Académique Documents

Professionnel Documents

Culture Documents

Fruit and Vegetable Storage

Transféré par

Tracey DeeCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fruit and Vegetable Storage

Transféré par

Tracey DeeDroits d'auteur :

Formats disponibles

PHILIPPINE AGRICULTURAL ENGINEERING STANDARD Agricultural Structures Fruit and Vegetable Storage

PAES 417:2002

Foreword The formulation of this national standard was initiated by the Agricultural Machinery Testing and Evaluation Center (AMTEC) under the project entitled Enhancing the Implementation of the AFMA Through Improved Agricultural Engineering Standards which was funded by the Bureau of Agricultural Research (BAR) of the Department of Agriculture (DA). This standard has been technically prepared in accordance with PNS 01-4:1998 (ISO/IEC Directives Part 3:1997 Rules for the Structure and Drafting of International Standards. It specifies the general requirements for the construction of fruit and vegetable storage. The word shall is used to indicate requirements strictly to be followed in order to conform to the standard and from which no deviation is permitted. The word should is used to indicate that among several possibilities one is recommended as particularly suitable, without mentioning or excluding others, or that a certain course of action is preferred but not necessarily required. In the preparation of this standard, the following references were considered: CIGR Handbook of Agricultural Engineering. American Society of Agricultural Engineers. United States of America, 1999. Fellows, P., Guidelines for Small Scale Fruit and Vegetable Processors. FAO Agricultural Services Bulletin-127. Rome, 1997. Handle Your Produce Better from Harvest to Retail. ASEAN-PHTRC Extension Bulletin No. 2, 1983. Henderson, S. and R. Perry, Agricultural Process Engineering, 3rd Edition. AVI Publishing Co.Westport, Connecticut, 1976. Layout and Design of Refrigerated Storages. Farm Structures. Agdex: 736, October 1989. Paltrinieri, G., F. Figuerola and L. Rojas, Technical Manual on Small-Scale Processing of Fruits and Vegetables. FAO Chile, 1997.

D-81

PHILIPPINE AGRICULTURAL ENGINEERING STANDARD Agricultural Structures Fruit and Vegetable Storage

PAES 417:2002

Scope

This standard specifies the minimum requirements of fruit and vegetable storage. It includes general, structural and functional requirements. Storage can be either free standing or built into an existing structure. This standard does not cover the controlled atmosphere storage. 2 Reference

The following normative document contains provisions which through reference in this text constitute provisions of this National Standard: National Building Code of the Philippines National Plumbing Code of the Philippines National Structural Code of Building PAES 414:2002 PAES 418:2002 Agricultural Structures Waste Management Structures Processing Plant for Fresh Fruit and Vegetable

Philippine Electrical Code 2000 3 Definition

For the purpose of this standard, the following definitions shall apply:

3.1 controlled atmosphere storage storage in an artificial atmosphere in which the proportion of carbon dioxide and/or oxygen is precisely controlled 3.2 bulk storage produce is piled in room-sized bins, which exerts forces that must be resisted by the building walls 3.3 pallet bin storage produce is placed in boxes or pallet bins which in turn are stacked in storage room

D-82

PAES 417:2002

3.4 pallet low portable platform made of wood or metal or plastic or in combination to facilitate handling, storage, or transport of materials as a unit load using a forklift 3.5 drip cooler storage structure with continuously wetted walls 3.6 burlap coarse cloth made of jute, flax or hemp 3.7 air cooled storage provided with good ventilation 3.8 vapor barrier materials used to prevent migration of moisture into a storage area 3.9 cell pack individual divisions in a carton formed by fiberboard dividers, each cell to contain one fruit 3.10 telescopic cartons cartons in which the cover is separate and fits snugly over the bottom part 4 4.1 4.2 Location The location shall conform to the land use plan of the area. There shall be provision for parking area.

