Académique Documents

Professionnel Documents

Culture Documents

02525

Transféré par

uddinnadeemDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

02525

Transféré par

uddinnadeemDroits d'auteur :

Formats disponibles

SECTION 02525 PRECAST CONCRETE CURBS 00000000PART 1 - GENERAL 1.1 SECTION INCLUDES A. 1.

2 Precast concrete curbs and wheel stoppers as indicated on Drawings.

REFERENCES A. SAUDI ARABIAN STANDARDS ORGANIZATION (SASO) SASO 1248 SASO 1249 SASO 1252 SASO 1253 SASO 570 SASO 226 B. Precast Concrete Kerbs and Edgings Methods of Test for Precast Concrete Kerbs and Edgings Preparation of Concrete Specimens for Compressive Strength Test Determination of the compressive strength of concrete specimens. Sulfate Resistant Portland Cement Methods for Sampling of Concrete Aggregates

Conform to the applicable requirements specified in Section 03300 - CAST-INPLACE CONCRETE.

1.3

SUBMITTALS A. B. C. Shop drawings indicating all dimensions of modules proposed for use, including composition of the various elements. Copies of all test reports indicating mix components and test results in compliance with specification requirements. The Contractor shall submit samples of precast concrete curbs and stoppers for approval of quality, color, finish and texture.

1.4

QUALITY ASSURANCE A. Conform to the applicable requirements of the following Divisions: 1. 2. Division 2 - SITEWORK Division 3 - CONCRETE For the requirements of materials and workmanship, testing and quality assurance.

ITCC in Riyadh Residential Complex J10-13300

02525-1

Precast Concrete Curbs

PART 2 - PRODUCTS 2.1 MATERIALS A. B. Materials used shall conform to the requirements of Section 03200 CONCRETE REINFORCEMENT and Section 03300 - CAST-IN-PLACE CONCRETE. Precast Concrete Curbs: 1. Construction: Manufacture precast curbs conforming to SASO 1248 and 1249 fabricated of Class 30 concrete conforming to the requirements of DIVISION 3 CONCRETE using Type V Portland cement conforming to SASO 143 or ASTM C 150. Dimensions: As indicated on Drawings. Fabrication: Concrete curbs shall be manufactured by hydraulic pressing in an approved machine using concrete produced in a fully automatic batching plant. Finished elements shall be of sound appearance with clean planar faces, free from segregation, honeycombing, pits, broken corners and other defects. Bullnoses and curved faces shall be of constant radius with a smooth change from radius to plan face. Manufacturing tolerances shall be 3 mm in any one dimension and end faces shall be truly perpendicular to the base.

2. 3.

C.

Precast Concrete Wheel Stoppers: 1. Construction: Manufactured from 30 MPa concrete using type I cement conforming to the requirements of DIVISION 3 - CONCRETE. Size and shape shall be as shown on the Drawings or as approved by the Engineer. Provide the finished elements with sound appearance and clean planar faces, free from segregation, honeycombing, pits, broken corners and other defects. Grout: As approved by the Engineer. a. Construction: High strength, non-shrink cementitious grout, ready-touse, supplied in powder form and requires only on-site addition of water to produce non-shrink grout of predictable performance.

2.

3.

Fabrication: Refer to fabrication of reinforced precast concrete curbs for Wadi.

ITCC in Riyadh Residential Complex J10-13300

02525-2

Precast Concrete Curbs

PART 3 - EXECUTION 3.1 INSTALLATION A. B. Elements shall be set out to lines and grades as shown. Under no circumstances shall levels be set by direct measurement. Foundation shall be excavated to the grades and sections shown and fully compacted and rolled to a smooth surface. Concrete shall not be placed until the foundation has been approved. Elements shall be laid either directly on a wet concrete base or on 1-3 cement-sand mortar bed, 20 mm thick on a previously laid concrete base. Base shall be constructed of Class 20 concrete conforming to the requirements of Section 03300-CAST-IN-PLACE CONCRETE. After elements have been laid, continuous concrete backing shall be poured. Backing concrete shall be of Class 20 conforming to the requirements of Section 03300 - CAST-IN-PLACE CONCRETE. Joints between curbs and paving tiles shall have a width of 4 mm, filled with 1-1 cement-sand mortar with one fifth hydrated lime and sufficient water to make the mixture plastic and easily smoothed and finished. A grooving tool shall be used to produce a smooth semi-circular groove not more than 3 mm deep in all joints. Precast Concrete Wheel Stoppers: Unless otherwise indicated on Drawings, secure wheel stops to the asphalt concrete surfaces using 19 mm diameter galvanized steel dowels embedded in precast units (minimum 2 dowels/unit). Adjust length of dowels so as not to penetrate the precast double-tee structures. Grout dowels using the approved cementitious grout.

