Académique Documents

Professionnel Documents

Culture Documents

Belt Life

Transféré par

Yogesh BadheTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Belt Life

Transféré par

Yogesh BadheDroits d'auteur :

Formats disponibles

belt lifetime is influenced with high amount of parameters and teoretical calculation is difficult, because some influence factors

multiply and some of them are independent. To determine the belt lifetime we use teoretical calculation and data acquired from several years long monitoring under specific condition. In case that the customer does not have such information, we are able to find in our database the conveyors with similiar operational conditions. For basic estimation of belt lifetime we need following parameters: - axis length of conveyor - length of the belt - speed of the belt - how many hours per year the belt is conveying the material - type of the belt (information from producer) - thickness of top and bottom rubber covers - category of rubber (X, Y or different category used by producer, all information on stamp) - information about conveyed material (type of material, lump size) - from which height falls the material on belt and under which angle Is your question related to belt you intend to replace or to new belt which is prepared for use. If this material is conveyed by more conveyors, do you have related information about lifetime of previously used belts? If yes, can you draw wear profile of rubber covers. We are interesting in which place the belt wears most quickly. Are you using high volume of conveyors and are you interested in long time monitoring of belt lifetime? nordell 1st February 2002, 10:45 Dear Sir: We have developed a wear prediction method based on modeling the granular flow dynamics as defined by the impact and shear work between particles(granular medium simulating ore bits) and belt or liner surfaces. Temperature drop alters the viscoelastic properties, specifically it increases the Dynamic Modulus(E') and Loss Modulus(E'') of rubber below the glass transition zone (varies with rubber - usually about -30 deg C). This is similar to inceasing the strain rate. If the rubber is dynamically strained due to high impingement velocity it may not be able to comply resulting in excessive wear. The concept can be physically modelled mathematically, if the rubber, granular dynamics, and geometry properties are definable. Field measurements will lead to better understanding of the wear mechanisms. We have published our approach. Contact me if you have further interest. Lawrence Nordell Conveyor Dynamics, Inc. phone 360/671-2200 Fax 360/671-8450 ADM Consulting 10th February 2002, 5:21

Dear Arkangel: As both respondents have indicated, there is more involved with projecting belt life than the type of belt being used and the material being carried. I have inspected fabric carcass SBR cover belts that are in excellent condition after thirty plus years of service (minor top & bottom cover wear only). I've also seen belts which have worn out within weeks. Belts should not wear appreciably, if they are treated properly. This includes "gentle" loading, properly adjusted skirting and cleaners, and good preventive maintenance practices. Abrasive materials can wear a belt out quickly if allowed to slide against the belt surface, which is not what a conveyor belt system is designed for. To give a guess, based on the information you gave and based on an intermediate level of system design and preventive maintenance a belt on your system would likely require replacement after 7 to 10 years. This reduction in service life from the original example reflects the general overworking of maintenance staff, that prevents a good PM program. Hope this helps. nordell 26th March 2002, 20:23 Another posting SBR is used to stabilize sun and ozone. Natural rubber has a better abrasion index. For this installation, material, proper cover selection, belt speed, and chute loading, and cycles of wear the belt could last your life time. We installed, in 1987, a ST-6600 N/mm, 1800mm 6600 t/h 4 m/s loading at 16 degrees conveyor transporting primary crushed copper ore (-300mm). The first belt wore out 18mm top cover in 3 years. The new chute increased the life an estimated 20-30 years. Belt is due to shut down after 8 years. Still has most life left. Lawrence Nordell President Conveyor Dynamics, Inc. 1111 West Holly St. Bellingham, WA 98225 USA ph 360/671-2200 fx 360/671-8450 email nordell@conveyor-dynamics.com www.conveyor-dyamics.com A.Banerjee 4th February 2008, 12:01 Dear Sir, I fully agree with Mr. Nordell as in INDIA with proper maintenance the expected belt life is 1520 years.

