Académique Documents

Professionnel Documents

Culture Documents

Internal Test 1

Transféré par

Sathish KumarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Internal Test 1

Transféré par

Sathish KumarDroits d'auteur :

Formats disponibles

V.S.B.

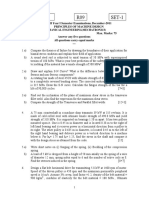

ENGINEERING COLLEGE, KARUR DEPARTMENT OF MECHANICAL ENGINEERING INTERNAL TEST-I DESIGN OF MACHINE ELEMENTS Year/Semester & Branch: III Year/V Semester B.E. Mech.Engg. (A & B Sections) Faculty Name: M.Sathishkumar Date: Max. Marks: 50 Time: 100 min PART-A Answer ALL Questions (5x2=10 Marks) 1. Differentiate between keys and splines. 2. What is meant by shaft? List the various types of stresses induced in the shaft. 3. State repeated stresses and fluctuating stresses. 4. List any two reasons for preferring hollow shaft over solid shaft. 5. Define endurance limit or fatigue limit. PART-B Answer ALL Questions (8+16+16=40 Marks) 6. (a) (i) Determine the rectangular key for shaft of 50 mm diameter. The shearing and crushing stresses for the key material are 42 MPa and 70 MPa. (4) (ii) A 15 kW, 960 rpm motor has a mild steel shaft of 40 mm diameter and the extension being 75 mm. The permissible shear and crushing stresses for the mild steel key are 56 MPa and 112 MPa. Design the keyway in the motor for shaft extension. Check the shear strength of the key against the normal strength of the shaft. (4) OR 6. (b) (i) Design a taper key for a shaft of diameter 100 mm transmitting 60 kW at 300 rpm. The allowable compressive stress may be taken as 175 N/m m2. (4) (ii) A square key 10x10x75 mm dimension is required to transmit 1100 N-m torque from a 60 mm diameter solid shaft. Determine whether the length is sufficient or not if the permissible shear stress and crushing stress intensities limited to 60 MPa and 170 MPa respectively. (4) 7. (a) A pulley is keyed to a shaft midway between two anti friction bearings. The bending moment at the pulley varies from -170N-m to 510N-m as the torsional moment in the shaft varies from 55 Nm to 165 N-m. The frequency of the variation of the loads is the same as the shaft speed. The shaft is made of cold drawn steel having an ultimate strength of 538 MPa and yield strength of 400 MPa. Determine the required diameter for an infinite life. The stress concentration factor for the keyway in bending and torsion may be taken as 1.6 and 1.3 respectively. Use design factor N = 1.5. (16) OR 7. (b) A simply supported beam has a concentrated at the centre which fluctuates from a value of P to 4P. The span of the beam is 500 mm and its cross section is circular with a diameter of 60 mm. Taking for the beam material an ultimate stress of 700 MPa, a yield stress of 500 MPa, endurance limit of 330 MPa for reversed bending and a factor of safety of 1.3, calculate the maximum value of P. Take a size factor of 0.85 and a surface finish factor of 0.9 (16) 8. (a) A shaft is supported on bearings A and B, 800 mm between centers. A 20 straight tooth spur gear having 60 mm pitch diameter, is located 200 mm to the right of the left hand bearing A, and a 700 mm diameter pulley is mounted 250 mm towards the left of bearing B. The gear is driven by a pinion with a downward tangential force while the pulley drives a horizontal belt having 180 angle of wrap. The pulley also serves as a flywheel and weighs 2000 N. The maximum belt tension is 3000 N and the tension ratio is 3: 1. Determine the maximum bending moment and the necessary shaft diameter if the allowable shear stress of the material is 40 MPa. (16) OR 8. (b) A hollow transmission shaft, having inside diameter 0.6 times the outside diameter is made of plain carbon steel 40C8 and the factor of safety is 3. A belt pulley, 1000 mm in diameter, is mounted on the shaft, which overhangs the left hand bearing by 250 mm. The belts are vertical

Form No. AC 08a Rev.No. 01 Effective Date: 08/08/2011

and transmit power to the machine shaft below the pulley. The tension on the tight and slack side of the belt is 3 kN and 1 kN respectively, while the weight of the pulley is 500 N. The angle of wrap of the belt on the pulley is 180. Calculate the outside and inside diameter of the shaft. (16) Prepared by (M.Sathishkumar) Approved by