C.

D.

E.

F. G.

3.2

TOLERANCES A. Units shall be laid to the lines and grades shown on Drawings with a tolerance of plus or minus 3 mm. END OF SECTION

ITCC in Riyadh Residential Complex J10-13300

02525-3

Precast Concrete Curbs

Vous aimerez peut-être aussi

- BS IndexDocument11 pagesBS IndexShirleyLiuPas encore d'évaluation

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarPas encore d'évaluation

- DMRB All Parts Jan 2012Document492 pagesDMRB All Parts Jan 2012vijaya guniputiPas encore d'évaluation

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselPas encore d'évaluation

- SH 7-83-Soil Suitability For Earthworks-MCV PDFDocument53 pagesSH 7-83-Soil Suitability For Earthworks-MCV PDFADF3000Pas encore d'évaluation

- ADG - Interlock Pavers (Installation Guidlines)Document12 pagesADG - Interlock Pavers (Installation Guidlines)mc3lawrinPas encore d'évaluation

- Highway PracticalDocument84 pagesHighway PracticalHassan AliPas encore d'évaluation

- Determination of The International Roughness Index (IRI) Using ARRB TR Walking ProfilerDocument9 pagesDetermination of The International Roughness Index (IRI) Using ARRB TR Walking Profilerतिप्लोकाची तिरुनचिपल्ली केरकेट्टा100% (1)

- Emulsified Asphalt: Standard Specification ForDocument1 pageEmulsified Asphalt: Standard Specification ForFRANZ RICHARD SARDINAS MALLCOPas encore d'évaluation

- BS 1881-5 Part 5 Methods of Testing Hardened Concrete For Other Than Strength PDFDocument15 pagesBS 1881-5 Part 5 Methods of Testing Hardened Concrete For Other Than Strength PDFjunqiangdong100% (1)

- Method B7 - The Determination of The Treton Impact Value of Aggregate.Document3 pagesMethod B7 - The Determination of The Treton Impact Value of Aggregate.GUO LEI100% (1)

- Masonry Section 13Document40 pagesMasonry Section 13Basker BaluPas encore d'évaluation

- Astm C 936-2007Document2 pagesAstm C 936-2007Nikolay DrumevPas encore d'évaluation

- Volucon+White+Paper+21062018r-5+ 1Document10 pagesVolucon+White+Paper+21062018r-5+ 1Giacgiomb100% (1)

- ASTM C 109 C109M-16aDocument10 pagesASTM C 109 C109M-16aMohammed AliPas encore d'évaluation

- Maufacturing of Dry Lean ConcreteDocument1 pageMaufacturing of Dry Lean ConcreteairpavsetPas encore d'évaluation

- CL 14 I Mastic Asphalt LayingDocument1 pageCL 14 I Mastic Asphalt LayingRayudu VVSPas encore d'évaluation

- Is 5512 1983 PDFDocument17 pagesIs 5512 1983 PDFBijaya RaulaPas encore d'évaluation

- C685C685M 14Document9 pagesC685C685M 14Alvin BaraPas encore d'évaluation

- Guide For Concrete Construction Quality Systems in Conformance With ISO 9001Document2 pagesGuide For Concrete Construction Quality Systems in Conformance With ISO 9001anigz570Pas encore d'évaluation

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972Pas encore d'évaluation

- Astm C 1064-2017Document3 pagesAstm C 1064-2017Mohammed AliPas encore d'évaluation

- 03AggregatesRID-ENSTP 2016Document95 pages03AggregatesRID-ENSTP 2016Jimmy RostantPas encore d'évaluation

