Académique Documents

Professionnel Documents

Culture Documents

Article Brightechvalves PDFValves - Safety & Thermal Relief Valves, Pressure Reducing Valves, Automatic Control Valves

Transféré par

Hitesh ShahCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Article Brightechvalves PDFValves - Safety & Thermal Relief Valves, Pressure Reducing Valves, Automatic Control Valves

Transféré par

Hitesh ShahDroits d'auteur :

Formats disponibles

Valves Types and Uses Devices that regulate the flow of fluids like gases, liquids or slurries are

e commonly known as valves. These are actually a kind of pipe fittings commonly used in fluid control applications in industrial, military, commercial, residential, and transportation sectors. Petrochemical, oil & gas, pharmaceuticals, water treatment, power, iron, mining, cement, food, paper, textile, drilling are some of the main industrial areas where valves are implemented for the efficient flow of fluids. Some of the popular kinds of industrial valves include safety and thermal relief valves, pressure reducing valves, automatic control valves, pneumatic control valves and plastic lined valves like FEP, PFA, ETFE, PTFE lined valves. Safety & Thermal Relief Valves

Safety valves are the devices that prevent excessive internal fluid pressure build-up in industrial systems. These get their name because of their functionality which is to safeguard the life and property by controlling the excess pressure or temperature often occurring in industrial processes occurring due to factors like imbalance of fluid flow rate, failure of cooling system and control instrumentation etc. There are two general types of fluid protections necessary in industries, thermal and flow protection. The valves used for flow protection are the safety relief valves where as those used for thermal protection are the thermal relief valves. The safety relief valves or pressure relief valves are responsible for the automatic release of a substance from a boiler or pressure vessel when the pressure or temperature exceeds preset limits, thus preventing any kinds of hazards to take place. On the other hand the thermal relief valves provide protection from excess pressure caused by thermal expansion in industrial processes.

Pressure Reducing Valves

Pressure reducing valves or downstream pressure control valves are the pressure regulating devices which automatically reduce high inlet pressure of a system to a steady lower downstream pressure. These are usually the piston operated devices designed for holding downstream pressures to the pre-determined limits. For continuous distribution applications usage of internally pilot controlled pressure reducing valves is recommendable. Automatic Control Valves

Automatic control valves are used for automatic control of conditions like flow, pressure, temperature, and liquid level in the industrial processes. These operate by automatic opening or closing in response to signals received from independent devices such as flow meters or temperature gauges. The control valves are usually fitted with hydraulic and pneumatic actuators and positioners that are responsible for valve opening and closing by sensing the changes of pressure or flow in the systems. Those fitted with pneumatic actuators and positioners are called pneumatic control valves and commonly used for handling a wide variety of process applications like air, water, steam, gas, oil and other fluids having wide flow range requirements. For more details of valves please Click here.

Vous aimerez peut-être aussi

- Prevention of Actuator Emissions in the Oil and Gas IndustryD'EverandPrevention of Actuator Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Advanced Temperature Measurement and Control, Second EditionD'EverandAdvanced Temperature Measurement and Control, Second EditionPas encore d'évaluation

- Pressure Relief Valve: Definition, Types, Working, Location, Sizing, Codes and StandardsDocument18 pagesPressure Relief Valve: Definition, Types, Working, Location, Sizing, Codes and StandardsMalcolm MoorePas encore d'évaluation

- Introduction To ValvesDocument11 pagesIntroduction To ValvesElton SitumeangPas encore d'évaluation

- Instrumentation and Process Control (2150504)Document16 pagesInstrumentation and Process Control (2150504)Ignesh ChislaPas encore d'évaluation

- Relief Valve and Trip Testing ProceduresDocument16 pagesRelief Valve and Trip Testing ProceduresDharshica MohanPas encore d'évaluation

- PSV ManualDocument55 pagesPSV Manualioan.tsiamisPas encore d'évaluation

- Introduction To Hydraulic and Pneumatic SystemsDocument22 pagesIntroduction To Hydraulic and Pneumatic SystemsSyama TripathyPas encore d'évaluation

- Types of Pressure Relief ValvesDocument22 pagesTypes of Pressure Relief ValvesFaraz MichPas encore d'évaluation

- Flow Control ValveDocument3 pagesFlow Control ValvealphadingPas encore d'évaluation

- To Read Futher Go To WikipediaDocument1 pageTo Read Futher Go To WikipediawakawakakumarPas encore d'évaluation

- Technical English 2.Document32 pagesTechnical English 2.Jhostin AntonioPas encore d'évaluation

- Pneumatic ValvlesDocument9 pagesPneumatic Valvleseach3117Pas encore d'évaluation

- Pressure Control Design Guide SummaryDocument10 pagesPressure Control Design Guide SummaryMarkPas encore d'évaluation

- Essential Equipment in Chemical Process PlantsDocument41 pagesEssential Equipment in Chemical Process PlantsEileen LowPas encore d'évaluation

