Académique Documents

Professionnel Documents

Culture Documents

Federal Brake Lining Specifications - CID a-A-52522B

Transféré par

Brian RenekerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Federal Brake Lining Specifications - CID a-A-52522B

Transféré par

Brian RenekerDroits d'auteur :

Formats disponibles

[METRIC] A-A-52522B June 10, 1997 SUPERSEDING A-A-52522A November 13, 1995

COMMERCIAL ITEM DESCRIPTION LINING BRAKE, AND LINING MATERIAL, BRAKE: AUTOMOTIVE (METRIC)

The General Services Administration has authorized the use of this commercial item description (CID) for all federal agencies. 1. SCOPE. This CID covers automotive brake lining sets and brake lining material used in commercial and military vehicles. Except for the following: heavy construction, heavy military, industrial aeronautical, and any other application where the friction material is compounded specifically for a special purpose vehicle. 2. CLASSIFICATION. Brake linings shall be classified as follows (see 7.2): Type I Type II Type III - Brake lining sets, rigid (molded) materials. - Brake lining material flexible (woven). - Brake lining material flexible (molded).

NOTE: 1. A rigid lining is formed to fit a specific drum or disc diameter. 2. A woven lining is one which is made with woven fabric as a base. 3. A flexible lining is one that is adaptable to brake drums, the diameter of which are equal to or greater than 250 millimeters (mm) [10 inches (in.)]. Category A Category B - Drum brakes. - Disc brakes.

Beneficial comments, recommendations, additions, deletions, clarifications, etc. and any other data which may improve this document should be sent by letter to: U.S. Army Tank-automotive and Armaments Command, ATTN: AMSTA-TR-E/BLUE, Warren, MI 48397-5000. AMSC N/A FSC 2530 DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

A-A-52522B Style I Style II Class L Class M Class H - For bonding. - Drilled for rivets or bolts. - Up to 2727 kilograms (kg) [Up to 6000 pounds (lbs)]. - 2728 to 4545 kg (6001 to 10 000 lbs). - Over 4545 kg (over 10 000 lbs).

3. SALIENT CHARACTERISTICS 3.1 Materials. Unless otherwise specified herein; materials shall be in accordance with the manufacturers material specification. Asbestos material shall not be used. The use of recovered materials made in compliance with regulatory requirements is acceptable providing that all requirements of this CID are met (see 4.1). 3.1.1 Stability. Lining shall not vary more than as specified in Table I, subsequent to testing in accordance with SAE J160. TABLE I. Allowable variation for lining thickness. Lining size Maximum variation in thickness mm in. mm in. Up to 10 Up to 0.38 0.3 0.010 10 - 19 0.38 - 0.75 0.4 0.015 Above 19 Above 0.75 0.5 0.020 3.1.1.1 Gogan hardness and specific gravity. Unless otherwise specified in the contract (see 7.2), Gogan (or other) hardness shall be certified by the contractor to meet the levels specified in SAE J379. Specific gravity shall be determined by using the procedure described in SAE J380. 3.1.2 Sets or roll(s). Set(s) shall consist of all components required for one axle, shall be preformed and prepared for attachment to specific brake shoes as required (see 7.2). Rolls shall consist of bulk material furnished in lengths, widths and thicknesses as specified (see 7.2). Sets shall be attached, or be prepared for attachment, in one of the following ways: a. Drilled with rivet or bolt holes for attachment to specific brake shoes. b. Undrilled, for bonding of lining to the backing shoes. c. Molded or mechanically attached disc brake pads. 3.1.3 Bonding agent. The bonding agent shall be of the thermo-setting variety. Lining applied to the shoe or pad shall have a shear force exerted to the bond joint per SAE J840. Shear strength of the bonding agent shall be certified by the contractor to meet agreed upon levels. The agent, when cured, shall be unaffected by grease, oil, brake fluid, cleaning fluid, or storage of up to 2

