents (Process)Document5 pagesDR - Reciprocating Compressor Table of Contents (Process)rutujaPas encore d'évaluation

- Sizing Forced Draft Fans For Fired HeatersDocument5 pagesSizing Forced Draft Fans For Fired Heatersdlalameen4471Pas encore d'évaluation

- Knockout DrumsDocument1 pageKnockout DrumsCheng Kai CongPas encore d'évaluation

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32Pas encore d'évaluation

- Mid-Term Training EvaluationDocument26 pagesMid-Term Training EvaluationVishalSharmaPas encore d'évaluation

- Automatic Recirculation ValveDocument3 pagesAutomatic Recirculation ValveIsares PodkohPas encore d'évaluation

- System OneDocument4 pagesSystem OnerasottoPas encore d'évaluation

- Control Valve Failure Relief Rate - Liquid ServiceDocument2 pagesControl Valve Failure Relief Rate - Liquid ServiceSaeid Rahimi MofradPas encore d'évaluation

- DS-TI Tower InternalsDocument10 pagesDS-TI Tower Internalschris100% (1)

- Centrifugal Compressor Surge and Surge ControlDocument32 pagesCentrifugal Compressor Surge and Surge ControlMoustafa HelmyPas encore d'évaluation

- GoyalDocument3 pagesGoyalVan LePas encore d'évaluation

- Glycol Contactor SizingDocument15 pagesGlycol Contactor SizingAnonymous 1JGftinPas encore d'évaluation

- Ejector technology for efficient and cost effective flare gas recoveryDocument10 pagesEjector technology for efficient and cost effective flare gas recoverySdadPas encore d'évaluation

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийPas encore d'évaluation

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIPas encore d'évaluation

- Air CompressorDocument51 pagesAir CompressorInaam Ur RehmanPas encore d'évaluation

- Gas Compression IIDocument13 pagesGas Compression IIAnuraag MulpuriPas encore d'évaluation

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocument7 pagesAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- Process Engineer - PSV Installation-GuideDocument3 pagesProcess Engineer - PSV Installation-GuideMannu SatPutePas encore d'évaluation

- Hydro ComDocument18 pagesHydro ComOmprakash_janaPas encore d'évaluation

- Air Cooler Design and Principle EIEPD 1696073698Document58 pagesAir Cooler Design and Principle EIEPD 1696073698Evandro Silva100% (1)

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocument3 pagesTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasPas encore d'évaluation

- Design of A Heat Exchanger Using HTRIDocument4 pagesDesign of A Heat Exchanger Using HTRIcenter010% (1)

- 4 Reciprocating Compressor IIDocument41 pages4 Reciprocating Compressor IIBassam AmirPas encore d'évaluation

- Pd-Va.4 (1996)Document15 pagesPd-Va.4 (1996)Santiago GarciaPas encore d'évaluation

- Refinery Experience Provides Guidelines For Centrifugal Pump SelectionDocument5 pagesRefinery Experience Provides Guidelines For Centrifugal Pump SelectionCal100% (1)

- Pump Boss - Intelligent Pump Control PowerpointDocument25 pagesPump Boss - Intelligent Pump Control PowerpointChem-FlowPas encore d'évaluation

- API Verses Non APIDocument19 pagesAPI Verses Non APIsandeshPas encore d'évaluation

- NPSH - Net Positive Suction HeadDocument12 pagesNPSH - Net Positive Suction HeadhbithoPas encore d'évaluation

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanPas encore d'évaluation

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodPas encore d'évaluation

- Korf BrochureDocument1 pageKorf Brochurelhphong021191Pas encore d'évaluation

- Pi Ups 1004Document39 pagesPi Ups 1004JOEL ARNAO CORTEGANAPas encore d'évaluation

- Mihir's Handbook Chapter 7Document10 pagesMihir's Handbook Chapter 7heyheyPas encore d'évaluation

- Entrainment Calculation PDFDocument1 pageEntrainment Calculation PDFnirmal_subudhiPas encore d'évaluation

- Design Separation Columns GuideDocument8 pagesDesign Separation Columns GuideDewi ApriyaniPas encore d'évaluation

- Three-Stage Compressor Power CalculationDocument6 pagesThree-Stage Compressor Power CalculationRifka Aisyah0% (1)

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaPas encore d'évaluation

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanPas encore d'évaluation

- Head Surface AeaDocument7 pagesHead Surface AeaShashi Kant KumarPas encore d'évaluation

- Compressors & Compressed Air System: Presented by Naushad Ahmad Department: Mechanical MaintDocument48 pagesCompressors & Compressed Air System: Presented by Naushad Ahmad Department: Mechanical Maintnaushadmnnit100% (1)

- Assignment Pump and Its PartsDocument19 pagesAssignment Pump and Its PartsSabyasachi PradhanPas encore d'évaluation

- Vibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwareDocument5 pagesVibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwarevikramPas encore d'évaluation

- Centrifugal Compressor SRL 454 - Ge Oil&gasDocument20 pagesCentrifugal Compressor SRL 454 - Ge Oil&gasKamal Buddy50% (2)

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89Pas encore d'évaluation

- Typical Compressor ArrangementDocument2 pagesTypical Compressor ArrangementkaitokidH3MPas encore d'évaluation

- Compressor Symbol Centrifugal CompressorDocument3 pagesCompressor Symbol Centrifugal CompressorPriscilla VidyaPas encore d'évaluation