- Relief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyDocument3 pagesRelief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyKhaled RabeaPas encore d'évaluation

- How Does A Pneumatic Solenoid Valve WorkDocument4 pagesHow Does A Pneumatic Solenoid Valve Worksushant_jhawerPas encore d'évaluation

- Relief Vs RegulatingDocument7 pagesRelief Vs Regulatingنور القمرPas encore d'évaluation

- PCSU Chapter 6Document16 pagesPCSU Chapter 6rawanisephiaPas encore d'évaluation

- Over Pressure Cases For Pressure Relief Valve SizingDocument2 pagesOver Pressure Cases For Pressure Relief Valve SizinginstrengPas encore d'évaluation

- Diaphragm Pump CharacteristicsDocument9 pagesDiaphragm Pump CharacteristicslamiaPas encore d'évaluation

- Training Program On: Pressure Relief ValveDocument71 pagesTraining Program On: Pressure Relief ValveShoaib JadoonPas encore d'évaluation

- Temperature Monitoring: FaizanDocument5 pagesTemperature Monitoring: FaizankjfenPas encore d'évaluation

- Working Principle of Control Valve With DiagramDocument10 pagesWorking Principle of Control Valve With DiagramKhamis AfendiPas encore d'évaluation

- Process Control Elements in The LoopDocument13 pagesProcess Control Elements in The LoopTimothy LeonardPas encore d'évaluation

- InstrumentationDocument26 pagesInstrumentationMitz Mae DatuPas encore d'évaluation

- 11 3-And-11 4Document3 pages11 3-And-11 4Reymond Clark AdasaPas encore d'évaluation

- Wip Control Valves Types, SelectionDocument11 pagesWip Control Valves Types, SelectionAkshay SalwePas encore d'évaluation

- Control Valve SourcebookDocument218 pagesControl Valve SourcebookJuanita JitomatePas encore d'évaluation

- Kele - Solutions Articles - The Instability of VAV SystemsDocument5 pagesKele - Solutions Articles - The Instability of VAV SystemsKumudu PereraPas encore d'évaluation

- Safety ValveDocument10 pagesSafety ValveVignesh WarPas encore d'évaluation

- Safety ValvesDocument65 pagesSafety Valvesserturkbudak_3448365Pas encore d'évaluation

- Valves in The Oil and Gas IndustryDocument55 pagesValves in The Oil and Gas IndustryK LandryPas encore d'évaluation

- Piping DesignDocument14 pagesPiping Designchinnak123Pas encore d'évaluation

- Flow Elements BrochureDocument37 pagesFlow Elements BrochurearavindPas encore d'évaluation

- HVACDocument72 pagesHVACvarshneyrk@rediffmail.comPas encore d'évaluation

- Water Distribution ValvesDocument35 pagesWater Distribution ValvesAbdullah ObeidatPas encore d'évaluation

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBavikbhaiPas encore d'évaluation

- All About ValvesDocument16 pagesAll About Valvesmazen zaloudPas encore d'évaluation

- Flow and Measurement in Oil and GasDocument17 pagesFlow and Measurement in Oil and GasGnanaseharan ArunachalamPas encore d'évaluation

- Safety Valve SelectionDocument56 pagesSafety Valve Selectionganesh82Pas encore d'évaluation

- Surge Relief Valve Definition Function Types Sizing SelectionDocument6 pagesSurge Relief Valve Definition Function Types Sizing Selectionkamala 123Pas encore d'évaluation

- Safety ValvesDocument66 pagesSafety ValvesMuhammad Afiq Mohd ZaidPas encore d'évaluation

- Control System Mini ProjectDocument14 pagesControl System Mini ProjectMuhammad Al-baihaqiPas encore d'évaluation

- Blowout Preventer Vs Christmas TreeDocument2 pagesBlowout Preventer Vs Christmas TreeHazraien Abdullah HashimPas encore d'évaluation

- Rocess: Process As Used in The Terms Process Control and Process IndustryDocument8 pagesRocess: Process As Used in The Terms Process Control and Process Industryankur neogPas encore d'évaluation

- Process Dynamics and ControlDocument11 pagesProcess Dynamics and ControlSALIFUPas encore d'évaluation

- FIKE RD Combo With Relief ValvesDocument11 pagesFIKE RD Combo With Relief ValvesAnkit GandhiPas encore d'évaluation

- HTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewDocument15 pagesHTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewPalash KayathwalPas encore d'évaluation

- Valves & Flare StackDocument9 pagesValves & Flare Stackrezad100% (1)

- Benchtop Pressure Process Control SystemDocument1 pageBenchtop Pressure Process Control SystemIram TahiraPas encore d'évaluation

- Instrumentation Advance Course Part 2Document69 pagesInstrumentation Advance Course Part 2FACE BOOKPas encore d'évaluation

- Total Product CatalogueDocument37 pagesTotal Product CatalogueFARIDPas encore d'évaluation

- Chapter Overview: 3: Sensors and ActuatorsDocument93 pagesChapter Overview: 3: Sensors and ActuatorsGigiPas encore d'évaluation

