Académique Documents

Professionnel Documents

Culture Documents

CSR Matrix (Example Only)

Transféré par

hmp90Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CSR Matrix (Example Only)

Transféré par

hmp90Droits d'auteur :

Formats disponibles

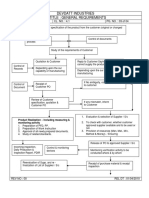

Customer-Specific Requirements Matrix

IMPORTANT NOTE: Customer-specific requirements are regularly updated. Check www.iaob.org and the Customer's websites for the latest requirements

1 2 3 4

IATF Requirements are in blue italics

May 2006

March 2006 Rev 08/31/06

ISO/TS 16949:2002

Clause Number and Title

Contents iii

DaimlerChrysler

Page Requirement Number and Title

General Motors

Requirement Number and Title

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Foreword Remarks for certification

vii viii ix ix ix xi xi xi xii 1 1 1 1 2 References (9) 2 References (10) 2 2 2 3 3 Definitions (7) 4.2.3 Special Characteristics not Identified with Symbols 3 Definitions (13) 1 Scope 1 Scope

Introduction

0.1 General 0.2 Process approach 0.3 Relationship with ISO 9004 0.3.1 IATF Guidance to ISO/TS 16949:2002 0.4 Compatibility with other management systems 0.5 Goal of this Technical Specification

Quality management systems - Requirements 1 Scope (Title only)

1.1 General 1.2 Application

2 Normative reference 3 Terms and definitions (See ISO 9000:2005)

3.1 Terms and definitions for the automotive industry

4 Quality Management System (Title only)

22 23 24 25 26 27

4.1 General requirements (Including a to f) 4.1.1 General requirements - supplemental 4.2 Documentation requirements (Title only) 4.2.1 General 4.2.2 Quality manual 4.2.3 Control of documents (Including a to g)

3 4 4 4 5 5

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

28 29

4.2.3.1 Engineering specifications 4.2.4 Control of records

5 6

30

4.2.4.1 Records retention

4.1.1 Records Retention

4.1.2 Records Retention

31 32 33

5 Management Responsibility (Title only)

5.1 Management commitment (Including a to e) 5.1.1 Process efficiency

6 6 6

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

34 35 36 37 38 39 40 41

5.2 Customer focus 5.3 Quality policy 5.4 Planning (Title only) 5.4.1 Quality objectives 5.4.1.1 Quality objectives - Supplemental 5.4.2 Quality management system planning 5.5 Responsibility, authority and communication (Title only) 5.5.1 Responsibility and authority

7 7 7 7 7 7 8 8

4.1.9 Customer Satisfaction

42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62

5.5.1.1 Responsibility for quality 5.5.2 Management representative 5.5.2.1 Customer representative 5.5.3 Internal communication 5.6 Management review (Title only) 5.6.1 General 5.6.1.1 Quality management system performance 5.6.2 Review input 5.6.2.1 Review input - supplemental 5.6.3 Review output

8 8 8 8 9 9 9 9 9 10 10 10 10 10 10 11 11 11 11 11 11

4.1.9 Customer Satisfaction 4.2.10 Management Review

6 Resource Management (Title only)

6.1 Provision of resources 6.2 Human resources (Title only) 6.2.1 General 6.2.2 Competence, awareness and training 6.2.2.1 Product design skills 6.2.2.2 Training 6.2.2.3 Training on the job 6.2.2.4 Employee motivation and empowerment 6.3 Infrastructure 6.3.1 Plant, facility and equipment planning

