Académique Documents

Professionnel Documents

Culture Documents

Air To Fuel

Transféré par

Ahmed Mahmoud ElgayedDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Air To Fuel

Transféré par

Ahmed Mahmoud ElgayedDroits d'auteur :

Formats disponibles

Air-fuel ratio

Air-fuel ratio

Air-fuel ratio (AFR) is the mass ratio of air to fuel present during combustion. If exactly enough air is provided to completely burn all of the fuel, the ratio is known as the stoichiometric mixture (often abbreviated to stoich). AFR is an important measure for anti-pollution and performance tuning reasons. Lambda () is an alternative way to represent AFR. stoichiometric mixture fraction The relative amounts of oxygen enrichment and fuel dilution can be quantified by the stoichiometric mixture fraction, Zst, defined as Zst=(1+YF,0WOvO/YO,0WFvF)1, where YF,0 and YO,0 represent the fuel and oxidizer mass fractions at the inlet, WF and WO are the species molecular weights, and vF and vO are the fuel and oxygen stoichiometric coefficients, respectively.[1] In industrial fired heaters, power plant steam generators, and large gas-fired turbines, the more common term is percent excess combustion air. For example, excess combustion air of 15 percent means that 15 percent more than the required stoichiometric air is being used. A stoichiometric mixture is the working point that modern engine management systems employing fuel injection attempt to achieve in light load cruise situations. For gasoline fuel, the stoichiometric air/fuel mixture is approximately 14.7; i.e. the approximate mass of air is 14.7 mass of fuel. Any mixture less than 14.7 to 1 is considered to be a rich mixture, any more than 14.7 to 1 is a lean mixture - given perfect (ideal) "test" fuel (gasoline consisting of solely n-heptane and iso-octane). In reality, most fuels consist of a combination of heptane, octane, a handful of other alkanes, plus additives including detergents, and possibly oxygenators such as MTBE (methyl tert-butyl ether) or ethanol/methanol. These compounds all alter the stoichiometric ratio, with most of the additives pushing the ratio downward (oxygenators bring extra oxygen to the combustion event in liquid form that is released at time of combustions; for MTBE-laden fuel, a stoichiometric ratio can be as low as 14.1:1). Vehicles using an oxygen sensor(s) or other feedback-loop to control fuel to air ratios (usually by controlling fuel volume) will usually compensate automatically for this change in the fuel's stoichiometric rate by measuring the exhaust gas composition, while vehicles without such controls (such as most motorcycles until recently, and cars predating the mid-1980s) may have difficulties running certain boutique blends of fuels (esp. winter fuels used in some areas) and may need to be rejetted (or otherwise have the fueling ratios altered) to compensate for special boutique fuel mixes. Vehicles using oxygen sensors enable the air-fuel ratio to be monitored by means of an air fuel ratio meter.

Synopsis

In theory a stoichiometric mixture has just enough air to completely burn the available fuel. In practice this is never quite achieved, due primarily to the very short time available in an internal combustion engine for each combustion cycle. Most of the combustion process completes in approximately 4-5 milliseconds at an engine speed of 6000 rpm. This is the time that elapses from when the spark is fired until the burning of the fuel air mix is essentially complete after some 80 degrees of crankshaft rotation. Catalytic converters are designed to work best when the exhaust gases passing through them show nearly perfect combustion has taken place. A stoichiometric mixture unfortunately burns very hot and can damage engine components if the engine is placed under high load at this fuel air mixture. Due to the high temperatures at this mixture, detonation of the fuel air mix shortly after maximum cylinder pressure is possible under high load (referred to as knocking or pinging). Detonation can cause serious engine damage as the uncontrolled burning of the fuel air mix can create very high pressures in the cylinder. As a consequence stoichiometric mixtures are only used under light load conditions. For acceleration and high load conditions, a richer mixture (lower air-fuel ratio) is used to produce cooler combustion products and thereby prevent detonation and overheating of the cylinder head.

Air-fuel ratio In the typical air to natural gas combustion burner, a double cross limit strategy is employed to ensure ratio control. (This method was used in World War 2). The strategy involves adding the opposite flow feedback into the limiting control of the respective gas (air or fuel).This assures ratio control within an acceptable margin.

Other terms used

There are other terms commonly used when discussing the mixture of air and fuel in internal combustion engines.

Mixture

Mixture is the predominant word that appears in training texts, operation manuals and maintenance manuals in the aviation world.

AFR

The Air fuel ratio is the most common reference term used for mixtures in internal combustion engines.