- 05-15 QCS 2014Document14 pages05-15 QCS 2014Raja Ahmed Hassan100% (2)

- Key - QC Buildings TestDocument4 pagesKey - QC Buildings TestKhurram ShehzadPas encore d'évaluation

- Standards For Cement, Aggregate, Gupsum. Definitions, Requirements and Test MethodsDocument33 pagesStandards For Cement, Aggregate, Gupsum. Definitions, Requirements and Test MethodsfoxmancementPas encore d'évaluation

- Delta Waterproofing - Method StatementDocument2 pagesDelta Waterproofing - Method Statementbilly wuPas encore d'évaluation

- Sec 400 MORTH Orange Book Fifth Edition Searchable 2013Document9 pagesSec 400 MORTH Orange Book Fifth Edition Searchable 2013tally3tallyPas encore d'évaluation

- Plain and Reinforced Concrete - Code of Practice (Fourth Revision)Document107 pagesPlain and Reinforced Concrete - Code of Practice (Fourth Revision)nafees92Pas encore d'évaluation

- Installation: Floor TileDocument17 pagesInstallation: Floor TileAli SaifPas encore d'évaluation

- Concrete Temp QCS 2014Document1 pageConcrete Temp QCS 2014alden cayagaPas encore d'évaluation

- Method Statement Floor and Speciality JointsDocument10 pagesMethod Statement Floor and Speciality JointsJamsheed Ap KadangodPas encore d'évaluation

- GFRCDocument11 pagesGFRCMhmd AbdoPas encore d'évaluation

- Specs-Pavement MarkingsDocument4 pagesSpecs-Pavement MarkingsAnsar Bedharudeen100% (1)

- Base CourseDocument3 pagesBase Courseprobook450_ehsanPas encore d'évaluation

- Preprufe 300R & 160R PDFDocument6 pagesPreprufe 300R & 160R PDForlandomcortezPas encore d'évaluation

- Properties Concrete Dune SandDocument6 pagesProperties Concrete Dune SandAlanSamPas encore d'évaluation

- Is2720 Part09Document6 pagesIs2720 Part09anvesh_kumar_16Pas encore d'évaluation

- PavementDocument11 pagesPavementJus CamungaoPas encore d'évaluation

- Series 4000 - Bituminous Layers and SealsDocument52 pagesSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- 9686-CPP-NCR - 0017 - Uncontrolled BackfillingDocument3 pages9686-CPP-NCR - 0017 - Uncontrolled BackfillingANIL PLAMOOTTIL100% (1)

- Letter To KSEBDocument1 pageLetter To KSEBSujithPas encore d'évaluation

- Astm C1586Document3 pagesAstm C1586Lydia100% (1)

- R0030 Manual of Aggregate and Concrete Testing1Document34 pagesR0030 Manual of Aggregate and Concrete Testing1Z MPas encore d'évaluation

- C1582C1582M-Aditivos Inhibidores de CorrosionDocument10 pagesC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanPas encore d'évaluation

- Production and Implementation of Asphalt Mixtures Designed With Superpave SystemDocument40 pagesProduction and Implementation of Asphalt Mixtures Designed With Superpave SystemAymanAlodainiPas encore d'évaluation

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliPas encore d'évaluation

- Aci 211.2 - 1998 PDFDocument18 pagesAci 211.2 - 1998 PDFBhavanishankar ShettyPas encore d'évaluation

- Testing Aggregates: BS 812: Part 120: 1989Document10 pagesTesting Aggregates: BS 812: Part 120: 1989AmanPas encore d'évaluation

- BS For Highways TestsDocument12 pagesBS For Highways Testsdbg2012Pas encore d'évaluation

- Sampling Bituminous Materials: Standard Method of Test ForDocument3 pagesSampling Bituminous Materials: Standard Method of Test ForEvert RiveraPas encore d'évaluation

- Conventional Block Pavement DesignDocument5 pagesConventional Block Pavement DesignPeyman MznPas encore d'évaluation

- C156 PDFDocument5 pagesC156 PDFMateriales FicPas encore d'évaluation

- Floor Surface Profile Measurement BrochureDocument2 pagesFloor Surface Profile Measurement BrochureErzaPas encore d'évaluation