- LAPORAN P2 After RevDocument16 pagesLAPORAN P2 After RevzakiPas encore d'évaluation

- Control Valve Selection PDFDocument218 pagesControl Valve Selection PDFSyed Ali100% (2)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Storage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionD'EverandStorage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionPas encore d'évaluation

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsD'EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Safety in The Use of Unfired Pressure VesselsDocument36 pagesSafety in The Use of Unfired Pressure Vesselsnvaradharajan1971Pas encore d'évaluation

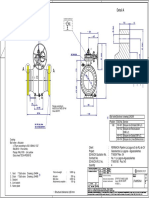

- Valvula de Bola GF-RF Nps30 Cl600 - Ag - GearDocument1 pageValvula de Bola GF-RF Nps30 Cl600 - Ag - GearJR RZPas encore d'évaluation

- MS - 304 - Dated 09.02.2001Document5 pagesMS - 304 - Dated 09.02.2001sujaraghupsPas encore d'évaluation

- 750+HSP+Parts+Manual MAVERICKDocument5 pages750+HSP+Parts+Manual MAVERICKSergio TorresPas encore d'évaluation

- FM 100.08 Bernoulli Theorem Apparatus - EdLabQuip 10.12Document18 pagesFM 100.08 Bernoulli Theorem Apparatus - EdLabQuip 10.12yonasPas encore d'évaluation

- SANY Hydraulic System 20 TonDocument19 pagesSANY Hydraulic System 20 TonPRASHANTH100% (3)

- RBI Vibration AssesmentDocument29 pagesRBI Vibration AssesmentRockny2011100% (1)

- Neltex Saniguard S-600 CertificateDocument4 pagesNeltex Saniguard S-600 CertificatejaymarPas encore d'évaluation

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFBonaventure NzeyimanaPas encore d'évaluation

- AirCom Quick LineDocument19 pagesAirCom Quick Linea ferreira e oliveiraPas encore d'évaluation

- Gardner Denver Nash CL Serien BroschyrDocument8 pagesGardner Denver Nash CL Serien BroschyrjorgekichiPas encore d'évaluation

- Reciprocating Compressor Seals Partner Savings From Compressor Rod PackingDocument20 pagesReciprocating Compressor Seals Partner Savings From Compressor Rod PackingONURPas encore d'évaluation

- ARO 66625X 66627X 2 Inch Metallic Diaphragm Pump DatasheetDocument2 pagesARO 66625X 66627X 2 Inch Metallic Diaphragm Pump Datasheetmohamed musaPas encore d'évaluation

- Air CompressorDocument2 pagesAir CompressorAli AimranPas encore d'évaluation

- Compressor Io ManualDocument58 pagesCompressor Io ManualasgharPas encore d'évaluation

- Multistage Pump RepairDocument5 pagesMultistage Pump RepairCheyanSathishPas encore d'évaluation

- Stationary Two-Stage Air Compressor: Description SpecificationsDocument12 pagesStationary Two-Stage Air Compressor: Description SpecificationsMireya Linares MoriPas encore d'évaluation

- TariqLNG - Technology SelectionDocument4 pagesTariqLNG - Technology SelectionAndrey KrPas encore d'évaluation

- Sihi lph55000Document10 pagesSihi lph55000mhsalihPas encore d'évaluation

- 5.15 FluidaDocument7 pages5.15 FluidaMuhammadPas encore d'évaluation

- CR 3-11 pump specsDocument3 pagesCR 3-11 pump specsLuis Miguel MartinezPas encore d'évaluation

- Oxygen Lance SystemDocument31 pagesOxygen Lance SystemsirishaPas encore d'évaluation

- DAIKIN WMT Dynamic ChillerDocument32 pagesDAIKIN WMT Dynamic ChilleretephPas encore d'évaluation

- Gas Power Cycles: Mehmet KanogluDocument29 pagesGas Power Cycles: Mehmet KanogluFiras Abu talebPas encore d'évaluation

- Compressible Flow - (Solved Problems) PDFDocument17 pagesCompressible Flow - (Solved Problems) PDFRimple MaheyPas encore d'évaluation

- Progressing Cavity Pump ApplicationsDocument63 pagesProgressing Cavity Pump Applicationsadtijanic-1100% (1)

- Pump Head Calculation Sheet: S U P P L Y P U M PDocument6 pagesPump Head Calculation Sheet: S U P P L Y P U M PGokul GopalakrishnanPas encore d'évaluation

- CFDSMSGDocument334 pagesCFDSMSG13594Pas encore d'évaluation

- CVE 112 (Hydraulics 2) : Lecture 1: Principles of HydrokineticsDocument13 pagesCVE 112 (Hydraulics 2) : Lecture 1: Principles of HydrokineticsAriel B. LumacadPas encore d'évaluation

- Level III - Ata 49 ApuDocument60 pagesLevel III - Ata 49 Apuwagdi100% (2)