Académique Documents

Professionnel Documents

Culture Documents

Grassracing Summer 73

Transféré par

Paul MartinDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grassracing Summer 73

Transféré par

Paul MartinDroits d'auteur :

Formats disponibles

.).

YAMAHA

GRASSRACING

~ . SUMMER '73

ltl Yemaha lnt emat ional Snowmobile Service Dept. July 17, 1973

WARNING

Thi$ tIook is t o provide info'mIIl ion 10 the f OC..- who i. intt'fE'Sl ed in obt. in-

ing I>iitt.... perf or mance from hi , production Yamaha Snowmobile,

Some of lhe modifica tions in this t>ooklel may ,horten the life of me m"""ine.

YAMAHA I NTERNATIONAL CORPORATION can no! be held respoll,i ble for

damage 10 the engine parI< '" chm,s as ' ...ult 01 modifica tions pr<!Sente<! in this

""'.

"lochi"'" thl ' are r&ee<l or run hard mould be inSl"'Cled frequentl y for

evidence of wear Or damage. Inspection 'l regular inte",. I, and replacement 01 any

worn part. will the life 01. facing moch ine.

A mochine tha t fail' may cause ex' . "" .., damage and be expensive to rebuild ,

Some machine failu,... moy ,,",u.e temporary 10.. of con trOl, result ing in injury 10 the

,..

Wh"" COtloidenng machine mod ifieat;"n, remember lha' l he perfor mance will be

.ffected. The "'hol e powlIr Cur"" will be ch.ngoed Il lhe engi ne i' mod ified ,

WHERE PERMIITEO BY LAW, YAMAHA SHALL NOT BE LI ABLE FOR I NCI -

DENTAL DR CONSEQUENTIAL DAMAGES, INCLUDI NG INJURY TO PERSON

OR PROPERTY,

YAMAHA MAKES NO WARRANTY OF ANY KINO, EXPRESSED OR IMPLIED:

AND ALL I MPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICU LAR PURPOSE ARE HEREBY DI SCLAIMED BY COMPANY,

,

J

WEIGHT REMOVAL

Sl<is: RemOYll m. lirst end mird spring

1. _ end shock IIb!ofber ......Illy. Reo

..- m. aWlderd _ bwI.. InsQIl

_ hum 1tI. GPG43B tPart Number

838-23731-(11-001. KIIIanezoo Engi.-ri ng

drill skis __ about 6 lbl. _ 191uned

y.."..nl skis.

Sen: The nod -' -.ould be ,," . K:Ned,

end rome form of ligtll Wligtll pad -.ould

be Illeched to tlte chusil. S4.0westion:

Use I mick 101m Nbbef pad held in

pllCe by I ....!#l ...yde WVlIf oecure:! witlt

uphob ll!ly ""lIP'.

GI S Tl nk : Th. Ilock t",k II not heavy by

IlselI. but il requirel I minimum gas 1.....1

tltlt Ildds exUlI _ighL Suggestion: Build

I tubullr link tltll mounts In I

palition. To prewnt fuel fromif\9 with low

fuel levels, 1I "9Illy conieel befll . pllte

-.ould be insllllied Iboul r hum the

boltom. Be sure to include I fuel filter in

the fuel line. The fuel outfet "'ould be It

the beck of the ta'lk. Th is I'(plI of unit is

__iIl ly irnporta'lt lor UIlI with Circle M

""'"'-

Molor Mounl : CuI olf ......, part 01 "'-

mow mounl Ihlt i.... t necessary 10 hol d

m. mow in piece or ..ppon the Me"""

dary ...11. The r'ItI'Iaini,.. portion <:en be

Ivr!her 1911ened by culti,.. OUt secti.onll or

drilli,.. holes.

Ski Spindle and Annt: The sid spindl es

<:en be drilled Irom the bottom up 10

191te'l m....... The spinele ..... c.1 be

191tened by II'IOdeme drilling. The spIi....

boa ..nich fiu __ the spindl. spIi..... an

be drill ed exte'lSi.ely.

81iu1rd alumi...m tpineln end IIPindII

ImII _ Iboul 2% IbI. end will fit the

standerd SR spindll boB. It will be

-..ry 10 modify the ri9'o1 spindle """

by welding on an "" U" M'ITI 10 hook up the

Iii rod. A SPKfI" under the spindl. """

will be nec:esIIry, lhey I re lonllllf til....

tile SR spindles.

Shrouds : Th. upper ....d lower shrouds can

be removed if il is 1.1 in your racing

llIOCialion, ot reoplK8d witll .. lightweight

substilute If it is nol IIglII In your lSSQCi..

lion . ClImber Company, 941 W. 18th SL.

