Académique Documents

Professionnel Documents

Culture Documents

Selectionof Pumps Basedon Efficiency Loadingfor Evaluationof Bids

Transféré par

Paijo TejoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Selectionof Pumps Basedon Efficiency Loadingfor Evaluationof Bids

Transféré par

Paijo TejoDroits d'auteur :

Formats disponibles

Selection of Pumps Based on Efficiency Loading for Evaluation of Bids

Introduction:- Designing of pumps for water supply schemes are usually based on total pumping quantity & total head as per system head curve. Accordingly, procurement of pumps is being carried out, in various configurations of working & standby arrangement for discharge & DPH as computed and evaluating Best Efficiency Point (BEP) of various offers & loading thereon, through tendering process, asking the bidders to provide pumps with fairly constant efficiency curve, within the head range of minimum & maximum levels of sump and HSR.

Do the pumps so selected operate at DPH and give optimum performance? Do we verify the fairly constant efficiency characteristics claimed by bidder? The exercise in the subject matter is to develop a model procedure, which validates and insure accurately; the operating system it represents and simple enough as well as practicable for implementation. The pumps all over the world consume about 50 % of electrical energy generated, and it is very much essential to have uniform norm for proper selection of pumps with optimum performance. Facts:- This assumption clearly indicates the Duty Point Head for pump so chosen is for parallel operation of pumps (No of working in the design data).

The actual operating head varies between head range due to one or all of the following parameters:1) Partial pumping (less than total no of working pumps as per design) 2) Level variations of sump and HSR/GSR/MBR/BPT 3) Variations in power supply frequency. In the tender conditions, the efficiency variation within this head range is not clearly defined quantitatively, such as percent of efficiency at BEP; rather it is mentioned as fairly constant. Accordingly we rely on the graphical representation of characteristic curves only. The actual operating point of pumps fluctuates within the head range; hence the loading of efficiency and acceptance of pumps for economic performance, on the presumption of operation at DPH & BEP seldom fails, considering the actual operation. The discharge & head at which pumps will operate will be decided by the system resistance curves. There will be different system resistance curves for different levels since static head will vary. If we superimpose pump performance curves of these system resistance curves, then the operating range becomes clear. If we consider minimum, normal & maximum levels then intersection points of pump performance curves with maximum & minimum water level decide the operating range (for single as well as parallel operation). Now the levels considered for this exercise, are reasonable approximation of actual pattern over the years. Field Conditions:- For Raw Water Pumps, weir level vary as per discharge from upstream dam/reservoir, it is observed that 10 % of the time the levels are low, 70 % of the time the levels are normal and 20 % of the time the levels are maximum over the year period For Pure Water Pumps, the sump water level varies hourly and it is observed that out of 24 hours; 5 hours levels are lowest, 5 hours levels are highest and about 14 hours levels are normal. Same is the case for HSR/GSR/MBR/BPT. Solution:- The most important point is that the correct assessment of bids for proper selection of pumps as per actual field condition by incorporating efficiencies in this operating zone and verification of optimum performance of pumps over the entire head range. The practical limitations from manufacturers point of view, for fairly constant performance of pumps within the entire head range are also need to be considered, due to manufacturing constraints, such as the impellers are cast & due to minor variations in the suction angle, discharge angle & the vane configurations, the efficiencies may vary for each cast impeller. Hence, by making some adjustments, to maintain Q, H at BEP, they offer guaranteed performance at Duty Point only. Also the actual performance may vary than the quoted values at high head & low head. Now the relevant IS also stipulates guarantee for duty point only, with or without tolerance. In my opinion, the time has come to adopt strict control over specifications/ranges/tolerances as a buyer, in view of scarcity of electricity and implementation of energy conservation. One more point relating to the subject issue, generally over sighted by presuming that, for a given duty point all the bidders (assuming various make of pumps) will have offered pumps having specific speed almost identical or in the nearby range and in consideration to this, the efficiency variation between high head, low head & duty point will be almost similar and hence the current practice of bid evaluation by using only duty point efficiency will be true indication of actual power consumption. It is to note here that without the standardize procedure to verify the committed figures of Q, H & for entire operating range quantitatively, one may quote for higher duty point performance by offering the pump with higher specific speed at par the cost by other, who may offer slightly lower duty point performance but fairly constant performance in entire head range.