4.1.10 Internal Auditor Qualifications

63 64 65

6.3.2 Contingency plans 6.4 Work environment 6.4.1 Personal safety to achieve product quality

12 12 12

66 67

6.4.2 Cleanliness of premises

12 12 www.janroovers.com jan@janroovers.com

7 Product Realization (Title only)

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

68

7.1 Planning of product realization

12

4.2.2 Product Creation Process

69 70

7.1.1 Planning of product realization - Supplemental 7.1.2 Acceptance criteria

13 13

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

71 72

7.1.3 Confidentiality 7.1.4 Change control

13 13

4.2.16 "Forever" RequirementsExtended Enterprise

4.1.6 Design Changes

73 74

7.2 Customer-related processes (Title only) 7.2.1 Determination of requirements related to the product

13 13

75

7.2.1.1 Customer-designated special characteristics

14

4.2.3 Special Characteristics not Identified with Symbols 4.2.4 The Shield <S>; also <E> 4.2.5 The Diamond <D>

4.1.5 Special Characteristics

76 77 78 79

7.2.2 Review of requirements related to the product 7.2.2.1 Review of requirements related to the product Supplemental. 7.2.2.2 Organization manufacturing feasibility 7.2.3 Customer communication

14 14 14 14 4.2.17 Electronic Communication

80

7.2.3.1 Customer communication - Supplemental

15

4.2.16 "Forever" RequirementsExtended Enterprise

4.1.3 Electronic Communication 4.1.4 Shipment Notification System

81 82

7.3 Design and development (Title only) 7.3.1 Design and development planning

15 15

83

7.3.1.1 Multidisciplinary approach

15

4.2.3 Special Characteristics not Identified with Symbols 4.2.4 The Shield <S>; also <E> 4.2.5 The Diamond <D> 4.2.15 PFMEAs and Control Plans

84 85 86 87

7.3.2 Design and development inputs 7.3.2.1 Product design input 7.3.2.2 Manufacturing process design input 7.3.2.3 Special characteristics

15 16 16 16 4.2.3 Special Characteristics not Identified with Symbols 4.2.4 The Shield <S>; also <E> 4.2.5 The Diamond <D>

88

7.3.3 Design and development outputs

16

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

89

7.3.3.1 Product design outputs - Supplemental

17

4.2.3 Special Characteristics not Identified with Symbols 4.2.4 The Shield <S>; also <E> 4.2.5 The Diamond <D> 4.2.14 Process Approval

90

7.3.3.2 Manufacturing process design output

17

91 92

7.3.4 Design and development review 7.3.4.1 Monitoring

17 17

93

7.3.5 Design and development verification

18

4.2.7 Design Verification (DV) and Production Validation (PV)

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

94 95 96 97

7.3.6 Design and development validation 7.3.6.1 Design and development validation - Supplemental 7.3.6.2 Prototype program 7.3.6.3 Product approval process

18 18 18 18

4.2.7 Design Verification (DV) and Production Validation (PV)

4.1.3 Production Part Approval Process 4.1.8 Part Approval Process See DaimlerChrysler PPAP 4th Ed. See GM Customer Specifics for PPAP Customer Specifics (May 2006) (Section 5, Pages 15-26, March 31, 2006)

98

7.3.7 Control of design and development changes

19

4.1.2 Design Changes

4.1.6 Design Changes

99 100 101 102

7.4 Purchasing (Title only) 7.4.1 Purchasing process 7.4.1.1 Regulatory conformity 7.4.1.2 Supplier quality management system development

19 19 19 19 4.1.5 Supplier Quality Management System Development 4.1.11 Supplier Quality Management System Development 4.1.11.2 Customer acceptance of 2nd Party Audits and Criteria for Approval 4.1.11.3 Supplier Development of Specially Designated Small Suppliers 4.1.12 Heat Treating Processes

103 104 105 106 107 108 109 110

7.4.1.3 Customer-approved sources 7.4.2 Purchasing information 7.4.3 Verification of purchased product 7.4.3.1 Incoming product quality 7.4.3.2 Supplier monitoring 7.5 Production and service provision (Title only) 7.5.1 Control of production and service provision 7.5.1.1 Control plan