(M.Arun) V.S.B. ENGINEERING COLLEGE, KARUR DEPARTMENT OF MECHANICAL ENGINEERING UNIT TEST-I DESIGN OF MACHINE ELEMENTS Year/Semester & Branch: III Year/V Semester B.E. Mech.Engg. (A & B Sections) Faculty Name: M.Sathishkumar Date: Max. Marks: 50 Time: 100 min PART-A Answer ALL Questions (5x2=10 Marks) 1. Mention the various types of keys and define Gib-head key. 2. List the various types of shaft and define transmission shaft and machine shaft. 3. State completely reversed or cyclic stresses and alternating stresses. 4. What is meant by whirling or critical speed of shaft? 5. Define endurance strength. PART-B Answer ALL Questions (8+16+16=40 Marks) 6. (a) A 40 kW power at 300 rpm is transmitted from 50 mm diameter shaft by means of Kennedy keys. The keys are made of C50 steel having yield strength 390 N/mm2 and the factor of safety of 3. Design the key. (8) OR 6. (b) Design a woodruff key to transmit 5 kW power at 300 rpm. The key is made of C45 steel and the factor of safety is 2. (8) 7. (a) A hot rolled steel shaft of 40 mm diameter is subjected to a torsional moment that varies from 330 N-m to -110 N-m and an applied bending moment which varies from 440 N-M to -220N-m. The material of the shaft has an ultimate strength of 550 MN/m2 and yield strength of 410 MN/m2. Determine the required shaft diameter. Take the endurance limit to be half the ultimate strength and size factor and surface finish factor to be 0.85 and 0.62. (16) OR 7. (b) A steel cantilever is 200 mm long. It is subjected to an axial load which varies from 150 N (compression) to 450 N (tension) and also a transverse load at its free end which varies from 80 N to 120 N. The cantilever is of circular cross section. It is of diameter 2d for the first 50 mm and of diameter d for the remaining length. Determine its diameter taking a factor of safety of 2. Assume the following values: Yield stress = 330 MPa, Endurance limit in reversed bending = 300 MPa, Correction factors for reversed axial bending and reversed bending are 0.7 and 1, Stress concentration factors for bending and axial loading are 1.44 and 1.64, Size effect factor = 0.85, surface effect factor = 0.90 and notch sensitivity index = 0.90. (16)

8. (a) A mild steel shaft transmits 23 kW at 200 rpm. It carries a central load of 900 N and is simply supported between the bearings 2.5 m apart. Determine the size of the shaft, if the allowable shear

Form No. AC 08a Rev.No. 01 Effective Date: 08/08/2011

stress is 42 MPa and the maximum tensile or compressive stress is not to exceed 56 MPa. What size of the shaft will be required, if it is subjected to gradually applied loads? (16) OR 8. (b) Power is transmitted to a shaft supported on bearings, 900 mm apart, by a belt drive, running on a 450 mm pulley, which overhangs the right bearing by 200 mm. Power is transmitted from the shaft through a belt drive, running on a 250 mm pulley, located mid-way between the bearings. The belt drives are at right angle to each other and the ratio of belt tensions is 3; with the maximum tension in both the belts being limited to 2kN. Determine the diameter of the shaft, assuming permissible tensile and shear stresses are 100 MPa and 60 MPa respectively. (16) Prepared by (M.Sathishkumar) Approved by (M.Arun)

Form No. AC 08a

Rev.No. 01

Effective Date: 08/08/2011

Vous aimerez peut-être aussi

- Register Number NIT Mechanical Design Machine Elements ExamDocument2 pagesRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanPas encore d'évaluation

- O level Physics Questions And Answer Practice Papers 2D'EverandO level Physics Questions And Answer Practice Papers 2Évaluation : 5 sur 5 étoiles5/5 (1)

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarPas encore d'évaluation

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsD'EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsPas encore d'évaluation

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiPas encore d'évaluation

- Machine Design Elements and AssembliesD'EverandMachine Design Elements and AssembliesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rPas encore d'évaluation