Com Mesa. Cefl'.

pI_ t o m....' lCIu.. I lilfltwe9lt one

piec8 shroud. The pric. is 515.00 N:h

plus shi pping.

Mud FlIP: The ori9Ni1 COi' ...... 'ent can be

. lfCtllngle:i!of one midi 01llgtlter malorial.

r

Chain and Sprockets; On the 292 a double

row chain i, suff icient , and on t he 433, a

triple row chain i"ufficiem. Don'! forget

to cut off the e ~ t r a sprocket roW$ and

insen . '1'''''''' in place ellham.

DRIVE

Tracie An inner drive track made of an

extremely flexi bl e material should be used.

Gales Rubber Compeny and Goodyear

Rubber Company manufactur. trackl of

thi. type. Care should be taken that the

drive sprocket! are matched to the type of

Irlll: k used. Gates inner dri ve trach and

drive components Can be obt ained from

K.IIll181oo Engineering, P.O. 80x 8154,

Grand Rapids, Michigan 49508, (616)

5343661. &/t- - ,.r.-f 2 _:::tt:. C; I

Suspension: There I re Ih. H choices of

suspension lVi'll ..... ilabla.

1. I....tall bogie wheel. and link plates,

either directl y in Itte Challi., or in a sub-

frame which is bolted to the challi.

2, Install a "bogie rail" type IUsperl.ion.

Kl lamazoo Engineering ma""faetur.. a sus

pension of Itti. type called the Saondblalter,

which is available seporltel y or in I com

plete gra.. racing kit .

3. Bell Industries Griswold (1 OB I High

way 3B E. at Junction 61. St. PaUl, Minne-

sota 55 109 ) manufactur.. a new type of

suspension . uitable for drag racing use,

called the Fiex-O-Bar. This is also available

es a complet e kit. t;:...J:Z 5

Spindles: If the ski. drag on the ground

dur ing acceleration, use the shor t est avail

able Ipindlel (Part Number 856- 23853-10-

00). These spindles mHlUre 10mm from

the ~ m e r of the ski pivot boh hole t o the

flit "IN . bove the hole.

ENGINE

Compression: Hi""'e. compression ~ n be

u,ed 1(>1" drag racing only, due to tha sho rt

length of the race. This increaMd com-

p"'$$;on i, in addition to the engi"" speci fi

cat ions shown in the incHvidual 8flgine

specifications, end .hould not be uwd for

",y race longer than a drag race.

To raise Itte compression, ClJt l mm (0.040")

from the cylinder Ilead gasket surface.

For operation at altitude1 above 2,000' , an

incr ease in compression will help to reogai n

part of the power 10$$. Cut '" additional

0.25mm (0.010") for each thOU$llnd feet

abo... 2,000 feet altitude.

Cut 00 more from the heldls) than corres-

pond. to the lowest altitude that you will

race at . " you race at widely diffeoring

altitude1, you may desire to have different

heaciJ for each altitude. Do not exceed

200 p..i. cranking prlllSUre.

\

i

~ r

!

I

-

Refer to Cylinder Head Modification, pg. 6.

for machining inst ructions.

Care mu<1 be 18k"" to avoid heal problem.

St. rt rich on carb<J'elion. cold on spark

plu!l'l . and work lowards the prope, settin!l'l

from the safe side.

SR 433C carburetor is recommended, but

shaWl thaI other carburetors of

the same size ara usually accepl able. Use

Ihe int ake funnel from Ihe SR 433 C

;part Number B23-14479-7j.(lOl or 1971-

72 SR 292 kil IP. rt Numbe r 823 14479-

70-OOl.

SR 292

NOle: Many of th_ modificat ions were

relealed dur ing the winter season in Bulle

tin No. 15. Carefully check 10 ..... which,

'I f any. of th..... modifications ha.e already

been made on your machi ne before pro-

ceeding.

Piston : Cut as indicated :

Cylinder: Incre. "" the widlh of the

h.ul! port 10 53mm by cutting 2.Omm

(0,080"'1 from each sioe of Ihe pOrt,

Refer to Chrome Pl ated Cylinde r Modi fica-

tion, pg. 7.

.I

-,

",

i--cr-- ' L-=1r- '--

,

CI.IT OFF

Garb<i,relor; Use a SOmm carburetor main

body with tne bottom Ifuel pump and

metering assembly) and fuel pump

trom tt>e origir\ll l SR 292 caroorelor, The

Reed Valv..: Be sure that the reed< ""al

complelely on t he rubber eeceree pl. te. If

they <!on't, turn the reeds o. er . The reeds

should be replaced when Ihey begin to

stand open aft er being turned or once.

