Académique Documents

Professionnel Documents

Culture Documents

Waste Tyre Management Plan and Fee Now Operational in South Africa

Transféré par

Bradley WaltmanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Waste Tyre Management Plan and Fee Now Operational in South Africa

Transféré par

Bradley WaltmanDroits d'auteur :

Formats disponibles

Waste Tyre Management Plan and Fee Now Operational In South Africa

The Integrated Industry Waste Tyre Management Plan aims to make tyre producers responsible for waste tyre recycling and environmentally friendly disposal by requiring all manufacturers and importers of tyres to pay R2.30 +VAT per kilogramme of tyre. The Waste Tyre Management Plan, an initiative of the Recycling and Economic Development Initiative of South Africa (REDISA), was approved on the 29 November 2012 and the first waste tyre management fee payments were made at the end of May 2013. Speaking at a recent Durban Chamber of Commerce and Industry Environmental Committee Meeting, Herman Erdmann, CEO of REDISA says, Some people argue that this is a tax, no, its the cost of manufacturing, and its something as a concept that we have to start rethinking in terms of the responsibility of a producer, that you are responsible for the whole lifecycle of the product. Erdmann added that the waste management tyre fee places money aside for dealing with tyres when their lifecycle comes to an end and that the funds will be used for transporting the tyres, helping to set up depots, providing training and funding research and development into reuse and recycling of tyres. By paying the waste tyre management fee, tyre manufacturers will not be required to handle the recycling of the tyres themselves, instead REDISA will take over this responsibility and manage the recycling process of transporting the tyres to depot and recycling plants and supporting the recycling of tyres into new products. Erdmann adds the manufacturers pay REDISA the waste tyre management fee which frees them from the liability as REDISA takes this over.

Erdmann explains that REDISAs Integrated Industry Waste Tyre Management Plan is the first Integrated Industry Waste Plan of many that are being commissioned by the Department of Environmental Affairs. In South Africa we have 38 waste streams and of this the tyre management plan is the first which has been registered with the Department of Environmental Affairs and approved. Erdmann further explains the reason that REDISA targeted tyres for their integrated waste management plan, We started with tyres as this is the easiest waste stream to deal with because when you are dealing with tyres it is one of those few things where the first kilometre of collection is not needed because when you change your tyres you bring them back to a shop and they exchange it for you so its very easy to do the first kilometre of collection REDISA is currently conducting research with Stellenbosch University to determine the most effective ways of dealing with waste tyres in the South African context and to look for secondary markets for tyres, says Erdmann. Erdmann explains that lots of products can be made from rubbercrumb. For instance it can be used in road construction, and to make manhole covers. Furthermore REDISA is also working closely with the Nelson Mandela Metropolitan University who are building a R60 million test facility for tyres that will help to support an environmental rating developed for tyres so that manufacturers that produce tyres that last longer will be rewarded by paying a reduced fee per kilogramme of tyre, explains Erdmann.

Erdmann adds that the plan will empower small transporters to transport tyres from the manufacturers to the recyclers and that the process will be managed by REDISA. Transporters will also receive a quota for the collection of tyres that have been dumped. These transporters will be paid by REDISA. Erdmann says that South Africa has approximately 11 million new tyres being sold annually in the country, and approximately 60 million tyres lying in the veld throughout South Africa. Waste tyres often illegally end up in stockpiles or on general landfills where they contribute to air pollution and are considered a fire hazard.

Vous aimerez peut-être aussi

- Bid Notice - Transnet Port TerminalsDocument1 pageBid Notice - Transnet Port TerminalsBradley WaltmanPas encore d'évaluation

- ICANN Durban Invitation For New Business AttendeesDocument1 pageICANN Durban Invitation For New Business AttendeesBradley WaltmanPas encore d'évaluation

- Supervisory Skills - Managing and Supervising Your StaffDocument1 pageSupervisory Skills - Managing and Supervising Your StaffBradley WaltmanPas encore d'évaluation

