Académique Documents

Professionnel Documents

Culture Documents

2627

Transféré par

hogoyoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2627

Transféré par

hogoyoDroits d'auteur :

Formats disponibles

CASE

CASES OF ASME BOILER AND PRESSURE VESSEL CODE

2627

Approval Date: September 30, 2009 Code Cases will remain available for use until annulled by the applicable Standards Committee.

Case 2627 Use of Aluminum Alloy EN AW-6060 T1 Extruded (Integrally) Finned Tube in the Manufacture of Hot Water Heating Boilers Section IV Inquiry: May aluminum alloy EN AW-6060 T1 extruded nned and coiled tube meeting the chemical composition listed in Table 1, the mechanical properties listed in Table 2, and heat treatment temper designation T1 according to EN 515 August 1993, be used in construction for hot water heating boilers under the rules of Section IV? Reply: It is the opinion of the Committee that aluminum alloy EN AW-6060 T1 extruded nned and coiled tube meeting the requirements described in the Inquiry may be used in Section IV, construction of hot water heating boilers, under the following conditions: (a) Maximum allowable working pressure shall not exceed 50 psi (350 kPa). (b) The maximum water temperature shall be 220F (105C).

(c) The maximum allowable stress values shall be as shown in Table 3 and Table 3M. (d) The material shall otherwise conform to the specications listed in Table 4. (e) The minimum allowable thickness shall be 0.079 in. (2 mm), except as noted in para. (g). (f) Separate welding procedure qualications conducted in accordance with Section IX shall be required for this material. (g) Minimum thickness, at the point where the tube is bent at the water inlet/outlet terminals, is 0.039 in. (1.0 mm), provided the tubes are enclosed by a shell, casing, or ducting, where such pipes or tubes are NPS 6 (DN 150) and less, and a proof test of the tubing is performed. (h) All other applicable parts of Section IV shall apply. (i) In case of conict with any of the referenced specications, this Code Case shall govern. (j) This Case number shall be referenced in the documentation and marking of the material and shown on the Manufacturers Data Report.

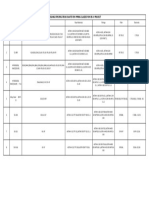

TABLE 1 CHEMICAL COMPOSITION OF EN AW-6060 ALLOY (AlMgSi)

Silicon Iron Copper Manganese Magnesium Chromium Zinc Titanium Others, total Aluminum

--``,,,``,`,,``,``````,``,,-`-`,,`,,`,`,,`---

0.300.6 0.100.30 0.10 max. 0.10 max. 0.350.6 0.05 max. 0.15 max. 0.10 max. 0.15 max. Balance

GENERAL NOTE: Ref. EN 573-3:2007; Table 6, Aluminium alloys 6 000 series AlMgSi; page 16.

The Committees function is to establish rules of safety, relating only to pressure integrity, governing the construction of boilers, pressure vessels, transport tanks and nuclear components, and inservice inspection for pressure integrity of nuclear components and transport tanks, and to interpret these rules when questions arise regarding their intent. This Code does not address other safety issues relating to the construction of boilers, pressure vessels, transport tanks and nuclear components, and the inservice inspection of nuclear components and transport tanks. The user of the Code should refer to other pertinent codes, standards, laws, regulations or other relevant documents.

1 (2627)

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS Licensee=Larsen and Toubro Ltd Baroda/5954522003, User=Dhanaraj M, Francis Not for Resale, 07/24/2010 22:59:54 MDT

CASE (continued)

2627

CASES OF ASME BOILER AND PRESSURE VESSEL CODE

TABLE 2 MINIMUM MECHANICAL PROPERTIES

Temperature, F 68

R p 0,2, ksi

7.3

R m , ksi

17.4

Temperature, C 20

R p 0,2, MPa

50

R m , MPa

120

A50, % 14

GENERAL NOTE: Ref. UNI 9006-1:1988, para. 5.1, page 2.

TABLE 3 MAXIMUM ALLOWABLE STRESS VALUES

For Metal Temperature Not Exceeding, F Up to 100 150 200 250 300 Maximum Allowable Stress, ksi 3.5 3.5 3.5 3.4 3.2

GENERAL NOTE: The maximum metal use temperature is 266F (130C). Data for 300F and 150C is provided for interpolation purposes.

