Académique Documents

Professionnel Documents

Culture Documents

Pressure Regulator Principles

Transféré par

jrz85Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pressure Regulator Principles

Transféré par

jrz85Droits d'auteur :

Formats disponibles

FUNDAMENTAL PRINCIPLES OF PRESSURE REGULATORS

Presented by Kevin Shaw Actaris Metering Systems

970 Hwy. 127 North, Owenton, Kentucky

INTRODUCTION The following paper will concentrate on the fundamentals and principles of natural gas pressure regulators. In the gas regulators conception it was mainly a device used to reduce high pressure to a more usable lower pressure. Today, more is expected from the performance of the pressure regulator. Pressure reduction is no longer the only function needed. The regulator is considered an integral measurement instrument that must adhere to the stringent codes put forth by the U.S. Federal Department of Transportation and many state Public Utility Commissions. In order to understand the principles of pressure regulation this paper will focus on: I. OPERTION II. DROOP VS. BOOST III. CHANGING IN INLET PRESSURE VS. MECHANICAL ADVANTAGE IV. SAFETY MECHANISMS V. KEYS TO SELECTION VI. CONCLUSIONS REGULATOR CLASSIFICATIONS With few exceptions, gas pressure regulators can be classified into either of the following two categories: 1. Self-Operated Regulators (also known as SpringLoaded) 2. Pilot Regulators Constant-Loaded (a.k.a. Pilot-Loaded) Pilot Operated (a.k.a. Two-Path Regulation) Pilot Unloading (a.k.a. Pressure Unloading) The Pilot Regulator category can further be classified into the three sub-categories of Constant-Loaded, Pilot Operated, and Pilot Unloaded. Make no mistake; these three design are vastly different and, thus, will exhibit significantly different performance characteristics. Each of these designs is covered in more detail later in the paper. REGULATOR DEFINITION A pressure regulator is a feedback control mechanism designed to maintain a constant downstream pressure through the manipulation of gas flow. By definition, a regulator is composed of three essential components (see Figure 1 illustration):

Loading Element Sensing Element

Restricting Element

FIGURE 1.

1. Restricting Element A restriction which allows gas to flow through the regulator at a reduced pressure to meet downstream demand. In most cases this consists of a resilient valve seat (plug) and a sharp edged orifice. 2. Measuring Element A device that continuously senses changes in downstream pressure caused by changes in downstream demand and transmits a signal to open or close the restricting element accordingly. This is typically an elastomeric diaphragm. 3. Loading Element Adjustable force which is continuously compared to the downstream pressure by the measuring element to determine what signal (open/close) to transmit to the restricting element. In pilot regulators the loading element is gas pressure. SPRING-LOADED REGULATOR OPERATION The main function of any regulator is to provide a flow of gas through the regulator to match the downstream demand while holding pressure constant. In a springloaded regulator three devices are employed to achieve this a restricting device (usually an orifice); a sensing device (diaphragm); and a loading device (spring or pressure). Tying these three things together is a

PAGE 26

2003 PROCEEDINGS

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

mechanical linkage (usually called the valve stem and/ or lever) that acts like a see-saw. The linkage works to balance the forces associated with the three above devices. A pseudo free-body diagram gives a representation of this balancing act is shown in Figure 2.

Fi = P1 Ao

Where: P1 = Inlet Pressure Ao = Orifice Area

[ ][ ]

The downstream pressure under the diaphragm creates a closing force (Fo) pushing against the diaphragm trying to close off the flow of gas. This force is calculated as:

Effective outlet Fo = X diaphragm pressure area

In normal operation, the diaphragm will sense the outlet pressure force change and provide a force to the linkage. The linkage moves to control the flow through the valve to maintain the set outlet pressure. For instance, if the outlet pressure drops from the set pressure, the force under the diaphragm Fo decreases allowing the spring force Fs to reposition the diaphragm. This downward travel acts to move the valve seat away from the orifice, bringing the outlet back to approximately the desired set pressure. If the outlet pressure increases, the reverse happens. The linkage responds to the increased outlet pressure force and tends to restrict the orifice. The flow is reduced and the outlet pressure once again returns approximately to the set pressure. In a perfect world our loading element (the spring) would supply a constant force, there would be no friction within the regulator or material hysteresis. If this were the case the regulator would supply a constant outlet pressure over an infinite range of gas flows. However, this performance is unattainable. Hindrances like 1) spring force linearity (Hookes Law) and 2) the change in effective diaphragm area as the valve travels, effect the performance of the regulator. In Figure 3 typical springloaded regulator performance is shown.

