Académique Documents

Professionnel Documents

Culture Documents

SAIC-K-2026 Rev 0

Transféré par

philipyapDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAIC-K-2026 Rev 0

Transféré par

philipyapDroits d'auteur :

Formats disponibles

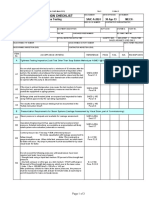

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Reciprocating Compressor Suction and Discharge Process Piping Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-K-2026

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA General Requirements 6.3 All reciprocating compressor cylinders operating at or within 5C of the saturated gas conditions at the compressor cylinder suction pressure shall take suction from a suction knock out drum. The knock out drum shall include the following: 1. An all stainless steel demister pad designed to limit liquid droplets at the outlet to 10 microns. 2. The knock out drum have automatic liquid drains and separate high and high-high level sensing instruments for alarm and shutdown. (NOTE: The automatic and manual liquid drains shall incorporate stainless steel internals. ) Pressure relief valves shall be installed on all knock out drums in accordance with SAES-J-600. The extension piping (inlet pipe) of the relief valve shall be kept to the minimum length possible, and provided with welded gussets at the attachment to the vessel. Suction piping downstream of the suction drums and pulsation suppression devices of compressors operating at or within 5C of the gas saturation temperature shall be heat traced, either with steam, electrically or a heat transfer fluid, and insulated to ensure that condensation of liquids does not occur. All piping, piping components and pulsation suppression equipment between the compressor cylinder suction flange up to and including the cylinder suction block valve shall be rated for the compressor discharge pressure. All process gas compressors shall be provided with vent piping on the suction and discharge sides of pulsation suppression devices, as close as practical to the cylinder nozzle connections. Vents (As described in item A2 above) shall be permanently connected to the flare header and shall include a check valve. A permanent spool-mounted stainless steel conical strainer 920 micron (20 mesh) of adequate strength shall be installed in all compressor cylinder inlet lines.. Note:Strainers in accordance with Standard Drawing AB-036764 may be used. A differential pressure gauge shall be installed to measure the differential pressure across the strainer

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-K-403, Para. 6.3

A2

SAES-K-403, Para. 6.3

A3

SAES-K-403, Para. 6.5 SAES-K-403, Para. 6.5

A4

A5

SAES-K-403, Para. 6.6

A6

SAES-K-403, Para. 6.7

A7

SAES-K-403 Para 6.9 SAES-K-403 Para 6.9

A8

A9

SAES-K-403 Para 6.10

A10

SAES-K-403 Para 6.10 SAES-K-403 Para 6.12

A single internally damped non-slam piston type check valve, specifically A11 designed for pulsating flow, is installed in the common discharge header downstream of all compressors

Page 1 of 2

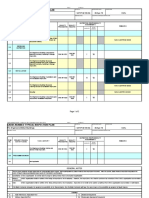

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Reciprocating Compressor Suction and Discharge Process Piping

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-K-2026

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE SAES-K-403 Para 6.13 SAES-K-403 Para 6.14 SAES-K-403 Para 6.15 SAES-K-403 Para 6.15

PASS

FAIL

N/A

RE-INSP DATE

A spectacle blind shall be installed in each compressor cylinder suction A12 and discharge line at a location adjacent to and on the cylinder side of the cylinder isolation valves. Each cylinder suction block valve shall be furnished with a inch bypass A13 line complete with a globe valve and spectacle blind to allow the compressor to be pressurized slowly A14 For hydrogen service (molecular weight less than 12), all block valves shall be of the double block arrangement

For compressors in hydrogen service (molecular weight less than 12), A15 the suction and discharge piping serving each cylinder shall use double block and bleed arrangements. All suction piping between each compressor cylinder pulsation suppression device and the first upstream vessel shall be chemically A16 cleaned. Note: Cleaning procedures shall be conducted after hydrotesting . A17 All vent lines to flare shall include a check valve to prevent the possibility of reverse flow from the flare header.