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

A-A-52522B 82 degrees Celsius (C) [180 degrees Fahrenheit (F)] for periods of up to 2 years. The contractor shall certify to these requirements. 3.1.4 Storage. Both the adhesive in its final cured state, and the lining, after being bonded to the shoe, shall show no undesirable change in properties after periods of up to two years of storage at temperatures ranging from minus (-) 54C (-65F) to plus (+) 82C (180F). Storage capability shall be certified by the contractor. 3.1.5 Mechanical strength. Lining shall have sufficient mechanical strength to permit secure attachment without damage during assembly or use. 3.2 Design and construction. Unless otherwise specified herein, the design and construction of the brake lining shall be in accordance with the manufacturers design standards. 3.2.1 Brake lining tolerance for drum brakes. 3.2.1.1 Lining thickness. Except when variation in thickness is a function of design, surfaces of the drum brake lining shall be essentially parallel. Maximum variation in thickness across the width of the lining shall not be greater than + 0.2 mm (+ 0.008 in.) 3.2.1.2 Rivets and bolts. When riveted or bolted material is specified, rivets or bolts conforming to SAE J663 shall be provided in the manner and size required for the applicable lining. 3.2.1.3 Radius of curvature. Unless otherwise specified (see 7.2), inside radius of rigid molded lining shall be held to + 0.64 mm (+ 0.025 in.). 3.2.1.4 Lining position. All lining segments shall be properly identified as to position, such as primary, secondary, forward, reverse, inner or outer. Intermixing of primary and secondary linings shall not be permitted. 3.2.2 Brake lining tolerances for disc brakes. Unless otherwise specified (see 7.2), tolerances for disc brake type linings shall be as follows: a. Flat within 0.15 mm (0.005 in.) on lining surface, and parallel within 0.25 mm (0.010 in.) for integrally molded assemblies. b. Flat within 0.25 mm (0.010 in.) on both lining surfaces when supplied blank or drilled, and parallel within 0.51 mm (0.020 in.) when assembled on the steel backing. 3.3 Performance. Lining shall perform as specified under the conditions described in SAE J661.

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

A-A-52522B 3.3.1 Coefficients of friction. Values for coefficients of friction shall not be less than as specified in Table II for the types, categories and classes shown. To meet minimum requirements, a brake lining shall have: a. Minimal normal friction coefficient as specified in Column a, based on the average of five tests. b. Minimal hot friction coefficient as specified in Column b, based on the average of five tests. c. Minimal coefficient of friction as specified in Column c, based on each of five tests at the following points: (1) Between 93C (200F) and 260C (500F), inclusive, on the second fade run. (2) Between 148C (300F) and 93C (200F), inclusive on the second recovery run. 3.3.2 Wear. Wear shall not exceed the values specified in Table II for the types, categories and classes shown. TABLE II. Coefficients of friction and wear tolerances. Type Category Class Friction coefficient Maximum wear a b c mm in. A L I 0.25 0.20 0.18 0.75 0.030 M 0.25 0.20 0.18 0.8 0.035 H 0.25 0.20 0.18 1.0 0.040 I B L M H 0.28 0.28 0.28 0.30 0.23 0.23 0.23 0.20 0.21 0.21 0.21 0.15 0.75 0.8 1.0 2.0 0.030 0.035 0.040 0.075

II & III

3.4 Identification and marking. Identification and marking of the brake lining shall be permanent and legible and shall include as a minimum, the manufacturers CAGE code and part or identification number (PIN). Lining furnished in rolls, shall be marked at intervals not to exceed 305 mm (12 in.) throughout the length of the roll. Month and year of manufacture, by numerical code or other means, shall also be marked on each item, or at each interval. 4. REGULATORY REQUIREMENTS 4.1 Recovered materials. The offeror/contractor is encouraged to use recovered materials to the extent practicable, in accordance with paragraph 23.403 of the Federal Acquisition Regulation (FAR).