Regards. A.Banerjee johngateley 5th February 2008, 11:37 There was a section dealing with belt life predictions at the back end of the old grey Yokohama conveyor belt manual. Can anyone recall the name/title of the formula quoted in the procedure? I G Mulani 7th February 2008, 18:15 Dear Mr. Arkangel, While predicting the belt life, it is essential to know about the features influencing the belt life. These are mainly as below : 1) Belt carcass weakening due to impact strain by the lumpy material. 2) Belt carcass weakening due to bending cycles and starting condition i.e. whether frequently applied sudden loads or gradually applied loads. 3) Belt cover wear at loading zone due to incoming material velocity component along belt and perpendicular to belt. The difference in velocity along belt contributes to the quantum of abrasion and perpendicular component will contribute to the pressing intensity of the abrasion. 4) Belt bottom cover wear while travelling on carrying run due to installation tolerance i.e. roller axis not being exactly perpendicular to belt travel. 5) Belt bottom cover wear due to casual slip between belt and drive pulley periphery particularly during start-up and inadequacy of the take-up tension. A properly designed and maintained conveyor would not have such occurrence. 6) Belt top cover wear due to subtle rubbing of the material on belt, during course of travel. As stated by Dunlop, this aspect cannot be ignored. 7) Belt top cover wear while travelling on the return run due to tolerance in idler installation i.e. roller axis not being exactly perpendicular to the belt travel. 8) Belt exposure to direct sunlight and surrounding atmosphere that means whether conveyor belt is open to the sky or it is in an enclosed gallery. This contributes to belt ageing, deterioration etc. 9) Proper design of take-up and regular upkeep of tension if the belt tension magnitude is maintained by manual screw take-up or motorised winch adjustment by manual attendance. As can be seen the belt life depends upon quality of design, quality of installation and also on quality of maintenance. It is also influenced by the quality of feeding equipment i.e. whether such equipment are maintaining feeding as per design condition or feeding erratically. There are design and calculation procedures to predict belt life, however while predicting such life it is essential to make a qualitative assessment of aforesaid points. The belt life prediction independent of the aforesaid points would be unreliable. The calculation procedure together with the feedback from industry gives reasonable judgement. Although the situation may look quite complex but for business organisation doing business in a particular sector of industry do not find difficulty in this matter. For example, particular company dealing with coal handling plant, already have the feedback about the life the customer is getting in context of the prevailing design practice, quality of the engineering and quality of installation

& maintenance. During service tenure we could easily tackle such matter for the concerned industries. Often talking to the plant operator provides factual information. Because of the interdependence of the belt quality and the conveyor quality, the belt manufacture is rarely able to give formal guarantee for the true expected life. He has to only consider such guarantee on safer side because many of the factors affecting the belt life are not under his control. Regards, Ishwar G Mulani. Author of Book : Engineering Science and Application Design for Belt Conveyors. Author of Book : Belt Feeder Design and Hopper Bin Silo Advisor / Consultant for Bulk Material Handling System & Issues. Pune, India. Tel.: 0091 (0)20 25871916 nordell 7th February 2008, 21:08 Dear Mr. Mulani, Some of your comments are valid if you consider designing a conveyor with inherent defects or poor design criteria. It is not clear if you are advacating for good conveyor design or belt design. Proper and modern design criteria will account for many of your points impacting the belt's life such as items: 1. Impact (gouging) resistant design due to know forces can be made tolerable with good chute design 2. Starting and stopping sudden events only influence belt cover life is there is drive slippage. 3. Modern chute design mitigates this event by multiples 4. True only with bad installation practices - modern installation criteria eliminate such wear this must be considered with the other noted good practices 5. With proper design the event is nil 6. In all my years of design and evaluation of plant and overland belts, I have never seen such an event. I have heard engineers talk about it. Maybe you can offer some installation references. We can deduce the nature of product retardation with respect to belt motion. The product moves maybe 100-200mm over a 10 km length of level (horizontal belt). It usually occurs when the product is lauched over the idler. The normal force is very small compared to the forces from chute impact and product slip to speed. High inclines can have pronounced slip between product and belt. This has been studied in some depth to correct for weigh scale readings. It amy become a wear issue if severe. Usually, this would occur with other obvious problems such as capacity and spillage.