FIGURE 2. Regulator Force Balance

In all regulators two types of forces exist: 1) opening and 2) closing forces. These two forces act on the mechanical linkage with one trying to close the valve (shutting off gas flow) while the other works to open the valve (increasing gas flow). Under steady operation the sums of the opening and closing forces are always equal but opposite in direction giving a static equilibrium condition. As in any static equilibrium condition, the valve will remain in a fixed position until one of the forces change, upsetting the equilibrium. The valve will then reposition again until the forces are again in equilibrium. In a spring-loaded regulator, the sum of forces on the mechanical linkage can be expressed as follows: Opening Forces = Closing Forces or Fi + Fs = Fo Where: Fi = Inlet Pressure Force Fs = Spring Force Fo = Outlet Pressure Force This equation assumes there are no frictional effects inside the regulator. The opening forces consist of one mechanical and one pneumatic load. The high-pressure inlet gas creates a pneumatic force (Fi) pushing on the face of the valve seat forcing open the valve. An adjustable spring force (Fs) assists the high inlet pressure by pushing on the sensing device (diaphragm), opening the valve to maintain the set pressure. These forces can be calculated as follows:

Fs = K x (Hookes Law)

Where: K = Spring Constant (lb./in.) x = Spring Compression (in.)

[ ][ ]

FIGURE 3. Typical Spring-Loaded Regulator Performance

The performance loss due to these effects is called pressure droop. Droop, and outlet pressure loss below set with increasing flow, is an ever-present problem in

2003 PROCEEDINGS

PAGE 27

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

the performance of the regulator. To combat the effects of droop, a method called boost is employed. A better understanding of these principles will follow in the next section.

Mechanical advantage can answer this dilemma. This advantage, know as power ratio, directly relates to the diaphragm size and linkage ratio or the amount of travel of the diaphragm with respect to the valve seat. The larger diaphragm gives more force at a given pressure and combined with the lever ratio will equalize the outlet pressure over a range of changing inlet pressures. Figure 4 shows a typical example of the effects of changing inlet pressure. Raising the inlet pressure from set pressure (curve set) tends to increase the outlet pressure (curve ). A reduction in inlet is observed in the bottom curve (). SAFETY MECHANISMS Under normal operation a regulator will deliver service around the clock. But in the event of a regulator failure, what type of safety features exist? Even though a regulator is built to give a constant outlet pressure, what happens if the valve fails to make the pressure reduction? An internal relief valve is incorporated into most self-operated regulators that have no other means of pressure relief. In the instance that a foreign object gets trapped between the valve seat and the orifice preventing a positive shut off, pressure can continually build exceeding the set pressure. If this pressure is allowed to increase, a dangerously elevated pressure situation will occur. This is where an internal relief valve steps in. The relief valve (Figure 5), usually a spring-loaded device, will allow the outlet to build to a small pre-determined amount over the set pressure before it opens, relieving gas through the diaphragm to the atmosphere. This relief pressure is typically not adjustable. The odorous gas smell will alert the customer and a service call will be made to repair the malfunction.