The practical solution for loading of efficiency for optimum performance & competitive comparison and to accommodate the commitment of fairly constant efficiency characteristic by bidders to achieve the proper selection of pumps, I would like to suggest the loading procedure as follows:Effective Efficiency Calculation:A) Raw Water Pumps:-

For raw water pumps, we should propose loading of efficiency by evaluating effective efficiency for complete head range as 20% of lowest head efficiency plus 70% of BEP condition plus 10% of highest head efficiency. effective = (20%lowhead + 70%DPH + 10%highhead ) B) Pure Water Pumps:-

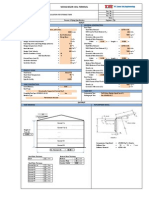

For pure water pumps, we should propose loading of efficiency by evaluating effective efficiency for complete head range as 20% of lowest head efficiency plus 60% of BEP condition plus 20% of highest head efficiency. effective = (20%lowhead + 60%DPH + 20%highhead ) The efficiency of the motor remains fairly constant in above loading conditions. The sample calculations by taking figures from the quoted values by bidders with present loading & proposed loading is tabulated below. Location Efficiency Quoted Loading Bidder 1 Bidder 2 Bidder 3 Raw Water Pumps Low head 20% 0.79 0.842 0.835 DPH 70% 0.872 0.863 0.86 High head 10% 0.81 0.823 0.825 0.8494 0.8548 0.8515 0.92 0.925 0.92 0.7814 0.7907 0.7834 Effective Efficiency of pump Motor Efficiency Overall Efficiency

Overall Efficiency by Current Method:Bidder 1:- 0.872 X 0.92 = 0.8022 Bidder 2:- 0.863 X 0.925 = 0.7983 Bidder 3:- 0.86 X 0.92 = 0.7912

Location Efficiency Quoted Loading Bidder 1 Bidder 2 Bidder 3

Pure Water Pump Low head 20% 0.79 0.842 0.835 DPH 60% 0.872 0.863 0.86 High head 20% 0.81 0.823 0.825

Effective Efficiency of pump

Motor Efficiency

Overall Efficiency

0.8432 0.8508 0.8480

0.92 0.925 0.92

0.7757 0.7870 0.7802

Overall Efficiency by Current Method:Bidder 1:- 0.872 X 0.92 = 0.8022 Bidder 2:- 0.863 X 0.925 = 0.7983 Bidder 3:- 0.86 X 0.92 = 0.7912 Considering the existing system of loading we may consider the pump from bidder 1 as highest efficiency; however as per modified approach to suit actual operating condition the pumps from bidder 2 will give optimum performance. The financial loading & present worth may be calculated based on effective efficiency so arrived. I have one more suggestion that there should be bonus for higher efficiency at site & penalty for lower efficiency at site, also sustenance of efficiency over prolonged period must be considered, rather initial efficiency. Otherwise, first few months, Pumps operate at good efficiency but later the efficiency drop is very fast. This should not happen. Worldwide there is trend of sustained efficiency. This may result into lower initial efficiency but for prolonged period efficiency will not deteriorate.

Dipak D. Dahake Assistant Engineer (E&M) MIDC, E&M Division, Mahad Email: dipak_dahake@rediffmail.com

Vous aimerez peut-être aussi

- Input EchoDocument42 pagesInput EchoPaijo TejoPas encore d'évaluation

- T-L R, (,li U $: LrillllDocument4 pagesT-L R, (,li U $: LrillllPaijo TejoPas encore d'évaluation

- Coefficient of Friction,..Document2 pagesCoefficient of Friction,..Paijo TejoPas encore d'évaluation

- DD DNV Gardu PLN Alt1 ModelDocument1 pageDD DNV Gardu PLN Alt1 ModelPaijo TejoPas encore d'évaluation

- Pages From Piusi Cube 70mc EspDocument1 pagePages From Piusi Cube 70mc EspPaijo TejoPas encore d'évaluation

- ICD EPC Volume 2 Final-ToCDocument6 pagesICD EPC Volume 2 Final-ToCPaijo TejoPas encore d'évaluation

- ICD EPC Volume 2 FinalDocument1 pageICD EPC Volume 2 FinalPaijo TejoPas encore d'évaluation

- Fire PumpDocument1 pageFire PumpPaijo TejoPas encore d'évaluation

- Valve ScheduleDocument2 pagesValve SchedulePaijo TejoPas encore d'évaluation

- LCC PumpDocument2 pagesLCC PumpPaijo TejoPas encore d'évaluation

- ST 3000 KLiter New SettingDocument3 pagesST 3000 KLiter New SettingPaijo TejoPas encore d'évaluation

- Tte033 7403 01 Filling Station DetailDocument1 pageTte033 7403 01 Filling Station DetailPaijo TejoPas encore d'évaluation