7. The same as point 4. 8. Aging produces oxidation. High temperature will accelerate ageing. Ultravilet attack is another ageing mechanism, as there are many other cover damaging methods such as iron ore and coal ores that suck out the plastisizers - big problem if the manufacturer does not correctoly compound for the product. 9. ???? 10. Missing: a. Designing for gouging verses abrasion resistance b. Idler junctions stress failure c. Trough angle - 45 are worse than 35 degrees due to higher pressure d. Shorten center roll influence on idler to belt pressure and slip e. Idler spacing more will produce more wear? Maybe not. f. Forward tilt of idler rolls - can produce unacceptable wear if yield strength of rubber is exceeded. WHo practices such analysis? g. Skirtboard design against trapping material and grooving belt h. High wear due to rip detection loops increased stiffening at impact point This list can go on and on. The point is the overall design against unacceptable wear is very complex. I G Mulani 16th February 2008, 3:43 Referring to my earlier reply and Mr. Nordells response; small clarification is as below for the numerous readers. I have drawn attention to various points, so that concerned designer (and the people introducing design related decisions), take care of these aspects to get better design, better equipment and better life of not only for belt but also for other items as an integrated approach. This is not in context of particular method or it is not addressed to experts or internationally top class conveyor designers. I stand for best of the design and equipment. I am referring to huge number of conveyors and plants, ranging from small to large, and as constructed across the world, and not to exceptional segment of conveyors. In the world scenario where huge number of conveyors are being made, we are not in the picture in their design etc. All the plants obviously will have workable design-construction, but workable designconstruction does not imply perfection on all counts, by all the people. The workable design will have degree of imperfections, and thereby resulting life would be accordingly. In a broader perspective, unfortunately business situations rarely provide free hand to designer all the time. Sometimes he is constrained by the market price, buyers technical preferences / beliefs / insistence, land constrain, own purchase department preferences, and so on. Such complexities are ground realities in business activities, wherein workable (or excellent workable) design is certainly achieved by them, but it will have different shades of perfectness. And so we

see very good plant, good plant, average plant etc. Regards, Ishwar G Mulani. Author of Book : Engineering Science and Application Design for Belt Conveyors. Author of Book : Belt Feeder Design and Hopper Bin Silo Advisor / Consultant for Bulk Material Handling System & Issues. Pune, India. Tel.: 0091 (0)20 25871916 John Paul 20th March 2008, 18:03 the main factor to the belt wear is the loading of the belt. Basically, the abrasion occurs o a short length of the top cover. But this abrasion is very intense. If you product is directed against your receiving belt the abrasion will be extreme. If you direct your load tangentially to the surface of the belt at, let say 80% of the speed of your belt, then the amount of energy needed to give the product the same speed is minimal. So is the abrasion. When the product is stabilized, you have no more abrasion on the top. But you still have a continuous abrasion on the bottom.(speed differential roller/belt to create rotation by friction). That's why on long overland conveyors, the bottom thickness is often equal to the top cover. SBR is not used for sun or O3 purpose as mentioned above. UV & O3 are natural vulcanizers. Specific additives such as PPP - also called by Michelin the "aspirin of rubber"- are added to control the overvulcanization of either SBR, NR or BR. Natural Rubber (NR) is not a good anti-abrasive. It is used in the "good compounds" because it brings a higher "tensile strength" (the value expressed by the manufacturer in MPa (typically from 15 to 25) and the "grip" for tires. NR actually degrades the abrasion, but allow the compound to stand impact and cut and gouge. It gives elasticity and resilience to the compound. SBR is a compromise between high abrasion resistant BR (but poor resilience) and high resilience NR (but poor abrasion). It used to be cheaper than NR when the oil was cheap. The real difference between compounds comes from the high priced additives and the sizing of the carbon black. But getting a regular source of very fine and cheap carbon black is a challenge! Best Regards JP nordell 20th March 2008, 20:12 Dear John, You comments on the nature of belt wear have been published here and in Bulk Solids Handling Magazine , in Australian, South African, europe, and in the USA forums for many years. The mechanics of abrasion, gouging damage, influence of age and temperature, and other cover

