Académique Documents

Professionnel Documents

Culture Documents

Blow Down For The - Slug-Catcher-Bl

Transféré par

chemeng1340Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Blow Down For The - Slug-Catcher-Bl

Transféré par

chemeng1340Droits d'auteur :

Formats disponibles

Slug Catcher Blowdown Study - Industrial Professionals - Cheresources.

com Community

Page 1 of 3

Cheresources.com Community General Chemical Engineering Forum Industrial Professionals

Process Control

Gas

Pipeline

Equipment

ChExpress Blog - 6/25/13 Read the latest news from the chemical industry in Christa's blog. Featured Articles Check out the latest featured articles. File Library Check out the latest downloads available in the File Library. New Article Product Viscosity vs. Shear

Featured File Compressor Settle Out Pressure and Temperature New Blog Entry How to Write a Plant Operating Manual- posted in Ankur's blog

Pipeline Engineering Inspection Plate Offshore

Slug Catcher Blowdown Study

Started by jprocess, Aug 15 2007 01:12 AM

Share this topic:

0

| More More

Oil and Gas Flow Hazop Study Pressure

Posted 15 August 2007 - 01:12 AM

jprocess

Dear All, Should we follow API 521 guidelines for blowdown study of slug catchers?

I read in an engineering practise by TECHNIP company that for special case of slug catcher we should follow the procedure that often used for "pipeline" depressuring and not the API 521 guideline because it will result in excessive flows to flare

http://www.cheresources.com/invision/topic/4157-slug-catcher-blowdown-study/

7/16/2013

Slug Catcher Blowdown Study - Industrial Professionals - Cheresources.com Community

Page 2 of 3

nework. Your valuable comments are appreciated. Cheers.

gvdlans

Are you aware of the Technical Interpretation 521-I-02/04, see http://committees.ap.../tech/reti.html (http://committees.api.org/standards/tech/reti.html) ? The Question to the API 521 committee was:

Posted 16 August 2007 - 05:42 AM

"Background: My company is working on the construction of a gas plant. There is an existing finger-type slug catcher in the inlet section of this plant that receives a three-phase gas stream from a 30-inch pipeline. This slug catcher has been designed based on ASME B31.8 but its design pressure is different with the incoming pipeline. I have the following question regarding of depressurization system for this part of the plant. Question: Is there any requirement to depressurize this system in case of fire detection? If yes, please let me know if the criteria are based on API 521, Section 3.19, or are there other criteria for this case?" and the formal answer was: "API 521 does not provide depressurization guidance for specific types of equipment or vessels. It is up to the user to define what equipment is depressured." In your case you could take a risk based approach and consider other measures to reduce risk of slug catcher rupture due to external fire (e.g. provision of drainage facilities, active and passive fire protection).

jprocess

Dear gvdlans, Thanks a lot for your reply.

Posted 18 August 2007 - 04:44 AM

But as I see in P&ID, a blowdown valve and a restriction orifice have been considered for slug catcher depressurizing.

gvdlans

Dear jprocess,

Posted 18 August 2007 - 01:24 PM

Is this orifice sized such that the slugcatcher pressure is reduced to 50% of the design pressure or 7 barg (whichever is lower) in 15 minutes? It could be that the orifice is sized for much slower depressurization, e.g. to prepare for maintenance activities... I worked on a gas plant in The Netherlands some 12 years ago. It had a finger type slugcatcher at the plant inlet to remove slugs that could form in the pipeline. From what I remember, in case of emergencies the slugcatcher was blocked in and not depressurized. However, facilities were there to depressurize the slugcatcher in about 2 hours (and not in 15 minutes).

Back to Industrial Professionals

Blowdown Of Pressure Vessels

Started by Guest_ChemEng Student_* , 09 Jul 2013

1 reply 107 views

09 Jul 2013

ANSWERED

Orifice Plates On Manual Blowdown Lines

Started by Guest_DavidAriyibi_* , 04 May 2013

5 replies 538 views

03 Jul 2013

Slug, Surge And Swell

Started by Guest_Balakrushna_* , 25 Jun 2013

1 reply 158 views 22 replies 568 views 2 replies 318 views

03 Jul 2013

ANSWERED

Blowdown Temperature

HOT

10 May 2013

Started by Guest_shan_* , 07 May 2013

Slug Volume From Olga Simulation

Started by Guest_MTQ80_* , 26 Apr 2013

26 Apr 2013

http://www.cheresources.com/invision/topic/4157-slug-catcher-blowdown-study/

7/16/2013

Slug Catcher Blowdown Study - Industrial Professionals - Cheresources.com Community

