Académique Documents

Professionnel Documents

Culture Documents

5 - Whole Metallurgy (Part I)

Transféré par

Antonio C. KeithDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

5 - Whole Metallurgy (Part I)

Transféré par

Antonio C. KeithDroits d'auteur :

Formats disponibles

I.

Metals

Light metals Heavy metals High melting Brittle Ductile

Non metals

Inert gases

Noble

Low melting

From the periodic table, it can be found that: Metals are on the left side. Nonmetals are on the right side. Metalloids or semiconductors are at the boundary between metals and nonmetals; e.g. Carbon, Silicon and Boron.

Properties of metals:

1- Ionized positively. 2- Crystalline solids at room temperature, except Hg and Ga. 3- Opaque and lustrous. 4- Thermally ad electrically conductors. 5- Hardness, melting and boiling points. 6- Density. 7- Ductile and malleable. 8- Melting range. 9- White in color except Au and Cu.

Pure metals in dentistry:

1- Au and Pt foils Restorations.

2- Pt foils

Porcelain.

3- Au and Sn

Ceramo metal restorations.

4- Ag and Cu

Electroplated dies.

5- Hg

Amalgam.

6- Ti

Implantology, Cr and Br (Procera).

Shaping of metals:

a) Casting: Liquid metal Crystalline solid

Solidification and thermal shrinkage 4-6%

b) Plastic forming (Cold working): Cast metal rod, wire, tube,

c) Sintering (Powder metallurgy): Powder

Heat Solid Pressure

Accompanied by Shrinkage, Density and Porosity

d) Electroforming: Ag and Cu electroplating.

C:\Documents

and

Settings\Mostafa

A.

Latif\My

Documents\My

Pictures\Dr.Azza\Metallurgy\078_Electroplating.mov

Solidification of metals:

A Liquid Temperature Plateau L+S Tf B B\ Supercooling C Solid D

Time Time temperature cooling curve for a pure metal

1- Nucleus formation: Liquid metal atomic aggregates embryos embryos

Penetration of super cooling

temp. Latent heat

2- Crystallization: Nuclei of crystallization Homogeneous

Dendrites Crystals Solid metal

Heterogeneous

Grains and grain boundaries:

Poly crystalline material Crystals with various orientation Crystals or grains have: Shape Size Orientation Distribution Grain Proper Boundary Grain boundary: - Transition zone (1-2 atomic distances). - Indicates discontinuity of space lattices planes. - Nearly noncrystalline. - Of higher energy. - Greater rate of diffusion. - Greater concentration of impurities. - More readily attacked by chemicals.

Microstructural variables of a single phase material

Grain size: - Size - Size

1

Number and location of nuclei. Grain boundary - area.

Control of grain size: Size Physical properties.

1 e.g. Y .S . r

1- Amount and rate of supercooling (Control number of grains and nuclei). 2- Rate of crystallization and rate of nucleation. 3- Nucleating agents.

Wrought metal Deformation

Cast Wrought

Recovery Grain growth Recrystallization

Cast metal Deformation of metals:

wrought metal Elastic Plastic

Elastic

Plastic

Lattice imperfections: a- Point defects: Vacancies

b- Line defects: Dislocations

Edge Dislocation

Screw Dislocation

Mixed Dislocation

c- Plane defects: Boundaries

Strain hardening: [Cold working] [Work hardening]: Dislocation is inhibited by: 1- Point defects. 2- Collision of 2 dislocation. 3- Foreign atom lattice. 4- Grain boundaries. Dislocation build up Stresses needed to proceed deformation So, Hardness, Strength and P.L.

Meanwhile, Ductility and Corrosion resistance

Annealing: It reverses the effects of cold working It involve three stages: 1- Recovery. 2- Recrystallization. 3- Grain growth. Factors affecting grain size and shape: 1- Rate of cooling. 2- Nucleating agents. 3- Cold working. 4- Annealing a) Recrystallization b) Grain growth.

Recovery

Tm (for few minutes) Relief of stresses

Recrystallization

0.3-0.6 Tm

Grain growth

Further annealing

Nucleation of stress free grains Growth of grains. at boundaries. .

and

St., P.L., and Hardness Ductility

Cold worked Recovery

and

Recryst.

