Académique Documents

Professionnel Documents

Culture Documents

SAIC-B-2001 Rev 0

Transféré par

philipyapDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAIC-B-2001 Rev 0

Transféré par

philipyapDroits d'auteur :

Formats disponibles

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

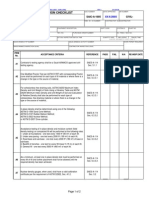

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure for Application of Proprietary Fireproofing (incl. Intumescent Epoxy Mastics and Lightweight Concretes)

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-B-2001

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA General Requirements Proprietary fireproofing was approved by the Chief Fire Prevention Engineer. Notes: a. Qualifying documentation of the fireproofing material is submitted to the Chief Fire Prevention Engineer for approval. b. Refer to Appendix 1 for a list of proprietary fireproofing materials that have been accepted for various applications and used in Saudi Aramco facilities. An application procedure approved by the fireproofing manufacturer is submitted to Inspection Department (manager) for approval. The procedure details the manufacturer's guidelines and requirements regarding ambient temperature, storage temperature, materials, proportioning, and mixing. The procedure indicates the requirement for application personnel to be trained and certified by the material manufacturer. The application procedure contains Quality control procedures and hold points for inspection of surface preparation and reinforcement. The application procedure includes the required surface preparation of steel surface to be covered with intumescent or other proprietary fireproofing materials. The procedure application for intumescent material specified the minimum wet thickness that will yield the required dry thickness. (API PUBL 2218, Para. 7.3.3.1) The procedure detailed the top coating requirements and the manner of application when required. The procedure shall provide details in the manner of applying the required top-coating approved by the fireproofing manufacturer.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-B-006, Para. 8.2.1

A2

SAES-B-006, Para. 8.2.1 SAES-B-006, Para. 8.2.3 SAES-B-006, Para. 8.2.2 SAES-B-006, Para. 8.2.4 SAES-B-006, Para. 8.4 SAES-B-006, Para. 5.2 & 8.2.3 SAES-B-006, Para. 8.6.4 SAES-B-006, Para. 8.6.4

A3

A4 A5

A6

A7

A8 A9

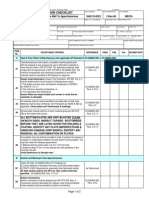

REMARKS: REFERENCE DOCUMENTS: 1. SAES-B-006, Fireproofing for Plants, (30 June, 2003) 2. API PUBL 2212, Fireproofing Practices in Petroleum and Petrochemical Processing Plants, (08/01/1999)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 1 of 2

#REF!

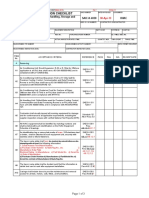

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure for Application of Proprietary Fireproofing (incl. Intumescent Epoxy Mastics and Lightweight Concretes)

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-B-2001

25-May-05

MECH-

Attachment 1 --

Page 2 of 2

Vous aimerez peut-être aussi

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistphilipyap100% (1)

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008Document2 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saic B 2001 WasitDocument6 pagesSaic B 2001 WasitAnonymous 4e7GNjzGWPas encore d'évaluation

- ChecklistDocument7 pagesChecklistIkram SyedPas encore d'évaluation

- Saic N 2033Document5 pagesSaic N 2033aamirapiPas encore d'évaluation

- SAIC-A-1005 Rev 3 Compaction TestingDocument2 pagesSAIC-A-1005 Rev 3 Compaction Testingimrankhan22Pas encore d'évaluation

- SAIC-H-2060 Rev 4Document3 pagesSAIC-H-2060 Rev 4Anonymous 4e7GNjzGWPas encore d'évaluation

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapPas encore d'évaluation

- Pre-Application Insp of Fireproofing MaterialsDocument4 pagesPre-Application Insp of Fireproofing Materialspookkoya thangalPas encore d'évaluation

- Saic K 4010Document3 pagesSaic K 4010mohamadPas encore d'évaluation

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentRickesh NunkooPas encore d'évaluation

- SAIC-B-2003 Rev 2Document2 pagesSAIC-B-2003 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistரமேஷ் பாலக்காடுPas encore d'évaluation