4.3 The area immediately surrounding the building shall be concreted, covered with asphalt or with similar material. The access road, walkways and parking areas shall be similarly treated. 4.4 4.5 5 5.1 5.1.1 The site shall be accessible to service roads, water supply and electric lines. The site shall be well drained. Classification According to method of storage Bulk

D-83

PAES 417:2002

5.1.2 5.2 5.2.1 5.2.2

Palletized According to environment control Drip cooling Air-cooled

5.2.2.1 Natural convection 5.2.2.2 Forced ventilation 5.2.3 5.2.4 6 Refrigerated Controlled atmosphere Space requirement

6.1 For palletized storage, floor area shall be determined by calculating volume of the boxes or pallet bins and dividing the volume by the maximum stacking height and adding area for aisles, room for forklift maneuvering, and staging areas. 6.2 For bulk storage, floor area shall be determined by knowing the weight of the produce and by dividing by the bulk density and pile depth (Table 1). Table 1 - Bulk density and pile depth for bulk storage of some vegetables Maximum pile depth m 4.2 - 6 0.6 - 1 3 - 3.6

Produce Potatoes Pumpkins and squash Onions 7 7.1 7.1.1 Structural requirements Roof

Average bulk density kg/m3 670 600 650

The roof structure shall be treated timber or steel with anti-rust paint.

7.1.2 Roofing materials shall be made of G.I. sheet and other steel sheeting with corrosion resistant coatings. 7.1.3 Roof vents, when provided, shall be properly screened.

7.1.4 For bulk storage, forces on roof system caused by wall pressure shall be considered in designing roof structure.

D-84

PAES 417:2002

7.2

Ceilings

7.2.1 Ceilings shall be at least 2.4 m from the finished floor line for manual handling and 6m for mechanical handling. 7.2.2 Ceilings shall be constructed to prevent the collection of dirt or dust that might sift through from the areas above or fall from overhead collecting surfaces onto equipment or exposed products. 7.2.3 7.3 Ceilings shall be painted with white emulsion or latex paint. Wall

7.3.1 The wall shall be concreted, smooth finished and properly painted. Internal surface of the walls should be painted with white emulsion or latex paint. 7.3.2 For pallet storage, wall shall be designed to withstand the pressure of piled fruit and vegetable. 7.3.3 All wall tops and ledges shall slope at 45o (Refer to Figure 1).

45

Hygienically surfaced walls Exterior smooth hard impermeable Cove tiled corners segmently

Figure 1 Finishing of a wall 7.3.4 It should be coved to the floor-wall and at wall-to-wall junctions with a radius of 50 mm - 60 mm. 7.4 7.4.1 Doors and access Door

Door shall be fitted with screens, air flaps or provided with air curtain. The width shall be at least 2.5 m.

D-85

PAES 417:2002

7.4.2

Access

Access door shall be provided for checking the commodity without opening the main door. It shall be constructed with a glass (reinforced) panel at eye level. The width shall be 600 mm750 mm. 7.4.3 Main entrances and exits shall be arranged so that the product generally moves in one direction through the facility. NOTE 7.5 Floor For cold storage room, provisions for ceilings, wall and access is optional.

7.5.1 Floor shall be concreted or tiled and properly reinforced to prevent cracks. It shall be designed to withstand concentrated loads. 7.5.2 Floor height should be leveled with the height of the vehicle being used in transporting the commodity. 7.5.3 7.5.4 Intersection with the wall shall be coved with 50 mm - 60 mm radius. The floor slope should be 2% - 4% towards the drain.

7.6 All other matters concerning structural design of the building not provided in this Standard shall conform with the provisions of the National Structural Code of Building. 8 8.1 Functional Requirements Receiving and sorting area

Refer to PAES 418:2002. 8.2 8.2.1 Storage area Drip cooling

8.2.1.1 The wall for the drip cooling should be made of burlap or porous materials and should be held in place by wire netting. 8.2.1.2 Water pipe with nozzles on the top of the wall or sprinkling hose shall be provided to trickle water down the walls. 8.2.1.3 Water collector made from curve metal sheet of gutter shall be provided.

8.2.1.4 If necessary, forced air circulation system to draw air from outside and ceiling exhaust fan to force air out should be provided.