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

A-A-52522B 5. QUALITY ASSURANCE PROVISIONS 5.1 Responsibility for inspection. The contractor is responsible for the performance of all inspections, examinations, and tests. 5.2 Product conformance. The products provided shall meet the salient characteristics of this commercial item description, conform to the producers own drawings, specifications, standards, and quality assurance practices, and be the same product offered for sale in the commercial market. The Government reserves the right to require proof of such conformance. 6. PACKAGING Preservation, packing, and marking shall be as specified in the contract or order (see 7.2). 7. NOTES (This section contains information of a general or explanatory nature that may be helpful but is not mandatory.) 7.1 Addresses for obtaining copies of referenced documents. 7.1.1 Government publications. Copies of the Code of Federal Regulations (CFR) are available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402. 7.1.2 Non-Government Publications. Copies of SAE J160 Swell, Growth, and Dimensional stability of Brake Linings; SAE J379 Gogan Hardness of Brake Lining; SAE J380 Specific Gravity of Brake Lining; SAE J661 Brake Lining Quality Control Test Procedure; SAE J663 Rivets For Brake Linings and Bolts for Brake Block; and SAE J840 Test Procedures for Brake Shoe and Lining Adhesives and Bonds are available from the Society of Automotive Engineers, Inc. (SAE), 400 Commonwealth Drive, Warrendale, PA 15096. 7.2 Ordering data. Acquisition documents must specify the following: a. Title, number, and date of this CID. b. Issue of Department of Defense Index of Specifications and Standards (DODISS) to be cited in the solicitation, and if required, the specific issue of individual documents referenced. c. Type, category, style and class of lining, (PIN) (see 2). d. Quality control level of Gogan (or other) hardness and specific gravity (see 3.1.1.1). e. Sets or rolls are to be furnished (see 3.1.2). f. If inside radius is other than + 0.64 mm (+ 0.025 in) (see 3.2.1.3).

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

A-A-52522B g. Disc brake lining tolerances (see 3.2.2). h. Selection of applicable level and packaging requirements (see 6). 7.3 Part or identification number (PIN). The PIN to be used for brake linings acquired to this CID is as follows: AA 52522 - X - X - X - X Class: L M H 1 2 A B 1 2 3 class L class M class H style I style II category A category B type I type II type III

Style:

Category:

Type:

CID Number Designates a CID 7.4 Cross reference data. Lining material conforming to this CID are interchangeable/ substitutable with lining materials conforming to HH-L-361G dated August 1, 1985.

MILITARY INTERESTS: Custodians: Army - AT Air Force - 99 Review Activity: DLA - CC

CIVIL AGENCY COORDINATING ACTIVITY GSA - FSS Preparing Activity: Army - AT (Project 2530-0395)

Source: http://www.assistdocs.com -- Downloaded: 2013-04-10T14:49Z Check the source to verify that this is the current version before use.

Vous aimerez peut-être aussi

- A A 60005Document28 pagesA A 60005ashishkesharwaniPas encore d'évaluation

- Mil-Dtl-27422d Tank, Fuel, Crash-Resistant, Ballistic Tollerant, AircraftDocument47 pagesMil-Dtl-27422d Tank, Fuel, Crash-Resistant, Ballistic Tollerant, AircraftfogdartPas encore d'évaluation

- Aa Spec 373001Document13 pagesAa Spec 373001JDPas encore d'évaluation

- Fabricated BogieDocument16 pagesFabricated BogiemailbkraoPas encore d'évaluation

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylanePas encore d'évaluation

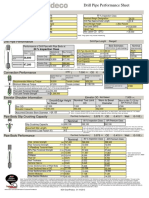

- Drill pipe performance and operational limitsDocument3 pagesDrill pipe performance and operational limitsGarcia C L AlbertoPas encore d'évaluation

- MR Num4-EnDocument14 pagesMR Num4-EnaminardakaniPas encore d'évaluation

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoPas encore d'évaluation

- Sae Ams S 13165Document27 pagesSae Ams S 13165sabrunoPas encore d'évaluation

- Specification For Machine For AbrasionDocument3 pagesSpecification For Machine For AbrasionSajidAliKhanPas encore d'évaluation

- A A 52524aDocument4 pagesA A 52524amuhammed emin akgülPas encore d'évaluation

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74Pas encore d'évaluation

- Bibby CouplingsDocument36 pagesBibby Couplingsmarklamb1hotmailcouk100% (1)

- ASME B31.3 & Expansion JointsDocument2 pagesASME B31.3 & Expansion JointsHomer SilvaPas encore d'évaluation

- ps1791s WELD SCREWS PROJECTION WELDINGDocument10 pagesps1791s WELD SCREWS PROJECTION WELDINGWinb SunPas encore d'évaluation

- Mil DTL 18240Document24 pagesMil DTL 18240Андрей ПятыгинPas encore d'évaluation

- Minimum RPD Standard Protects Off-Road VehiclesDocument12 pagesMinimum RPD Standard Protects Off-Road VehiclesTSP HSEPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- Anchor ShackleDocument11 pagesAnchor ShackleMacan SumatraPas encore d'évaluation

- Packer Shoes Casing Manual Section 7Document22 pagesPacker Shoes Casing Manual Section 7Tong Chaipanyakul100% (1)