loss properties have also been discussed. We and others use Discrete Element Modeling and laboratory measurements to determine the degree of abrasion and gouging damage as these relate to chute design, material properties, belt life, and construction, etc. You are new to this forum. Please read many prior discussions on the points you speak to. You do not agree with others, and specifically with my posts on this thread. We are all eager to learn more to advance the industry. I ask you to be specific in making claims that support your position. One such claim is the notion the NR rubber compounds are abrasion inferior to other rubbers. Do you have a manufacturer and products in mind to spuuport this claim? Publish your knowledge on the DIN Abrasion Index regarding NR and other rubbers that make your case. Then we will have a better understanding on the accuracy of your claims or so inform you to the contrary. Regarding your 80% tangential belt velocity is a lofty and noble but very difficult to obtain. Again, read the literature. Gain understanding on why this might be so. Also, take account of the material properties and their influence on this claim such as moisture, cohesion, fines, plasticity, et al. There are other strong influences on wear. One is the idler alignment, the use of forward tilt, local pressure between belt and roller surface, ambient temperature, et al. Silica can aid some of the wear properties as well as carbon black, depending on the nature of rubber damage. nordell 21st March 2008, 0:19 Dare I waste my time to note: a) you are not about joining this forum to assist and inform others. b) you did not support my request to offer facts. c) did not appologize for your arrogance to the Forum Provider. Let us hope you find yourself and become worthy and informative. nordell 21st March 2008, 5:25 Dear John, John, I think the Arab proverb fits you to a tee:: "When you know not and know not you know - you should be avoided."

"When you know not and know you know not - learn." "When you know and know you know not - listen and do not speak" What do you know of real equipment? Speak of your top ten accomplishements. Let us see the measure of your success. Deeds not words. Mockery seems to be your only subject. Luckily, for me I don't get all your sarcasm. As semms obvious, you cannot help yourself or others in the delight of engineering. We do note, you have offered nothing by sarcasm. No details on your claims. Beat the list, any item: 1. Longest troughed belt overland > 20 km 2. Strongest belt ST-10,000 N/mm 3. Strongest dynamic splice efficiency - fabric or steel cord St-10000 N/mm with > 50% efficiency 3. Highest powered overland > 10,000 kW 4. Least cost to operate as measured in tons/kW/km 5. Lowest rolling resistance rubber compound - pick the temp. and frequency 6. Highest tons transported per millimeter of cover wear 7. Speeds exceeding 8 m/s 8. BR vs NR - tell us of your installations

I predict - All Hat and No Cattle. John Paul 21st March 2008, 10:32 Larry, All the jobs you claim have been done by the big names of the industry. You are not part of them. johngateley 21st March 2008, 12:24 Well; I'm glad you've got that off your chests. Take it easy lads; its only a bit of rubber when all's said and done.