D-86

PAES 417:2002

8.2.2 8.2.2.1

Air-cooled Natural convection

Air inlets shall be located near the floor level and outlets shall be near the roof. 8.2.2.2 Forced ventilation

There shall be provision for regulating inside temperature by a ventilation system. Entry of air should be mechanically controlled using fan and installing automatically regulated openings or dampers. Table 2 shows the recommended ventilation rates of some vegetables. Table 2 - Recommended ventilation for selected vegetables Produce Cabbage Carrots Potatoes Pumpkins and squash Onions Ventilation (L/s)/ton 20-30 20-30 6-10 15-20 10-12

8.2.3 8.2.3.1

Refrigerated There shall be provision for pre-cooling facilities.

8.2.3.2 Refrigeration system should be designed to maintain the appropriate storage temperature and relative humidity of the commodity. 8.2.3.3 Ceiling, wall and floor shall be provided with vapor barriers and shall be insulated with minimum R-values as shown in Table 3. Annex A shows the thermal properties of selected insulating materials and refer to Annex B for the sample calculations of R-value. Table 3 Recommended insulation for refrigerated room Minimum R-Value 5 (R-30) 3.5 (R-20) 1.76 (R- 10)

Ceiling Wall Floor 8.2.3.4 8.2.3.5 8.3

An 80 mm air plenum should be provided between the floor and stack. Door should be sliding type and should be made of heavy gauge metal. Piling system

8.3.1 Stack should be about 80 mm away from outer walls and 100 mm 120 mm away from the wall that is exposed to the sun.

D-87

PAES 417:2002

8.3.2 8.3.3 box. 8.3.3.1

Space between the ceiling and the stack shall be 300 mm. Within a stack, a minimum of 10 mm vertical air path shall be provided between each

Space between stack and sides and floor shall be 150 mm 200 mm.

8.3.3.2 Stacking height shall be up to 12 units for the cell pack and 8 units high for telescopic tray pack cartons. 8.4 8.4.1 Facilities and equipment Lighting

8.4.1.1 Artificial lighting shall always be available for use during the night or darkened periods of the day. 8.4.1.2 Table 4 shows the recommended lighting intensity for fruit and vegetable storage. Table 4 - Recommended lighting intensity for fruit and vegetable storage Area Outside the building General Working table Refrigerated storage room

* Refer to Annex D

Lighting intensity* lux (lumen/m2) 100 200 500 50

8.4.1.3 All electrical design and installation shall conform to Philippine Electrical Code. 8.4.2 Water supply and Plumbing facilities

8.4.2.1 The water supply shall be ample and potable with adequate pressure and with facilities for distribution. 8.4.2.2 Drainage and plumbing system for the fruit and vegetable storage shall be in accordance with the National Plumbing Code. 8.4.3 Toilet and hand-washing facilities

8.4.3.1 Toilets and hand-washing facilities shall be provided inside the building. 8.4.3.2 Toilet rooms shall not open directly into areas where the product is exposed unless steps have been taken to prevent airborne contamination (example: double doors, positive airflow). 8.4.3.3 Toilet rooms must have self-closing doors.

D-88

PAES 417:2002

8.4.3.4 Adequate and convenient hand-washing and, if necessary, hand-sanitizing facilities should be provided anywhere in the building where the nature of employees jobs requires that they wash, sanitize and dry their hands. 8.4.4 Fire extinguishing system

Construction of fire extinguishing system shall conform with the provision of the National Building Code of the Philippines. 9 Waste disposal

For waste management, refer to PAES 414:2002 Agricultural Structures Waste Management Structures.

D-89

PAES 417:2002

Annex A (informative) Thermal properties of selected insulating materials

Material Fiberglass batts Fiberglass, loose Fiberglass, board Cellular glass Styrofoam, extruded Styrofoam, beadboard Polyurethane, board Polyurethane, foamed-in-place Polyisocyanurate, board

R Factor (m2 oK/W)/cm 0.230 0.177 0.277 0.198 0.346 0.289 0.433 0.433 0.488

D-90

PAES 417:2002

Annex B (informative) Example calculation of R-value

A.1

Wall R factor (m2 oK/W) 0.049 3.21 0.926 0.11 0.03 4.32 [24.60 (h.ft2 oF/BTU)]

Outside air 140 mm fiberglass 25 mm rigid insulation 13 mm plywood Inside air

A.2

Ceiling R factor (m2 oK/W) 0.049 3.21 1.85 0.11 0.03 5.25 [29.86 (h.ft2 oF/BTU)]