FIGURE 4. Inlet Pressure Effect on Performance

DROOP VS. BOOST One contributor to droop is spring effect. Spring effect is a result of the reduction in spring force when the diaphragm and valve are in the wide-open position (fully down). The reduction in the spring force requires a lower outlet pressure to balance it. The second contributor to droop is diaphragm effect. As with spring effect, the wide open valve position (fully down) is again the problematic diaphragm position. The effective diaphragm area increases giving the outlet pressure more area to act upon, which in turn means a lower outlet pressure is needed to balance the see-saw. Acting together, both spring and diaphragm effect can cause a considerable mount of droop. To combat this performance deficiency, raising the outlet pressure to compensate is necessary. Boost is a method that uses gas velocity at high flow to create a low pressure under the diaphragm relative to the downstream pressure. This lower sensed pressure aids in the lowering of the diaphragm causing the valve to open and elevating the outlet pressure. The boosting needed to overcome the negative droop can be attained by various methods; angled valve seats, pitot tubes, and loading rings to name a few. Droop is not the only factor which effects the outlet pressure adversely. Varying inlet pressure can be a nuisance as well. CHANGING IN INLET PRESSURE VS. MECHANICAL ADVANTAGE As discussed earlier, one of the forces in the balancing act is the inlet pressure acting on the valve seat through the orifice opening. As the inlet pressure drops, the force trying to push open the valve also declines. This in turn allows the valve seat to reposition closer to the orifice thus decreasing the flow rate and downstream pressure. Again, the regulator needs to overcome this obstacle.

FIGURE 5. Internal Relief

PAGE 28

2003 PROCEEDINGS

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

Another built-in safety feature is the restricting orifice. As gas passes through the reduction in area there is a natural pressure drop. This drop varies with the area of the orifice opening. The smaller the opening, the larger the pressure drop. This translates to a smaller pressure buildup downstream in a failure situation. Safety is the key when dealing with a device that regulates the delivery of volatile gases to business and homes around the world. PRINCIPLES OF PILOT REGULATORS Why Use A Pilot Regulator? Self-operated regulators may take a variety of forms. They can be single ported, double ported, balanced or unbalanced. All types have one common limitation which is spring effect, resulting in some control inaccuracy. Self-operated regulators are exceptional devices for their simplicity, performance and cost. However, when more accurate regulation is desired, spring effect along with other mechanical factors will cause the self-operated style to fall short of expectations and needs. These shortcomings can be solved, by replacing the spring with a more constant diaphragm loading force. The result is a significant accuracy increase throughout the entire range of flow as shown in Figure 6. CONSTANT-LOADED REGULATORS A constant force from gas pressure can be used in place of a simple loading spring to eliminate this spring effect. Constant-loaded regulators were designed with straight line regulation in mind (Figure 6).

FIGURE 7. Pilot Loaded Regulator

Constant-loaded regulators respond poorly to fast off or shock loads. The nature of the design causes slow response to sudden load decreases. When the regulator is asked to shut off flow quickly, it takes time for this pressure difference to be communicated to the pilot through the bleed hole in the main diaphragm. The pilot relies on its pressure sensing through a bleed hole in the diaphragm and thus is not directly sensing and responding to the downstream pressure. Constant-loaded regulators also require higher lock-up pressures under no flow conditions. The increased lock-up is needed to fully close the main valve as well as the pilot valve. This adds to the additional lock-up force needed. In special applications these characteristics can not be tolerated, therefore the need for a spring-loaded design is required. PILOT-OPERATED REGULATORS To obtain the advantage of both the spring-loaded and constant-loaded regulator performance, one must explore the use of pilot-operated regulators. With the use of a more complex pilot and pressure sensing lines, the pilot-operated regulator can make rapid changes to downstream demand since the pilot is continuously sensing the downstream pressure. However, this design is still slower than the spring-loaded design due to the number of mechanical steps the regulator must undergo in order to open or close. Due to the gain and accuracy of the pilot, these regulators can control pressure with flat line response without many of the shortcomings of the constant-loaded style. There are two basic types of pilot-operated regulators that will be discussed in the following: 1. Dual-path control 2. Pressure Unloading system

FIGURE 6. Spring vs. Pilot Regulator

Constant-loaded regulators use the outlet pressure from an additional pilot regulator as the constant loading force needed (Figure 7). The pilot regulator can supply a virtually constant pressure to the diaphragm throughout its range of movement. This constant force adds to the usable capacity range of a regulator by eliminating any droop caused by the loading spring. Outlet pressure will remain stable for essentially the full valve travel of the main regulator, achieving accuracy of 1% of the absolute outlet pressure or better. Increased flow rates are also expected results with the constant-loaded regulators. The increased capacity does not occur without some disadvantages, however.