By the way the comment about the dollar value is a bit rich. It doesn't go up and down quite as much as North East football clubs. DarrellW 21st March 2008, 13:22 Originally posted by John Paul the main factor to the belt wear is the loading of the belt. Basically, the abrasion occurs o a short length of the top cover. But this abrasion is very intense. If you product is directed against your receiving belt the abrasion will be extreme. If you direct your load tangentially to the surface of the belt at, let say 80% of the speed of your belt, then the amount of energy needed to give the product the same speed is minimal. So is the abrasion. When the product is stabilized, you have no more abrasion on the top. But you still have a continuous abrasion on the bottom.(speed differential roller/belt to create rotation by friction). That's why on long overland conveyors, the bottom thickness is often equal to the top cover. SBR is not used for sun or O3 purpose as mentioned above. UV & O3 are natural vulcanizers. Specific additives such as PPP - also called by Michelin the "aspirin of rubber"- are added to control the overvulcanization of either SBR, NR or BR. Natural Rubber (NR) is not a good anti-abrasive. It is used in the "good compounds" because it brings a higher "tensile strength" (the value expressed by the manufacturer in MPa (typically from 15 to 25) and the "grip" for tires. NR actually degrades the abrasion, but allow the compound to stand impact and cut and gouge. It gives elasticity and resilience to the compound. SBR is a compromise between high abrasion resistant BR (but poor resilience) and high resilience NR (but poor abrasion). It used to be cheaper than NR when the oil was cheap. The real difference between compounds comes from the high priced additives and the sizing of the carbon black. But getting a regular source of very fine and cheap carbon black is a challenge! Best Regards JP Beyond the verbal fight, the above is 100% right. This guy may be new to the forum, but he knows what he's talking about... Darrell Author 25th March 2008, 18:36 This verbal fight will hurt our forum and I am not willing to accept its continuance. In my opinion, John Paul is going too far. I believe his language is really not acceptable. I would appreciate your comments on how far a discussion can go without destroying too much or perhaps all. We did have similar problems in other areas (for instance silos) and some of my good friends are not participating any more. The beginning of the end.

I must do something against this.

Reinhard Wohlbier Administrator designer 25th March 2008, 19:33 My life, there's some venom here. Must be a personality clash. John Paul, why not add you company name? If I Google your quoted post code I get :-Continental Conveyor Ltd. - Contact Us > Contact Details SR5 2TD Tel: 0191 516 5353 Fax: 0191 516 5399 ... Continental Conveyor Ltd - West Quay Road, Sunderland Enterprise Park, Sunderland SR5 2TD. www.continental-conveyor.co.uk/contact_us/contact_details.htm - 4k - Cached - Similar pages Continental Conveyor Ltd. johngateley 26th March 2008, 6:30 Administrator's statements are quite correct. We must impose a large measure of self discipline. Our business is not the flavour of the month with an environmentally obsessed generation. If the forums collapse then the youngsters will have to carry on with a lot of guidance no longer available. Their mistakes will not be tolerated like the older generations' mistakes were & our business will become even less popular as a result. Many threads plainly present a lazy quest for advice which is freely available on the internet. It is difficult not to be derisive towards addressing such threads: often very difficult. Some threads are fascinating & tempt reply regardless of the potential decapitaion by peers. It is admirable to see somebody stick his or her neck out for a reasonable cause. As professional engineers we criticise the work, not the worker. In the contentious recent threads, which are disturbing to the Administrator, and others, there is still a lot of knowledge being imparted by the participants. With so much knowledge posted the participants must realise that judgement becomes strictly secondary to learning in the the eyes of the beholder. Tell us what YOU know. Don't tell us how much HE doesn't know. Most of us didn't even know a small percentage of what some of you know, until it went on the forums. Thanks for the forums, please continue & keep the banter loose & friendly. Sorry to be so long winded. A.Banerjee 26th March 2008, 7:24 Dear Dr. R. H. Wohlbier, I requested you to take action for the same instances which was happened to me long back. I received very bad reply from Mr. Graham Sprigg & Mr. Nordell. I did not write any thing but I approached to you only. But no action was taken by you so far. I stoped giving reply& lost my registration.You can observed the same with MR. Johngateley. Kindly excuse me for highlighting once again.