Outside air 140 mm fiberglass 50 mm rigid insulation 13 mm plywood Inside air

A.3

Floor R factor (m2 oK/W) 1.85 0.077 0.03 1.96 [11.12 (h.ft2 oF/BTU)]

50 mm rigid insulation 100 mm concrete Inside air

D-91

PAES 417:2002

Annex C (informative)

Recommended conditions for storage of fresh fruits and vegetables Commodity Ampalaya Atis Avocado Banana Cavendish, green Lacatan, green Saba, green Beans Bush sitao Dolichos lablab (batao pods) Lima bean pods (patani) Snap beans Winged bean Bottle gourd (upo) Cabbage Caimito, ripe Carambola Carrot Cashew Cassava Cauliflower snowball Celery Chayote Chico Chinese broccoli Citrus Calamondin Pomelo Szinkon orange Valencia orange Coconut Corn, sweet Cucumber Durian Eggplant Gabi Garlic, (bulbs), dry Ginger Guava Guyabano Horseradish

D-92

Storage temperature 12-13 4-5.5 13 13-14.5 13-15.5 10 5.6 0-1.5 5-6 4-7 10 7.5 0 3 9-10 0 0-2 0-5 0 0 7 19.5-21 0 9-10 7.5-9 7.5-9 6.5-9 0-1.5 0 10-13 4-6 12 11.5-12.5 10-12.5 13 5-10 13 -1-0

Relative humidity 85-90 85-90 85-90 85-90 85-90 85-90 88-95 90 95 95 90 85-90 98-100 90 85-90 95-100 85-90 85-90 95-98 98-100 85-90 85-90 95-100 90 85-90 85-90 88-92 80-85 95-98 95 85-90 90-95 85-90 90 65 90 85-90 98-100

PAES 417:2002

Commodity Jackfruit Lanzones Lettuce Mango Mangosteen Mushroom Muskmelon Honeydew Cantaloup Okra Onion, green (immature) Onion, red Onion, white Papaya Passion fruit Patola (Trichosanthes) Pea, green Pechay Pepper, bell Pepper, hot Pepper, sweet Pineapple Pineapple guava Potato, Irish Radish, topped Rambutan Santol Squash Star fruit Sweet potato Tamarind Taro root Tomato, mature-green Tomato, firm-ripe Watermelon White asparagus Yams

Storage temperature 13 11.5-14 0 13 13 0 7.5 0-2 7-10 0 0 1.1 7-13 7-10 5.5-7 0 0 7-10 5-10 7-13 7-13 5-10 3.3-4.4 0 12 7-9 5-10 9-10 13-15 7 7-10 18-22 13-15 10-15 0-2 16

Relative humidity 85-90 85-90 98-100 85-90 85-90 95 85 95 90-95 95-100 70-75 70-75 85-90 85-90 85-90 95-98 95 95-98 85-95 90-95 85-90 90 85 88-92 90-95 85-90 95 85-90 85-90 90-95 85-90 90-95 90-95 90 95-100 70-80

D-93

PAES 417:2002

Annex D (informative)

Lighting Requirements No. of Bulbs Required per m2 Incandescent lamp 60W 100W 150W 200W 1.052 0.520 0.314 0.226 0.842 0.416 0.251 0.181 0.631 0.312 0.189 0.136 0.421 0.208 0.126 0.090 0.316 0.156 0.094 0.068 0.210 0.104 0.063 0.045 0.105 0.052 0.031 0.023 0.021 0.010 0.006 0.005

Lighting Intensity lux 500 400 300 200 150 100 50 10

25W 3.935 3.148 2.361 1.574 1.180 0.787 0.393 0.079

40W 1.989 1.591 1.193 0.796 0.597 0.398 0.199 0.040

Fluorescent lamp 20W 40W 0.682 0.266 0.546 0.213 0.409 0.160 0.273 0.107 0.205 0.080 0.136 0.053 0.068 0.027 0.014 0.005

D-94

Vous aimerez peut-être aussi

- Organic Resistance: The Struggle over Industrial Farming in Postwar FranceD'EverandOrganic Resistance: The Struggle over Industrial Farming in Postwar FranceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Familiar Talks on Science—World-Building and Life. Earth, Air and Water.D'EverandFamiliar Talks on Science—World-Building and Life. Earth, Air and Water.Pas encore d'évaluation