It is the ratio between the mass of air and the mass of fuel in the fuel-air mix at any given moment. For pure octane the stoichiometric mixture is approximately 14.7:1 or of 1.00 exactly. In naturally aspirated engines powered by octane, maximum power is frequently reached at AFRs ranging from 12.5 - 13.3:1 or of 0.850 - 0.901.

FAR

Fuel Air ratio is commonly used in the gas turbine industry as well as in government studies of internal combustion engine and refers to the ratio of fuel to the air, it is 1/AFR.

Lambda

Most practical AFR devices actually measure the amount of residual oxygen (for lean mixes) or unburnt hydrocarbons (for rich mixtures) in the exhaust gas. Lambda () is the ratio of actual AFR to stoichiometry for a given mixture. Lambda of 1.0 is at stoichiometry, rich mixtures are less than 1.0, and lean mixtures are greater than 1.0. There is a direct relationship between lambda and AFR. To calculate AFR from a given lambda, multiply the measured lambda by the stoichiometric AFR for that fuel. Alternatively, to recover lambda from an AFR, divide AFR by the stoichiometric AFR for that fuel. This last equation is often used as the definition of lambda:

Because the composition of common fuels varies seasonally, and because many modern vehicles can handle different fuels, when tuning, it makes more sense to talk about lambda values rather than AFR.

Air-fuel ratio

Equivalence ratio

The equivalence ratio of a system is defined as the ratio of the fuel-to-oxidizer ratio to the stoichiometric fuel-to-oxidizer ratio. Mathematically,

where, m represents the mass, n represents number of moles, suffix st stands for stoichiometric conditions.

stoichiometric mixture fraction

The advantage of using equivalence ratio over fuel-to-oxidizer ratio is that it does not have the same dependence as fuel-to-oxidizer ratio on the units being used. For example fuel-to-oxidizer ratio based on mass of fuel and oxidizer is not same as one define based on number of moles. This is not the case for equivalence ratio. The following example can help clarify the point. Consider a mixture of one mole of ethane (C2H6) and one mole of oxygen (O2). fuel-to-oxidizer ratio of this mixture based on the mass of fuel and air is

fuel-to-oxidizer ratio of this mixture based on the number of moles of fuel and air is Clearly the two values are not equal. To compare it to the equivalence ratio, we need to determine the fuel-to-oxidizer ratio of ethane and oxygen mixture. For this we need to consider the stoichiometric reaction of ethane and oxygen,

This gives,

Thus we can determine the equivalence ratio of the give mixture as,

or equivalently as,

Another advantage of using the equivalence ratio is that ratios greater than one always represent excess fuel in the fuel-oxidizer mixture than would be required for complete combustion (stoichiometric reaction) irrespective of the fuel and oxidizer being used, while ratios less than one represent a deficiency of fuel or equivalently excess oxidizer in the mixture. This is not the case if one uses fuel-to-oxidizer ratio, which will take different values for different mixtures. Equivalence ratio is related to (defined previously) as follows,

Air-fuel ratio

References

[1] Kumfer, B.; Skeen, S. & Axelbaum, R. Soot inception limits in laminar diffusion flames with application to oxy-fuel combustion Combustion and Flame, 2008, 154, 546-556

External links

HowStuffWorks: fuel injection (http://auto.howstuffworks.com/fuel-injection.htm), catalytic converter (http:/ /auto.howstuffworks.com/catalytic-converter.htm) University of Plymouth : Engine Combustion primer (http://www.tech.plym.ac.uk/sme/ther305-web/ Combust1.PDF) Kamm, Richard W. "Mixed Up About Fuel Mixtures?" (http://www.amtonline.com/publication/article. jsp?pubId=1&id=1171). Aircraft Maintenance Technology (February 2002). Retrieved 2009-03-18.

Article Sources and Contributors

Article Sources and Contributors

Air-fuel ratio Source: http://en.wikipedia.org/w/index.php?oldid=414185770 Contributors: Abortz, Aeroknight, Aitias, Akela, Alansohn, Anticipation of a New Lover's Arrival, The, Biscuittin, Colorbow, Conscious, Dav115, DeLarge, Depakote, DmitryKo, Dolphin51, Heron, Hooperbloob, Interiot, Iytbboy, Jaganath, Jhapk, Jpogi, K12479, KTMRACER, Liyuan0611, Maniac18, Mbeychok, Mmeijeri, Mutiny, Mythealias, Nseidm1, Qura, Radagast83, Randy549, Rich Farmbrough, Rios, RoyBoy, Rynol, Ryt, Saeed.Veradi, TechEdge, Tedder, Texmexcowboy7, Tide rolls, Typ932, Uruiamme, WatchingYouLikeAHawk, Wtshymanski, 106 anonymous edits