St., P.L. Ductility

Grain growth

Tensile strength

A) Cold worked B) Recovery C) Recrystallization D) Grain growth

Ductility

Vous aimerez peut-être aussi

- MSM M 1& 2 Imp QnsDocument18 pagesMSM M 1& 2 Imp Qnssangei2093Pas encore d'évaluation

- Extractive Metallurgy 1: Basic Thermodynamics and KineticsD'EverandExtractive Metallurgy 1: Basic Thermodynamics and KineticsPas encore d'évaluation

- Properties of MetalsDocument10 pagesProperties of MetalsKawaii SamaPas encore d'évaluation

- Underground Treasures: How and Where to Find Them: A Key for the Ready Determination of All the Useful Minerals Within the United StatesD'EverandUnderground Treasures: How and Where to Find Them: A Key for the Ready Determination of All the Useful Minerals Within the United StatesPas encore d'évaluation

- BY Dr. Bibin BhaskaranDocument51 pagesBY Dr. Bibin BhaskarannvemanPas encore d'évaluation

- Metals: Igcse O LevelDocument21 pagesMetals: Igcse O LevelLeniPas encore d'évaluation

- METALS NON METALS TheoryDocument23 pagesMETALS NON METALS TheoryweyiPas encore d'évaluation

- Metals and Non-Metals NE (L)Document21 pagesMetals and Non-Metals NE (L)Aryan BhuraPas encore d'évaluation

- Metallugy BasicDocument62 pagesMetallugy Basicatique islamPas encore d'évaluation

- MetalDocument16 pagesMetalEdgar Apaza HuallpaPas encore d'évaluation

- CPE 601-Corrosion Week 5Document74 pagesCPE 601-Corrosion Week 5Nur AqilahPas encore d'évaluation

- Class 12 Chemistry PPT D Block Chemistry July 2023Document17 pagesClass 12 Chemistry PPT D Block Chemistry July 2023Sheetal TrivediPas encore d'évaluation

- TDK ... P CORROSION & IGC ........ Add ........ B4TDocument21 pagesTDK ... P CORROSION & IGC ........ Add ........ B4Tdwi sutiknoPas encore d'évaluation

- Project and Facility ManagementDocument26 pagesProject and Facility ManagementKumaResan SubramaniamPas encore d'évaluation

- Chapter - 8 MetalDocument12 pagesChapter - 8 Metalamit_idea1Pas encore d'évaluation

- Chemistry 1000 Lecture 10: Metals and Crystal Structures: Marc R. RousselDocument17 pagesChemistry 1000 Lecture 10: Metals and Crystal Structures: Marc R. RousselShahid KhanPas encore d'évaluation

- MetalDocument9 pagesMetaldjtomcraftPas encore d'évaluation

- Grade X - Teaching Notes: Metals and Non-Metals GlossaryDocument25 pagesGrade X - Teaching Notes: Metals and Non-Metals GlossaryAkshith KottaPas encore d'évaluation

- Anglais ScientifiqueDocument4 pagesAnglais Scientifiqueali BourenanePas encore d'évaluation

- Metal and Alloy 24 Nov.2023Document28 pagesMetal and Alloy 24 Nov.2023lvvjkhpoggpskjzcpwPas encore d'évaluation

- Metals Used in ProsthodonticsDocument43 pagesMetals Used in ProsthodonticsnavneetkhanPas encore d'évaluation

- Manufacturing Science and MetallurgyDocument47 pagesManufacturing Science and MetallurgyAppu bjPas encore d'évaluation

- Chapter+4+ +Imperfections+in+CrystalsDocument25 pagesChapter+4+ +Imperfections+in+Crystalspramod_kPas encore d'évaluation

- Publication 3 26810 199 PDFDocument11 pagesPublication 3 26810 199 PDFnagarajPas encore d'évaluation

- Manufacturing Processes: Dra. Martha P. Guerrero Mata Dra. Adriana Salas ZamarripaDocument67 pagesManufacturing Processes: Dra. Martha P. Guerrero Mata Dra. Adriana Salas ZamarripaBrayan AlvarezPas encore d'évaluation

- Chapter 2Document70 pagesChapter 2劉德信Pas encore d'évaluation

- HGHFFDocument2 pagesHGHFFJob ShortsPas encore d'évaluation

- Chemistry Endurance Race 5070Document29 pagesChemistry Endurance Race 507024avesh.kumarPas encore d'évaluation

- Metaullargy NotesDocument14 pagesMetaullargy Noteswama ojhaPas encore d'évaluation