- TDS005-Grade 2 and ASTM A307 BoltingDocument2 pagesTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthPas encore d'évaluation

- Supervising Highway Engineer: Passbooks Study GuideD'EverandSupervising Highway Engineer: Passbooks Study GuidePas encore d'évaluation

- Structural Analysis 1: Statically Determinate StructuresD'EverandStructural Analysis 1: Statically Determinate StructuresPas encore d'évaluation

- 02515Document5 pages02515uddinnadeemPas encore d'évaluation

- SECTION 8 (Incidental Construction) (FINAL) PDFDocument119 pagesSECTION 8 (Incidental Construction) (FINAL) PDFMohammad SahmoudPas encore d'évaluation

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemPas encore d'évaluation

- Electrical Engineer CV (M Bilal M)Document4 pagesElectrical Engineer CV (M Bilal M)uddinnadeemPas encore d'évaluation

- Generator MaintenanceDocument24 pagesGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (9)

- Electrical Engineer CV (M Bilal M)Document4 pagesElectrical Engineer CV (M Bilal M)uddinnadeemPas encore d'évaluation

- FireDocument8 pagesFireuddinnadeemPas encore d'évaluation

- Green Grounding ManualDocument23 pagesGreen Grounding Manualuddinnadeem100% (1)

- XXXXXX: Voltage Drop& Cable Sizing CalculationsDocument5 pagesXXXXXX: Voltage Drop& Cable Sizing CalculationsPradeesh Vijayan (v.prathi)Pas encore d'évaluation

- Nicet AlarmsDocument23 pagesNicet AlarmsWERMERMPas encore d'évaluation

- Lightning ProtectionDocument3 pagesLightning ProtectionuddinnadeemPas encore d'évaluation

- Submittal ReviewDocument22 pagesSubmittal ReviewuddinnadeemPas encore d'évaluation

- Industrial Visit - QuestiannaireDocument5 pagesIndustrial Visit - QuestiannaireMj Payal70% (10)

- SECTION 01300 Submittals 1.01 General: Vocational Training CenterDocument11 pagesSECTION 01300 Submittals 1.01 General: Vocational Training CenterulyjohnignacioPas encore d'évaluation

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemPas encore d'évaluation

- 15400Document27 pages15400uddinnadeemPas encore d'évaluation

- Where Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisingDocument1 pageWhere Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisinguddinnadeemPas encore d'évaluation

- 3 CH 2Document20 pages3 CH 2Mary HarrisonPas encore d'évaluation

- DimnjaciDocument70 pagesDimnjacijack-bcPas encore d'évaluation

- 16716-Voice & Data SystemDocument13 pages16716-Voice & Data SystemuddinnadeemPas encore d'évaluation

- 16721-Fa SystemDocument17 pages16721-Fa SystemuddinnadeemPas encore d'évaluation

- 16504-Home Automation SystemDocument23 pages16504-Home Automation SystemuddinnadeemPas encore d'évaluation

- 16715-Voice & Data CablingDocument16 pages16715-Voice & Data Cablinguddinnadeem100% (1)

- 16720ip - Telephone SystemDocument24 pages16720ip - Telephone SystemuddinnadeemPas encore d'évaluation

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemPas encore d'évaluation

- GroundingDocument6 pagesGroundinguddinnadeemPas encore d'évaluation

- Panel BoardDocument7 pagesPanel BoarduddinnadeemPas encore d'évaluation

- 16461-Dry Type TransformerDocument8 pages16461-Dry Type TransformeruddinnadeemPas encore d'évaluation

- LightingDocument13 pagesLightinguddinnadeemPas encore d'évaluation

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemPas encore d'évaluation

- GroundingDocument6 pagesGroundinguddinnadeemPas encore d'évaluation

- 16441-Lv SWGR & SWBDDocument7 pages16441-Lv SWGR & SWBDuddinnadeemPas encore d'évaluation

- Alloy 34MnB5Document2 pagesAlloy 34MnB5Javo RodriguezPas encore d'évaluation

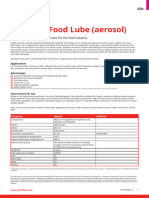

- ROSADO - FT - 8374 - TDS - GB - en - Interflon - Food - Lube - AerosolDocument1 pageROSADO - FT - 8374 - TDS - GB - en - Interflon - Food - Lube - AerosolNyriamPas encore d'évaluation

