Académique Documents

Professionnel Documents

Culture Documents

Turbine Meter Nuflo

Transféré par

Jaime SeguraDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Turbine Meter Nuflo

Transféré par

Jaime SeguraDroits d'auteur :

Formats disponibles

MEASUREMENT SYSTEMS

NUFLO

Liquid Turbine Flowmeters

Accurate Flow Measurement

In 1957, this flowmeter was developed with a tungsten-carbide shaft and bearing to withstand the rugged conditions of the oil field. Over the years, it has earned an unsurpassed reputation for withstanding severe punishment while maintaining operational and measurement integrity. Today, it remains a bestseller among Camerons NUFLO liquid measurement products. NUFLO turbine flowmeters indicate flow rate and measure total throughput of a liquid line. As liquid flows through the meter and over the rotor, the rotor turns at a speed that is directly proportional to the flow rate. A magnetic pickup senses the rotor blades as they pass and generates an electrical (sine wave) signal. These electrical pulses are then transmitted to the flow measurement readout equipment.

Benefits

Accurate and repeatable measurement An economical solution for turbine flowmeter applications Easy installation and a variety of end connections Minimum maintenance required Long service life even in severe applications

First Class Design Delivers First Class Performance

1. Permanent 1-in. MNPT conduit connection is standard. 2. ROTOR is pitched and pre-calibrated to determine accuracy. 3. END CONNECTIONS available: flanged, threaded, grooved, EZ-IN, and WECO 1502. 4. FLOW VANES increase performance at low rates. 5. FLOW VANE HUB supports rotor assembly.

6. ROTOR SHAFT, BEARINGS, AND THRUST BALL are made of tungsten carbide for long service without lubrication other than by the process liquid. 7. RETAINING RINGS make disassembly easy. 8. FLOWMETER BODY is sturdy, one-piece construction, precision finished.

Applications

Cameron offers turbine flowmeters in a variety of end connections and accuracy levels. Typical applications are: Water-injection measurement Heater treaters Test and production separators Disposal wells CO2 injection Steam generator fuel and feed water Metering liquid fertilizer Water, fuel, and chemical measurement in plant settings Chemical tank loading and unloading Measuring liquid propane Insitu mining and leaching

Accuracy

Cameron offers two meter grades to satisfy various linearity requirements. The Standard Grade meter is a cost-effective solution for applications equiring accuracy of 1% or less. For higher accuracy, an Industrial Grade meter can be used. Still greater accuracy may be achieved if the expected flow range is specified.

Meter Grade Linearity Repeatability

Standard* Industrial* Enhanced accuracy

1% of reading 0.5% of reading Consult factory

0.05% 0.02% Consult factory

* For 3/8 in. meters, linearity is 2% of reading (standard) and 1% of reading (industrial).

MEASUREMENT SYSTEMS

Temperature Range (magnetic pickup)

Temperature Range Flowmeter Size

Meter Size Selection

Flowmeter size selection should be based on the instantaneous flow rate of the line into which the meter will be mounted, and on the meter pressure drop. Meter size should never be based on the nominal piping size of the installation. Refer to the Linear Flow Range chart below and the pressure drop curve on page 7 for meter size selection. The meter will remain accurate at flow rates higher than its rating, but over-ranging a meter for long periods can cause excessive bearing wear and pressure drop and shorten the life span of the meter. NUFLO flowmeters can be over-ranged by 10% for short periods without damage.

Standard Medium

-67 to 250F -55 to 107C -67 to 250F -55 to 121C -67 to 450F -55 to 232C

3/8 in. through 3/4 in. 7/8 in. through 8 in. all sizes

Note: Consult Cameron's Measurement Systems division for any use of turbine flowmeters below -20F (-29C) or above 250F (121C).

Compliances

CSA certified for hazardous areas, Class I, Div. 1, Groups A, B, C, D Meters with maximum working pressures below 7500 psi are compliant with ANSI 12.27.01-2003 Single Seal EZ-IN meters and WECO 1502 union meters available with CE mark for Pressure Equipment Directive (PED, 97/23/EC)

Installation

The meter should be installed so that the arrow on the meter body corresponds to the flow direction of the line. A 10-diameter length of straight unrestricted pipe must be upstream and a 5-diameter length of straight unrestricted pipe must be downstream of the flowmeter. Both pipe sections should be the same nominal pipe size as the flowmeters end connection. Throttling/control valves should be located downstream of the flowmeter.