- Typical P&ID Arrangement For Centrifugal Compressor SystemsDocument2 pagesTypical P&ID Arrangement For Centrifugal Compressor SystemsajaysapruPas encore d'évaluation

- Centrifugal Compressor P&ID GuideDocument4 pagesCentrifugal Compressor P&ID Guidenaveenbaskaran1989100% (1)

- Api 682Document7 pagesApi 682msaroladanPas encore d'évaluation

- Mechanical SealDocument14 pagesMechanical SealmsaroladanPas encore d'évaluation

- Introduction to Piping Materials Department ActivitiesDocument23 pagesIntroduction to Piping Materials Department Activitiesvikas2510100% (1)

- Process Control SystemsDocument242 pagesProcess Control SystemsAbdul_KSAPas encore d'évaluation

- Processcontrol PDFDocument13 pagesProcesscontrol PDFSIVAPas encore d'évaluation

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-IDocument16 pagesPressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-Isabi_shiPas encore d'évaluation

- Pressure Relief Safety ValvesDocument52 pagesPressure Relief Safety Valveswah_ma100% (3)

- ZH & ZH+ Series (355-3150 KW) - ENDocument24 pagesZH & ZH+ Series (355-3150 KW) - ENisfakPas encore d'évaluation

- Methodology Transfer Air CoolerDocument8 pagesMethodology Transfer Air CoolermaniPas encore d'évaluation

- Marine & Ind. ScaniaDocument141 pagesMarine & Ind. ScaniaAbi JithPas encore d'évaluation

- Assignment#3Document2 pagesAssignment#3Ashish ManwarPas encore d'évaluation

- FMINTPOLODocument24 pagesFMINTPOLOClaudiu PunkkPas encore d'évaluation

- Man Heavy TruckDocument3 pagesMan Heavy Truckcharles100% (1)

- Atlas Copco ZH 350 ENDocument12 pagesAtlas Copco ZH 350 ENAtlas Copco Compressor Technique100% (1)

- Dados Tec - c2500Document5 pagesDados Tec - c2500Sandro MunizPas encore d'évaluation

- 5110B Prod Bulletin (TEJB7050)Document40 pages5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- Coolant Pump Replacement PDFDocument6 pagesCoolant Pump Replacement PDFISRRAELPas encore d'évaluation

- Gas Turbine Exam ProblemsDocument7 pagesGas Turbine Exam ProblemsPatricia PachecoPas encore d'évaluation

- Sany Excavators SY215CDocument9 pagesSany Excavators SY215Ccsbersama82% (11)

- Leader in MINI Performance for 30+ YearsDocument36 pagesLeader in MINI Performance for 30+ YearsDustin ShampPas encore d'évaluation

- Ranger Motor 3.2Document86 pagesRanger Motor 3.2Lula MarquesPas encore d'évaluation

- Iosh PDFDocument3 pagesIosh PDFEng Mamon StiPas encore d'évaluation

- Daihatsu DC-32 Instruction Manual (Operation)Document105 pagesDaihatsu DC-32 Instruction Manual (Operation)Виктор Медведев100% (3)

- Condenizator MB w211Document3 pagesCondenizator MB w211Tomica TišljarićPas encore d'évaluation

- Kit Turbo TTEDocument64 pagesKit Turbo TTENokxaPas encore d'évaluation

- Project Guide VM43C Propulsion - 08.2012Document104 pagesProject Guide VM43C Propulsion - 08.2012ricardoPas encore d'évaluation

- Quincy QGD 30 HPDocument80 pagesQuincy QGD 30 HPLuis Fernando Bravo100% (1)

- S12H Pta PDFDocument4 pagesS12H Pta PDFNos GotePas encore d'évaluation

- Sauer SohnDocument12 pagesSauer SohnHanif FadIllah Budiman AkbarPas encore d'évaluation

- JCB Dieselmax 444 Turbocharged Aftercooled Tier3 74.2Kw (100Hp) & 85Kw (114Hp)Document4 pagesJCB Dieselmax 444 Turbocharged Aftercooled Tier3 74.2Kw (100Hp) & 85Kw (114Hp)Виктор ЯковлевPas encore d'évaluation

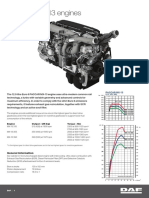

- DAF PACCAR MX-13 Engines EN PDFDocument4 pagesDAF PACCAR MX-13 Engines EN PDFAbdo FreedomPas encore d'évaluation

- SGE-S Series Gas Engines and Gen-Sets BiogasDocument6 pagesSGE-S Series Gas Engines and Gen-Sets Biogasmohsen_cumminsPas encore d'évaluation

- Rexton - Service Manual - ENGINE PDFDocument587 pagesRexton - Service Manual - ENGINE PDFdanila99Pas encore d'évaluation

- Operation Manual BVM 640Document588 pagesOperation Manual BVM 640TariqMaqsood100% (1)

- The Sullair 600H Portable Air Compressor: 600 CFM at 150 Psig 17 M /min at 10 BarDocument2 pagesThe Sullair 600H Portable Air Compressor: 600 CFM at 150 Psig 17 M /min at 10 BarSlVPas encore d'évaluation

- Tuty Court Genset ESTIMATES NewDocument42 pagesTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanPas encore d'évaluation

- Portable Air CompressorsDocument3 pagesPortable Air CompressorsAhmed Sherif CupoPas encore d'évaluation