19 20 20 20 20 21 21 21

4.1.9 Customer Satisfaction

4.2.15 PFMEA's and Control Plans

4.2.6 Customer Signature on Control Plan

111 112

7.5.1.2 Work instructions 7.5.1.3 Verification of job set-ups

21 21

113

7.5.1.4 Preventive and predictive maintenance

22 www.janroovers.com jan@janroovers.com

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

114 115

7.5.1.5 Management of production tooling 7.5.1.6 Production scheduling

22 22

4.1.1 Management of production tooling

116 117 118 119 120

7.5.1.7 Feedback of information from service 7.5.1.8 Service agreement with customer 7.5.2 Validation of processes for production and service provision 7.5.2.1 Validation of processes for production and service provision - Supplemental 7.5.3 Identification and traceability

22 22 23 23 23

121 122

7.5.3.1 Identification and traceability - Supplemental 7.5.4 Customer property

23 24

123 124

7.5.4.1 Customer-owned production tooling 7.5.5 Preservation of product

24 24

4.2.13 Packaging, Shipping and Labeling

4.2.4 UPC Labeling for Commercial Service Applications

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

125 126

7.5.5.1 Storage and inventory 7.6 Control of monitoring and measuring devices

24 24

127 128 129 130 131 132 133 134 135 136 137

7.6.1 Measurement system analysis 7.6.2 Calibration/verification records 7.6.3 Laboratory requirements (Title only) 7.6.3.1 Internal laboratory 7.6.3.2 External laboratory

25 25 25 25 25 26 26 26 26 26 26

8 Measurement, analysis and improvement (Title)

8.1 General 8.1.1 Identification of statistical tools 8.1.2 Knowledge of basic statistical concepts 8.2 Monitoring and measurement (Title only) 8.2.1 Customer satisfaction

138

8.2.1.1 Customer satisfaction - Supplemental

26

4.1.4 Certification Body/Registrar Notification

4.1.9 Customer Satisfaction 4.2.8 Certification Body Notification and Certification Status - "New Business Hold - Quality"

139

8.2.2 Internal audit

27

4.2.9 Internal Quality Audits

140 141

8.2.2.1 Quality management system audit 8.2.2.2 Manufacturing process audit

27 27

4.2.9.1 Layered Process Audits 4.2.9.2 Special Process Assessments 4.2.9.2.1 Heat Treating Processes

4.1.12 Heat Treating Processes

142 143 144 145 146

8.2.2.3 Product audit 8.2.2.4 Internal audit plans 8.2.2.5 Internal auditor qualification 8.2.3 Monitoring and measurement of processes 8.2.3.1 Monitoring and measurement of manufacturing processes

27 27 28 28 28 www.janroovers.com jan@janroovers.com

4.1.10 Internal Auditor Qualifications

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

147

8.2.4 Monitoring and measurement of product

29

4.2.8 Continuing Conformance

148

8.2.4.1 Layout inspection and functional testing

29

4.2.6 Annual Layout

4.2.5 Layout Inspection and Functional Test

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

149

8.2.4.2 Appearance items

29

4.2.12 Appearance Masters

150

8.3 Control of nonconforming product

29

151 152 153 154

8.3.1 Control of nonconforming product - Supplemental 8.3.2 Control of reworked product 8.3.3 Customer information 8.3.4 Customer waiver

30 30 30 30

155 156 157 158 159 160 161

8.4 Analysis of data 8.4.1 Analysis and use of data 8.5 Improvement (Title only) 8.5.1 Continual improvement 8.5.1.1 Continual improvement of the organization 8.5.1.2 Manufacturing process improvement 8.5.2 Corrective action

30 31 31 31 31 31 31

4.2.10 Corrective Action Plan

162 163 164 165 166

8.5.2.1 Problem solving 8.5.2.2 Error-proofing 8.5.2.3 Corrective action impact 8.5.2.4 Rejected product test/analysis 8.5.3 Preventive action

32 32 32 32 32

167 168 169 170 171 172

Annex A (normative) Control plan A.1 Phases of the control plan A.2 Elements of the control plan