Magnetic Pickup/Electronics Installation

Materials of Construction

Meter Body (Standard) Meter Body (High Pressure) Vanes Rotor Shaft & Bearings Grade 316L stainless steel* A286 stainless steel* Grade 316L stainless steel CD-4MCu Tungsten carbide

* Traceability of pressure-containing components available on request.

Optional Materials

Shaft

Binderless carbide for enhanced corrosion resistance to selected chemicals.

Shaft & Bearings

The meters permanent conduit connection has 1-in. MNPT threads for attaching an electronic readout instrument. The conduit connection is designed for use with a 5/8-18 threaded magnetic pickup, sold separately by Cameron.

Silver brazing to withstand temperatures to 550F and chemicals that attack epoxy bonding bearing materials.

Rotor

Nickel plating for enhanced corrosion resistance to selected chemicals (especially acids that corrode ferrous materials).

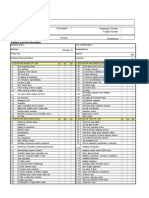

Linear Flow Range (1, 2, 3)

Flowmeter size (3) mm Nominal (2) Calibration Factor GPM m /HR

3

BPD

Pulses Gallon

Pulses x 1000/m3

Maximum Output Frequency Pulses/Sec

P at Maximum Flow (2) psi kPa

3/8 3/8 1/2 3/4 7/8 1 1-1/2 2 3 4 6 8

1. 2. 3.

10 10 13 19 22 25 38 51 76 102 152 203

0.3 - 3 0.3 - 3 0.75 - 7.5 2 - 15 3 - 30 5 - 50 15 - 180 40 - 400 80 - 800 100 - 1200 250 - 2500 350 - 3500

0.068 - 0.68 0.068 - 0.68 0.17 - 1.70 0.45 - 3.41 0.68 - 6.81 1.14 - 11.36 3.41 - 40.88 9.09 - 90.85 18.16 - 181.66 22.71 - 272.55 56.78 - 567.82 79.49 - 794.94

10 - 100 10 - 100 25 - 250 68 - 515 100 - 1000 170 - 1700 515 - 6000 1300 - 13000 2750 - 27500 3400 - 41000 8600 - 86000 12000 - 120000

22000 22000 14500 2950 2350 900 325 55 57 30 7 3

(5812) (5812) (3830) (780) (621) (238) (86) (14.5) (15.2) (7.9) (1.8) (.8)

1100 1100 1815 740 1175 750 975 365 760 600 290 175

4.0 4.0 12.0 18.0 20.0 20.0 16.0 22.0 20.0 10.0 10.0 6.0

28 28 83 124 138 138 110 152 138 69 6 41

The linear flow range of liquids with non-lubricating characteristics is limited to the upper 60% of rating. Based on water. Consult Cameron's Measurement Systems division for engineering assistance with applications involving liquids of viscosities greater than 5 centistokes on 3/8-in. through 3/4-in. meters.

End Connections

NUFLO flowmeters are available in a variety of end connections: threaded grooved flanged EZ-IN WECO 1502

Flowmeter Size x End Connection Size Working Pressure psi MPa in. Length mm

3/8 x 1 in. 1/2 x 1 in. 3/4 x 1 in. 7/8 x 1 in. 1 x 1 in. 1-1/2 x 1-1/2 in. 1-1/2 x 2 in. 2 x 2 in. 3 x 3 in. 4 x 4 in.

7500 7500 7500 5000 5000 5000 5000 5000 1000 1000

51.7 51.7 51.7 34.5 34.52 34.5 34.5 34.5 6.9 6.9

4.0 4.0 4.0 4.0 4.0 6.0 6.0 10.0 12.5 12.0

102 102 102 102 102 152 152 254 318 305

Threaded (NPT) End Connection

Threaded meter sizes range from 3/8-in. to 2-in. Meter sizes from 3/8-in. to 1-in. pipe all have 1-in. NPT end connections to simplify meter size changes. All meter sizes other than the 2-in. have male threads.