- Saic N 2036Document6 pagesSaic N 2036aamirapiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-B-2001 Rev 6Document6 pagesSAIC-B-2001 Rev 6pookkoya thangalPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saudi Aramco Hardness Testing Procedure ReviewDocument3 pagesSaudi Aramco Hardness Testing Procedure ReviewphilipyapPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saudi Aramco Exhaust Fan ChecklistDocument2 pagesSaudi Aramco Exhaust Fan ChecklistBilalPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Receiving Inspection of Fireclay Bricks and Mortar SAIC-N-2037 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Receiving Inspection of Fireclay Bricks and Mortar SAIC-N-2037 25-May-05 MechphilipyapPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalPas encore d'évaluation

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic H 2023Document2 pagesSaic H 2023Sivaratnam NavatharanPas encore d'évaluation

- Review PWHT Specs, Procedures and TablesDocument19 pagesReview PWHT Specs, Procedures and TablesIrshad IqbalPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289Pas encore d'évaluation

- Saic N 2028Document4 pagesSaic N 2028aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection ChecklistMainuddin AliPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289Pas encore d'évaluation

- Saic Q 1049Document2 pagesSaic Q 1049Gian Carlo100% (1)

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistpookkoya thangalPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistmohamadPas encore d'évaluation

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaPas encore d'évaluation

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- SAIC-H-2032 Rev 4.Document6 pagesSAIC-H-2032 Rev 4.Mohamed Farhan B PositivePas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapPas encore d'évaluation

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistphilipyapPas encore d'évaluation

- Saic P 3314Document4 pagesSaic P 3314Arshad ImamPas encore d'évaluation

- Saic K 4001Document2 pagesSaic K 4001BilalPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistphilipyapPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 pageSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapPas encore d'évaluation

- Saudi Aramco Refractory Receiving ChecklistDocument4 pagesSaudi Aramco Refractory Receiving ChecklistphilipyapPas encore d'évaluation

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument4 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTkarthi51289Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument7 pagesSaudi Aramco Inspection ChecklistaamirapiPas encore d'évaluation

- General boxes inspection checklistDocument10 pagesGeneral boxes inspection checklistEnginerShahzadGhaffarPas encore d'évaluation

- Saic Q 1048Document1 pageSaic Q 1048Gian Carlo100% (1)

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06Document23 pagesSaudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06ரமேஷ் பாலக்காடுPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Machinery Component Maintenance and RepairD'EverandMachinery Component Maintenance and RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisD'EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPas encore d'évaluation

- Panel BoardDocument7 pagesPanel BoardphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapPas encore d'évaluation

- Raceway Selection GuideDocument10 pagesRaceway Selection GuidephilipyapPas encore d'évaluation

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- Resilent FlooringDocument7 pagesResilent FlooringphilipyapPas encore d'évaluation

- Low Voltage Wires and Cables SpecificationDocument9 pagesLow Voltage Wires and Cables SpecificationphilipyapPas encore d'évaluation

- Saudi Aramco Ductwork SpecificationsDocument5 pagesSaudi Aramco Ductwork SpecificationsphilipyapPas encore d'évaluation

- Chilled Water PumpDocument6 pagesChilled Water PumpphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Exterior LightingDocument8 pagesExterior LightingphilipyapPas encore d'évaluation

- Finish CarpentryDocument17 pagesFinish CarpentryphilipyapPas encore d'évaluation

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapPas encore d'évaluation

- FanDocument7 pagesFanphilipyap100% (1)

- Fan Coil UnitsDocument3 pagesFan Coil UnitsphilipyapPas encore d'évaluation

- Roof and Deck InsulationDocument3 pagesRoof and Deck InsulationphilipyapPas encore d'évaluation

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapPas encore d'évaluation

- SignageDocument4 pagesSignagephilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapPas encore d'évaluation

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapPas encore d'évaluation

- Control SystemDocument21 pagesControl SystemphilipyapPas encore d'évaluation

- Variable Air UnitDocument4 pagesVariable Air UnitphilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- Floor MatsDocument3 pagesFloor MatsphilipyapPas encore d'évaluation

- Swimming PoolDocument4 pagesSwimming PoolphilipyapPas encore d'évaluation

- G.furniture & FixturesDocument2 pagesG.furniture & FixturesphilipyapPas encore d'évaluation

- 03210-Epoxy Coated Conc ReoDocument7 pages03210-Epoxy Coated Conc ReophilipyapPas encore d'évaluation