- Final Sum ADocument2 pagesFinal Sum APaijo TejoPas encore d'évaluation

- Miang Besar Coal Terminal: Calculation For Diesel Oil Transfer PumpDocument1 pageMiang Besar Coal Terminal: Calculation For Diesel Oil Transfer PumpPaijo TejoPas encore d'évaluation

- Water CadDocument29 pagesWater CadPaijo TejoPas encore d'évaluation

- Form LCC PumpDocument1 pageForm LCC PumpPaijo TejoPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Compressed Natural Gas (CNG) Is ADocument6 pagesCompressed Natural Gas (CNG) Is ASarvesh JaiswalPas encore d'évaluation

- IR 10-1 Rev01!06!12 Egress IlluminationDocument2 pagesIR 10-1 Rev01!06!12 Egress Illuminationap00Pas encore d'évaluation

- 582-2003-004 1Document21 pages582-2003-004 1BluemulPas encore d'évaluation

- TV LineupDocument142 pagesTV LineupAjit NairPas encore d'évaluation

- J CarouselDocument37 pagesJ CarouselRamon VallePas encore d'évaluation

- Catalogue - LS-Titan Position SwitchesDocument33 pagesCatalogue - LS-Titan Position SwitchesRicardo CalmonPas encore d'évaluation

- Acs 108Document13 pagesAcs 108Giovanni ManzolilloPas encore d'évaluation

- Steel Tube HandbookDocument124 pagesSteel Tube HandbookOzanPas encore d'évaluation

- Burnertronic Bt300: Quick Reference For EndusersDocument48 pagesBurnertronic Bt300: Quick Reference For Endusersjesus paezPas encore d'évaluation

- Etrobility Latform: Installation & User GuideDocument30 pagesEtrobility Latform: Installation & User GuideYoel ArmasPas encore d'évaluation

- Nphies - Web Services IntegrationDocument29 pagesNphies - Web Services IntegrationShabbir ShamsudeenPas encore d'évaluation

- IC EngineDocument5 pagesIC EngineVignesh MahalingamPas encore d'évaluation

- NS Examples For Wireless ScenarioDocument44 pagesNS Examples For Wireless ScenarioSatish KumarPas encore d'évaluation

- C61 Mobile ComputerDocument2 pagesC61 Mobile ComputerAnkit ParasharPas encore d'évaluation

- Catalog VaneDocument16 pagesCatalog VanehbcbmwtuningPas encore d'évaluation

- enDocument44 pagesenRegistr Registr90% (10)

- 1670.1-2018 Fire Detection and AlarmsDocument152 pages1670.1-2018 Fire Detection and Alarmsn.zabihiPas encore d'évaluation

- Aws A5.14 A5.14m (1997) PDFDocument30 pagesAws A5.14 A5.14m (1997) PDFnaspauzan100% (2)

- Soil NailingDocument5 pagesSoil NailingVishweshwaran MPas encore d'évaluation

- X52Document16 pagesX52cj_kamPas encore d'évaluation

- As 3596-1992 Energy Management Programs - Guidelines For Definition and Analysis of Energy and Cost SavingsDocument7 pagesAs 3596-1992 Energy Management Programs - Guidelines For Definition and Analysis of Energy and Cost SavingsSAI Global - APACPas encore d'évaluation

- Quality Risk Management: Ghada HaddadDocument13 pagesQuality Risk Management: Ghada HaddadVijay KumarPas encore d'évaluation

- QT 44Document16 pagesQT 44biraj57Pas encore d'évaluation

- Kupasan Artikel KEPIMPINAN DISTRIBUTIFDocument42 pagesKupasan Artikel KEPIMPINAN DISTRIBUTIFAngsPas encore d'évaluation

- Catalogo Chumaceras Link BeltDocument309 pagesCatalogo Chumaceras Link BeltHejage Kecuca Decuca100% (1)

- Oil - Capacity - Chart BRIGGS & STRATTON PDFDocument8 pagesOil - Capacity - Chart BRIGGS & STRATTON PDFgarry thornePas encore d'évaluation

- Edited IT4405 2017 Part2 AnsDocument9 pagesEdited IT4405 2017 Part2 AnsfahadPas encore d'évaluation

- Search and Rescue Robotic Systems: A Case StudyDocument20 pagesSearch and Rescue Robotic Systems: A Case Studymonica_804238794Pas encore d'évaluation

- Pressure Reducing and Surplussing valves-SB-GCH-29-ENDocument18 pagesPressure Reducing and Surplussing valves-SB-GCH-29-ENMalik DaniyalPas encore d'évaluation

- CH 05 TestjDocument16 pagesCH 05 TestjUttam MNPas encore d'évaluation