MEASUREMENT SYSTEMS

Flanged End Connection

Turbine flowmeters with flanged end connections are available in both raised-face (RF) models and ring-type joint (RTJ) models. Flanged NUFLO meters are constructed with carbon steel or stainless steel slip-on flanges or machined from a single block of stainless steel. Slip-on flanges are welded to the outside of the meter to ensure that the flange never comes into contact with the process fluid. The flanges are designed to mate with ANSI B16.5 flanges. Contact the factory for availability of materials and construction types for a desired meter size.

Flowmeter Size x End Connection Size

Flange Pressure Rating

in.

Length mm

3/8 x 1/2 in. 1/2 x 1/2 in. 3/4 x 3/4 in. 7/8 x 1 in. 1 x 1 in. 1-1/2 x 1-1/2 in. 2 x 2 in. 3 x 3 in.

150, 300, 600 # 900, 1500, 2500 # 150, 300, 600 # 900, 1500, 2500 # 150, 300, 600 # 900, 1500, 2500 # 150, 300, 600, 900, 1500, 2500 # 150, 300, 600, 900, 1500, 2500 # 150, 300, 600, 900, 1500, 2500 # 150, 300, 600, 900, 1500, 2500 # 150, 300, 600, 900 # 1500 # 2500 # 150, 300, 600, 900 # 1500 # 2500 # 150, 300, 600, 900 # 1500 # 150, 300, 600, 900 #

5.0 6.25 5.0 6.25 5.0 6.25 6.0 6.0 7.0 8.5 10.0 12.0 15.0 12.0 14.0 16.5 12.0 16.0 12.0

127.0 158.8 127.0 158.8 127.0 158.8 152.4 152.4 177.8 215.9 254.0 304.8 381.0 304.8 355.6 419.1 304.8 406.4 304.8

4 x 4 in.

6 x 6 in. 8 x 8 in.*

*Contact factory for other flange classifications above 900 #.

Maximum Working Pressure

Flange

Pressure Rating

Design-Operating

Temperature Range

Flange Material

Carbon Steel Stainless Steel

150 #

-20 to 100F -20 to 200F -20 to 400F -20 to 450F -20 to 100F -20 to 200F -20 to 400F -20 to 450F -20 to 100F -20 to 200F -20 to 400F -20 to 450F -20 to 100F -20 to 200F -20 to 400F -20 to 450F -20 to 100F -20 to 200F -20 to 400F -20 to 450F -20 to 100F -20 to 200F -20 to 400F -20 to 450F

(-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C) (-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C) (-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C) (-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C) (-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C) (-28.8 to 37.7C) (-28.8 to 93.3C) (-28.8 to 204.4C) (-28.8 to 232C)

285 psi 260 psi 200 psi 185 psi 740 psi 680 psi 635 psi 620 psi 1480 psi 1360 psi 1265 psi 1235 psi 2220 psi 2035 psi 1900 psi 1855 psi 3705 psi 3395 psi 3170 psi 3093 psi 6170 psi 5655 psi 5280 psi 5153 psi

1.96 mPa 1.79 mPa 1.38 mPa 1.28 mPa 5.10 mPa 4.69 mPa 4.38 mPa 4.27 mPa 10.2 mPa 9.38 mPa 8.72 mPa 8.52 mPa 15.3 mPa 14.0 mPa 13.1 mPa 12.6 mPa 25.5 mPa 23.4 mPa 21.8 mPa 21.3 mPa 42.5 mPa 39.0 mPa 36.4 mPa 35.5 mPa

275 psi 235 psi 195 psi 183 psi 720 psi 600 psi 495 psi 480 psi 1440 psi 1200 psi 995 psi 963 psi 2160 psi 1800 psi 1490 psi 1443 psi 3600 psi 3000 psi 2485 psi 2408 psi 6000 psi 5000 psi 4140 psi 4010 psi

1.89 mPa 1.62 mPa 1.34 mPa 1.26 mPa 4.96 mPa 4.14 mPa 3.41 mPa 3.31 mPa 9.92 mPa 8.27 mPa 6.86 mPa 6.64 mPa 14.9 mPa 12.4 mPa 10.3 mPa 9.95 mPa 24.8 mPa 20.7 mPa 17.1 mPa 16.6 mPa 41.3 mPa 34.5 mPa 28.5 mPa 27.6 mPa

300 #

600 #

900 #

1500 #

2500 #

Test Pressure: 1.5 times maximum working pressure at -20 to 100 F (-28.8 to 37.7 C)

Grooved End Connection

Flowmeters with grooved end connections are available in 7/8-in. through 8-in. sizes.