2003 PROCEEDINGS

PAGE 29

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

FIGURE 8. Dual-Path Regulator FIGURE 9. Pressure Unloaded Regulator

DUAL-PATH CONTROL The first style of pilot-operated is a dual-path control system (Figure 8). The dual-path system incorporates a fixed and a variable orifice within the control system. The loading pressure that is generated between the fixed and variable orifice gives the pilot its gain and ability to quickly position the main valve with accuracy. With a small downstream pressure change, a high gain pilot can completely position the main operating valve from closed to fully open. This quick re-positioning of the valve MUST be controlled to insure stability. As the load varies, the main valve will tend to respond quickly to re-position its valve; however, it is uncontrolled and can become unstable. The solution to this problem is to combine a high gain pilot with a slightly dampened main valve to give accurate and stable control. The sensing of the downstream pressure coupled with the loading pressure in the main case provide what might be called a shock absorbing quality. However, at higher inlet pressures some regulators of this design can still become unstable due to the high gain of the regulator. In these cases a pilot supply regulator must be employed in order to reduce the inlet pressure supplied to the pilot and, thus, desensitize the unit. PRESSURE UNLOADING SYSTEM KEYS TO SELECTION The unloading regulator system is used mainly in the flexible element valves (Figure 9). The pilot functions to control the differential pressure across the flexible element causing it to open or close depending on the demand. This system also employs a fixed restriction and variable restriction. The fixed restriction is typically tuned to achieve a particular rate of response. Upon a downstream demand increase, the pressure drop is sensed through the static line in the control chamber. Next, the pilot adjustment spring pushes the seat off the Matching the regulator to the application is most important. Accurate knowledge of the system in which the regulator will be placed is very crucial. The following are the variables that must be understood in order to select an appropriate regulator: Minimum and Maximum Inlet Pressure Minimum and Maximum Capacity Rate of Load change Load Diversity bleed orifice allowing the loading chamber pressure to escape downstream. The bleed orifice now exhausts loading pressure faster than it can be replenished due to the fixed restriction. The bleed orifice is then controlled by the pressure difference across the measuring element between the loading chamber and the control chamber. Finally, the reduced pressure behind the flexible element causes the flow to increase around the main valves annular seal restoring the set pressure. Upon a no flow condition, outlet pressure rises forcing the pilot seat to close the variable pilot orifice. The pressure in the loading chamber equalizes with the inlet pressure across the fix restriction. Finally, the resiliency of the rubber forms a positive no flow condition in the main valve. The unloading pilot can supply exceptional accuracy only when the system is properly tuned to its application. Certain situations will cause stability problems that can be addressed by a few methods. One method is to provide an adjustable inlet restriction to control the speed of pilot response. Another method regulates the speed of response through an independent proportional band chamber. Both methods use pilot control to eliminate the source of instability.

PAGE 30

2003 PROCEEDINGS

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

Values for the minimum and maximum inlet pressures, as well as the maximum capacity for the regulator, need to be clear and accurate. Other factors such as rate of load change and load diversity must be take into consideration. Rate of load change refers to the on/off nature of the equipment downstream. For example, some boilers are equipped with snap-acting burner valves that open and close very quickly which then requires that regulator be able to respond at the same rate. Loaded Diversity refers to the probability that all equipment downstream will be operating simultaneously. If this probability is low, sizing the regulator for the total connected load may cause over-sizing of the regulator and ultimately instability at low flow rates. The following rules of thumb should be applied when sizing any regulator: Use minimum inlet pressure expected and maximum flow required when considering capacity needs Choose the smallest orifice available that can meet capacity requirements Use maximum inlet pressure expected when considering lock-up and relief performance Choose the lightest adjustment spring available that can meet outlet pressure requirements (i.e., choose set point at upper end of spring range)