- CHE882Unit3 L15Document8 pagesCHE882Unit3 L15Ms Mayank YadavPas encore d'évaluation

- CorrosionDocument15 pagesCorrosionSohila A. MabroukPas encore d'évaluation

- Metal PropertiesDocument17 pagesMetal PropertiesParag AlamyanPas encore d'évaluation

- Corrosion Protection 7.1 Causes of Corrosion:: (2) Combined StateDocument10 pagesCorrosion Protection 7.1 Causes of Corrosion:: (2) Combined Stateحاتم غيدان خلفPas encore d'évaluation

- GoldDocument7 pagesGoldHammad zia 32Pas encore d'évaluation

- Metals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument43 pagesMetals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDheeraj KumarPas encore d'évaluation

- 06 - Uet FM LecDocument48 pages06 - Uet FM LecAbcPas encore d'évaluation

- Unit 1Document280 pagesUnit 1Abhishek ChavanPas encore d'évaluation

- Structure, Properties, Process, and Aplications of GoldDocument10 pagesStructure, Properties, Process, and Aplications of GoldMahfud EffendiPas encore d'évaluation

- Non Ferrous-Metal - Group-2 - Written-Report - ME3Document11 pagesNon Ferrous-Metal - Group-2 - Written-Report - ME3ELLIEPas encore d'évaluation

- Alkali Metals: MetalDocument8 pagesAlkali Metals: MetalKaitlynRanaPas encore d'évaluation

- Ceramics: Classification and Properties of Ceramic MaterialsDocument36 pagesCeramics: Classification and Properties of Ceramic MaterialsMadhumita KumarPas encore d'évaluation

- Lesson 7 Metals and Non MetalsDocument5 pagesLesson 7 Metals and Non MetalsSoham APas encore d'évaluation

- METALSDocument4 pagesMETALSAyan BarbonPas encore d'évaluation

- CHEM 252 Lecture 1Document18 pagesCHEM 252 Lecture 1Adjei DanielPas encore d'évaluation

- Alloys: I) IntroductionDocument12 pagesAlloys: I) IntroductionNikhil ShelarPas encore d'évaluation

- Occurrence of MetalsDocument24 pagesOccurrence of MetalsPamo CaytanoPas encore d'évaluation

- Class 2 Materials in Metal Manufacturing: Crystalline StructureDocument5 pagesClass 2 Materials in Metal Manufacturing: Crystalline StructureAlef BergPas encore d'évaluation

- Unit 1-Constitution of AlloyDocument51 pagesUnit 1-Constitution of Alloyvenkatesan palaniPas encore d'évaluation

- Metallic Structure: Group 2: Ngo Giang Nam Trinh Hoang Minh Nguyen Phu HuyDocument30 pagesMetallic Structure: Group 2: Ngo Giang Nam Trinh Hoang Minh Nguyen Phu HuyhuycanphuPas encore d'évaluation

- Corrosion 15012019 PDFDocument61 pagesCorrosion 15012019 PDFDeepak SainiPas encore d'évaluation

- Basic Mettalurgy of The Precious Metal Part IDocument38 pagesBasic Mettalurgy of The Precious Metal Part ILinda LindawatiPas encore d'évaluation

- 4.5 Alloy 2023Document21 pages4.5 Alloy 2023Zahrani AssyifaPas encore d'évaluation

- Santa Fe Symposium: Basic Metallurgy of Precious MetalsDocument33 pagesSanta Fe Symposium: Basic Metallurgy of Precious MetalsaripPas encore d'évaluation

- Metallurgy 5th Ed 1977 PDFDocument483 pagesMetallurgy 5th Ed 1977 PDFanon_435115635Pas encore d'évaluation

- By:-Utsah Sharma - at Crazy ScienceDocument21 pagesBy:-Utsah Sharma - at Crazy ScienceUtsah SharmaPas encore d'évaluation

- Worksheet 6.1Document1 pageWorksheet 6.1annnyyyaaaaaPas encore d'évaluation

- Bahan Konstruski Dan Korosi - Pertemuan 2Document40 pagesBahan Konstruski Dan Korosi - Pertemuan 2sri utariPas encore d'évaluation

- Dental Casting Alloys FinalDocument175 pagesDental Casting Alloys FinalNiaz Ahammed0% (1)