Flowmeter Size x End Connection Size Length mm Working Pressure psi MPa

WECO 1502 Union End Connection

Flowmeters with WECO 1502 end connections are commonly used in high-pressure oilwell service applications. Meter sizes 1, 1-1/2 and 2 have 2 union end connections with a wing nut on one end and threads on the other end. The 3" meters have 3" union end connections with the option of a wing nut on one end and threads on the other, or threads on both ends. All WECO 1502 union end connection meters have two pickup adapters.

in.

7/8 x 1 in. 1 x 1 in. 1-1/2 x 1-1/2 in. 1-1/2 x 2 in. 1-1/2 x 2 in. 2 x 2-1/2 in. 3 x 3 in. 4 x 4 in. 6 x 6 in. 8 x 8 in.

4.0 4.0 6.0 6.0 6.0 10.0 12.5 12.0 12.0 12.0

102 102 152 152 152 254 318 305 305 305

1000 1000 1000 1000 2500 1000 1000 1000 800 800

6.9 6.9 6.9 6.9 17.2 6.9 6.9 6.9 5.5 5.5

Flowmeter Size x End Connection Size

in.

Length mm

Working Pressure psi MPa

1 x 2 in. 1-1/2 x 2 in. 2 x 2 in. 3 x 3 in.

8.00 8.60 9.00 13.0

203.3 218.4 228.6 330.2

15000 15000 15000 15000

103 103 103 103

EZ-IN End Connection

EZ-IN Series turbine flowmeters provide a cost-effective alternative to typical flanged meters. They offer the accuracy, rugged construction, and maintenance-free operation of conventional NUFLO flowmeters plus the following advantages: Lower installation cost. Less expensive than a conventional, flanged meter. Easy installation, removal, and inspection. Mates to any raised-face flange rated ANSI 150# to 1500#. Mates to any ring joint flange rated ANSI 900#, 1500# or 2500#.

Meters for use with Raised Face Flanges*

Flowmeter Size x End Connection Size 1 in.

4.0 (102) 4.0 (102) 4.0 (102) 4.0 (102) 4.0 (102)

2 in.

2.5 (63.5) 2.5 (63.5) 2.5 (63.5) 2.5 (63.5) 2.5 (63.5) 2.5 (63.5) 2.5 (63.5)

Lengths, in. (mm) 3 in. 4 in.

4.25 (108) 4.25 (108) 5.0 (127)

6 in.

5.75 (146.1)

8 in.

6.25 (158.8)

3/8 x 1 in. 3/8 x 2 in. 1/2 x 1 in. 1/2 x 2 in. 3/4 x 1 in. 3/4 x 2 in. 7/8 x 1 in. 7/8 x 2 in. 1 x 1 in. 1 x 2 in. 1-1/2 x 2 in. 2 x 2 in. 2 x 3 in. 3 x 3 in.

Specialized Flowmeters

High pressure Nitrogen CO2 Cement slurry Corrosive service Drilling fluids

4 x 4 in. 6 x 6 in. 8 x 8 in.**

* Specify flange type (raised face or ring joint) when ordering. ** CE-marked meter requires special centering rings.

Contact Cameron's Measurement Systems division for application assistance.

MEASUREMENT SYSTEMS

Meters for use with Ring Joint Flanges*

Flowmeter Size x End Connection Size 1 in. 2 in. Lengths, in. (mm) 3 in. 4 in. 6 in. 8 in.

1 x 2 in. 1-1/2 x 2 in. 2 x 2 in. 3 x 3 in. 4 x 4 in. 6 x 6 in. 8 x 8 in.

3.5 (88.9)

3.5 (88.9) 3.5 (88.9)

4.25 (108)

5.0 (127)

5.75 (146.1)

6.25 (158.8)

* Specify flange type (raised face or ring joint) when ordering.