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajPas encore d'évaluation

- 16mu315 - Machine Design Question Bank: Ut Yt B TDocument3 pages16mu315 - Machine Design Question Bank: Ut Yt B THarishPas encore d'évaluation

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28Pas encore d'évaluation

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajPas encore d'évaluation

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarPas encore d'évaluation

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63Pas encore d'évaluation

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaPas encore d'évaluation

- Assignment - 2Document4 pagesAssignment - 2vaijanath patilPas encore d'évaluation

- DMM 1Document2 pagesDMM 1Madhu SagarPas encore d'évaluation

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyPas encore d'évaluation

- DMM Question BankDocument2 pagesDMM Question Bankzubair ahmedPas encore d'évaluation

- Me 6503 Design of Machine Elements QBDocument3 pagesMe 6503 Design of Machine Elements QBDeepak SPas encore d'évaluation

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SPas encore d'évaluation

- Question For IcDocument4 pagesQuestion For IcPrem MPas encore d'évaluation

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26Pas encore d'évaluation

- PART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESDocument12 pagesPART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESMadhu MithaPas encore d'évaluation

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJPas encore d'évaluation

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoPas encore d'évaluation

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanPas encore d'évaluation

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshPas encore d'évaluation

- Machine Design Question BankDocument4 pagesMachine Design Question BankManivannanPas encore d'évaluation

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaPas encore d'évaluation

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechPas encore d'évaluation

- Fatigue Consideration in Design TutorialDocument2 pagesFatigue Consideration in Design Tutorialdjadja nakamayaPas encore d'évaluation

- DME 1 Question BankDocument5 pagesDME 1 Question BankRahul YedduPas encore d'évaluation

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74Pas encore d'évaluation

- QuestionsDocument11 pagesQuestionsSundara MoorthyPas encore d'évaluation

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuPas encore d'évaluation

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsPas encore d'évaluation

- 15me53 Important Questions Paper-3Document3 pages15me53 Important Questions Paper-3Karthi SiddhPas encore d'évaluation

- ShaftsDocument1 pageShaftsNhlaka ZuluPas encore d'évaluation

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarPas encore d'évaluation

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadPas encore d'évaluation

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986Pas encore d'évaluation

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSPas encore d'évaluation

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuPas encore d'évaluation

- KINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKDocument11 pagesKINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKVenkat RajaPas encore d'évaluation

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- MDDocument5 pagesMDYogesh DanekarPas encore d'évaluation

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTAPas encore d'évaluation

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliPas encore d'évaluation

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaPas encore d'évaluation

- Final Design Work SheetDocument7 pagesFinal Design Work SheetKINDUPas encore d'évaluation

- DMM I Assignment - 4Document2 pagesDMM I Assignment - 4Konduru Vinay Kumar ReddyPas encore d'évaluation

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghPas encore d'évaluation

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocument8 pagesDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekPas encore d'évaluation

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariPas encore d'évaluation

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariPas encore d'évaluation

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshPas encore d'évaluation

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GPas encore d'évaluation

- Energy Eff BiosensorDocument5 pagesEnergy Eff BiosensorSathish KumarPas encore d'évaluation

- TAMIL NADU TEACHERS EDUCATION UNIVERSITY B.Ed. EXAM TIMETABLEDocument2 pagesTAMIL NADU TEACHERS EDUCATION UNIVERSITY B.Ed. EXAM TIMETABLESathish KumarPas encore d'évaluation

- Design WSN Sharing ResourceDocument10 pagesDesign WSN Sharing ResourceSathish KumarPas encore d'évaluation

- Developing Low-Cost Intelligent Wireless Sensor Networks For Aquatic EnvironmentsDocument6 pagesDeveloping Low-Cost Intelligent Wireless Sensor Networks For Aquatic EnvironmentsSathish KumarPas encore d'évaluation

- Biosensors For Diagnosis and Bio DefenseDocument7 pagesBiosensors For Diagnosis and Bio DefenseSathish KumarPas encore d'évaluation

- Bio ElectrochemistryDocument7 pagesBio ElectrochemistrySathish KumarPas encore d'évaluation

- Bio-Sensors For Health ApplicationsDocument17 pagesBio-Sensors For Health ApplicationsSathish KumarPas encore d'évaluation