Page 3 of 3

Cheresources.com Community General Chemical Engineering Forum Industrial Professionals

http://www.cheresources.com/invision/topic/4157-slug-catcher-blowdown-study/

7/16/2013

Vous aimerez peut-être aussi

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Document222 pagesMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesPas encore d'évaluation

- Safety Alert - Purity of N2 SupplyDocument7 pagesSafety Alert - Purity of N2 SupplysixejoPas encore d'évaluation

- PSV Sizing OrificeDocument4 pagesPSV Sizing OrificeRupak PatilPas encore d'évaluation

- Plug Valves enDocument24 pagesPlug Valves enAtty AttyPas encore d'évaluation

- Din 48204Document3 pagesDin 48204Thanh Dang100% (4)

- Debate Lesson PlanDocument3 pagesDebate Lesson Planapi-280689729Pas encore d'évaluation

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- Blowdown Valve Allowable BackpressureDocument4 pagesBlowdown Valve Allowable BackpressureDoctorOberman100% (1)

- Mech Seal System Difference 53 A B CDocument3 pagesMech Seal System Difference 53 A B CAmol Patki100% (1)

- Depressuring Flow - Quick Manual MethodDocument3 pagesDepressuring Flow - Quick Manual MethodElton Situmeang100% (1)

- Flare SystemDocument29 pagesFlare SystemBaba Johneh100% (1)

- Reciprocating Compressor Discharge TemperatureDocument6 pagesReciprocating Compressor Discharge TemperaturesalleyPas encore d'évaluation

- Boiler Technical TermsDocument44 pagesBoiler Technical Termskeerthi dayarathnaPas encore d'évaluation

- API Standard 521 - Guide For Pressure-Relieving and Depressuring Systems PDFDocument9 pagesAPI Standard 521 - Guide For Pressure-Relieving and Depressuring Systems PDFYosmar Guzman100% (3)

- Compressor Bleed Valve FunctionDocument2 pagesCompressor Bleed Valve Functionramakrishna100% (1)

- Typical Questions For Piping EngineerDocument6 pagesTypical Questions For Piping EngineerVenkataratnam Gollapalli100% (1)

- Bursting Disks For Shell & Tube Heat Exchanger Overpressure ProtectionDocument6 pagesBursting Disks For Shell & Tube Heat Exchanger Overpressure ProtectionTONPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- ESD ValvesDocument19 pagesESD Valvesrkubal100% (1)

- Esd Valve Actuator SizingDocument19 pagesEsd Valve Actuator Sizingshinojbaby4148Pas encore d'évaluation

- Flare SystemDocument29 pagesFlare Systemvikkoo7100% (4)

- PSV and PRV PDFDocument5 pagesPSV and PRV PDFMetoo ChyPas encore d'évaluation

- Relief Design For Laboratories and Pilot PlantsDocument3 pagesRelief Design For Laboratories and Pilot PlantsNattapong Pongboot100% (1)

- PIPING Questions and AnswersDocument3 pagesPIPING Questions and AnswersNam Dang50% (2)

- 2013aicheammoniasafetysymposiumquestions AnswersDocument27 pages2013aicheammoniasafetysymposiumquestions AnswersRindeshPas encore d'évaluation

- Prevention of Actuator Emissions in the Oil and Gas IndustryD'EverandPrevention of Actuator Emissions in the Oil and Gas IndustryPas encore d'évaluation

- 521 TiDocument4 pages521 Tisa.somaPas encore d'évaluation

- Set Pressure Too Close To Operating PressureDocument5 pagesSet Pressure Too Close To Operating PressurebtjajadiPas encore d'évaluation

- Cold Stack Design - Pipelines, Piping and Fluid Mechanics Engineering - Eng-Tips PDFDocument3 pagesCold Stack Design - Pipelines, Piping and Fluid Mechanics Engineering - Eng-Tips PDFDeepak DubeyPas encore d'évaluation

- Chemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleDocument3 pagesChemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleomeshchemPas encore d'évaluation

- Stop Stupidity With Relief DevicesDocument2 pagesStop Stupidity With Relief DevicesDefenceDogPas encore d'évaluation