Pressure Drop Curve for NUFLO Turbine Flowmeters

Flow Rate - BPD

30 (206.84) 5 10 50 100 500 1,000 5,000 10,000 50,000 100,000

10 (68.95) 5 (34.47)

Pressure Drop - PSI (kPa)

1 (6.90) 0.5 (3.45)

3/4 7/8 1 2 1-1/2 1/2 4 6 3/8 8

0.1 (.690) 0.05 (.345)

0.01 (.069)

0.1 (.02)

0.5 (.11)

1 (.23)

5 10 (1.14) (2.27)

50 100 (11.36) (22.71)

500 1000 (113.6) (227.1)

5000 (1136.4)

Flow Rate - GPM (m3/hr)

(Fluid is water @ 68F)

MEASUREMENT SYSTEMS

WECO is a federally registered trademark of FMC Technologies, Inc.

MEASUREMENT SYSTEMS

HOUSTON H EAD O FFICE

281. 5 82. 9500

N ORT H AMERICA

1.8 00 .6 5 4 . 3 7 6 0

ms-us @ c-a-m.com

ASIA PACIFIC

+6 0 3 . 5 5 6 9 . 050 1

ms-k l @c-a-m.com

EUROPE, MIDDLE EAST & AFRICA

+ 4 4 . 1 2 4 3.8 2 6 7 4 1

ms-uk@c-a-m.com

U S A C A N A D A U K C H I N A U A E A L G E R I A M A L AY S I A I N D I A R U S S I A

w w w. c - a - m . c o m / f l o

TUR-LIQ NF00001 1208

Copyright 2012 Cameron International Corp. All Rights Reserved.

Vous aimerez peut-être aussi

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosPas encore d'évaluation

- FLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFDocument6 pagesFLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFOctavio CharryPas encore d'évaluation

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftPas encore d'évaluation

- Nuflo Ez-InDocument8 pagesNuflo Ez-InAnonymous Wu6FDjbPas encore d'évaluation

- NuFlo Liquid Turbine FlowmetersDocument6 pagesNuFlo Liquid Turbine FlowmetersphostyPas encore d'évaluation

- INVALCO CatalogDocument24 pagesINVALCO Catalogemuno008Pas encore d'évaluation

- Principle of Operation: Target Inline FlowmeterDocument7 pagesPrinciple of Operation: Target Inline Flowmeterابزار دقیقPas encore d'évaluation

- Section 21 - Liquid Turbine MeterDocument9 pagesSection 21 - Liquid Turbine MeterhammamiPas encore d'évaluation

- Ad00489m Barton 7400Document6 pagesAd00489m Barton 7400robercl51Pas encore d'évaluation

- Invalco Brochure PDFDocument20 pagesInvalco Brochure PDFMargaret DaughertyPas encore d'évaluation

- Tur-Flwmtr Nf00152 0912fDocument2 pagesTur-Flwmtr Nf00152 0912fAntonio ImperiPas encore d'évaluation

- 585 Annubar DatasheetDocument16 pages585 Annubar DatasheetAbolhasanPas encore d'évaluation

- Cilindros e Servo CilindrosDocument16 pagesCilindros e Servo CilindrosluisbottonPas encore d'évaluation

- Barton 7000Document8 pagesBarton 7000Abrakain69Pas encore d'évaluation

- 400-10 (Meters & Accessories 49093) PDFDocument52 pages400-10 (Meters & Accessories 49093) PDFmetal_dung2Pas encore d'évaluation

- Octave Leaflet 8pages August 2013Document8 pagesOctave Leaflet 8pages August 2013Sem LesanPas encore d'évaluation

- Sanitary TurbinaDocument4 pagesSanitary TurbinaCindy MateusPas encore d'évaluation

- Meters SatamDocument12 pagesMeters SatamAnoop ChulliyanPas encore d'évaluation

- F8026-woltex-M EN PB 07-10Document4 pagesF8026-woltex-M EN PB 07-10Dan ChiriacPas encore d'évaluation

- Smith Meter Prime 4Document2 pagesSmith Meter Prime 4gerosuca800Pas encore d'évaluation

- Sbin 001Document24 pagesSbin 001Julián CamargoPas encore d'évaluation

- TurbineDocument2 pagesTurbineprachimaggiPas encore d'évaluation

- Ap B14 02L 01e - Akm - 38750 PDFDocument4 pagesAp B14 02L 01e - Akm - 38750 PDFsamsungloverPas encore d'évaluation

- Flostar M, Pliant Nou, enDocument4 pagesFlostar M, Pliant Nou, ensergethomas2010Pas encore d'évaluation