- Bio Sensors in AgricultureDocument3 pagesBio Sensors in AgricultureSathish KumarPas encore d'évaluation

- E Noise SensorsDocument54 pagesE Noise SensorsSathish KumarPas encore d'évaluation

- Biosensor Devpt Around WorldDocument12 pagesBiosensor Devpt Around WorldSathish KumarPas encore d'évaluation

- Ansys Analysis GuideDocument82 pagesAnsys Analysis GuidePrabhanjan BhatPas encore d'évaluation

- Ricardo Joao MSC ThesispublicDocument80 pagesRicardo Joao MSC ThesispublicSathish KumarPas encore d'évaluation

- Children Enjoy To Their HeartDocument2 pagesChildren Enjoy To Their HeartSathish KumarPas encore d'évaluation

- Unit Test-1Document2 pagesUnit Test-1Sathish KumarPas encore d'évaluation

- Quotation For Material SupplyDocument1 pageQuotation For Material SupplySathish KumarPas encore d'évaluation

- FM Lab. ManualDocument63 pagesFM Lab. ManualSathish KumarPas encore d'évaluation

- Status of Equipment, MachineryDocument12 pagesStatus of Equipment, MachinerySathish KumarPas encore d'évaluation

- Design For TorsionDocument4 pagesDesign For TorsionChhim RothyPas encore d'évaluation

- Theory of Failure by VivekDocument13 pagesTheory of Failure by VivekVivek DaundkarPas encore d'évaluation

- Hydraulics and Geotechnical Refresher Course ProblemsDocument4 pagesHydraulics and Geotechnical Refresher Course ProblemsELMERPas encore d'évaluation

- Cooling TowersDocument3 pagesCooling TowersThiruvilan Arakkonam MohanPas encore d'évaluation

- 07 01ChapGereDocument14 pages07 01ChapGereChristina BucklePas encore d'évaluation

- Solar Water Purification by Thermal Method (Chem)Document22 pagesSolar Water Purification by Thermal Method (Chem)Myla Maheedhar100% (1)

- Modeling Large Deformation and Failure of Expanded Polystyrene Crushable Foam Using Ls DynaDocument8 pagesModeling Large Deformation and Failure of Expanded Polystyrene Crushable Foam Using Ls DynaNguyễn TúPas encore d'évaluation

- LS-DYNA Applications in Shipbuilding SimulationDocument17 pagesLS-DYNA Applications in Shipbuilding SimulationAdnan NajemPas encore d'évaluation

- AutoPIPE Nozzle Report for sss.Noz ModelDocument8 pagesAutoPIPE Nozzle Report for sss.Noz ModelRrrrrrrPas encore d'évaluation

- Chapter 3 - Microscopic Displacement Eficiency - Part IIDocument40 pagesChapter 3 - Microscopic Displacement Eficiency - Part IIMohamed ModerPas encore d'évaluation

- PermeabilityDocument36 pagesPermeabilityJazmine ValenzonaPas encore d'évaluation

- Assessment of Stability of Large Caverns in Himalayas Using 3D Numerical ModellingDocument14 pagesAssessment of Stability of Large Caverns in Himalayas Using 3D Numerical Modellingpradhith kattaPas encore d'évaluation

- Greenesol HPH Safety Valve Data SheetDocument11 pagesGreenesol HPH Safety Valve Data SheetRavi YadavPas encore d'évaluation

- Punching Shear and One Way Shear Check.Document2 pagesPunching Shear and One Way Shear Check.ElancheliyanPas encore d'évaluation

- Sterling Sihi GMBH: Product Identification Folder PT Sihi MSLDocument3 pagesSterling Sihi GMBH: Product Identification Folder PT Sihi MSLRini Yuni SaraPas encore d'évaluation

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDocument18 pagesJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Pas encore d'évaluation

- Designing Shotcrete As Primary Support in TunnelsDocument6 pagesDesigning Shotcrete As Primary Support in TunnelsAnonymous VkzquW39Pas encore d'évaluation

- Gas Dynamics and Jet Propulsion 2 Marks All 5 UnitsDocument22 pagesGas Dynamics and Jet Propulsion 2 Marks All 5 UnitsDinesh KumarPas encore d'évaluation