SAES-K-403 Para 6.17

SAES-K-403 Para 6.19

REMARKS:

REFERENCE DOCUMENTS: 1. SAES-K-403 -- Reciprocating Compressors, (30 June, 2003)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 2

Vous aimerez peut-être aussi

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanPas encore d'évaluation

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistSajid ShaikhPas encore d'évaluation

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanPas encore d'évaluation

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWPas encore d'évaluation

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06Pas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77Pas encore d'évaluation

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiPas encore d'évaluation

- Piping Components Spec for Low Temp ServiceDocument6 pagesPiping Components Spec for Low Temp ServiceFlorante NoblezaPas encore d'évaluation

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyPas encore d'évaluation

- 04 Samss 051 PDFDocument9 pages04 Samss 051 PDFJuned BagdadiPas encore d'évaluation

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioPas encore d'évaluation

- Saes G 006Document4 pagesSaes G 006AdnanAtifPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandPas encore d'évaluation

- Sabp D 002Document16 pagesSabp D 002engforever AdnanPas encore d'évaluation

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387Pas encore d'évaluation

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWPas encore d'évaluation

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelPas encore d'évaluation

- Active Doc ListDocument310 pagesActive Doc Listsalman1111aPas encore d'évaluation

- 32 Samss 017Document11 pages32 Samss 017naruto256Pas encore d'évaluation

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalPas encore d'évaluation

- Inspection Procedure for Determining Retirement Thickness of PipingDocument6 pagesInspection Procedure for Determining Retirement Thickness of Pipingmalika_00Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- 34 Samss 611Document8 pages34 Samss 611naruto256Pas encore d'évaluation

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinPas encore d'évaluation

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINPas encore d'évaluation

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.Pas encore d'évaluation

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanPas encore d'évaluation

- Saudi Aramco Exhaust Fan ChecklistDocument2 pagesSaudi Aramco Exhaust Fan ChecklistBilalPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinPas encore d'évaluation

- Saep 3101DDocument14 pagesSaep 3101DKhaja MoinPas encore d'évaluation

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387Pas encore d'évaluation

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaPas encore d'évaluation

- 32 Samss 016Document14 pages32 Samss 016naruto256Pas encore d'évaluation

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNAPas encore d'évaluation

- Saudi Aramco tank inspection requirementsDocument2 pagesSaudi Aramco tank inspection requirementssridhar100% (1)

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinPas encore d'évaluation

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshPas encore d'évaluation

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMIPas encore d'évaluation

- Preparing Saudi Aramco Engineering StandardsDocument9 pagesPreparing Saudi Aramco Engineering StandardsDemac SaudPas encore d'évaluation

- Mechanical Completion Procedure for HPCL Visakh ProjectDocument18 pagesMechanical Completion Procedure for HPCL Visakh ProjectLegend AnbuPas encore d'évaluation

- Saes B 005Document13 pagesSaes B 005Karu 2100% (1)

- Saep 115Document12 pagesSaep 115Anonymous 4IpmN7OnPas encore d'évaluation

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- SAIC-D-2007 Rev 2Document4 pagesSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULPas encore d'évaluation

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniPas encore d'évaluation

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocument11 pagesSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasinePas encore d'évaluation

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsD'EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Piping ChecklistDocument3 pagesSaudi Aramco Piping ChecklistphilipyapPas encore d'évaluation

- SAUDI ARAMCO Scraper Trap Installation ChecklistDocument9 pagesSAUDI ARAMCO Scraper Trap Installation ChecklistphilipyapPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechphilipyapPas encore d'évaluation

- Panel BoardDocument7 pagesPanel BoardphilipyapPas encore d'évaluation

- FanDocument7 pagesFanphilipyap100% (1)

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Fan Coil UnitsDocument3 pagesFan Coil UnitsphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapPas encore d'évaluation

- Resilent FlooringDocument7 pagesResilent FlooringphilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- Finish CarpentryDocument17 pagesFinish CarpentryphilipyapPas encore d'évaluation

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapPas encore d'évaluation

- Variable Air UnitDocument4 pagesVariable Air UnitphilipyapPas encore d'évaluation

- Low Voltage Wires and Cables SpecificationDocument9 pagesLow Voltage Wires and Cables SpecificationphilipyapPas encore d'évaluation

- Raceway Selection GuideDocument10 pagesRaceway Selection GuidephilipyapPas encore d'évaluation

- Chilled Water PumpDocument6 pagesChilled Water PumpphilipyapPas encore d'évaluation

- Exterior LightingDocument8 pagesExterior LightingphilipyapPas encore d'évaluation

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapPas encore d'évaluation

- Saudi Aramco Ductwork SpecificationsDocument5 pagesSaudi Aramco Ductwork SpecificationsphilipyapPas encore d'évaluation

- G.furniture & FixturesDocument2 pagesG.furniture & FixturesphilipyapPas encore d'évaluation

- Control SystemDocument21 pagesControl SystemphilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- SignageDocument4 pagesSignagephilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- 03210-Epoxy Coated Conc ReoDocument7 pages03210-Epoxy Coated Conc ReophilipyapPas encore d'évaluation