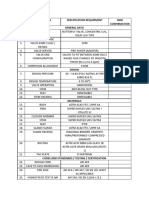

Table 1 Regulator Summary Comparison

Parameter Typical Application Stability Minimum Differential Required Sensing Line Required Sensitive to gas contaminants Variable Gain Speed of Response Susceptible to inlet pressure swing Product Cost Spring Loaded Service Regulator Good No No No No Fast Yes Low Cost Constant Loaded Service Regulator Good Very little No No No Relatively Fast Yes Moderate Pilot Operated Service Regulator/ District Can be unstable Very little Some No Some Relatively Fast Yes Expensive Pressure Unloading District/ Gate Station Regulator Can be unstable Yes Yes Yes Yes Slow Yes Expensive

The selection procedure then dictates the smallest orifice size to be implemented while allowing required flow capacity at minimum inlet pressures. The smallest orifice gives two benefits. First, it allows the smallest pressure buildup downstream in the event of a failure when using an internal relief type regulator. Secondly, it optimizes mechanical advantage by allowing less fluctuation in outlet pressure for a given inlet pressure change. Another good practice is to use the lightest adjustment spring that will give you the outlet will minimize spring effect, which causes droop. In addition, the internal relief valve has to work against the main adjustment spring to open. The relief valve will open at a lower outlet buildup given the lighter adjustment spring. For spring-loaded regulator, the power ratio of a regulator is another selection criterion. This ratio, as previously discussed, is based upon diaphragm size and linkage or lever ratio. It is a measure of how well the regulator utilizes the downstream pressure to close against the upstream pressure. The larger the ratio the lower the lockup pressure will be. However, with increasing power ratios come cost hindrances. A larger power ratio means a physically larger regulator and a higher price.

FA STEST

Spring

Pilot Operated (two-path)

Pilot (Constant) Loaded

When considering rate of loaded change, beware of the order of rate of response of various regulator types as shown in Figure 10. CONCLUSIONS Every type of regulator represents a compromise involving factors such as price, capacity, accuracy, stability, simplicity, safety and speed of response. Table 1 below summarizes the advantages and disadvantages of the various regulator designs available. It is important

SLOWEST

Flexible Element (boot)

FIGURE 10. Regulator Rates of Response

2003 PROCEEDINGS

PAGE 31

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

that manufacturers, utility engineers, and field service personnel alike understand the workings of self-operated and pilot regulators. A correct analysis of the application will give the customer clean, safe, and accurately

controlled gas. Working closely with the manufacturer and matching the right regulator to the right application will also lead to a problem free life.

Kevin Shaw

PAGE 32

2003 PROCEEDINGS

AMERICAN SCHOOL OF GAS MEASUREMENT TECHNOLOGY

Vous aimerez peut-être aussi

- Regulations for City Gas Distribution NetworksDocument56 pagesRegulations for City Gas Distribution NetworksHoney Narang100% (3)

- Bahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009Document5 pagesBahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009IvanRodriguezPas encore d'évaluation

- A6.Piping Joints HandbookDocument161 pagesA6.Piping Joints Handbookphunghalong100% (1)

- BS en 15266-2007Document56 pagesBS en 15266-2007Rachid MounirPas encore d'évaluation

- GMR RFQDocument142 pagesGMR RFQumamahesh259Pas encore d'évaluation

- Aeration Products PDFDocument16 pagesAeration Products PDFMuhammadObaidullahPas encore d'évaluation

- Filter Vessel Calculations Per As Me Viii 1Document40 pagesFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2Pas encore d'évaluation

- Trunnion Mounted Ball Valves TMBVDocument32 pagesTrunnion Mounted Ball Valves TMBVanwarhas05100% (1)

- Training Development Courses CatalogDocument100 pagesTraining Development Courses Catalogsugandaraj522Pas encore d'évaluation

- Thermowell CatalogueDocument12 pagesThermowell Catalogueeddy hendraPas encore d'évaluation

- Emerson - SAPAG Butterfly ValveDocument14 pagesEmerson - SAPAG Butterfly ValvekuraimundPas encore d'évaluation