- Chemical Engineering Interview Questions and Answers 90Document25 pagesChemical Engineering Interview Questions and Answers 90dpnmmbs9mhPas encore d'évaluation

- Pipe VelocityDocument7 pagesPipe Velocityنور القمرPas encore d'évaluation

- Steam Blowing - Disturbance Factor Discusstion2 PDFDocument5 pagesSteam Blowing - Disturbance Factor Discusstion2 PDFchem_taPas encore d'évaluation

- PROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalDocument6 pagesPROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalcsPas encore d'évaluation

- Vacuum DesignDocument6 pagesVacuum DesignSalman RasheedPas encore d'évaluation

- ZZbellows BaloneyDocument2 pagesZZbellows Baloneypunitg_2Pas encore d'évaluation

- Design Part 3 - Sizing Orifices and PipingDocument11 pagesDesign Part 3 - Sizing Orifices and PipingtrebsantiaPas encore d'évaluation

- HeadsUP Stellite Delamination in HP, HRH Steam ValveDocument3 pagesHeadsUP Stellite Delamination in HP, HRH Steam Valveabdulyunus_amirPas encore d'évaluation

- Appointment of ContractorDocument5 pagesAppointment of ContractorvishnuPas encore d'évaluation

- Bleed Valve FunctionDocument2 pagesBleed Valve FunctionajaysapruPas encore d'évaluation

- Piping Info Blogspot Com Piping 20questionsDocument53 pagesPiping Info Blogspot Com Piping 20questionsravirawat15Pas encore d'évaluation

- Piping Info Blogspot Com Piping 20questionsDocument53 pagesPiping Info Blogspot Com Piping 20questionsArya AryanPas encore d'évaluation

- Basic Questions Asked in Piping Engineer's Interview For Reference - Piping DesignDocument9 pagesBasic Questions Asked in Piping Engineer's Interview For Reference - Piping Designdevika11Pas encore d'évaluation

- 205HRSGuserrev2Final PDFDocument15 pages205HRSGuserrev2Final PDFvtbkPas encore d'évaluation

- (Done) Basic Questions Asked in Piping EngineerDocument4 pages(Done) Basic Questions Asked in Piping EngineerFerinoviardiPas encore d'évaluation

- Hazards 29 Paper 11Document6 pagesHazards 29 Paper 11NisharPas encore d'évaluation

- Drdiecast January2016Document2 pagesDrdiecast January2016sobheysaidPas encore d'évaluation

- Bleed Valve FunctionDocument7 pagesBleed Valve FunctionUWT10Pas encore d'évaluation

- Regarding Design Pressure of A Boiler - Power Industry - Cheresources - Com CommunityDocument3 pagesRegarding Design Pressure of A Boiler - Power Industry - Cheresources - Com Communitygreek_testerPas encore d'évaluation

- Chemical & Process Technology - Combine Anti-Surge Control (ASC) & Capacity Control (CC) FunctionsDocument3 pagesChemical & Process Technology - Combine Anti-Surge Control (ASC) & Capacity Control (CC) FunctionsTrịnh Đức HạnhPas encore d'évaluation

- Introduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFDocument5 pagesIntroduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFonizuka-t2263Pas encore d'évaluation

- Sealing System Jun05Document2 pagesSealing System Jun05jrri16Pas encore d'évaluation

- Pneumatic TestDocument6 pagesPneumatic TestSubbarayan SaravanakumarPas encore d'évaluation

- The Trouble With Turndown - Avoiding Problems From Excessive Design Margins - Chem Engg Magazine (Rajiv, IHS)Document10 pagesThe Trouble With Turndown - Avoiding Problems From Excessive Design Margins - Chem Engg Magazine (Rajiv, IHS)daraj darajPas encore d'évaluation

- Astava Interlocking SolutionsDocument11 pagesAstava Interlocking SolutionsatrevinomPas encore d'évaluation

- ICI SAFETY NEWSLETTER No 61 PDFDocument6 pagesICI SAFETY NEWSLETTER No 61 PDFИванов ИванPas encore d'évaluation

- Globe Sprinkler CompanyDocument20 pagesGlobe Sprinkler CompanyWinard WantogPas encore d'évaluation

- Literature Review On Air CompressorDocument7 pagesLiterature Review On Air Compressorofahxdcnd100% (1)