33 33 33 34

4.2.15 PFMEA's and Control Plans

4.2.6 Customer Signature on Control Plan

Bibliography

Other

4.2.1 Third-Party Registration Requirements

Other

4.1.7 Official Language Version

173

4.1.11.1 Customer acceptance of QS-9000:1998

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

174

4.2.11 e-CIMS

4.2.1 Third-Party Registration Requirements 4.2.2 General Procedures and Other Requirements (14)

175

176

4.2.3 ISO/TS 16949:2002 Applicability

177 178

4.2.7 GM Holdens-Specific Requirements 4.2.9 Controlled Shipping Level II (CSII) - Notice to Certification Body

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

er-Specific Requirements Matrix

October 2006

ents are regularly updated. Check www.iaob.org and the Customer's websites for the latest requirements

Ford Motor Company

Requirement Number and Title

1 Scope

2 References (24)

3 Definitions (24)

4.14 Planning of Product Realization 4.1 Scope of Quality Manual

4.2 Control of Documents JAN ROOVERS ASSOCIATES, INC. January 27, 2007 www.janroovers.com jan@janroovers.com

4.3 Engineering Specifications

4.4 Control of Records

4.7 Management Review 4.11 Plant, Facility and Equipment Planning

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.5 Customer Focus 4.38 Customer Satisfaction

4.14 Planning of Product Realization 4.14 Planning of Product Realization

4.6 Customer Representative

4.7 Management Review

4.8 Management Review Input

4.10 Provision of Resources 4.10 Provision of Resources 4.9 Training 4.10 Provision of Resources 4.9 Training 4.9 Training 4.10 Provision of Resources 4.11 Plant, Facility and Equipment Planning 4.12 Contingency Plans

4.13 Cleanliness of Premises

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.14 Planning of Product Realization

4.40 Monitoring and measurement of manufacturing processes 4.15 Acceptance Criteria

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.16 Customer related Processes

4.21 Special Characteristics

4.17 Review of requirements related to the product - supplemental 4.18 Manufacturing Feasibility

4.19 Customer communication supplemental

4.22 Design and Development Review 4.14 Planning of Product Realization 4.20 Multidisciplinary approach

4.21 Special Characteristics Table A - Qualification of All Product Characteristics

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.11 Plant, Facility and Equipment Planning 4.20 Multidisciplinary approach

4.20.1 Control Item (s) Fasteners 4.20.1.1 Mat'l Analysis - H-T Parts 4.20.1.2 Mat'l Analysis - Non H-T 4.20.1.3 Lot Traceability

4.22 Design and Development Review

4.14 Planning of Product Realization 4.23 Design and Development Verification 4.3 Engineering Specifications

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.22 Design and Development Review 4.24 Prototype Program 4.25 Product Approval Process See Ford Motor Company CustomerSpecific Requirements for use with PPAP 4th Edition, March 31, 2006

4.26 Regulations 4.27 Subcontractor Development

4.27.1 "Subcontractors to achieve...." 4.27.2 "Successful assessment of the subcontractor...."

4.28 Customer approved sources

4.29 Incoming Product Quality 4.30 Scheduling subcontractors 4.40 Monitoring and measurement of manufacturing processes

4.31 Job (Work) Instructions

4.32 Verification of Job Set-ups 4.33 Preventive Maintenance JAN ROOVERS ASSOCIATES, INC. January 27, 2007 www.janroovers.com jan@janroovers.com

4.40 Monitoring and measurement of manufacturing processes

4.34 Identification and traceability, preservation, storage and inventory

4.34 Identification and traceability, preservation, storage and inventory

4.34 Identification and traceability, preservation, storage and inventory

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.34 Identification and traceability, preservation, storage and inventory

4.35 Measurement systems analysis 4.36 Laboratory Requirements 4.36 Laboratory Requirements

4.37 Statistical tools and concepts 4.37 Statistical tools and concepts

4.38 Customer Satisfaction

4.39 Internal Quality Audits - Internal Auditor Qualifications

4.39.1 "Be trained and evaluated...." 4.39.2 "Or, have conducted...." - Internal Auditor Trainer Qualifications 4.39.3 "The training listed in 4.39.1...." 4.39.4 "Process and Product audits...."