- As 1777-2005 Aluminium Cylinders For Compressed Gases - Seamless - 0.1kg To 130kgDocument7 pagesAs 1777-2005 Aluminium Cylinders For Compressed Gases - Seamless - 0.1kg To 130kgSAI Global - APACPas encore d'évaluation

- The Evolution of Underwater Pelletizing PDFDocument4 pagesThe Evolution of Underwater Pelletizing PDFhuuquocPas encore d'évaluation

- O-Ring Failure AnalysisDocument5 pagesO-Ring Failure Analysismoganna73Pas encore d'évaluation

- Tescom RegulatorDocument4 pagesTescom RegulatormiaberyPas encore d'évaluation

- Functioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisDocument10 pagesFunctioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisSpecial Sicim ProcessesPas encore d'évaluation

- Pressure Drop CalculationDocument1 pagePressure Drop CalculationCak NhassPas encore d'évaluation

- Everything you need to know about strainersDocument64 pagesEverything you need to know about strainersSanket SavlaPas encore d'évaluation

- Eliminate Leaks From Reciprocating Compressor PackingsDocument4 pagesEliminate Leaks From Reciprocating Compressor PackingsJorge Rodriguez RuizPas encore d'évaluation

- Valve TrainingDocument25 pagesValve TrainingSameOldHat100% (1)

- ACC FAC and Cycle Chemistry SessionDocument37 pagesACC FAC and Cycle Chemistry Sessionchemicalchouhan9303Pas encore d'évaluation

- Pleated Filter Pressure Drop PDFDocument12 pagesPleated Filter Pressure Drop PDFAmbrish SinghPas encore d'évaluation

- Safety Maintenance-Cleaning For Oxygen ServiceDocument2 pagesSafety Maintenance-Cleaning For Oxygen ServiceleapswitchPas encore d'évaluation

- Eb-33 Oxygen Cleaning ProceduresDocument1 pageEb-33 Oxygen Cleaning ProceduresMeesookPas encore d'évaluation

- PVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFDocument6 pagesPVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFmatteo_1234Pas encore d'évaluation

- StrainersDocument88 pagesStrainersRoccinantePas encore d'évaluation

- Pipe Thickness Calculator As Per ASME B31.3Document3 pagesPipe Thickness Calculator As Per ASME B31.3anh thoPas encore d'évaluation

- Decree enDocument9 pagesDecree enmalakayjr100% (1)

- Fugitiveemissionsisa2013 131216022519 Phpapp01Document34 pagesFugitiveemissionsisa2013 131216022519 Phpapp01Ashok SureshPas encore d'évaluation

- Safety Valve LaserDocument15 pagesSafety Valve Lasersajjad_naghdi241Pas encore d'évaluation

- NDT Non Distructive TestsDocument18 pagesNDT Non Distructive TestsOmar MamdouhPas encore d'évaluation

- Datasheet For Butterfly ValveDocument3 pagesDatasheet For Butterfly ValvevishnuvarthanPas encore d'évaluation

- Sample Chiller SpecificationDocument5 pagesSample Chiller Specificationjlcheefei9258Pas encore d'évaluation

- The Effects of Electropolishing (EP) Process Parameters On Corrosion Resistance of 316L Stainless SteelDocument5 pagesThe Effects of Electropolishing (EP) Process Parameters On Corrosion Resistance of 316L Stainless SteelHamnah HosanyPas encore d'évaluation

- Valve Selection PDFDocument1 pageValve Selection PDFRajesh KPas encore d'évaluation

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartDocument6 pagesFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- Practical Piping CurseDocument46 pagesPractical Piping Cursemsaad2100% (1)

- Flowserve Multiphase PumpsDocument8 pagesFlowserve Multiphase PumpsveronrazvyPas encore d'évaluation

- Tank Loss EstimateDocument123 pagesTank Loss EstimateAndreea AntohiPas encore d'évaluation