- ITR HV CablesDocument2 pagesITR HV CablesYulianti Rahmi PurnamawatiPas encore d'évaluation

- How The IPC 2221A Standard Impact PCB Insulation DesignDocument9 pagesHow The IPC 2221A Standard Impact PCB Insulation DesignjackPas encore d'évaluation

- CE 370 Tutorial Note 4Document5 pagesCE 370 Tutorial Note 4Ibrahim AlmohannaPas encore d'évaluation

- Low Cost Eco Friendly Building Material A Case Study in Ethiopia With Cover Page v2Document6 pagesLow Cost Eco Friendly Building Material A Case Study in Ethiopia With Cover Page v2Sossi SosPas encore d'évaluation

- R.C.C Beam DesignDocument2 pagesR.C.C Beam DesignPankaj Chopra64% (14)

- Technical Textiles - Composites - PDF Test 25 PDocument25 pagesTechnical Textiles - Composites - PDF Test 25 Psayedmorsy100% (1)

- LIGMANDocument1 pageLIGMANDessouki SamakPas encore d'évaluation

- Dual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresMOhammed PatelPas encore d'évaluation

- Seminar ReportDocument20 pagesSeminar ReportAbhishek ThakurPas encore d'évaluation

- BNi-7 TDSDocument2 pagesBNi-7 TDSQuang Thuận NguyễnPas encore d'évaluation

- False CeilingDocument33 pagesFalse CeilingAbhay SinghPas encore d'évaluation

- Bom MepDocument100 pagesBom Mepvorleak77777Pas encore d'évaluation

- Grinding Burn TestDocument55 pagesGrinding Burn TestsubbuPas encore d'évaluation

- MCQ - Cement and Concrete - 1Document4 pagesMCQ - Cement and Concrete - 1divithPas encore d'évaluation

- Sample Cost EstimationDocument2 408 pagesSample Cost Estimationarif khanPas encore d'évaluation

- Dupont Compounds UL 1446Document20 pagesDupont Compounds UL 1446alex696Pas encore d'évaluation

- Other Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979Document1 pageOther Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979apurv bhartiPas encore d'évaluation

- Overview On Metamaterial - History, Types and Applications - ScienceDirectDocument3 pagesOverview On Metamaterial - History, Types and Applications - ScienceDirectHOD PhysicsPas encore d'évaluation

- Bobbinarticle PDFDocument6 pagesBobbinarticle PDFhuynh thi y viPas encore d'évaluation

- FCO Wall VentilatorDocument2 pagesFCO Wall VentilatorkimcucspktPas encore d'évaluation

- Sikafiber Ppm-12: Polypropylene Fibers For Mortar and ConcreteDocument3 pagesSikafiber Ppm-12: Polypropylene Fibers For Mortar and ConcreteAli KayaPas encore d'évaluation

- Solid Block Manufacturing ProcessDocument4 pagesSolid Block Manufacturing Processa paul jayakumarPas encore d'évaluation

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division) Grasim Industries Ltd. (Chemical Division)Document3 pagesDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division) Grasim Industries Ltd. (Chemical Division)GAURAV AHUJAPas encore d'évaluation

- Catalogo Top ZaDocument148 pagesCatalogo Top Zamoy16Pas encore d'évaluation

- Process Industry Practices Insulation: PIP INSH2000 Installation of Hot Service Insulation SystemsDocument15 pagesProcess Industry Practices Insulation: PIP INSH2000 Installation of Hot Service Insulation Systemsantonio diazPas encore d'évaluation

- Tle 7 2nd Quarter ExamDocument3 pagesTle 7 2nd Quarter ExamRaymond Alvarez Arabejo100% (2)

- Byk - P 4102 - TDS - 1643511993Document2 pagesByk - P 4102 - TDS - 1643511993swapon kumar shillPas encore d'évaluation

- QAP 3.0 3 Surface Inspection Acceptance CriteriaDocument6 pagesQAP 3.0 3 Surface Inspection Acceptance CriteriaPablo OchoaPas encore d'évaluation