Table B - Ongoing Process and Product Monitoring + Glossary 4.40 Monitoring and measurement of manufacturing processes JAN ROOVERS ASSOCIATES, INC. January 27, 2007 www.janroovers.com jan@janroovers.com

4.5 Customer Focus 4.41 Monitoring and measurement of product Table A - Qualification of All Product Characteristics Table B - Ongoing Process and Product Monitoring 4.42 Layout Inspection and Functional Testing

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

4.43 Appearance Items 4.44 Control of Nonconforming Product

4.41 Monitoring and measurement of product 4.45 Customer waiver

4.5 Customer focus

4.44 Control of Nonconforming Product

4.44 Control of Nonconforming Product

4.20 Multidisciplinary approach

Other

4.46 Automotive certification scheme for ISO/TS 16949:2002, Rules for Achieving IATF Recognition 4.47 Guidance for implementation of ISO/TS 16949

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

JAN ROOVERS ASSOCIATES, INC.

January 27, 2007

www.janroovers.com jan@janroovers.com

Vous aimerez peut-être aussi

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhanePas encore d'évaluation

- Automotive Quality Management System Manual: Century Metal Recycling LimitedDocument7 pagesAutomotive Quality Management System Manual: Century Metal Recycling LimitedsunilPas encore d'évaluation

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhanePas encore d'évaluation

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- System QSB First Step Fast Response PDFDocument19 pagesSystem QSB First Step Fast Response PDFPrabagarane RamachandranPas encore d'évaluation

- IATF 16949 - 2016-Exam Paper With AnswersDocument11 pagesIATF 16949 - 2016-Exam Paper With Answersrashwin singhPas encore d'évaluation

- IATF 16949 Mandatory Records and DocumentsDocument3 pagesIATF 16949 Mandatory Records and DocumentsSathyaprakash Hs100% (2)

- Turtle Diagrams ExplainedDocument3 pagesTurtle Diagrams ExplainedTatiana Rilo0% (1)

- APQP & PPAP Training ProgramDocument1 pageAPQP & PPAP Training Programbalakumar rajaram100% (1)

- ISO 9001 Management Review InputsDocument4 pagesISO 9001 Management Review Inputscesar jntPas encore d'évaluation

- Transitioning to IATF-16949:2016Document39 pagesTransitioning to IATF-16949:2016Joseph StephenPas encore d'évaluation

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduPas encore d'évaluation

- Layered Process Audits TemplateDocument3 pagesLayered Process Audits TemplatemajidrashidPas encore d'évaluation

- Iatf 3year Internal Audit PlanDocument6 pagesIatf 3year Internal Audit Planrajesh sharmaPas encore d'évaluation

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (2)

- ISO 9001 Key Process Turtle TemplateDocument1 pageISO 9001 Key Process Turtle TemplateShirleyPas encore d'évaluation

- Project Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneDocument2 pagesProject Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneNikita Fatah EntingPas encore d'évaluation

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Free Ts 16949 Audit ChecklistDocument8 pagesFree Ts 16949 Audit ChecklistKumaravel100% (1)

- ISO 9001 Quality Procedure Context of the OrganizationDocument1 pageISO 9001 Quality Procedure Context of the OrganizationKarim HakimPas encore d'évaluation

- Turtle Diagram & Its Usage in ISO 9001Document4 pagesTurtle Diagram & Its Usage in ISO 9001Gopalakrishnan100% (1)

- MAstering IATFDocument20 pagesMAstering IATFGyanesh_DBPas encore d'évaluation

- VDA 6.3 Process Audit and Checklist For The Car Industry - NimonikAppDocument6 pagesVDA 6.3 Process Audit and Checklist For The Car Industry - NimonikApprodolfo barbosaPas encore d'évaluation