- Gas Lift ThesisDocument8 pagesGas Lift Thesisfjbr4n2n100% (2)

- 4 Energy Control ProceduresDocument7 pages4 Energy Control ProceduresFriday IjokgwungPas encore d'évaluation

- 10CS 33 LOGIC DESIGN UNIT - 2 Combinational Logic CircuitsDocument10 pages10CS 33 LOGIC DESIGN UNIT - 2 Combinational Logic CircuitsMallikarjunBhiradePas encore d'évaluation

- Terasaki FDP 2013Document40 pagesTerasaki FDP 2013MannyBaldonadoDeJesus100% (1)

- Operation ManagementDocument4 pagesOperation ManagementHananiya GizawPas encore d'évaluation

- Benchmark Leadership Philosphy Ead 501Document5 pagesBenchmark Leadership Philosphy Ead 501api-494301924Pas encore d'évaluation

- English 2 Q3 Week 7 DLLDocument7 pagesEnglish 2 Q3 Week 7 DLLEste R A BulaonPas encore d'évaluation

- Résumé Emily Martin FullDocument3 pagesRésumé Emily Martin FullEmily MartinPas encore d'évaluation

- CompTIA A+ Lesson 3 Understanding, PATA, SATA, SCSIDocument8 pagesCompTIA A+ Lesson 3 Understanding, PATA, SATA, SCSIAli Ghalehban - علی قلعه بانPas encore d'évaluation

- Remediation of AlphabetsDocument34 pagesRemediation of AlphabetsAbdurahmanPas encore d'évaluation

- Amberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerDocument2 pagesAmberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerJaime SalazarPas encore d'évaluation

- SCHEMA - Amsung 214TDocument76 pagesSCHEMA - Amsung 214TmihaiPas encore d'évaluation

- SQL TestDocument10 pagesSQL TestGautam KatlaPas encore d'évaluation

- Nicole Rapp Resume 3Document2 pagesNicole Rapp Resume 3api-341337144Pas encore d'évaluation

- 3 - Risk Opportunity RegisterDocument4 pages3 - Risk Opportunity RegisterArmando CorboPas encore d'évaluation

- Asian Paints Final v1Document20 pagesAsian Paints Final v1Mukul MundlePas encore d'évaluation

- 1013CCJ - T3 2019 - Assessment 2 - CompleteDocument5 pages1013CCJ - T3 2019 - Assessment 2 - CompleteGeorgie FriedrichsPas encore d'évaluation

- OMN-TRA-SSR-OETC-Course Workbook 2daysDocument55 pagesOMN-TRA-SSR-OETC-Course Workbook 2daysMANIKANDAN NARAYANASAMYPas encore d'évaluation

- 103-Article Text-514-1-10-20190329Document11 pages103-Article Text-514-1-10-20190329Elok KurniaPas encore d'évaluation

- Building g5Document45 pagesBuilding g5ammarsteel68Pas encore d'évaluation

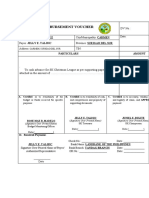

- Disbursement VoucherDocument7 pagesDisbursement VoucherDan MarkPas encore d'évaluation

- Stellite 6 FinalDocument2 pagesStellite 6 FinalGumersindo MelambesPas encore d'évaluation

- Nielsen Report - The New Trend Among Indonesia's NetizensDocument20 pagesNielsen Report - The New Trend Among Indonesia's NetizensMarsha ImaniaraPas encore d'évaluation

- TakeawaysDocument2 pagesTakeawaysapi-509552154Pas encore d'évaluation

- Unit 1: Power and Responsibility: 1. Important Leadership QualitiesDocument6 pagesUnit 1: Power and Responsibility: 1. Important Leadership QualitiesTrần Thanh MinhPas encore d'évaluation

- 10 - SHM, Springs, DampingDocument4 pages10 - SHM, Springs, DampingBradley NartowtPas encore d'évaluation

- Chapter 3 PayrollDocument5 pagesChapter 3 PayrollPheng Tiosen100% (2)

- Angelina JolieDocument14 pagesAngelina Joliemaria joannah guanteroPas encore d'évaluation

- CNNPX310R-6P: General SpecificationsDocument5 pagesCNNPX310R-6P: General SpecificationsZoheir KacimiPas encore d'évaluation