Be sure to use loctil e on Ihe SCrews,

,

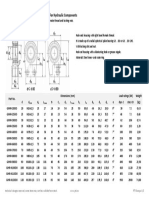

Belt : On the SR 292 only. a standard

IB061 belt may be used for d,ag no,i ng.

The standard belt, being th inn., and mo,e

flexible, i. more efficient t han the SR (820)

belt ,

When you chose to u.. the 806 belt in' tearl

01 the 820 belt on t he SR 292, check t he

806 belt to be ,ur. it .. with the

tel erane.. lor the racing (8201 !>ell. The

length. and tolera""". a,. '

File the Ilat e<lge i....ide Ihe peak 01 the

py'omid to a Vsh.pe Using a l ine l ile,

remove the rid""" along the . id.. 01 the

ir>d i.idual reed hoi... DO NOT remo. e any

malerial f,om the ,eed ... tiog area , Trim

off t he screw end. that protr ude int o t he

inside 01 t he pyramid,

E. po....ion Chamber; Remove 50mm 12,0" )

f"'''' t he head pipe (bet"""'" the cylinder

and first cone). Relocate t he ",ri"9 hook.

if necessa,y. Reduce t he ins"", diameter

01 t he tail pipe I., ingerl to 23mm (0.92'" -

59/54" ). The finished pipe will be diUerent

from t he original equipment lunmodified l

pipe &$ shown below.

820: 1101

+ 0.0

- 8.Omm

'33' + 0,0 in.

. - 0 ,32

SR 433C

f

I

+ 0 ,0

- 16,Omm

19Oition Timing: With the modilie<l ""gi no,

the i9Oitlon timing shoold be 2.Omm 8TDC.

0 19

,

Maximum rpm - 8500

Note: These measurements are ta ken on

the outside ein:uml. r""". 01 the bell . The

diU",ent me.... ' '''''. nts DO NOT ir>d iate .

di ffe,en t lunet i""aI lengt h, They simply

,. fl eet the di Uefence in t hickn... between

the 806 ar>d 820

806; 1097

SHORTEN BY

50 ....

'( REDUCfTO 23",,,, I. D-

A

I

f,

---

s....u.e of ...nout ~ -.olllnd

duri", the ....n.- ........ it ill not rKOIn-

""'oded 10 modify tho SA 6438 ongiIw.

Ua " " ,., . if you "-.... no ->ous ..

lI'abl""b 'f"!, ....t if ....t only if y fell

tNl e little ....... ~ ....nsiWlifi.

CoWltl., imlln:Mo you. ......11. you CoWl II"/'

the loI'-ing -..ggesti"....

SA 6438

Meximum hon ep<>wor rpm B50CI

Cylinder Held: Cui 0.25mm 10. 010")

'rom 1M gasket ... , 1.... Re' er 10 Cylinder

Held Modificati on . pg.6 .

E ~ a..nbw: II you h......1Ndy

modiroed you r a>qMtItion m..nt.rs ~

ing 10 SR BulIWn No. 17. you .-d only

.....- -.t -.Idltionlll IOmm10. " 1313r1

from thI hud p i ~ . n. ...-t_iIII ......Id

w owed !Tom tho fitR 80mm 01 It

p i ~ . vohich tIM no ~ . Relocale thI

~ hooks il .. WV. The Iiniohtd

JIipe will "" di-t from tt.. origi ....

equipment (unmodi IiMl) p ; ~ ItIOWI'l

..-

"':"OV' 11 .....

It l.": t l Ol

O" l 'f

CIIT ot r

, .J

,.

., ,

u.t

,

..

I

Piston : ~ thI itIt1l<e lleirt lonlyl

IItlgtt'l 10 68mrn ..-.11Id !rom !he edge

of !he crown 10 tho bonom 01 !he IItirt.

Pul 0.5mm 10.D2O'1 .... on ...

froIhly ""I edgI.

O(I i""": R.a.!he..m.u.t pan 10 2lImm

from thI lop of me cy1indlf . R"ter 10

0._PI.ted Cylindtr ModifiQlion. P\I. 7.

,

,

,

Cylinder: Rai'" the nhaust port to 35mm

fmm tile lop of t he cylinder. Refer to

Chroom Cylinder Modificalion, PlI. 7.

I, I,

, ,

t'

.. L.

1

'

.."