- PAES 417-Fruit & Vegetable StorageDocument14 pagesPAES 417-Fruit & Vegetable StorageFarouk PagsPas encore d'évaluation

- Philippine Agricultural Engineering Standard Paes 417:2002 Agricultural Structures - Fruit and Vegetable StorageDocument14 pagesPhilippine Agricultural Engineering Standard Paes 417:2002 Agricultural Structures - Fruit and Vegetable StorageDiana DainaPas encore d'évaluation

- Fresh Fruit Processing PlantDocument12 pagesFresh Fruit Processing PlantDiana DainaPas encore d'évaluation

- Paes 412Document10 pagesPaes 412Denver LangahinPas encore d'évaluation

- Broiler Housing StandardsDocument10 pagesBroiler Housing StandardsEgay LumenPas encore d'évaluation

- Broiler Housing StandardsDocument10 pagesBroiler Housing StandardsDenver LangahinPas encore d'évaluation

- Code of Practice for Installing Cellular PVC Roofline SystemsDocument14 pagesCode of Practice for Installing Cellular PVC Roofline SystemsmazniseinPas encore d'évaluation

- Pns 412 2004Document14 pagesPns 412 2004pawn1000kPas encore d'évaluation

- PAES 422-1-2012 - Agricultural Structures - Poultry Dressing Slaughtering Plan - Part 1 Small Sca PDFDocument32 pagesPAES 422-1-2012 - Agricultural Structures - Poultry Dressing Slaughtering Plan - Part 1 Small Sca PDFJohn VelacioPas encore d'évaluation

- Plant Tissue Culture LabDocument9 pagesPlant Tissue Culture LabannjoyceajajPas encore d'évaluation

- Application of Exterior Insulation and Finish Systems Class PIDocument7 pagesApplication of Exterior Insulation and Finish Systems Class PIHumberto GutierrezPas encore d'évaluation

- Green CodeDocument14 pagesGreen CodeZaveena Andrea Dela CruzPas encore d'évaluation

- InsulationDocument158 pagesInsulationAnthony Bonafide Dakush100% (5)

- Best Practice Guide (Mechanical Insulation)Document158 pagesBest Practice Guide (Mechanical Insulation)Sky LarksPas encore d'évaluation

- SBC 601 2007 - Saudi Building Code (Energy Conservation)Document13 pagesSBC 601 2007 - Saudi Building Code (Energy Conservation)abidch143Pas encore d'évaluation

- Paes 409Document12 pagesPaes 409Denver LangahinPas encore d'évaluation

- PAES 409 Agricultural Structures Standard for Milking ParlorsDocument12 pagesPAES 409 Agricultural Structures Standard for Milking Parlorsjoselito dumdumPas encore d'évaluation

- Chapter 2.02 - Fire-Resistive Requirements and Standards For Fire ProtectionDocument5 pagesChapter 2.02 - Fire-Resistive Requirements and Standards For Fire ProtectionChristian AlmeydaPas encore d'évaluation

- Philippine Agricultural Engineering Standard Paes 415:2001 Agricultural Structures - GreenhousesDocument22 pagesPhilippine Agricultural Engineering Standard Paes 415:2001 Agricultural Structures - GreenhousesPaida Heart100% (1)

- PAES 416: PHILIPPINE STANDARD FOR PLANT TISSUE CULTURE LABDocument9 pagesPAES 416: PHILIPPINE STANDARD FOR PLANT TISSUE CULTURE LABChitoLadiosPas encore d'évaluation

- Natural Ventilation Methods for Domestic BuildingsDocument27 pagesNatural Ventilation Methods for Domestic BuildingsFirrdhaus SahabuddinPas encore d'évaluation

- 2.9.1 - 80 - General Comments - National Building CodeDocument8 pages2.9.1 - 80 - General Comments - National Building CodemelsabaePas encore d'évaluation

- 21-28 - EtaDocument5 pages21-28 - EtaModern DesignsPas encore d'évaluation

- Compliance Statement ElmDocument5 pagesCompliance Statement ElmdeepakjoyinPas encore d'évaluation