- Harmonized Standards of Pressure Equipment 97-23-EECDocument16 pagesHarmonized Standards of Pressure Equipment 97-23-EECexedatPas encore d'évaluation

- Safety Valves and Relief Valves.Document17 pagesSafety Valves and Relief Valves.Shikhar SwaroopPas encore d'évaluation

- Fabricated Basket Strainer DimensionsDocument3 pagesFabricated Basket Strainer DimensionsmusaveerPas encore d'évaluation

- Gs-Flange SystemDocument188 pagesGs-Flange SystemMarcin MarcinkiewiczPas encore d'évaluation

- PCDDocument649 pagesPCDSiddhu DudwadkarPas encore d'évaluation

- Pressure Vessel - WikipediaDocument11 pagesPressure Vessel - Wikipediaramthecharm_46098467Pas encore d'évaluation

- RP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalDocument7 pagesRP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalAlif Rahmat FebriantoPas encore d'évaluation

- Magnus Piping Design & EquipmentDocument5 pagesMagnus Piping Design & EquipmentbalaasenthilPas encore d'évaluation

- 03 Sanitary TapwareDocument24 pages03 Sanitary TapwareEmanuel EmanuelPas encore d'évaluation

- Design of Pipe JointsDocument27 pagesDesign of Pipe JointsAlexander Holt50% (2)

- Sizing Vacuum PumpsDocument3 pagesSizing Vacuum PumpsIka SetyaningsihPas encore d'évaluation

- Dry Gas Seal BrochureDocument9 pagesDry Gas Seal BrochureArash Sotoudeh100% (1)

- Nasa STD 8719.12a PDFDocument142 pagesNasa STD 8719.12a PDFDizzixxPas encore d'évaluation

- Vishal Tripathi - Training ReportDocument38 pagesVishal Tripathi - Training ReportVishalTripathiPas encore d'évaluation

- GWC Valve International - Dual Plate Check ValvesDocument20 pagesGWC Valve International - Dual Plate Check ValvesGWC Valve InternationalPas encore d'évaluation

- Fundamental Principles of Pressure RegulatorsDocument7 pagesFundamental Principles of Pressure RegulatorsArunvpmPas encore d'évaluation

- The Function of Control Valve Actuators & PositionersDocument25 pagesThe Function of Control Valve Actuators & PositionersFlowealthPas encore d'évaluation

- Fundamental Principles of Pilot-Operated RegulatorsDocument4 pagesFundamental Principles of Pilot-Operated Regulatorsramkeshmit_413125668Pas encore d'évaluation

- Control Valve Actuators and PositionersDocument23 pagesControl Valve Actuators and PositionersPg LisenPas encore d'évaluation

- Study and testing of industrial pressure relief valvesDocument4 pagesStudy and testing of industrial pressure relief valvesBhargava S PadmashaliPas encore d'évaluation

- Basics of Pressure RegulationDocument18 pagesBasics of Pressure Regulationar174_569868987Pas encore d'évaluation

- Inprocess-BP Lingen Project ArticleDocument3 pagesInprocess-BP Lingen Project Articlejrz85Pas encore d'évaluation

- Valves Election EssentialsDocument8 pagesValves Election EssentialsmailmaverickPas encore d'évaluation

- VALTEK Valve Size PDFDocument16 pagesVALTEK Valve Size PDFalbahbahaneePas encore d'évaluation

- Boeing Fuel Cell AirplaneDocument1 pageBoeing Fuel Cell Airplanejrz85Pas encore d'évaluation

- AspenPhysPropMethodsV7 2 RefDocument240 pagesAspenPhysPropMethodsV7 2 RefAyo87Pas encore d'évaluation

- Fuel Cells EfficiencyDocument4 pagesFuel Cells Efficiencyjrz85Pas encore d'évaluation

- Chemistry 12: Provincial ExaminationDocument25 pagesChemistry 12: Provincial ExaminationCát TriệuPas encore d'évaluation

- My Medications ListDocument5 pagesMy Medications Listhussain077Pas encore d'évaluation

- Shapes FlashcardsDocument5 pagesShapes FlashcardsHome Organising by JRPas encore d'évaluation