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoPas encore d'évaluation

- Section 34 Abrasive Wheels: RequirementsDocument11 pagesSection 34 Abrasive Wheels: RequirementsnagaPas encore d'évaluation

- Specification For Gear Type Flexible Couplings: IPSS:1-01-005-18 (First Revision)Document7 pagesSpecification For Gear Type Flexible Couplings: IPSS:1-01-005-18 (First Revision)kaustavPas encore d'évaluation

- Is 15466 (2004)Document16 pagesIs 15466 (2004)slamienkaPas encore d'évaluation

- E1844Document4 pagesE1844DannyChaconPas encore d'évaluation

- SAE J 673-1993 Automotive Safety Glasses PDFDocument9 pagesSAE J 673-1993 Automotive Safety Glasses PDFmonkey1929100% (1)

- HacksawDocument5 pagesHacksawSimbu ArasanPas encore d'évaluation

- JDS 240.3Document9 pagesJDS 240.3phoenixenggworkPas encore d'évaluation

- Mil H 6000Document17 pagesMil H 6000Eric EPas encore d'évaluation

- Source: Http://assist - Dla.mil - Downloaded: 2020-12-23T21:32Z Check The Source To Verify That This Is The Current Version Before UseDocument12 pagesSource: Http://assist - Dla.mil - Downloaded: 2020-12-23T21:32Z Check The Source To Verify That This Is The Current Version Before UsejcPas encore d'évaluation

- S SE EC CT Tiio ON N 1 1: Section 1Document14 pagesS SE EC CT Tiio ON N 1 1: Section 1Miguel Hernandez Barbosa100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoPas encore d'évaluation

- Cylinder Liner - Install: Disassembly and AssemblyDocument4 pagesCylinder Liner - Install: Disassembly and AssemblysatyaPas encore d'évaluation

- HKKJR LJDKJ Jsy Ea KyDocument18 pagesHKKJR LJDKJ Jsy Ea KymailbkraoPas encore d'évaluation

- 125 1193218825specificationDocument7 pages125 1193218825specificationSardar Gurpreet SinghPas encore d'évaluation

- RAILWAY SPECIFICATION FOR NON-ASBESTOS BRAKE BLOCKSDocument16 pagesRAILWAY SPECIFICATION FOR NON-ASBESTOS BRAKE BLOCKSmailbkraoPas encore d'évaluation

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaPas encore d'évaluation

- Manufactured Traffic Calming DevicesDocument3 pagesManufactured Traffic Calming DevicesAnees RahmanPas encore d'évaluation

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаPas encore d'évaluation

- Mil S 13165Document20 pagesMil S 13165Francisco Ribeiro FernandesPas encore d'évaluation

- CSM Tamping Cylinder SpecificationDocument4 pagesCSM Tamping Cylinder SpecificationtotoPas encore d'évaluation

- Grinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsDocument2 pagesGrinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsRay LujanPas encore d'évaluation

- Mil DTL 6000Document17 pagesMil DTL 6000John Néstor Ramirez CalderónPas encore d'évaluation

- Mil PRF 27260Document11 pagesMil PRF 27260Mervyn EatonPas encore d'évaluation

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Pas encore d'évaluation

- Trunnion Support ClampDocument10 pagesTrunnion Support ClampMosa Elnaid ElnaidPas encore d'évaluation

- ASME B31.3 & Expansion Joints PDFDocument2 pagesASME B31.3 & Expansion Joints PDFsammar_10Pas encore d'évaluation

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFDocument3 pages216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFubaldo caraballoPas encore d'évaluation

- A A 52550Document8 pagesA A 52550HayleyPas encore d'évaluation

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualPas encore d'évaluation

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyD'EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)D'EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Évaluation : 1 sur 5 étoiles1/5 (3)

- VW Transporter T4 Workshop Manual Diesel 2000-2004D'EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Évaluation : 5 sur 5 étoiles5/5 (5)

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesD'EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesÉvaluation : 1 sur 5 étoiles1/5 (1)

- Laws Thermodynamics LectureDocument7 pagesLaws Thermodynamics Lecturexx_aleksa_hrvatska_xxPas encore d'évaluation

- Regulations of The UEFA Futsal Champions LeagueDocument64 pagesRegulations of The UEFA Futsal Champions Leaguesebastian ferrer vargasPas encore d'évaluation