- Des 6628 - 3Document28 pagesDes 6628 - 3biniPas encore d'évaluation

- Ripening ChambersDocument12 pagesRipening Chambersneeragarwal.lko6015Pas encore d'évaluation

- 04-ANNEXURE-01-ECBC 2017 (Mandatory Requirements) - For Electrical ConsultantDocument18 pages04-ANNEXURE-01-ECBC 2017 (Mandatory Requirements) - For Electrical Consultantyuva_86Pas encore d'évaluation

- Air 3-101Document24 pagesAir 3-101753rgsPas encore d'évaluation

- Method Statement External Wall Template Issue 4Document9 pagesMethod Statement External Wall Template Issue 4thelast_aienPas encore d'évaluation

- Underground Piping SystemsDocument5 pagesUnderground Piping SystemsBinodh DanielPas encore d'évaluation

- Chapter 2. Retail FacilitiesDocument16 pagesChapter 2. Retail FacilitiesMantenimientoValdezGutierrezPas encore d'évaluation

- General Specification: Split Type Air Conditioning SystemDocument2 pagesGeneral Specification: Split Type Air Conditioning SystemLasandu WanniarachchiPas encore d'évaluation

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1Pas encore d'évaluation

- Lehe1880 03Document9 pagesLehe1880 03Zouheir SnouciPas encore d'évaluation

- Section 07500 - Membrane Roofing: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument5 pagesSection 07500 - Membrane Roofing: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDPas encore d'évaluation

- Ac 12Document24 pagesAc 12Asghar MahmoodPas encore d'évaluation

- Air BarrierDocument7 pagesAir BarrierkeldisneyPas encore d'évaluation

- Astm C547Document7 pagesAstm C547Javier Orna100% (1)

- LST I BurekDocument7 pagesLST I Burektroscian7Pas encore d'évaluation

- Scope: Plant Buildings For Operation and Storage IP 4-3-1Document8 pagesScope: Plant Buildings For Operation and Storage IP 4-3-1Sixto Gerardo Oña AnaguanoPas encore d'évaluation

- Certifications File 12Document9 pagesCertifications File 12Mark GoducoPas encore d'évaluation

- Paes 418: Agricultural Structures - Primary Processing Plant For Fresh Fruit and VegetableDocument22 pagesPaes 418: Agricultural Structures - Primary Processing Plant For Fresh Fruit and VegetableRonie LusaresPas encore d'évaluation

- Thermal Enclosure Checklist Writeable - 6202012Document4 pagesThermal Enclosure Checklist Writeable - 6202012Prof_TheaPas encore d'évaluation

- H Im 68Document12 pagesH Im 68Maria DazaPas encore d'évaluation

- Power Control Room (PCR) Guide Specification v6Document5 pagesPower Control Room (PCR) Guide Specification v6solvoltraPas encore d'évaluation

- SP-PS-430 Rev 1.01Document7 pagesSP-PS-430 Rev 1.01MePas encore d'évaluation

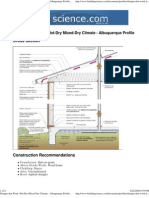

- Designs That Work Hot DryMixed Dry Climate AlbuquerquePr..Document8 pagesDesigns That Work Hot DryMixed Dry Climate AlbuquerquePr..Kosar MuradiPas encore d'évaluation

- NAFDAC guidelines for food manufacturing plant establishmentDocument9 pagesNAFDAC guidelines for food manufacturing plant establishmentJohn Nen BiniPas encore d'évaluation

- Audit Checklist Sterile Production AreaDocument17 pagesAudit Checklist Sterile Production AreaRutuja Chougale100% (2)

- 39HQM Guide SpecificationsDocument8 pages39HQM Guide SpecificationsAyman KamelPas encore d'évaluation

- Specification Concrete Deck/Between Slab (Reinforced)Document6 pagesSpecification Concrete Deck/Between Slab (Reinforced)Baugh Graphic DesignPas encore d'évaluation

- Installation and Commissioning of Ventilation SystemsDocument45 pagesInstallation and Commissioning of Ventilation SystemsDraganPas encore d'évaluation