License

Creative Commons Attribution-Share Alike 3.0 Unported http:/ / creativecommons. org/ licenses/ by-sa/ 3. 0/

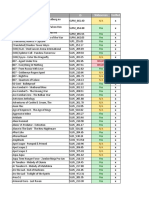

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Flame Detector PDFDocument4 pagesFlame Detector PDFAhmed Mahmoud ElgayedPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Heater ControlDocument24 pagesHeater Controlmohamedyoussef1Pas encore d'évaluation

- FI01 en Start PDFDocument1 pageFI01 en Start PDFAhmed Mahmoud ElgayedPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 3697 Fall 2010 Pub Cat - Lo Res PDFDocument28 pages3697 Fall 2010 Pub Cat - Lo Res PDFAhmed Mahmoud ElgayedPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- ABB - 4 Biggest MistakesDocument7 pagesABB - 4 Biggest MistakesAnargha BhattacharyaPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Fired Heater Optimization ISA ADDocument12 pagesFired Heater Optimization ISA ADNagaphani Kumar RavuriPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Chapter 01 Fundamental and Derived QuantitiesDocument7 pagesChapter 01 Fundamental and Derived QuantitiesAlicia WilliamsPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Chess AI: Competing Paradigms For Machine Intelligence: Shiva Maharaj Nick Polson Alex TurkDocument15 pagesChess AI: Competing Paradigms For Machine Intelligence: Shiva Maharaj Nick Polson Alex TurkDomingo IslasPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

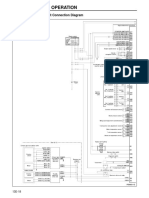

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocument16 pagesStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- INT PL 2020 Web 01-20 PDFDocument320 pagesINT PL 2020 Web 01-20 PDFAndriana Vilijencova100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Sect. 4 Tech Docum PC7 AutoLube - 1209 PDFDocument46 pagesSect. 4 Tech Docum PC7 AutoLube - 1209 PDFAlexis MikePas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusPas encore d'évaluation

- 12 ĀnurũpyenaDocument7 pages12 ĀnurũpyenashuklahousePas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Silenat Berhanu SimaDocument6 pagesSilenat Berhanu SimaSilenat BerhanuPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Malraux Anti-MemoiresDocument9 pagesMalraux Anti-MemoiresNevenaRistićPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- ZTE V4 RNC Commissioning and Integration TrainingDocument2 pagesZTE V4 RNC Commissioning and Integration TrainingBeena SinghPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Validation For A Login PageDocument2 pagesValidation For A Login PageAmal RajPas encore d'évaluation

- Century 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthDocument8 pagesCentury 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthJohn0% (4)

- Focus On Teaching - Jim KnightDocument213 pagesFocus On Teaching - Jim KnightFernando TeixeiraPas encore d'évaluation

- SAP Group Reporting 1909Document28 pagesSAP Group Reporting 1909SUDIPTADATTARAY86% (7)

- 07 Endodontic RetreatmentDocument64 pages07 Endodontic RetreatmentGayathriPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungPas encore d'évaluation

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyPas encore d'évaluation

- History of Computer ReviewerDocument10 pagesHistory of Computer ReviewerNeil Andrew Aliazas78% (9)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- One Plan Student 1Document7 pagesOne Plan Student 1api-465826207Pas encore d'évaluation

- Digital Signal Processing Lab ManualDocument61 pagesDigital Signal Processing Lab ManualOmer Sheikh100% (6)

- SOL-Logarithm, Surds and IndicesDocument12 pagesSOL-Logarithm, Surds and Indicesdevli falduPas encore d'évaluation

- Strategic Cost AnalysisDocument24 pagesStrategic Cost AnalysisBusiness Expert Press100% (10)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Da Insem AllDocument217 pagesDa Insem AllTECOA136TejasJadhavPas encore d'évaluation

- WebpdfDocument276 pagesWebpdfprateekvPas encore d'évaluation

- Automatic Control ExercisesDocument183 pagesAutomatic Control ExercisesFrancesco Vasturzo100% (1)

- MLAB 3 - BoilerDocument3 pagesMLAB 3 - BoilerReden LopezPas encore d'évaluation

- ASME Geometric Dimension Ing and Tolerance Professional CertificationDocument20 pagesASME Geometric Dimension Ing and Tolerance Professional CertificationPaul Anthony Red60% (5)

- Of Personality Traits of Only and Sibling School Children in BeijingDocument14 pagesOf Personality Traits of Only and Sibling School Children in BeijingMuhammad Hamza AsgharPas encore d'évaluation

- Ideal Vs Real OttoDocument5 pagesIdeal Vs Real Ottoa7med SoulimanPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)