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentPas encore d'évaluation

- Matrix CSRDocument6 pagesMatrix CSRDiego Jordan Hernández100% (1)

- Company Name: Engineering Location: Customer Name: Model Year / PlatformDocument45 pagesCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- ISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontDocument3 pagesISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontPratik Ardhapurkar100% (1)

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocPas encore d'évaluation

- QMS Audit Report Sample IatfDocument39 pagesQMS Audit Report Sample IatfMANGESH100% (2)

- Woxevekototaporilube PDFDocument2 pagesWoxevekototaporilube PDFharish puPas encore d'évaluation

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaPas encore d'évaluation

- MBO CQI 11 2020 2nd EditionDocument81 pagesMBO CQI 11 2020 2nd EditionHoang TanPas encore d'évaluation

- 2 Handout IATF 16949 Clause Map 2016 To 2009 PDFDocument5 pages2 Handout IATF 16949 Clause Map 2016 To 2009 PDFMohini Marathe100% (2)

- Process Audit Turtle DiagramDocument1 pageProcess Audit Turtle DiagramJoel Alcantara100% (3)

- Iatf Gap Analysis ToolDocument100 pagesIatf Gap Analysis ToolKumaravel100% (3)

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideRahul SharmaPas encore d'évaluation

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJPas encore d'évaluation

- Vda 63 Potenzialanalyse Version r3 EnglDocument18 pagesVda 63 Potenzialanalyse Version r3 EnglSudhagarPas encore d'évaluation

- ISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingDocument7 pagesISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingSudhagarPas encore d'évaluation

- 11.process Turtile DiagramDocument20 pages11.process Turtile DiagrammuthuselvanPas encore d'évaluation

- Iso Iatf Quality System Manual PDFDocument53 pagesIso Iatf Quality System Manual PDFKrishnamoorthyPas encore d'évaluation

- Process Name: QMS Process Process Name: QMS Process: Turtle DiagramDocument4 pagesProcess Name: QMS Process Process Name: QMS Process: Turtle DiagramLesly Les100% (1)

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaPas encore d'évaluation

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- GM 1927 36 Group D Elements BIQSDocument41 pagesGM 1927 36 Group D Elements BIQSVanessa GurrolaPas encore d'évaluation

- Assessment Manual ExamDocument19 pagesAssessment Manual ExamSaurabhPas encore d'évaluation

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoPas encore d'évaluation

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarPas encore d'évaluation

- IATF Quality Manual-GEC U-2 PDFDocument53 pagesIATF Quality Manual-GEC U-2 PDFNarendra100% (1)

- Apqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderDocument7 pagesApqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderAdrian Alcorta100% (1)

- Go digital with safety checklistsDocument84 pagesGo digital with safety checklists88No1FanPas encore d'évaluation

- CQI19 FormsDocument7 pagesCQI19 FormsEmre TekinPas encore d'évaluation

- Deptwise IATF RequirementDocument3 pagesDeptwise IATF RequirementShaili SharmaPas encore d'évaluation

- Cracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingD'EverandCracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingPas encore d'évaluation

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationD'EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationPas encore d'évaluation

- HOSTAFORMC2521Document6 pagesHOSTAFORMC2521hmp90Pas encore d'évaluation

- Plastic Omnium Implements 8D Non-Conformity SolutionDocument1 pagePlastic Omnium Implements 8D Non-Conformity Solutionhmp90100% (1)

- USE GRR DATASHEET AND REPORTDocument8 pagesUSE GRR DATASHEET AND REPORThmp90Pas encore d'évaluation

- VDA Volume Field Failure AnalysisDocument22 pagesVDA Volume Field Failure Analysishmp90Pas encore d'évaluation

- Process Verification Audit ChecklistDocument6 pagesProcess Verification Audit Checklisthmp90Pas encore d'évaluation