E, pan, ion Chamoof: Remove 50mm 12.0")

from the ""ad pipe lbot...,.", t he cyli nder

and the first c""el on each e' p"r"l$ion

chamt>e<.

Cylinder HNd: Cut 0.5mm (0.020'llrom

the gMket .urfooe. Ref... 10 Cylinder Head

Modil icali"",

Ma.i mum honepo_ r rpm . 80IXl

Cylinder HNd Modificati",, : To incre..

comp reaion, materi el mU$! bo remOWll

lrom the l!"'ket ....rfoce l oce 01 the cylinder

Alter t he meterial ha. been ,"", ...e<!, t he

diamete< 01 the $Quish ..ea must 00 check

ed. it sIlould bo lmm 10.040") 1"!lOr

than t he bore diemet... .

The c1e..ance between Ihe pi""" crown

and cylinder l>ead shou ld be chec ked. The

proper cle.._ e i< bet ween 0.8 . 1.2mm

{Q,032 - 0 ,048"1, depe<><ling "" bore size.

The minimu m cle.,ance il O.8mm (Q.032"I.

Uwally t he be1t procedure i< to receu t he

$Quish "re" by O.5mm 10.020" ). The

sQuish angle i< u.ually 14, oot the best

procedure is 10 copy the original angle. 00

nOl radiul the edge where the $quith

angle ",",,11 the main combullion chamOOr.

Round l he COmer jull enou!t> 10 re move

the therp edge (sar>ding with a medium gr;1

..ndpaper is ul ually enoo!t ,

_ _ _ _ _ _ _ _ _ _ 1

Ill! ..... th Jt .11 1)011 joinu. ..

m.!dMd 10 ell".;..... "fllIP'" that ........

1Iow. Don'I owtrlook gHkm (cyIi....

_ "",,all, ...-b gMkm, etc.) may

utend into "_ P' g I, Trim oft .,y

-';eI thai Iand IftlidlI m. 1)011.

Q'lro"" Cylinder Modlflcalion: Tha

modi!H;Jtlon of c;!Irome p1. ted eylinde<l

_ be ........ *Y ca..fully 10

10 "'" chrome plating, lithe< <Iur.

in; 1M modification """""". Of do.ring

.,gi.... opemon .Ito...do.

If you "" I 10 r=0VII l ite ""t.l, be

...rl t ltJt oil CUlling Itrok....I IW.... from

!tie ben. .-- rnaI<Ii cutting IUOkI

_ 1M bon. as tltis wil l dMp the

dItome plating.

The finlttled POt1 sh_ WId t he rldi... on

the ed gtS Ilhould be t ho _"l ho OIigi nll

"'_ and radi"L The only chlll" Ih<>uld

be in "'" '*'" cimenoionl of tlt. port.

_ !he port .... -. ....1'lIId and

thliPtd properly. 1M edJII of tho chrome

should .. f ..tho.... with an olillone 0<

oandpoper to redllC1l tho po$Slbili l y of being

SMJIIIlI by m. oorne< of tI>o';"9. dlmllJ"

in; both 1M ring and p1Jting.

... _ . I .

".... ",. , ..

"."'.....

....... "..,

.....

DRAG RACE TUNING

O"!dles: a"ld>. gig .$ .1 -' for

5'- drag r.cint will UIUIIIIy be hi..than

Ior_tw:i"" E. gl g ,t lP"d r-'ed

will vary lOCCoro;ng 10 ...gi.... POW, ri<ler

welghl, of track. l rod 11",,1"5.

Primary Spring: The primary spring I. ..

Iangth ",-Id be d.cbd """,,*,dy 10 be

..... that II is within &-8nvrt of 111_

"""".

ShIlVI Cap W.ighu: Tha t iP!' of welghll

.nd l ite o.m ring Ihould be cheokl f,.

q....., t1 y to< I Xcessiw we...

Oll1dl AI......t. c..w DistaQ, and

Ofhft : n- IdjustrNna ... utrernllV

imporunt in drllJ rICin;, 1:6' ...1 they

I Ueoot 1I1e tr....f... of q .... power 10 t ho

trk, Adj"ltmenl ohotJld be chec ked

bef_ ..:t> r_dr,r.

FOf information on dtrtdt Wi ...... 'e"1I.

{........II, 1IIWi.... ete.1 Of IdjuItmonU. I1!Mr

10 VBeIt Torque eon-....- WId

Adj"$lIMnt. ""'ich will ...... I. bIe .fter

h t.

Gunng: Gurin; IhouId ..."cll!d ..

tNl the following condit:ionl ... mft..