- Building Materials & AssemblesDocument85 pagesBuilding Materials & AssemblesAlskduiPas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Quotes N QuotesDocument98 pagesQuotes N Quotesabdallah.mohammed6311Pas encore d'évaluation

- Application For Building PermitsDocument8 pagesApplication For Building PermitsTracey DeePas encore d'évaluation

- Labor Code of The PhilippinesDocument25 pagesLabor Code of The PhilippinesTopher Astraquillo60% (5)

- Civil Engineering Pocket DictionaryDocument131 pagesCivil Engineering Pocket DictionaryTracey DeePas encore d'évaluation

- The Underlying Reasons in Practical Civil Engineering WorksDocument76 pagesThe Underlying Reasons in Practical Civil Engineering WorksTracey DeePas encore d'évaluation

- Catholic Prophecy Yves DupontDocument124 pagesCatholic Prophecy Yves DupontTracey DeePas encore d'évaluation

- 101 MotivationDocument27 pages101 Motivationkyashwanth100% (85)

- Quotes N QuotesDocument98 pagesQuotes N Quotesabdallah.mohammed6311Pas encore d'évaluation

- Catholic Prophecy Yves DupontDocument124 pagesCatholic Prophecy Yves DupontTracey DeePas encore d'évaluation

- V-Belts and Pulleys For Agricultural Machines Specifications and ApplicationsDocument20 pagesV-Belts and Pulleys For Agricultural Machines Specifications and ApplicationsTracey DeePas encore d'évaluation

- The Zen of ResultsDocument17 pagesThe Zen of ResultsTracey DeePas encore d'évaluation

- St. Thomas, teacher of prayerDocument2 pagesSt. Thomas, teacher of prayerTracey DeePas encore d'évaluation

- 9 Day Novena For Sto. NinoDocument2 pages9 Day Novena For Sto. NinoJared C. Ramos75% (4)

- Rice Mill SpecificationsDocument7 pagesRice Mill SpecificationsTracey DeePas encore d'évaluation

- Plant Tissue Culture LaboratoryDocument9 pagesPlant Tissue Culture LaboratoryTracey DeePas encore d'évaluation

- Philippine Agricultural Engineering Standard Paes 415:2001 Agricultural Structures - GreenhousesDocument22 pagesPhilippine Agricultural Engineering Standard Paes 415:2001 Agricultural Structures - GreenhousesPaida Heart100% (1)

- USDA Soil ClassificationDocument50 pagesUSDA Soil ClassificationAnonymous 1BdR0EQgbuPas encore d'évaluation

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Concrete Mix DesignDocument36 pagesConcrete Mix Designamitbd80% (5)

- Water Supply EnggDocument119 pagesWater Supply Enggbasina_us89% (18)

- Training Plan OAP NCIIDocument3 pagesTraining Plan OAP NCIIRonnie NaagPas encore d'évaluation

- Milkfish culture techniques for fishpondsDocument17 pagesMilkfish culture techniques for fishpondsNiño Jess Mar MechaPas encore d'évaluation

- Agricultural Land Use Suitability Analysis Using GIS and AHP Technique PDFDocument12 pagesAgricultural Land Use Suitability Analysis Using GIS and AHP Technique PDFMaicol Camargo HernandezPas encore d'évaluation

- Review of Related Literature The Origin of The TomatoDocument3 pagesReview of Related Literature The Origin of The Tomatoxylene cuaresma60% (5)

- Wheat Production, Marketing and Consumption in EthiopiaDocument10 pagesWheat Production, Marketing and Consumption in EthiopiaSajitsew WadimPas encore d'évaluation

- Letter To President Re: U.S. Department of Agriculture ViolationsDocument6 pagesLetter To President Re: U.S. Department of Agriculture ViolationsC4CPas encore d'évaluation

- B. List at Least 3 Iot Applications That Are Most Needed in Today'S Living. What Effect Will The Internet of Things (Iot) Have On Our Daily Lives?Document2 pagesB. List at Least 3 Iot Applications That Are Most Needed in Today'S Living. What Effect Will The Internet of Things (Iot) Have On Our Daily Lives?Yan MariPas encore d'évaluation

- Past Tenses, Activities & QuestionsDocument12 pagesPast Tenses, Activities & QuestionsNeng wiwiPas encore d'évaluation