- Lean and Accounting: The Role of The CEO and CFO: Orest J. Fiume Retired Vice President - Finance The Wiremold CompanyDocument44 pagesLean and Accounting: The Role of The CEO and CFO: Orest J. Fiume Retired Vice President - Finance The Wiremold Companyjitendrasutar1975Pas encore d'évaluation

- Risk Based Thinking in ISO 9001 2015 PaperDocument5 pagesRisk Based Thinking in ISO 9001 2015 PapersjmpakPas encore d'évaluation

- VDA FMEA Process AnalysisDocument54 pagesVDA FMEA Process Analysishmp90Pas encore d'évaluation

- OutsourcedDocument4 pagesOutsourcedSupri YantoPas encore d'évaluation

- Teste - Inglês - 5 Ano-2biDocument2 pagesTeste - Inglês - 5 Ano-2bihmp90Pas encore d'évaluation

- Quality Management PDFDocument37 pagesQuality Management PDFhmp90100% (1)

- 4.2.2 Control of DocumentsDocument6 pages4.2.2 Control of Documentshmp90Pas encore d'évaluation

- John Deere Process Audit InstructionsDocument10 pagesJohn Deere Process Audit Instructionshmp90Pas encore d'évaluation

- Sample Size Control Limit DesignDocument10 pagesSample Size Control Limit Designhmp90Pas encore d'évaluation

- 4.1QM06 Process Flow ChartDocument2 pages4.1QM06 Process Flow Charthmp90100% (1)

- 32 QS-F-05 Audit Summary Report R1Document1 page32 QS-F-05 Audit Summary Report R1hmp90Pas encore d'évaluation

- Sample Size Control Limit DesignDocument10 pagesSample Size Control Limit Designhmp90Pas encore d'évaluation

- John Deere supplier survey guideDocument68 pagesJohn Deere supplier survey guidehmp90Pas encore d'évaluation

- ECR ECR Meeting ECN: PurposeDocument1 pageECR ECR Meeting ECN: Purposehmp90Pas encore d'évaluation

- Supplier Information Survey enDocument68 pagesSupplier Information Survey enhmp90Pas encore d'évaluation

- Red Flags SurveyDocument6 pagesRed Flags Surveyhmp90Pas encore d'évaluation

- Supplier Environmental Assessment SupplierDocument9 pagesSupplier Environmental Assessment Supplierhmp90Pas encore d'évaluation

- JDS-G223 Training AidDocument52 pagesJDS-G223 Training Aidhmp90Pas encore d'évaluation

- Ford Q1 and QOS Quality Operating System ScheduleDocument1 pageFord Q1 and QOS Quality Operating System Schedulehmp90Pas encore d'évaluation

- DS G223X1Document28 pagesDS G223X1hmp90Pas encore d'évaluation

- Ford Q1 and QOS Quality Operating System ScheduleDocument1 pageFord Q1 and QOS Quality Operating System Schedulehmp90Pas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- APQP Check ListDocument17 pagesAPQP Check Listhmp90Pas encore d'évaluation

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9060% (5)

- An Architect's Core ProcessDocument1 pageAn Architect's Core Processhmp90Pas encore d'évaluation

- Baseline Switch 2226 Plus: User GuideDocument92 pagesBaseline Switch 2226 Plus: User GuideOswaldoPas encore d'évaluation

- Preparedness of Interns For Hospital Practice Before and After An Orientation ProgrammeDocument6 pagesPreparedness of Interns For Hospital Practice Before and After An Orientation ProgrammeTanjir 247Pas encore d'évaluation

- Test 1: (Units 1-2)Document59 pagesTest 1: (Units 1-2)Elena MH100% (1)

- Sensors & Accessories User ManualDocument114 pagesSensors & Accessories User ManualAbrakain69Pas encore d'évaluation

- Reading - Zeeshan UsmaniDocument25 pagesReading - Zeeshan UsmaniHanif AbbasPas encore d'évaluation