1. Ai II. Ilion from I rundil'lt f1t II

Sl rong,

2. The drM bell _ complll oly 10

"'" top of the primary clu1Ch It Of very

..... the fini"., This =-> be et.d<od

by mlIfI<ing the primary _ with

manei", pen {from "'" 08II1J1f to 1M oul

tide "":oJ. and d>ecking 10 _ if.1I of l ho

m.rk w" romoved . fter. run 01 1I1e wne

I"""" .. the r_. If the mark is not wipold

ITem the top of !he at- by the bolt. the

...in; ill 100 It.,. If !he""'" is .......-1

I

and the engi"" rpm doesn't rise drMtically

near the end of the rac. , Ih. gearing i.

"""eel. II l he mar k il but the

""91"" rpm ' ;<e$ d'80,ical ly near the end 01

the race,lhe gearing is 100 low.

TrilCk Ten.ion: Track l l!O'; oo &djustment

be ,I i!llll y 00 the loose side. A

is horde' to t um than on e which

is .1;!tIl ly loose.

raced a' previousl y. or go 10 similar

tr<>ek, yoo can wve t ime and improve per

form"""e by "f..ning'" the... OOIe$.

Cl>eck Lin: Memor ize 0. copy t he follow-

iog check lin. and 9" over il before each

race day.

Track Alignment: Track alignment has .,

eff e<o t on how $lrai!f1t l he machine runs,

and can CDu$\! excessive friction if i' rubs

on the l un r>el. It should be ch""ked t>e lo

each race day. If YOU have a problem wi th

"pulling" 10 either side, during accel era t ion

011 l he ".rti ng line. you may be obi. 10

counteract the pu ll 10 f(lme degree by

slightl y biasing the llI i!T'me<lt 10 orH! side.

Drive Line Drag: Excessive drag in the

drive line reduces power Iil.bre It t he

t rack. Poinu to check .re:

Brake ltdju<tment, driW! ch.in I djust ment.

bad bearingJ on axl... Or wIleeh, etc.

Fuel T.nk: It i. be" to the luel l"",,1

in the tank at lea$1 h.11 full, """n thoult> it

con tain> enoult> fuel for ....er. 1run. Thi.

hel"" to IlVoOd _ation 01 the '""I,

Carburetor Fuer Level' If t hrottle r<1$ponJe

i. 1'00', and can't be improved by ltdjuO!

ment of low or hilt> ocrews, r.i.ing

t he fuer level mlY improve i l.

Adju<tment for Spe<: ific RICe TrICks: If

yt>u race at mnre than one trICk, and th ey

diller enoult> to require different gearing,

carburetor ltdjustmenu, or ntt>er diffe<ent

lllning MlttingJ, it i. USt.,lIy bes t to writ e

the changed sett ings in I notebook. When

you return to One 01 the tracks you have

.

ENGINE _

CHECK LI ST

IgniliO<) Timing

Compre,<i " n

$pa'k plugs Icondilion and gap)

ExtW"'l pipes h p, in!l' , c'lICk., denl<, etc.l

Corbu"' I" , "'ll ings and fuel level

(re le, 10 nole>la kffi at previOUI ' lICe)

Slarle. rope condit ion

CLUTCHES AND DRIVE -

Cenler I " cenler di" ance

CIUlcll off set and alignment

Primary spri ng I, ... lengt h

She""" cap """i!t'llip condilion

Bel' condition and length

O. i..... chain adjustment

Brake adj u"menl

Track adju"menl lalignment and I""lion l

Dri"", sprockel condili" n

Wh...1and bearing condi ti""

Track condi l'"n

Geari ng (refe' to ".,Iel taken al pl'elliou' ' acel

CASSIS -

Ski alignment ....d condilion

Nut and bol t. lti \tltenl

Ch....i. bel"Kk, <lenIS, ""d c' llCkl

OTHER -

Start engine, m&ke short tesl run (il possible)

Vous aimerez peut-être aussi

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Theory and Maintenance: Reciprocating Engines OralDocument28 pagesTheory and Maintenance: Reciprocating Engines OralLohnJittlePas encore d'évaluation

- 1949 - 1954 Chevrolet Chevy Shop ManualDocument499 pages1949 - 1954 Chevrolet Chevy Shop ManualDevin Benson60% (5)

- C15 & B40 Service Sheets Book 00-4082 X PDFDocument90 pagesC15 & B40 Service Sheets Book 00-4082 X PDFLos Ángeles Customs GaragePas encore d'évaluation