Regards. A.Banerjee DarrellW 26th March 2008, 21:00 Dear Dr Wohlbier As mentioned by Mr Banerjee, the aggressive stances from Mr Nordell and his friends do not seem to disturb you. Aggressivity against our Indian friends do not have the same impact on your forum ? Please explain why in some threads, our Indian colleagues are treated like inferiors. (and "should see their opticians...") It's disturbing. You should rather do something on that issue. johngateley 26th March 2008, 21:24 I can take that as a strong hint then. It was interesting but cheerio. Enough is enough. nordell 26th March 2008, 21:38 Dear Darrell & All other parties, I appologize for my aggresive stance to all on the forum and hereby resign from further input to this forum. designer 26th March 2008, 22:29 John, Lawrence, don't be rash. Hang in there and keep posting. You have many, many posts between you (far more than other posters) and for me your contributions have been worthwhile, even if I haven't always understood them. John Paul 27th March 2008, 9:45 Originally posted by Author This verbal fight will hurt our forum and I am not willing to accept its continuance. In my opinion, John Paul is going too far. I believe his language is really not acceptable. I would appreciate your comments on how far a discussion can go without destroying too much or perhaps all. We did have similar problems in other areas (for instance silos) and some of my good friends are not participating any more. The beginning of the end. I must do something against this.

Reinhard Wohlbier Administrator Dear Mr Wohlbier,

I apologize for the inconvenience and inappropriate exchange. What you must do is very simple: delete all my messages which are both pointless and useless. As a newcomer on this forum, I did not understand it was some kind of private club. Sorry. I do not like the bully style of Mr Nordell, but I apologize for my inappropriate language. Please delete my login and password as well. I wish you a lot of success and I still have a lot of respect for your BSH publication. Best Regards John. Author 27th March 2008, 11:38 Dear Larry, dear John, I am extremely sorry reading your posts. The "Belt Conveyor Forum" is the absolute leader of all our Forums, and this is to a high degree due to your heavy involvement. Many people come to this forum to read your messages and share your know-how. You did not have to call yourself "Gurus", because for many users/readers you were just that, not only in the field of belt conveyors but also in several other related technologies. Please see how GOOGLE finds you on our Portal: http://www.google.com/search?client=safari&rls=de-de&q=nordell+site:bulkonline.com&ie=UTF-8&oe=UTF-8 http://www.google.com/search?client=safari&rls=de-de&q=johngateley+site:bulkonline.com&ie=UTF-8&oe=UTF-8 You both are in the group of our "Super Posters", i.e. nordell (1509); Mulani (791); johngateley (667); lzahari (629); George Baker (605); designer (593) (the forums started in 2001). Our forums have the difficulty of addressing a large number of international users with different engineering backgrounds, from industry starters to real experts. It happens quite often that simple questions, with too few technical details, are formulated in bad English language. And of course it happens that some answers to these questions may sound "arrogant" or "harsh", or "aggressive", but certainly no one is treated here "like inferiors", as some one states. I still cannot grasp this sudden development.

It started with a thread on Belt Life originally posted on October 15, 2001 which was revived on February 4, 2008 and continued until a "newcomer to this forum" started a personal assault with unacceptable language and few helpful arguments. This forum is not a place to fight but to inform and advise. There are many engineers eager to learn more fast. They are looking for help. And there are seasoned engineers who offer this help and spend their valuable time doing this. I kow many people in this industry who tell me that they would never give away "free advice". I feel sorry for them and their egoism. Dear John, dear Larry, please re-consider. Thank you. Reinhard H. Wohlbier Joseph A. Dos Santos 29th March 2008, 18:29 Dr. Wohlbier Thanks for the pause and call to order. We all are pretty passionate about our work and and sometimes, in our excitement, we may appear to inflate our worth when we are qualifying our points. If this is then interpreted as a putdown of those to whom we are responding, based on my long participation, I believe this is not the intent, and for my part I am truly sorry if I have offended. I will continue to read and post on this forum because it is a great place to exchange ideas and experience. I will try to be more careful and respectful, at least for a while. Let's all take a deep breath and, with the utmost respect for each other (which is deserved by all) let's continue on.