- NLE 08 Test IDocument7 pagesNLE 08 Test IBrenlei Alexis NazarroPas encore d'évaluation

- 17-185 Salary-Guide Engineering AustraliaDocument4 pages17-185 Salary-Guide Engineering AustraliaAndi Priyo JatmikoPas encore d'évaluation

- Deflected Profile of A BeamDocument2 pagesDeflected Profile of A BeamPasindu MalithPas encore d'évaluation

- Sales & Distribution Management Presentation NewDocument35 pagesSales & Distribution Management Presentation NewVivek Sinha0% (1)

- Detect3D Fire and Gas Mapping Report SAMPLEDocument29 pagesDetect3D Fire and Gas Mapping Report SAMPLEAnurag BholePas encore d'évaluation

- RMET Score Sheet AnalysisDocument1 pageRMET Score Sheet AnalysisJohnPas encore d'évaluation

- Fire Exit Doors SizeDocument3 pagesFire Exit Doors SizeBerlin Andrew SionPas encore d'évaluation

- William Gilpin On Picturesque TravelDocument7 pagesWilliam Gilpin On Picturesque Travelcordia ghoshPas encore d'évaluation

- Tanbin Chowdhury ResumeDocument2 pagesTanbin Chowdhury ResumeTanbin RafeePas encore d'évaluation

- Past Progressive WorksheetDocument3 pagesPast Progressive WorksheetSantiago VargasPas encore d'évaluation

- Coventor Tutorial - Bi-Stable Beam Simulation StepsDocument45 pagesCoventor Tutorial - Bi-Stable Beam Simulation Stepsrp9009Pas encore d'évaluation

- Helical Axes of Skeletal Knee Joint Motion During RunningDocument8 pagesHelical Axes of Skeletal Knee Joint Motion During RunningWilliam VenegasPas encore d'évaluation

- Finding Buyers Leather Footwear - Italy2Document5 pagesFinding Buyers Leather Footwear - Italy2Rohit KharePas encore d'évaluation

- Compiled Lecture in Engineering Economy PDFDocument78 pagesCompiled Lecture in Engineering Economy PDFLJ dela PazPas encore d'évaluation

- IIT Ropar Calculus Tutorial Sheet 1Document2 pagesIIT Ropar Calculus Tutorial Sheet 1jagpreetPas encore d'évaluation

- Data & InformationDocument48 pagesData & InformationDave DearingPas encore d'évaluation

- Silver Bells Convent School Annual Examination 2021-22: Duration:2hours Subject: Science M. M.: 40 Class: IXDocument2 pagesSilver Bells Convent School Annual Examination 2021-22: Duration:2hours Subject: Science M. M.: 40 Class: IXAnkit SharmaPas encore d'évaluation

- Arduino Project: Smart Irrigation SystemDocument13 pagesArduino Project: Smart Irrigation SystemAleeza AnjumPas encore d'évaluation

- Semi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoDocument3 pagesSemi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoRuth Matriano100% (2)

- 6 Grade English Language Arts and Reading Pre APDocument3 pages6 Grade English Language Arts and Reading Pre APapi-291598026Pas encore d'évaluation

- PrimarySeries EN PDFDocument2 pagesPrimarySeries EN PDFRufus ElliotPas encore d'évaluation

- Black Platinum announces Dara East Gas Field PPoDDocument3 pagesBlack Platinum announces Dara East Gas Field PPoDWahyudin IlyasPas encore d'évaluation

- Guidance On Energy AuditsDocument6 pagesGuidance On Energy AuditsTesfahun Girma100% (1)

- Chapter 4.1 Decision Theory Part 2Document38 pagesChapter 4.1 Decision Theory Part 2erniePas encore d'évaluation

- English Test: Dash-A-Thon 2020 'The Novel Coronavirus Pandemic'Document5 pagesEnglish Test: Dash-A-Thon 2020 'The Novel Coronavirus Pandemic'William Phoenix75% (4)