- Roof and Deck InsulationDocument3 pagesRoof and Deck InsulationphilipyapPas encore d'évaluation

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapPas encore d'évaluation

- Swimming PoolDocument4 pagesSwimming PoolphilipyapPas encore d'évaluation

- Floor MatsDocument3 pagesFloor MatsphilipyapPas encore d'évaluation

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapPas encore d'évaluation

- Product Data: DescriptionDocument2 pagesProduct Data: Descriptionjhon vargasPas encore d'évaluation

- 4.0 Radiometry PhotometryDocument25 pages4.0 Radiometry PhotometrynidharshanPas encore d'évaluation

- Design of Gap SlabDocument15 pagesDesign of Gap Slabvivek100% (1)

- IctionDocument7 pagesIctionFullo Flores MarvilonePas encore d'évaluation

- Part Wave Transformation-01Document6 pagesPart Wave Transformation-01Shivam PundirPas encore d'évaluation

- NanoCoat Leaflet PDFDocument1 pageNanoCoat Leaflet PDFProsun RoyPas encore d'évaluation

- Materials 15 05633 v2Document40 pagesMaterials 15 05633 v2Nadia ArroussePas encore d'évaluation

- Hysys 2020 PDFDocument357 pagesHysys 2020 PDFMagdy Saleh100% (4)

- P-17004 - Final Report - Bearing LP Turbine 3&4Document18 pagesP-17004 - Final Report - Bearing LP Turbine 3&4Komang Khrisna Satya NarayanaPas encore d'évaluation

- Chapter 14 Review: EM Wave Propagation FundamentalsDocument4 pagesChapter 14 Review: EM Wave Propagation FundamentalsNico RobinPas encore d'évaluation

- SCIE 10 - Chapter 1Document3 pagesSCIE 10 - Chapter 1Crishia joy J. EstrellaPas encore d'évaluation

- Atlas Copco Ewd 330 Manual PDFDocument6 pagesAtlas Copco Ewd 330 Manual PDFMahammadhusain100% (3)

- 2946 0263 02 Cooling Water QualityDocument6 pages2946 0263 02 Cooling Water QualityNicholas MurondaPas encore d'évaluation

- Offshore Fabrication NDT TestingDocument1 pageOffshore Fabrication NDT TestingRudolph RednosePas encore d'évaluation

- Study On Properties of Polymer Modified Mortars Used As Repair MaterialsDocument6 pagesStudy On Properties of Polymer Modified Mortars Used As Repair MaterialsIJSTE100% (1)

- Curie Temperature: Electronic StructureDocument21 pagesCurie Temperature: Electronic Structurejose carlos julca eleraPas encore d'évaluation

- Sae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickDocument9 pagesSae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickAliakbar SaifeePas encore d'évaluation

- Building Materials and Structures - 2/2020Document89 pagesBuilding Materials and Structures - 2/2020MPBGDPas encore d'évaluation

- Solutions Manual Chapter10Document41 pagesSolutions Manual Chapter10linearequPas encore d'évaluation

- June 2018 MS - Paper 1 OCR (A) Chemistry AS-LevelDocument18 pagesJune 2018 MS - Paper 1 OCR (A) Chemistry AS-LevelRunPas encore d'évaluation

- Geography NotesDocument4 pagesGeography NotesPassw0rdPas encore d'évaluation

- PNS 1990 2004 Hot-Dip Zinc-Coated Carbon Steel SheetsDocument23 pagesPNS 1990 2004 Hot-Dip Zinc-Coated Carbon Steel SheetsStandpro Testing CenterPas encore d'évaluation

- 8 - Chemical FloodingDocument76 pages8 - Chemical FloodingSyafrina Putri100% (3)

- Soil Mechanics Settlement Calculation Stress IncreasesDocument15 pagesSoil Mechanics Settlement Calculation Stress Increasestolgadurmaz100% (1)

- 1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineDocument19 pages1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineMohamed Nihaj100% (1)

- Hydrogen Reformer Furnace Failure PDFDocument10 pagesHydrogen Reformer Furnace Failure PDFJacekPas encore d'évaluation

- Simple distillation model analysisDocument9 pagesSimple distillation model analysisSheryll de GuzmanPas encore d'évaluation

- 1 Principles of Chemical Reactions 2Document21 pages1 Principles of Chemical Reactions 2prathap394Pas encore d'évaluation

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument10 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method ForPavan KumarPas encore d'évaluation

- Introductory Guide To Glass-Lined Steel EquipmentDocument8 pagesIntroductory Guide To Glass-Lined Steel EquipmentMahmoud Al HomranPas encore d'évaluation