Vous aimerez peut-être aussi

- PM Master List For TestingDocument17 pagesPM Master List For TestingYogesh BadhePas encore d'évaluation

- Portable Fire Extinguisher Plan PolicyDocument2 pagesPortable Fire Extinguisher Plan PolicyYogesh BadhePas encore d'évaluation

- Argos ManualDocument212 pagesArgos ManualYogesh BadhePas encore d'évaluation

- Master Sensor K-N ThermocoupleDocument1 pageMaster Sensor K-N ThermocoupleYogesh BadhePas encore d'évaluation

- Manual For Calibration OrderDocument12 pagesManual For Calibration OrderYogesh BadhePas encore d'évaluation

- Batch MischerDocument5 pagesBatch MischerYogesh BadhePas encore d'évaluation

- 110 KW GA 1LE7501-3AB03-5AA4 - 2D - Dimension - Withframe - enDocument1 page110 KW GA 1LE7501-3AB03-5AA4 - 2D - Dimension - Withframe - enYogesh BadhePas encore d'évaluation

- Difference in Emhart & BotteroDocument4 pagesDifference in Emhart & BotteroYogesh BadhePas encore d'évaluation

- Tpi106 de UsDocument10 pagesTpi106 de UsYogesh BadhePas encore d'évaluation

- 601-10-14-V3.7.38 (Ware Handling)Document81 pages601-10-14-V3.7.38 (Ware Handling)Yogesh BadhePas encore d'évaluation

- 07 Accessories Accessori enDocument11 pages07 Accessories Accessori enYogesh BadhePas encore d'évaluation

- ARKEMA-Operation Manual Updated Version 8 April 2013Document10 pagesARKEMA-Operation Manual Updated Version 8 April 2013Yogesh BadhePas encore d'évaluation

- Iwater Ion ExchangeDocument9 pagesIwater Ion ExchangeYogesh BadhePas encore d'évaluation

- Calasys 1500BBDocument1 pageCalasys 1500BBYogesh BadhePas encore d'évaluation

- CNSK - Pocket Fits06-Fits and ClearancesDocument15 pagesCNSK - Pocket Fits06-Fits and Clearancesswamymk100% (1)

- MTBF - MTTRDocument11 pagesMTBF - MTTRYogesh BadhePas encore d'évaluation

- Highlights Document-3307Document2 pagesHighlights Document-3307Yogesh BadhePas encore d'évaluation

- Chapter - 1: "Studies On Radial Tipped Centrifugal Fan"Document21 pagesChapter - 1: "Studies On Radial Tipped Centrifugal Fan"Yogesh Badhe100% (1)

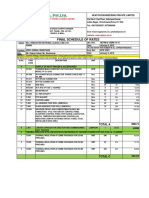

- Final Schedule of Rates-R6Document2 pagesFinal Schedule of Rates-R6Yogesh BadhePas encore d'évaluation

- Wooden RackDocument4 pagesWooden RackYogesh BadhePas encore d'évaluation

- 11 SubstationDocument13 pages11 SubstationYogesh BadhePas encore d'évaluation

- LCM Brochure MinDocument12 pagesLCM Brochure MinYogesh BadhePas encore d'évaluation

- IIT Delhi - EPPM - 4 JulyDocument12 pagesIIT Delhi - EPPM - 4 JulyYogesh BadhePas encore d'évaluation

- Purchase Order for Gas Detection EquipmentDocument6 pagesPurchase Order for Gas Detection EquipmentYogesh BadhePas encore d'évaluation

- Executive Development Programme in Leadership and Change ManagementDocument6 pagesExecutive Development Programme in Leadership and Change ManagementYogesh BadhePas encore d'évaluation

- A3 Template 110121Document1 pageA3 Template 110121Yogesh BadhePas encore d'évaluation

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraPas encore d'évaluation

- Q. What Is Reverse Osmosis (RO) ?Document6 pagesQ. What Is Reverse Osmosis (RO) ?Yogesh BadhePas encore d'évaluation

- M.Tech. in Ceramic Engineering ProspectusDocument8 pagesM.Tech. in Ceramic Engineering ProspectusYogesh BadhePas encore d'évaluation

- SKF Electronic Stethoscope TMST 3: Easily Pinpoints Bearing and Machine NoiseDocument2 pagesSKF Electronic Stethoscope TMST 3: Easily Pinpoints Bearing and Machine NoiseYogesh BadhePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Calculations and units in analytical chemistryDocument17 pagesCalculations and units in analytical chemistryangelaPas encore d'évaluation