- Chiller EngDocument1 pageChiller EngemonwrePas encore d'évaluation

- Jespersen 8e Lecture ch06-1Document172 pagesJespersen 8e Lecture ch06-1Lee KaysiaPas encore d'évaluation

- Design of Steel Chimney According to IS StandardsDocument24 pagesDesign of Steel Chimney According to IS StandardsG S Deshpande100% (1)

- VTU Tribology Lesson PlanDocument3 pagesVTU Tribology Lesson Plankumar100% (1)

- Helical SpringsDocument20 pagesHelical SpringsVINAYAK SHARMAPas encore d'évaluation

- Propellant Fracturing RevisitedDocument12 pagesPropellant Fracturing RevisitedFanata Yudha100% (1)

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyPas encore d'évaluation

- Application of Multichannel Analysis of Surface Waves and Seismic Refraction To Define The Engineering Properties of SoilDocument37 pagesApplication of Multichannel Analysis of Surface Waves and Seismic Refraction To Define The Engineering Properties of Soilbestelot yinesuPas encore d'évaluation

- Water Pressure MRSM 2008 P3BDocument6 pagesWater Pressure MRSM 2008 P3Bsylent gohPas encore d'évaluation

- Sec4 6 PDFDocument2 pagesSec4 6 PDFpolistaPas encore d'évaluation

- Japan Welding Society Transactions Report on TRC Test for High Strength SteelDocument6 pagesJapan Welding Society Transactions Report on TRC Test for High Strength SteelDanilo BarbosaPas encore d'évaluation

- 05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodDocument10 pages05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodPzynae FlorentinoPas encore d'évaluation

- Guidelines for Implementing Process Safety ManagementD'EverandGuidelines for Implementing Process Safety ManagementPas encore d'évaluation

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesD'EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Inherently Safer Chemical Processes: A Life Cycle ApproachD'EverandInherently Safer Chemical Processes: A Life Cycle ApproachÉvaluation : 5 sur 5 étoiles5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Incidents That Define Process SafetyD'EverandIncidents That Define Process SafetyPas encore d'évaluation

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsD'EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsÉvaluation : 4 sur 5 étoiles4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesD'EverandChemical Process Safety: Learning from Case HistoriesÉvaluation : 4 sur 5 étoiles4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryD'EverandSafety Fundamentals and Best Practices in Construction IndustryPas encore d'évaluation

- LNG Risk Based Safety: Modeling and Consequence AnalysisD'EverandLNG Risk Based Safety: Modeling and Consequence AnalysisPas encore d'évaluation

- Introduction to Petroleum Process SafetyD'EverandIntroduction to Petroleum Process SafetyÉvaluation : 3 sur 5 étoiles3/5 (2)

- A Complete Guide to Safety Officer Interview Questions and AnswersD'EverandA Complete Guide to Safety Officer Interview Questions and AnswersÉvaluation : 4 sur 5 étoiles4/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersD'EverandRules of Thumb for Maintenance and Reliability EngineersÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationD'EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationPas encore d'évaluation

- The Invisible Rainbow: A History of Electricity and LifeD'EverandThe Invisible Rainbow: A History of Electricity and LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Radium Girls: Women and Industrial Health Reform, 1910-1935D'EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Évaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Fire Fighting Pumping Systems at Industrial FacilitiesD'EverandFire Fighting Pumping Systems at Industrial FacilitiesÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849D'EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Évaluation : 4 sur 5 étoiles4/5 (5)

- The Single Cure: Human Life Extension to 300+ YearsD'EverandThe Single Cure: Human Life Extension to 300+ YearsPas encore d'évaluation

- Establishing an occupational health & safety management system based on ISO 45001D'EverandEstablishing an occupational health & safety management system based on ISO 45001Évaluation : 4 sur 5 étoiles4/5 (5)

- Fire in the Night: The Piper Alpha DisasterD'EverandFire in the Night: The Piper Alpha DisasterÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ED'EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EÉvaluation : 3 sur 5 étoiles3/5 (6)

- One Health: Integrated Approach to 21st Century Challenges to HealthD'EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataPas encore d'évaluation

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceD'EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceÉvaluation : 5 sur 5 étoiles5/5 (1)