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersDocument7 pages2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraPas encore d'évaluation

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouPas encore d'évaluation

- Product Data Sheet Rosemount Seniorsonic 3414 en 8727396Document32 pagesProduct Data Sheet Rosemount Seniorsonic 3414 en 8727396Zaki nouiPas encore d'évaluation

- Description: M0300 Strap-On Saddle Flow MeterDocument5 pagesDescription: M0300 Strap-On Saddle Flow MeterJamesh BabuPas encore d'évaluation

- Upvc Pressure Pipes and FittingsDocument8 pagesUpvc Pressure Pipes and FittingsjafarkhansfPas encore d'évaluation

- Prime 4 PD MeterDocument4 pagesPrime 4 PD Metertiualbert8729100% (1)

- Flow MeterDocument8 pagesFlow MeterDGWPas encore d'évaluation

- 2 4CRDocument4 pages2 4CRNestramiPas encore d'évaluation

- Om004 Om008 Integral ManualDocument9 pagesOm004 Om008 Integral ManualistopiPas encore d'évaluation

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032Pas encore d'évaluation

- Jain PE Gas Piping SystemDocument4 pagesJain PE Gas Piping Systemkishore@scribdPas encore d'évaluation

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanPas encore d'évaluation

- QUALITY INDUSTRIAL FLOWMETERS PROFILEDocument24 pagesQUALITY INDUSTRIAL FLOWMETERS PROFILESaravanan MathiPas encore d'évaluation

- AllDocument88 pagesAllRavi KumarPas encore d'évaluation

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresPas encore d'évaluation

- Accurately measure oil, water and gas flow without separationDocument4 pagesAccurately measure oil, water and gas flow without separationCristhian Torres0% (1)

- Solvent Flow Meter Catalogue PDFDocument6 pagesSolvent Flow Meter Catalogue PDFJR DadisPas encore d'évaluation

- Manual Ecoflux en - KrohneDocument14 pagesManual Ecoflux en - Krohnemmihai_popa2006Pas encore d'évaluation

- Delta - Brochure Delta Rotary ItronDocument8 pagesDelta - Brochure Delta Rotary Itronadriansya7Pas encore d'évaluation

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123Pas encore d'évaluation

- Nuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetDocument3 pagesNuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetPad TruPas encore d'évaluation

- Bidirectional Ultrasonic Gas Meter SeniorJrSonicDocument16 pagesBidirectional Ultrasonic Gas Meter SeniorJrSonicsapperbravo52Pas encore d'évaluation

- Low Speed Subsonic Wind TunnelsDocument8 pagesLow Speed Subsonic Wind TunnelscparamesPas encore d'évaluation

- Visual Flow Indicator Guide from Flow-MonDocument12 pagesVisual Flow Indicator Guide from Flow-Mondhanu_aquaPas encore d'évaluation

- PPR-C Pipe SpecificationDocument25 pagesPPR-C Pipe SpecificationAlex Dulay85% (13)

- Medidor de Gas - Smith MeterTM Turbine Meters FMCDocument5 pagesMedidor de Gas - Smith MeterTM Turbine Meters FMCjplutodPas encore d'évaluation

- Series 806YD Specification SheetDocument2 pagesSeries 806YD Specification SheetFEBCOPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- ManifoldDocument86 pagesManifoldSrta IncognitaPas encore d'évaluation

- Ls200 Level Switch MurphyDocument4 pagesLs200 Level Switch MurphyJaime SeguraPas encore d'évaluation

- Vegapuls 60 SeriesDocument20 pagesVegapuls 60 SeriesJaime SeguraPas encore d'évaluation

- Introduction To P&ID Reading & DesignDocument45 pagesIntroduction To P&ID Reading & DesignJaime Segura100% (1)

- NIVOMAG MK-200 SERIES MAGNETIC FLOAT LEVEL SWITCHESDocument4 pagesNIVOMAG MK-200 SERIES MAGNETIC FLOAT LEVEL SWITCHESJaime SeguraPas encore d'évaluation

- Bomba CiDocument1 pageBomba CiJaime SeguraPas encore d'évaluation

- Hazardous Duty Motors: Data, Facts and DetailsDocument2 pagesHazardous Duty Motors: Data, Facts and Detailschand_yelPas encore d'évaluation