- General Conditions of Contract - GCC 2010-15-16 July 2013 DurbanDocument5 pagesGeneral Conditions of Contract - GCC 2010-15-16 July 2013 DurbanBradley WaltmanPas encore d'évaluation

- Customer Service ExcellenceDocument1 pageCustomer Service ExcellenceBradley WaltmanPas encore d'évaluation

- SAPLATO 2 Mentorship Programme Press Release 06 June 2013Document2 pagesSAPLATO 2 Mentorship Programme Press Release 06 June 2013Bradley WaltmanPas encore d'évaluation

- Ipap 2013Document21 pagesIpap 2013Bradley WaltmanPas encore d'évaluation

- Bio - Ashish J ThakkarDocument1 pageBio - Ashish J ThakkarBradley WaltmanPas encore d'évaluation

- World Transplant Games 50 DaysDocument3 pagesWorld Transplant Games 50 DaysBradley WaltmanPas encore d'évaluation

- Notice of Road ClosureDocument1 pageNotice of Road ClosureBradley WaltmanPas encore d'évaluation

- Corporate Breakfast InvitationDocument1 pageCorporate Breakfast InvitationBradley WaltmanPas encore d'évaluation

- Submission of Workplace Skills Plans June 2013Document1 pageSubmission of Workplace Skills Plans June 2013Bradley WaltmanPas encore d'évaluation

- Advertising RatesDocument1 pageAdvertising RatesBradley WaltmanPas encore d'évaluation

- Advertising OpportunitiesDocument1 pageAdvertising OpportunitiesBradley WaltmanPas encore d'évaluation

- A Different Opportunity - Education FundingDocument1 pageA Different Opportunity - Education FundingBradley WaltmanPas encore d'évaluation

- WACE World Conference On Co-Operative & Work-Integrated EducationDocument1 pageWACE World Conference On Co-Operative & Work-Integrated EducationBradley WaltmanPas encore d'évaluation

- Notice of Road ClosureDocument1 pageNotice of Road ClosureBradley WaltmanPas encore d'évaluation

- Outward Mission Guidelines April 2011 FinalDocument26 pagesOutward Mission Guidelines April 2011 FinalDurban Chamber of Commerce and IndustryPas encore d'évaluation

- Supervisory Skills - Managing and Supervising Your StaffDocument1 pageSupervisory Skills - Managing and Supervising Your StaffBradley WaltmanPas encore d'évaluation

- MEA Weekly Newsletter May 1-8Document16 pagesMEA Weekly Newsletter May 1-8Bradley WaltmanPas encore d'évaluation

- Durban's Street Circuit For Top Gear Festival 2013Document5 pagesDurban's Street Circuit For Top Gear Festival 2013Bradley WaltmanPas encore d'évaluation

- Customer Service ExcellenceDocument1 pageCustomer Service ExcellenceBradley WaltmanPas encore d'évaluation

- NEW Services Application FormDocument6 pagesNEW Services Application FormBradley WaltmanPas encore d'évaluation

- NEW Services Application FormDocument6 pagesNEW Services Application FormBradley WaltmanPas encore d'évaluation

- Invitation OSM Malaysia and IndonesiaDocument1 pageInvitation OSM Malaysia and IndonesiaBradley WaltmanPas encore d'évaluation

- Invitation OSM Malaysia and IndonesiaDocument1 pageInvitation OSM Malaysia and IndonesiaBradley WaltmanPas encore d'évaluation

- EMIA Manufacturing ApplicationDocument6 pagesEMIA Manufacturing ApplicationDurban Chamber of Commerce and IndustryPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Req 181276 0Document1 pageReq 181276 0Abdo NaserPas encore d'évaluation

- Ramlan Bin YusopDocument3 pagesRamlan Bin YusopnorikmalPas encore d'évaluation

- Rules on Judicial Bar Council qualifications for Philippine courtsDocument2 pagesRules on Judicial Bar Council qualifications for Philippine courtsMLeePas encore d'évaluation