- A.M. No. 08-11-7-SCDocument18 pagesA.M. No. 08-11-7-SCStenaArapocPas encore d'évaluation

- Volume 46, Issue 35, August 28, 2015Document40 pagesVolume 46, Issue 35, August 28, 2015BladePas encore d'évaluation

- Material Safety Data Sheet (MSDS) : 1. IdentificationDocument8 pagesMaterial Safety Data Sheet (MSDS) : 1. IdentificationPlant Head PrasadPas encore d'évaluation

- 15 USC 1641 - Liability of Assignees - LII: Legal Information InstituteDocument4 pages15 USC 1641 - Liability of Assignees - LII: Legal Information InstituteJulio VargasPas encore d'évaluation

- Lim Kim Chuan Hearsay Evidence RulingDocument4 pagesLim Kim Chuan Hearsay Evidence RulingstarrRiverPas encore d'évaluation

- Crime Against WomenDocument16 pagesCrime Against Womenshowkat waniPas encore d'évaluation

- Terminal v. Philippine Ports AuthorityDocument13 pagesTerminal v. Philippine Ports AuthorityBeltran KathPas encore d'évaluation

- Ans 1Document2 pagesAns 1bhupendra barhatPas encore d'évaluation

- 195 BCA PresentationDocument36 pages195 BCA PresentationCA Sagar WaghPas encore d'évaluation

- 1334747078785-2 D&A RulesDocument9 pages1334747078785-2 D&A RulesWilliam BennettPas encore d'évaluation

- Labour Law Proj SatyajitDocument56 pagesLabour Law Proj Satyajita_r_ghadgePas encore d'évaluation

- 1 Title Page Curfew Ordinance ABM Final 10 Files MergedDocument68 pages1 Title Page Curfew Ordinance ABM Final 10 Files MergedChristopher PerazPas encore d'évaluation

- KLTPS 1310 W620 Tech 150610Document26 pagesKLTPS 1310 W620 Tech 150610kinner3Pas encore d'évaluation

- Unaninous Special Verdict 2-17-16Document2 pagesUnaninous Special Verdict 2-17-16Nancy Duffy McCarronPas encore d'évaluation

- 9 TortDocument6 pages9 TortrahulPas encore d'évaluation

- Agenda Item: Backgrou NDDocument18 pagesAgenda Item: Backgrou NDMichael JamesPas encore d'évaluation

- Legal Writing Principles ExplainedDocument8 pagesLegal Writing Principles ExplainedSayan SenguptaPas encore d'évaluation

- PPSTA MAS Claim RequirementsDocument2 pagesPPSTA MAS Claim RequirementsAngiePas encore d'évaluation

- Horse Purchase and Sale AgreementDocument2 pagesHorse Purchase and Sale AgreementPANASONIC TELEVISIONPas encore d'évaluation

- Rule 43 Appeals FRM Cta QjaDocument3 pagesRule 43 Appeals FRM Cta QjaMartin FontanillaPas encore d'évaluation

- Sweet Lines v. Teves: Exclusivity of venue clause invalidDocument3 pagesSweet Lines v. Teves: Exclusivity of venue clause invalidalyPas encore d'évaluation

- Labor Review Week 3 and Week 4 Full Text Cases PDFDocument629 pagesLabor Review Week 3 and Week 4 Full Text Cases PDFtepi7wepiPas encore d'évaluation

- Consortium AgreementDocument2 pagesConsortium AgreementAshesh Tiwari100% (1)

- Idrocrete MSDSDocument8 pagesIdrocrete MSDSMohd Khairul Md DinPas encore d'évaluation

- ch29 PDFDocument29 pagesch29 PDFRodrigo S QuirinoPas encore d'évaluation

- SPECIAL POWER OF ATTORNEyalbertDocument3 pagesSPECIAL POWER OF ATTORNEyalbertRick AranetaPas encore d'évaluation

- Third Party Debt CollectionDocument2 pagesThird Party Debt CollectionShannon Collum100% (14)

- 10 10 13 62104 Motion IFP Writ Prohibition Mandamus RJC RMC Etc 13-30280 72675 71437 Administrative Order 2013-01Document267 pages10 10 13 62104 Motion IFP Writ Prohibition Mandamus RJC RMC Etc 13-30280 72675 71437 Administrative Order 2013-01NevadaGadflyPas encore d'évaluation