TABLE 3M MAXIMUM ALLOWABLE STRESS VALUES

For Metal Temperature Not Exceeding, C Up to 40 65 100 125 150 Maximum Allowable Stress, MPa 24.0 24.0 24.0 23.3 22.3

GENERAL NOTE: The maximum metal use temperature is 266F (130C). Data for 300F and 150C is provided for interpolation purposes.

TABLE 4 APPLICABLE SPECIFICATIONS

UNI 9006-1, September 1988 Wrought primary aluminum and aluminum alloys. Aluminum-magnesium-silicon alloys. Al Mg 0.5 Si 0.4 Fe 0.2 (6060) alloy. Aluminum and aluminum alloys. Wrought products. Temper designation. Aluminum and aluminum alloys. Chemical composition and form of wrought products Part 3: Chemical composition and form of products. Aluminum and aluminum alloys. Extruded rod/bar, tube, and proles. Part 1: Technical conditions for inspection and delivery. Metallic materials. Tensile testing. Part 1: Method of test at ambient temperature.

EN 515, August 1993 EN 573-3, August 2007 EN 755-1, March 2008 EN 10002-1, July 2001

--``,,,``,`,,``,``````,``,,-`-`,,`,,`,`,,`---

GENERAL NOTES: (a) See Section II, Part B, Appendix A for ordering information to obtain English copies. (b) Copy of the Italian Standard UNI 9006 can be obtained from: UNI, via Sannio 2, 20137 Milano, Italy.

2 (2627)

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS Licensee=Larsen and Toubro Ltd Baroda/5954522003, User=Dhanaraj M, Francis Not for Resale, 07/24/2010 22:59:54 MDT

Vous aimerez peut-être aussi

- Case 2256 Valve Markings Section IV: Inquiry: HG-402.1 of Section IV Permits The MarkingDocument2 pagesCase 2256 Valve Markings Section IV: Inquiry: HG-402.1 of Section IV Permits The MarkinghogoyoPas encore d'évaluation

- 2488 2Document2 pages2488 2hogoyoPas encore d'évaluation

- List of Phobias PDFDocument11 pagesList of Phobias PDFhogoyoPas encore d'évaluation

- Case 1923-4 Restricting Lift To Achieve Reduced Relieving Capacities of Full Lift, Nozzle Type, Flat Seated Safety and Safety Relief Valves Section IDocument2 pagesCase 1923-4 Restricting Lift To Achieve Reduced Relieving Capacities of Full Lift, Nozzle Type, Flat Seated Safety and Safety Relief Valves Section IhogoyoPas encore d'évaluation

- 2276 1Document2 pages2276 1hogoyoPas encore d'évaluation

- 1876 3Document4 pages1876 3hogoyoPas encore d'évaluation

- 1855 1Document2 pages1855 1hogoyoPas encore d'évaluation

- 1750 22Document4 pages1750 22hogoyoPas encore d'évaluation

- Reply: It Is The Opinion of The Committee That TheDocument2 pagesReply: It Is The Opinion of The Committee That ThehogoyoPas encore d'évaluation

- 2192 6Document2 pages2192 6hogoyoPas encore d'évaluation

- Case 2270 Ultrasonic Examination of Welds Made by The Electron Beam Process Section VIII, Division 1Document2 pagesCase 2270 Ultrasonic Examination of Welds Made by The Electron Beam Process Section VIII, Division 1hogoyoPas encore d'évaluation

- 09mae324 - PD30Document1 page09mae324 - PD30hogoyoPas encore d'évaluation

- Case 2305-1 Exemption From Postweld NDE Requirements of UG-93 (D) (4) (B) On Fig. UW-13.2 (D) Construction Section VIII, Division 1Document2 pagesCase 2305-1 Exemption From Postweld NDE Requirements of UG-93 (D) (4) (B) On Fig. UW-13.2 (D) Construction Section VIII, Division 1hogoyoPas encore d'évaluation

- 1518 5Document2 pages1518 5hogoyoPas encore d'évaluation

- Case 1924-2 Nickel-Molybdenum-Chromium Alloy (UNS N10276) Section IDocument2 pagesCase 1924-2 Nickel-Molybdenum-Chromium Alloy (UNS N10276) Section IhogoyoPas encore d'évaluation