- r05320202 Microprocessors and Micro ControllersDocument7 pagesr05320202 Microprocessors and Micro ControllersSri LalithaPas encore d'évaluation

- Khasi Community of MeghalayaDocument3 pagesKhasi Community of MeghalayaMidhat FatimaPas encore d'évaluation

- Mitchella Partridge Berry Materia Medica HerbsDocument3 pagesMitchella Partridge Berry Materia Medica HerbsAlejandra GuerreroPas encore d'évaluation

- Textile Pretreatment and Finishing 2023Document205 pagesTextile Pretreatment and Finishing 2023Aweru gebremariamPas encore d'évaluation

- Combustion Cat 2008Document32 pagesCombustion Cat 2008Miguel LinaresPas encore d'évaluation

- Qand ADocument5 pagesQand AJoshua PascasioPas encore d'évaluation

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanPas encore d'évaluation

- Computational Kinematics Assignment 2021Document2 pagesComputational Kinematics Assignment 2021Simple FuturePas encore d'évaluation

- H. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)Document310 pagesH. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)ITALO HERRERA MOYAPas encore d'évaluation

- Adeptus Evangelion 2.5 - Operations ManualDocument262 pagesAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- Time and Work Assignments PDFDocument8 pagesTime and Work Assignments PDFpavan0% (1)

- The Quill Vol. LVIII Issue 1 1-12Document12 pagesThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardePas encore d'évaluation

- Hairpin tube arrangements and multiple-bend designs for superheatersDocument2 pagesHairpin tube arrangements and multiple-bend designs for superheatersMArifHidayahPas encore d'évaluation

- Hot Tub BrochureDocument124 pagesHot Tub BrochureMai Tuan AnhPas encore d'évaluation

- Radar PPNDocument5 pagesRadar PPNSawaf MfPas encore d'évaluation

- Presentation 123Document13 pagesPresentation 123Harishitha ManivannanPas encore d'évaluation

- EiaDocument14 pagesEiaRamir FamorcanPas encore d'évaluation

- 35.2 - ING - El Puente NewsletterDocument13 pages35.2 - ING - El Puente NewsletterIrmali FrancoPas encore d'évaluation

- Lect 17 Amp Freq RespDocument22 pagesLect 17 Amp Freq RespBent777Pas encore d'évaluation

- Ethics Module 2 - NotesDocument1 pageEthics Module 2 - Notesanon_137579236Pas encore d'évaluation

- ADDC Construction QuestionairesDocument19 pagesADDC Construction QuestionairesUsman Arif100% (1)

- D6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDocument9 pagesD6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDayana HernandezPas encore d'évaluation

- IotDocument88 pagesIotLalithyaPas encore d'évaluation

- National Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979Document106 pagesNational Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979alvychuPas encore d'évaluation

- Pembangkit ListrikDocument2 pagesPembangkit ListrikDede MulyamanPas encore d'évaluation

- Nitocote WP DDocument4 pagesNitocote WP DdaragPas encore d'évaluation

- Schaeffler - Account Insights - Mar 2020Document13 pagesSchaeffler - Account Insights - Mar 2020mohit negiPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsD'EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsPas encore d'évaluation

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilD'EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilPas encore d'évaluation

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisD'EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisPas encore d'évaluation

- Pipeline Integrity: Management and Risk EvaluationD'EverandPipeline Integrity: Management and Risk EvaluationÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesD'EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesPas encore d'évaluation

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsD'EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fire in the Night: The Piper Alpha DisasterD'EverandFire in the Night: The Piper Alpha DisasterÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Subsea Valves and Actuators for the Oil and Gas IndustryD'EverandSubsea Valves and Actuators for the Oil and Gas IndustryÉvaluation : 5 sur 5 étoiles5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignD'EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationD'EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisD'EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Corrosion Control in the Oil and Gas IndustryD'EverandCorrosion Control in the Oil and Gas IndustryÉvaluation : 4 sur 5 étoiles4/5 (12)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)