- Irma RahayuDocument3 pagesIrma RahayuIrma Rahayu NingrumPas encore d'évaluation

- Target 2021 Government Schemes I WWW - Iasparliament.com2Document264 pagesTarget 2021 Government Schemes I WWW - Iasparliament.com2Himanshu SinghPas encore d'évaluation

- British Enclosure MovementDocument7 pagesBritish Enclosure MovementBiancaPas encore d'évaluation

- Best Agriculture ExamsDocument98 pagesBest Agriculture ExamsSylvia NyakujawaPas encore d'évaluation

- Chapter 9 - Correctional Institution For Women, Davao Prison and Penal Farm, Iwahig Prison and PDocument6 pagesChapter 9 - Correctional Institution For Women, Davao Prison and Penal Farm, Iwahig Prison and Pkim ryan uchiPas encore d'évaluation

- Esd Project Report: Solar Water Pumps in IndiaDocument19 pagesEsd Project Report: Solar Water Pumps in Indiamanvi singhPas encore d'évaluation

- Agricultural Technology Graduate Seeks Quality Control RoleDocument1 pageAgricultural Technology Graduate Seeks Quality Control RoleLove EnvironmentPas encore d'évaluation

- Exercise 2: Choose One Given Phrase Verb To Complete Each Sentence. You May Have To Change The Verb Form But Can Not Use One Phrase Verb TwiceDocument4 pagesExercise 2: Choose One Given Phrase Verb To Complete Each Sentence. You May Have To Change The Verb Form But Can Not Use One Phrase Verb TwiceTùng Lò GạchPas encore d'évaluation

- AGR 3102-3rd WeekDocument48 pagesAGR 3102-3rd WeekSleeping BeautyPas encore d'évaluation

- Modified Stem NMSSDocument6 pagesModified Stem NMSSPrazwal RegmiPas encore d'évaluation

- Chesticuffs - Rules and Items!Document12 pagesChesticuffs - Rules and Items!Madeleine BorkhuisPas encore d'évaluation

- Effects of tire pressure on vertical stress and matric suction in agricultural soilsDocument14 pagesEffects of tire pressure on vertical stress and matric suction in agricultural soilsjuanalfredotorricoPas encore d'évaluation

- Anthropology Current Affairs Magazine SEPTEMBER 2021.Document59 pagesAnthropology Current Affairs Magazine SEPTEMBER 2021.Bharathi RamakrishnanPas encore d'évaluation

- Agrarian RevolutionDocument17 pagesAgrarian RevolutiondominiquePas encore d'évaluation

- Ewert Et Al 2023 Agroecology For A Sustainable Agriculture and Food System From Local Solutions To Large Scale AdoptionDocument34 pagesEwert Et Al 2023 Agroecology For A Sustainable Agriculture and Food System From Local Solutions To Large Scale AdoptionJorge GarzaPas encore d'évaluation

- Warud ExpoDocument6 pagesWarud Exponikhil indoreinfolinePas encore d'évaluation

- Case Analysis - ASF PDFDocument7 pagesCase Analysis - ASF PDFaleachonPas encore d'évaluation

- Crop Recommendation System Using KNN and Random Forest Considering Indian DatasetDocument13 pagesCrop Recommendation System Using KNN and Random Forest Considering Indian DatasetNishith GuptaPas encore d'évaluation

- Boost Soil Health with Bio-FertilizersDocument22 pagesBoost Soil Health with Bio-FertilizersDhanushika Sakthi VBPas encore d'évaluation

- Chapter 5 - Unleashing The Promise of Biotechnology T - 2020 - Biotechnology EntDocument13 pagesChapter 5 - Unleashing The Promise of Biotechnology T - 2020 - Biotechnology EntazizaPas encore d'évaluation

- Production and Marketing Practices of Bunching Onion (Allium Fistulosum L.) Farmers in Pangil, LagunaDocument15 pagesProduction and Marketing Practices of Bunching Onion (Allium Fistulosum L.) Farmers in Pangil, LagunaIJAR JOURNALPas encore d'évaluation

- Syllabus UPSC CSE Pre 2021Document129 pagesSyllabus UPSC CSE Pre 2021Sandeep SinghPas encore d'évaluation