- The Disintegration of An Engineered Material Into Its Constituent AtomsDocument41 pagesThe Disintegration of An Engineered Material Into Its Constituent Atomsanudeep009Pas encore d'évaluation

- Preserving The Past: The Role of Historic Preservation in Architecture #MNO345Document5 pagesPreserving The Past: The Role of Historic Preservation in Architecture #MNO345Antonio C. KeithPas encore d'évaluation

- Redefine 101Document6 pagesRedefine 101Antonio C. KeithPas encore d'évaluation

- The Impact of Technology On Modern Architecture #ABC123Document4 pagesThe Impact of Technology On Modern Architecture #ABC123Antonio C. KeithPas encore d'évaluation

- FuturaVista 8165Document6 pagesFuturaVista 8165Antonio C. KeithPas encore d'évaluation

- The Evolution of Urban Design: From The Ancient World To The Modern Metropolis #GHI789Document4 pagesThe Evolution of Urban Design: From The Ancient World To The Modern Metropolis #GHI789Antonio C. KeithPas encore d'évaluation

- Norm 456Document6 pagesNorm 456Antonio C. KeithPas encore d'évaluation

- Mix 456Document6 pagesMix 456Antonio C. KeithPas encore d'évaluation

- EcoSphere 4321Document6 pagesEcoSphere 4321Antonio C. KeithPas encore d'évaluation

- Urban Oasis-6934Document6 pagesUrban Oasis-6934Antonio C. KeithPas encore d'évaluation

- Play 789Document6 pagesPlay 789Antonio C. KeithPas encore d'évaluation

- Export Codex Ashburnham Facsimile PDFDocument1 pageExport Codex Ashburnham Facsimile PDFAntonio C. KeithPas encore d'évaluation

- CopperToxicity PDFDocument7 pagesCopperToxicity PDFAntonio C. KeithPas encore d'évaluation

- Horizon 123Document10 pagesHorizon 123Antonio C. KeithPas encore d'évaluation

- Pardigmas 2Document5 pagesPardigmas 2Antonio C. KeithPas encore d'évaluation

- CopperToxicity PDFDocument7 pagesCopperToxicity PDFAntonio C. KeithPas encore d'évaluation

- Dingledy The Corpus Juris Civilis A Guide To Its History and Use Accepted Manuscript VersionDocument41 pagesDingledy The Corpus Juris Civilis A Guide To Its History and Use Accepted Manuscript VersionAntonio C. KeithPas encore d'évaluation

- Civitai ApiDocument17 pagesCivitai ApiAntonio C. KeithPas encore d'évaluation

- Information Codes of Mutant Forms: Arch. Bojan BaleticDocument15 pagesInformation Codes of Mutant Forms: Arch. Bojan BaleticAntonio C. KeithPas encore d'évaluation

- tp132 c2 PDFDocument9 pagestp132 c2 PDFAntonio C. KeithPas encore d'évaluation

- Pedsim: Quick Start GuideDocument6 pagesPedsim: Quick Start GuideAntonio C. KeithPas encore d'évaluation

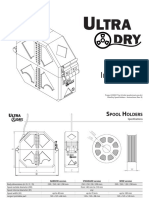

- UltraDry Spool Holders - Instructions PDFDocument15 pagesUltraDry Spool Holders - Instructions PDFAntonio C. KeithPas encore d'évaluation

- History of CAD - CAE CompaniesDocument5 pagesHistory of CAD - CAE CompaniesAntonio C. KeithPas encore d'évaluation

- StarCraft II A New Challenge For Reinforcement LearningDocument20 pagesStarCraft II A New Challenge For Reinforcement LearningAntonio C. KeithPas encore d'évaluation

- DA PAM 415 28 Guide To Army Real Property Category CodesDocument483 pagesDA PAM 415 28 Guide To Army Real Property Category CodesAntonio C. Keith100% (1)

- Discrete Shells: Eurographics/SIGGRAPH Symposium On Computer Animation (2003) D. Breen, M. Lin (Editors)Document7 pagesDiscrete Shells: Eurographics/SIGGRAPH Symposium On Computer Animation (2003) D. Breen, M. Lin (Editors)Antonio C. KeithPas encore d'évaluation

- Slope Deflection Assignment - 2023Document2 pagesSlope Deflection Assignment - 2023Andrew ChikuselaPas encore d'évaluation

- Types of ContractsDocument7 pagesTypes of ContractsThandie ChirambaPas encore d'évaluation