- 900 RRmanualDocument407 pages900 RRmanualChris ChapmanPas encore d'évaluation

- JopDocument10 pagesJopAnonymous nHT1rzjmcPas encore d'évaluation

- L Series 1770Document76 pagesL Series 1770JuprayPas encore d'évaluation

- Projects For The Unimat Part 2Document95 pagesProjects For The Unimat Part 26KILLER100% (2)

- Intruction Manual FSADocument10 pagesIntruction Manual FSAtrantuan74Pas encore d'évaluation

- Juki LH 512 LH 515Document31 pagesJuki LH 512 LH 515brenco13Pas encore d'évaluation

- Dinli 50cc ManualDocument33 pagesDinli 50cc Manualbdr2000Pas encore d'évaluation

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarPas encore d'évaluation

- Taylorcraft Service Manual BB12Document48 pagesTaylorcraft Service Manual BB12Jessie BechaydaPas encore d'évaluation

- Lambretta 175 TV - Owners Manual - #3676Document32 pagesLambretta 175 TV - Owners Manual - #3676Mariano KokoPas encore d'évaluation

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell93% (15)

- Toyota v160 Transmission Repair Manual RM351EDocument75 pagesToyota v160 Transmission Repair Manual RM351EfrazPas encore d'évaluation

- Link-Belt RTC-8030 Series IIDocument50 pagesLink-Belt RTC-8030 Series IIraffiali100% (2)

- Yamaha Xj650 750 Fours 653cc 748cc 1980 1985 Owners Workshop Manual Haynes Manuals CompressDocument279 pagesYamaha Xj650 750 Fours 653cc 748cc 1980 1985 Owners Workshop Manual Haynes Manuals Compresszbynek3765Pas encore d'évaluation

- Onan BF Ms - ServiceDocument48 pagesOnan BF Ms - ServiceTimmye Cochran100% (2)

- td2 8-SuppDocument58 pagestd2 8-SuppAna Raos StupaloPas encore d'évaluation

- Victoria 121Document24 pagesVictoria 121Edowaye Nwagbara100% (2)

- Panther Dowty ForksDocument9 pagesPanther Dowty ForksThunderbird3100% (1)

- Winche Neumatico JoyDocument6 pagesWinche Neumatico JoyWilliam QuilichePas encore d'évaluation

- Massey Ferguson MF 15 MF 20 Baler Operators ManualDocument60 pagesMassey Ferguson MF 15 MF 20 Baler Operators ManualLuciana Nicoleta75% (12)

- G 97Document188 pagesG 97Bhabani Shankar NaikPas encore d'évaluation

- Tuning BMC Sports CarsDocument82 pagesTuning BMC Sports CarsMichael Carnell100% (3)

- Reloading For The M1 Rifle - J. ClarkeDocument5 pagesReloading For The M1 Rifle - J. Clarkebpm990d100% (6)

- Honda Xr250r Service Manual Repair 1986-1995 Xr250Document258 pagesHonda Xr250r Service Manual Repair 1986-1995 Xr250ronald.197893% (15)

- How To Run A Lathe 1966 Pt1 PDF1 PDFDocument22 pagesHow To Run A Lathe 1966 Pt1 PDF1 PDFSergio Gon100% (1)

- Cable HoistDocument4 pagesCable HoistUrip S. SetyadjiPas encore d'évaluation

- The Norton CarburetorDocument3 pagesThe Norton Carburetorbill_wattPas encore d'évaluation

- 2 Fire DamperDocument28 pages2 Fire Damperntt_121987Pas encore d'évaluation

- Lotus EngineeringDocument63 pagesLotus EngineeringLotusEnthusiast100% (2)

- How To Make Disposable Silencers Vol IDocument86 pagesHow To Make Disposable Silencers Vol IChris Breezley78% (9)

- Cheap Wind Water PumpDocument16 pagesCheap Wind Water PumpSean100% (1)

- Babani-Crystal Set ConstructionDocument16 pagesBabani-Crystal Set ConstructionRonLayton100% (2)

- Spitfire IX, XI and XVIDocument26 pagesSpitfire IX, XI and XVIXIII Legion Training Staff100% (5)

- Dremel 57 2Document4 pagesDremel 57 2egizio60100% (1)

- 0A - General InformationDocument12 pages0A - General InformationDionny BuenoPas encore d'évaluation

- Honda Goldwing Common Service Manual-EC21BDocument393 pagesHonda Goldwing Common Service Manual-EC21BDamian NowińskiPas encore d'évaluation

- Radionicki Prirucnik 540 - 549Document124 pagesRadionicki Prirucnik 540 - 549Гајо Боске Јокић78% (78)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesD'EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionD'EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionPas encore d'évaluation