- Madharasathul Ahmadhiyya: First Term ExaminationDocument9 pagesMadharasathul Ahmadhiyya: First Term Examinationafoo1234Pas encore d'évaluation

- Van Der Waals Interaction (Also Known As London Dispersion Energies)Document6 pagesVan Der Waals Interaction (Also Known As London Dispersion Energies)Sumair AhmedPas encore d'évaluation

- 2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Document14 pages2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Vicente SosaPas encore d'évaluation

- Set 1 Section A (45 MARKS) : X X y X DX DyDocument2 pagesSet 1 Section A (45 MARKS) : X X y X DX DyMuhammad SaifudinPas encore d'évaluation

- 7solutions Datasheet Gaztox enDocument2 pages7solutions Datasheet Gaztox enForum PompieriiPas encore d'évaluation

- Welcome To Calibration Basics!Document30 pagesWelcome To Calibration Basics!Ver Bautista100% (1)

- Physics Formula SheetDocument2 pagesPhysics Formula SheetExtremeVelocity67% (6)

- Chem 10Document5 pagesChem 10robert1789Pas encore d'évaluation

- Carbon Dioxide MsdsDocument6 pagesCarbon Dioxide MsdsrashaesharpePas encore d'évaluation

- Coordinate Systems and Curvature of Shell SurfacesDocument29 pagesCoordinate Systems and Curvature of Shell SurfacesParth ShahPas encore d'évaluation

- SCM25 steel alloy properties and applicationsDocument1 pageSCM25 steel alloy properties and applicationsPeterWayPas encore d'évaluation

- Dapust 21Document5 pagesDapust 21Dewo BontangPas encore d'évaluation

- ProjectDocument48 pagesProjectManoj Kumar B0% (1)

- Mobilith AW SeriesDocument3 pagesMobilith AW SeriesDavid SalgueroPas encore d'évaluation

- Thesis Ge TFET Source OnlyDocument123 pagesThesis Ge TFET Source OnlySumeet KalraPas encore d'évaluation

- Evaluation of stucco binder for agglomeration in copper ore heap leachingDocument8 pagesEvaluation of stucco binder for agglomeration in copper ore heap leachingDr. Khan MuhammadPas encore d'évaluation

- BEng Chemical Engineer Seeks ExperienceDocument3 pagesBEng Chemical Engineer Seeks ExperienceNur JihanPas encore d'évaluation

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Air Quality Guidelines For EuropeDocument288 pagesAir Quality Guidelines For EuropeAlex OliveiraPas encore d'évaluation

- Daily Lesson PlanDocument8 pagesDaily Lesson PlanTamie P. Galindo100% (1)

- Separations and Reactors Design Project Production of Allyl ChlorideDocument8 pagesSeparations and Reactors Design Project Production of Allyl ChloridefathiPas encore d'évaluation

- SOP of Media PreparationDocument8 pagesSOP of Media PreparationaKureishiPas encore d'évaluation

- Factor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoDocument3 pagesFactor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoBhupesh MulikPas encore d'évaluation

- Ticona Molded Plastic Gear DesignDocument6 pagesTicona Molded Plastic Gear DesignpolumathesPas encore d'évaluation

- White Paper 05 PDFDocument8 pagesWhite Paper 05 PDFAnonymous ULRVLcPas encore d'évaluation

- Foodpharma MaterialoverviewpdfDocument2 pagesFoodpharma MaterialoverviewpdfJai BhandariPas encore d'évaluation

- PILE FOUNDATION REPORTDocument24 pagesPILE FOUNDATION REPORTGagan NagpalPas encore d'évaluation

- Is 6396 - 2000 De-CarburisationDocument10 pagesIs 6396 - 2000 De-CarburisationDheeraj Chavan100% (1)

- Caterpillar Service Welding GuideDocument77 pagesCaterpillar Service Welding GuideGaston Gingarelli100% (1)