- Course Outline: CHAPTER ONE (0.5 Week)Document4 pagesCourse Outline: CHAPTER ONE (0.5 Week)nimcanPas encore d'évaluation

- Polypipe Underfloor HeatingDocument52 pagesPolypipe Underfloor HeatingAli MustafaPas encore d'évaluation

- A Brief Presentation On Shoe-Sole MakingDocument15 pagesA Brief Presentation On Shoe-Sole MakingTahmidPas encore d'évaluation

- PHE Notes 1Document126 pagesPHE Notes 1SY 37 - Purnima PanditPas encore d'évaluation

- Water: PN 16 DN 100Document2 pagesWater: PN 16 DN 100AhmedRamadanPas encore d'évaluation

- D From The Face of The Support. Any Shear: 6.2.2 Members Not Requiring Design Shear ReinforcementDocument1 pageD From The Face of The Support. Any Shear: 6.2.2 Members Not Requiring Design Shear ReinforcementArun PrakashPas encore d'évaluation

- Design Seta (Latest)Document13 pagesDesign Seta (Latest)steven bianesPas encore d'évaluation

- PillarsDocument14 pagesPillarsIvanze BenlotPas encore d'évaluation

- Module 7 (Maintenance Practices) Sub Module 7.15 (Welding, Brazing, Soldering and Bonding) PDFDocument14 pagesModule 7 (Maintenance Practices) Sub Module 7.15 (Welding, Brazing, Soldering and Bonding) PDFAamir JavaidPas encore d'évaluation

- FYP Presentation TemplateDocument20 pagesFYP Presentation TemplateAliPas encore d'évaluation

- Pressure Vessel Inspection Record: in Accordance With API 510, 10th EditionDocument2 pagesPressure Vessel Inspection Record: in Accordance With API 510, 10th Editionbgonzalez1981Pas encore d'évaluation

- Steel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheDocument6 pagesSteel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheJoao SilvaPas encore d'évaluation

- A S EnterprisesDocument7 pagesA S EnterprisesKaizen interioPas encore d'évaluation

- At Buildersguide PDFDocument50 pagesAt Buildersguide PDFOscarKonzultPas encore d'évaluation

- API RP-576 Inspection of Pressure-Relieving DevicesDocument67 pagesAPI RP-576 Inspection of Pressure-Relieving DevicesIbrahim Eldesoky100% (9)

- 1 BT1 Doors and WindowsDocument1 page1 BT1 Doors and Windowsdeng liPas encore d'évaluation

- Eurocell Building Plastics: Specification GuideDocument68 pagesEurocell Building Plastics: Specification GuideWilton Antony QcPas encore d'évaluation

- Buildings LandscapeDocument62 pagesBuildings LandscapeAkash SrivastavaPas encore d'évaluation

- Case Study Shanghai TowersDocument1 pageCase Study Shanghai TowersShinde ShubhamPas encore d'évaluation

- Ashrae 2019 SmokeDocument30 pagesAshrae 2019 Smokeسيف الدين أحمد محمد عمرPas encore d'évaluation

- IJSDR190491Document21 pagesIJSDR190491RohimPas encore d'évaluation

- Principles of PrestressingDocument20 pagesPrinciples of PrestressingBinatilio GoalPas encore d'évaluation

- 31) Method Statement For Shaft WorksDocument3 pages31) Method Statement For Shaft WorksNikhil Manjrekar0% (1)

- Rule 16 - Plastics (Book Format)Document3 pagesRule 16 - Plastics (Book Format)Thea AbelardoPas encore d'évaluation

- DO 005 s2017Document195 pagesDO 005 s2017Tina Rosales0% (1)

- Flexible Type Sis or Xhhw-2: 90°C Wet or Dry, 600 Volts. Flexible Stranded Tinned Copper Conductor. XLPE InsulationDocument2 pagesFlexible Type Sis or Xhhw-2: 90°C Wet or Dry, 600 Volts. Flexible Stranded Tinned Copper Conductor. XLPE InsulationEduardo CarrilloPas encore d'évaluation

- 9 TH Plate (Sub)Document12 pages9 TH Plate (Sub)hemantPas encore d'évaluation

- Performance Assessment Report QPSDocument1 pagePerformance Assessment Report QPSALFREDO JR. ARIOS CLAROPas encore d'évaluation