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheD'EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentD'EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentPas encore d'évaluation

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversD'EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversÉvaluation : 5 sur 5 étoiles5/5 (2)

- The Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairD'EverandThe Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoD'EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoPas encore d'évaluation

- Scientific American Supplement, No. 787, January 31, 1891D'EverandScientific American Supplement, No. 787, January 31, 1891Pas encore d'évaluation

- ME432STI Service Manual - Pages.1 24Document24 pagesME432STI Service Manual - Pages.1 24Paul MartinPas encore d'évaluation

- GYTR Power TunerDocument1 pageGYTR Power TunerPaul MartinPas encore d'évaluation

- 2014-2018 Optional Rear Suspension SpringsDocument3 pages2014-2018 Optional Rear Suspension SpringsPaul MartinPas encore d'évaluation

- Improving The Performance of Two-Stroke Motorcycle With Tuned Adjustable Exhaust PipeDocument7 pagesImproving The Performance of Two-Stroke Motorcycle With Tuned Adjustable Exhaust PipePaul MartinPas encore d'évaluation

- Percussion Tips ZivkovicDocument3 pagesPercussion Tips Zivkovicgizzy9dillespiePas encore d'évaluation

- Quicksilver ManualDocument134 pagesQuicksilver ManualthesaneronePas encore d'évaluation

- Quicksilver ManualDocument134 pagesQuicksilver ManualthesaneronePas encore d'évaluation

- Oil Premix 6Document6 pagesOil Premix 6justin_86Pas encore d'évaluation

- VANTAGE 2000: Performance DataDocument18 pagesVANTAGE 2000: Performance DataPaul MartinPas encore d'évaluation

- Reichard's 4403 V-Max 4 Dyno Tune Kit InstructionsDocument4 pagesReichard's 4403 V-Max 4 Dyno Tune Kit InstructionsPaul MartinPas encore d'évaluation

- 1987 YAMAHA YSR 50T Service ManualDocument232 pages1987 YAMAHA YSR 50T Service Manualablond2100% (18)

- Force35 150Document36 pagesForce35 150Paul MartinPas encore d'évaluation

- Quicksilver ManualDocument134 pagesQuicksilver ManualthesaneronePas encore d'évaluation

- ATV and Snowmobile Belt Dimensional and Identification GuideDocument4 pagesATV and Snowmobile Belt Dimensional and Identification GuidePaul MartinPas encore d'évaluation

- 4 Stroke Top End and PerformanceDocument20 pages4 Stroke Top End and PerformancePaul MartinPas encore d'évaluation

- 1998 TracksDocument11 pages1998 TracksPaul MartinPas encore d'évaluation

- Piston Problem TroubleshootingDocument5 pagesPiston Problem TroubleshootingPaul MartinPas encore d'évaluation

- Dbike July84 Yam WrenrepDocument2 pagesDbike July84 Yam WrenrepPaul MartinPas encore d'évaluation

- Instruction Booklet: Fully Automatic Burr Grind & Brew CoffeemakerDocument14 pagesInstruction Booklet: Fully Automatic Burr Grind & Brew CoffeemakerPaul MartinPas encore d'évaluation

- Instruction Sheet For: Woa, Wob, Wo, Wra, WR, Wro Series: Maintenance InstructionsDocument2 pagesInstruction Sheet For: Woa, Wob, Wo, Wra, WR, Wro Series: Maintenance InstructionsPaul MartinPas encore d'évaluation

- Carb Cleaning and JettingDocument18 pagesCarb Cleaning and JettingPaul MartinPas encore d'évaluation

- Do It Yourself MachingDocument5 pagesDo It Yourself MachingPaul MartinPas encore d'évaluation

- Model Tuning Tips Honda CRDocument15 pagesModel Tuning Tips Honda CRPaul MartinPas encore d'évaluation

- Maintaining Johnson 1974-1992Document64 pagesMaintaining Johnson 1974-1992fokaiboi67% (3)

- Instruction Booklet: Fully Automatic Burr Grind & Brew Thermal CoffeemakerDocument14 pagesInstruction Booklet: Fully Automatic Burr Grind & Brew Thermal CoffeemakerPaul MartinPas encore d'évaluation

- Instruction Sheet For: Woa, Wob, Wo, Wra, WR, Wro Series: Maintenance InstructionsDocument2 pagesInstruction Sheet For: Woa, Wob, Wo, Wra, WR, Wro Series: Maintenance InstructionsPaul MartinPas encore d'évaluation

- Nissan Outboard Motor: Ns 5B Ns 5BsDocument44 pagesNissan Outboard Motor: Ns 5B Ns 5Bssurgrom1280Pas encore d'évaluation