- Notice: Federal Agency Urine Drug Testing Certified Laboratories Meeting Minimum Standards, ListDocument2 pagesNotice: Federal Agency Urine Drug Testing Certified Laboratories Meeting Minimum Standards, ListJustia.comPas encore d'évaluation

- Securing ClearancesDocument5 pagesSecuring Clearancesmina villamorPas encore d'évaluation

- Punjab Health FoundationDocument29 pagesPunjab Health FoundationAhsan 11Pas encore d'évaluation

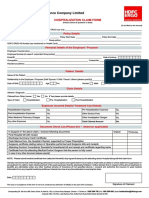

- HDFC ERGO hospital claimDocument1 pageHDFC ERGO hospital claimAnil AkkalaPas encore d'évaluation

- Commercial Work Injury Compensation FaqsDocument5 pagesCommercial Work Injury Compensation FaqsHihiPas encore d'évaluation

- Bibliography on Urban Waste ManagementDocument45 pagesBibliography on Urban Waste ManagementRavikar ShyamPas encore d'évaluation

- Compendium of Right To Food Laws in The Philippines - Volume III: Food Safety LawsDocument198 pagesCompendium of Right To Food Laws in The Philippines - Volume III: Food Safety LawsPeoples Development InstitutePas encore d'évaluation

- Business permit not a contract but a regulatory privilegeDocument1 pageBusiness permit not a contract but a regulatory privilegeDexter John SuyatPas encore d'évaluation

- Form Form of Application For The Renewal of Driving (See Rule 18 (1) )Document4 pagesForm Form of Application For The Renewal of Driving (See Rule 18 (1) )Chandru ChristurajPas encore d'évaluation

- APSEMO A Guide For City MayorsDocument68 pagesAPSEMO A Guide For City MayorspdccPas encore d'évaluation

- Brandie Conrad counseling infoDocument2 pagesBrandie Conrad counseling infoMarianLaloPas encore d'évaluation

- Treasury Financial Manual 11-08Document57 pagesTreasury Financial Manual 11-08topramenPas encore d'évaluation

- dm2019 0112Document6 pagesdm2019 0112DOH RO X RLEDPas encore d'évaluation

- Building State Capability - HarvardDocument276 pagesBuilding State Capability - HarvardMaajid BashirPas encore d'évaluation

- FW Leaflet DropDocument3 pagesFW Leaflet DropLuke PearsonPas encore d'évaluation

- A Yorkshire Town - The Making of DoncasterDocument142 pagesA Yorkshire Town - The Making of DoncasterAnders FernstedtPas encore d'évaluation

- Economic Impact of Relief Package in PakistanDocument10 pagesEconomic Impact of Relief Package in PakistanNadia Farooq100% (1)

- Security Inspection ChecklistDocument2 pagesSecurity Inspection Checklisttimisite24750% (2)

- 19 City of OzamisDocument14 pages19 City of Ozamisrgtan3Pas encore d'évaluation

- Bayhydrol® A 2542 PDFDocument3 pagesBayhydrol® A 2542 PDFAnonymous uSePUqqoFPas encore d'évaluation

- UNT MeningitisprintDocument1 pageUNT MeningitisprintPeipur Chakravarthy TejaPas encore d'évaluation

- A) Rourkela Steel Plant (RSP), A Unit of Steel Authority of India Limited (SAIL) - ADocument6 pagesA) Rourkela Steel Plant (RSP), A Unit of Steel Authority of India Limited (SAIL) - AnortheastjobsadminPas encore d'évaluation

- 2019 Budget: Full SpeechDocument174 pages2019 Budget: Full SpeechThe Independent GhanaPas encore d'évaluation

- DOH Pharmacist Activity ReportDocument8 pagesDOH Pharmacist Activity ReportAleiah Jean LibatiquePas encore d'évaluation

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationDocument3 pagesEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationMATHIVANANPas encore d'évaluation

- Design Management PlanDocument22 pagesDesign Management PlanValentin RadaceanuPas encore d'évaluation

- Admin Order - Cpes UpouDocument1 pageAdmin Order - Cpes UpouKenneth Isaac Dela CruzPas encore d'évaluation