- Table - Minimum Values For The Ratio of The Stress at Proof Limit 0.2% at Elevated Temperature (Et) To The MinimumDocument1 pageTable - Minimum Values For The Ratio of The Stress at Proof Limit 0.2% at Elevated Temperature (Et) To The MinimumhogoyoPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Is 4454 Spring Steel WireDocument2 pagesIs 4454 Spring Steel Wireprasad.s.n KumarPas encore d'évaluation

- Alum 1 PDFDocument6 pagesAlum 1 PDFSavaPas encore d'évaluation

- Intenship PresentationDocument22 pagesIntenship PresentationArpita FundePas encore d'évaluation

- Mstube BrochureDocument8 pagesMstube Brochuresatish3682Pas encore d'évaluation

- Frank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Document532 pagesFrank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Carlos Bermejo Alvarez100% (1)

- Borrower's Log BookDocument20 pagesBorrower's Log BookZaire GalvezPas encore d'évaluation

- 철강에서 미량 불순물 원소들의 영향-1995Document174 pages철강에서 미량 불순물 원소들의 영향-1995BUKANG - R&DPas encore d'évaluation

- 4.5 MetalsDocument22 pages4.5 Metalsbradley omariPas encore d'évaluation

- Astm F836M-16Document7 pagesAstm F836M-16arcadioscoPas encore d'évaluation

- Ions ChargeDocument1 pageIons Chargeshashankshukla676100% (1)

- Welding Specifications ChartDocument1 pageWelding Specifications ChartAbhinit KumarPas encore d'évaluation

- SolderingDocument34 pagesSolderingMrinal PathakPas encore d'évaluation

- Reapir and Altertaion Section 8Document52 pagesReapir and Altertaion Section 8waqas pirachaPas encore d'évaluation

- New Microsoft Office Excel WorksheetDocument11 pagesNew Microsoft Office Excel WorksheetUmar NazarPas encore d'évaluation

- Gating-Risering Sec2Document35 pagesGating-Risering Sec2jagan_4u100% (1)

- Crucible and High-Frequency MethodsDocument6 pagesCrucible and High-Frequency Methodsmaanka tuduPas encore d'évaluation

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- JISG3459Document39 pagesJISG3459Son-Tuan PhamPas encore d'évaluation

- Failure Analysis of Sheared Shaft of A Brine Recycle Pump...Document12 pagesFailure Analysis of Sheared Shaft of A Brine Recycle Pump...Pd RarPas encore d'évaluation

- 2.0 Beng. 17 Introduction To Structural Steel Design-1Document19 pages2.0 Beng. 17 Introduction To Structural Steel Design-1Erick Elvis ThomassPas encore d'évaluation

- La Frase Nominal-Practice MECANICADocument3 pagesLa Frase Nominal-Practice MECANICAAgustin GalvanPas encore d'évaluation

- Module 6 Metal Properties and Destructive TestingDocument46 pagesModule 6 Metal Properties and Destructive TestingMiki Jaksic100% (6)

- ERCUDocument1 pageERCURogério JuniorPas encore d'évaluation

- 12 Alloys - SDocument3 pages12 Alloys - SisabellePas encore d'évaluation

- Metal CastingDocument11 pagesMetal Castingআজিজুর রহমান চৌধুরীPas encore d'évaluation

- Updated - Type Test Schedule - Ams 5719 - 16-12-2023 - SignedDocument13 pagesUpdated - Type Test Schedule - Ams 5719 - 16-12-2023 - SignedGyanendraPas encore d'évaluation

- ST52-3 (PLATE) Mechanical PropertiesDocument1 pageST52-3 (PLATE) Mechanical Propertiesistasyonbaykusu100% (1)

- SP-1097 DSS Welding Specs PDFDocument48 pagesSP-1097 DSS Welding Specs PDFHari Prakash GrandheyPas encore d'évaluation

- Non Ferrous-Metal - Group-2 - Written-Report - ME3Document11 pagesNon Ferrous-Metal - Group-2 - Written-Report - ME3ELLIEPas encore d'évaluation

- Plate Steel CatalogueDocument73 pagesPlate Steel CatalogueMelele MuPas encore d'évaluation