- Kawasaki Jetski 800 SX R 2003 Service ManualDocument3 pagesKawasaki Jetski 800 SX R 2003 Service ManualPaul MartinPas encore d'évaluation

- MERCURY OUTBOARD MOTOR PCM DiagnosticsDocument20 pagesMERCURY OUTBOARD MOTOR PCM DiagnosticsKaivan Kalyaniwalla100% (2)

- JohnsonDocument5 pagesJohnsonPaul MartinPas encore d'évaluation

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuPas encore d'évaluation

- QCD Fire Pump Check ListDocument3 pagesQCD Fire Pump Check ListAnoirPas encore d'évaluation

- Massey PartsDocument54 pagesMassey PartsOhioBound100% (1)

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDocument1 pageGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinPas encore d'évaluation

- F 90Document35 pagesF 90ulises100% (1)

- Sem Question BanksDocument3 pagesSem Question BanksthangarajelectresPas encore d'évaluation

- Lecture 2 - Internal CombussionDocument80 pagesLecture 2 - Internal Combussionchoongwenkang100% (1)

- BIG ToolingDocument324 pagesBIG Toolingtrevorwoest0% (1)

- Cold Start Injector Installation: Fuel Drop: One Drop or Less Per MinuteDocument1 pageCold Start Injector Installation: Fuel Drop: One Drop or Less Per MinuteGuadalupe Chambi ApazaPas encore d'évaluation

- Tilt TableDocument2 pagesTilt TablenikhilPas encore d'évaluation

- Vs VSR Inj Manual 3 2004Document17 pagesVs VSR Inj Manual 3 2004Mark DiPas encore d'évaluation

- 518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFDocument109 pages518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFChemist - Aban DD8Pas encore d'évaluation

- 337 4pages Maintenance ChartDocument4 pages337 4pages Maintenance ChartwangPas encore d'évaluation

- NEHS0901NEHS0901-01 - Maquina de Bruñido CaterpillarDocument40 pagesNEHS0901NEHS0901-01 - Maquina de Bruñido CaterpillarCarlosPas encore d'évaluation

- 600@1800 Kta19 M3 Tontek PowerDocument3 pages600@1800 Kta19 M3 Tontek PowerStenny LumiPas encore d'évaluation

- Design and Analysis of Go-Kart Steering SystemDocument5 pagesDesign and Analysis of Go-Kart Steering SystemIJIERT-International Journal of Innovations in Engineering Research and TechnologyPas encore d'évaluation

- ARB220CW Tech SheetDocument2 pagesARB220CW Tech SheetJohn TrippPas encore d'évaluation

- Hatz Repair ManualDocument174 pagesHatz Repair ManualGeert Vda92% (12)

- Brake System FundamentalsDocument97 pagesBrake System FundamentalsRiley ReaumePas encore d'évaluation

- CNC Turning Skt28 Series IDocument16 pagesCNC Turning Skt28 Series IcncturPas encore d'évaluation

- Hhi-Emd: Engine & Machinery DivisionDocument27 pagesHhi-Emd: Engine & Machinery DivisionAhmed AteepPas encore d'évaluation

- C6 6Document34 pagesC6 6alejandro sanchez100% (1)

- Chapter 15 Control SystemsDocument25 pagesChapter 15 Control SystemsPrabir Kumar PatiPas encore d'évaluation

- Rounding MachinesDocument4 pagesRounding Machinesarbnor_morinaPas encore d'évaluation

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator SetsBilel Ben SlamaPas encore d'évaluation

- HRD K3V K5V Series Parts DiagramsDocument27 pagesHRD K3V K5V Series Parts Diagramsaiulica2098% (47)

- Brochure Makita 18v Cordless Impact WrenchDocument36 pagesBrochure Makita 18v Cordless Impact WrenchHidaayah Ngabas NoorPas encore d'évaluation

- Precision Products and Solutions: Smoother. Faster. LongerDocument60 pagesPrecision Products and Solutions: Smoother. Faster. LongerVladimir Illich Pinzon BallenPas encore d'évaluation

- Shaper MachineDocument12 pagesShaper MachineMuhammad Fahad Khan 51-FET/BSCMET/F19Pas encore d'évaluation

- EASA-TCDS-E.042 Rolls - Royce Plc. RB211 Trent 700 Series Engines-02-29112013 PDFDocument9 pagesEASA-TCDS-E.042 Rolls - Royce Plc. RB211 Trent 700 Series Engines-02-29112013 PDFObakengPas encore d'évaluation