- R2102011CHECKLIST For ElevdumbwaiterDocument2 pagesR2102011CHECKLIST For ElevdumbwaiterAlim Ur RahmanPas encore d'évaluation

- OLPG S1-01 - OESA LPG Depots and Filling PlantsDocument38 pagesOLPG S1-01 - OESA LPG Depots and Filling PlantsGogne Rodolph100% (1)

- Orifice FlangeDocument70 pagesOrifice FlangePaulo SousaPas encore d'évaluation

- Sunflo P3000 JrnlBrgs IOM June00Document104 pagesSunflo P3000 JrnlBrgs IOM June00Tirta BudiawanPas encore d'évaluation

- Chapter 8Document35 pagesChapter 8Nandish MPas encore d'évaluation

- Iso 20172-1 2017Document11 pagesIso 20172-1 2017Dinh Quang NhamPas encore d'évaluation

- Rotodrago 6080 - 200 Oven: Instruction Manual For Use and MaintenanceDocument72 pagesRotodrago 6080 - 200 Oven: Instruction Manual For Use and MaintenanceAshraf100% (1)

- Writing ToR For An Evaluation (2004)Document4 pagesWriting ToR For An Evaluation (2004)Tukang UsilPas encore d'évaluation

- Panasonic Dmc-Fs35eb Service ManualDocument68 pagesPanasonic Dmc-Fs35eb Service ManualABUTALEB_535364936Pas encore d'évaluation

- Future of The BIM CMMDocument19 pagesFuture of The BIM CMMJohnDecaprioPas encore d'évaluation

- Guidelines For AbstractDocument4 pagesGuidelines For AbstractYoga Alfian NoorPas encore d'évaluation

- Krohne Flow Meter PDFDocument40 pagesKrohne Flow Meter PDFavabhyankar9393Pas encore d'évaluation

- 12 Ka 4Document58 pages12 Ka 4Gunjesh GunjanPas encore d'évaluation

- ABC AccessoriesDocument15 pagesABC Accessorieshd2000bwPas encore d'évaluation

- Tier Certification Is The AccountabilityDocument4 pagesTier Certification Is The AccountabilitydexterPas encore d'évaluation

- TP201.1E Leak Rate and Cracking Pressure of Pressure-Vacuum Vent Valves PDFDocument8 pagesTP201.1E Leak Rate and Cracking Pressure of Pressure-Vacuum Vent Valves PDFCésar Oswaldo Aguilera OjedaPas encore d'évaluation

- Difference Between Voltage Tap & Test TapDocument3 pagesDifference Between Voltage Tap & Test TapaocalayPas encore d'évaluation

- RTU560CID11Document15 pagesRTU560CID11Ly HàPas encore d'évaluation

- RME Refresher April 4 2009 PEC 5 KeyDocument7 pagesRME Refresher April 4 2009 PEC 5 KeyCharlene Mae Sta Teresa-ZambalePas encore d'évaluation

- UCSP Module 2 - ActivitiesDocument4 pagesUCSP Module 2 - ActivitiesTeds TV80% (5)

- BSS Troubleshooting Manual PDFDocument220 pagesBSS Troubleshooting Manual PDFleonardomarinPas encore d'évaluation

- CBLM Facilitate Learning SessionsDocument179 pagesCBLM Facilitate Learning SessionsFidel ZapataPas encore d'évaluation

- Site Specific Safety PlanDocument12 pagesSite Specific Safety PlanMatthew OdoPas encore d'évaluation

- CIVI 321 2018 Lab Manual - PD PDFDocument41 pagesCIVI 321 2018 Lab Manual - PD PDFOumar FofPas encore d'évaluation

- S Qe Master Test Plan TemplateDocument7 pagesS Qe Master Test Plan TemplateRomiSayagoPas encore d'évaluation

- Dinesh Op. Mgmt.Document26 pagesDinesh Op. Mgmt.Nino Dinesh TaringPas encore d'évaluation

- Battle Card - Fortinet Vs Cisco ASA Series11 PDFDocument2 pagesBattle Card - Fortinet Vs Cisco ASA Series11 PDFMuhd AlifPas encore d'évaluation

- LTMC For Master Data Step by Step Process - SAP BlogsDocument24 pagesLTMC For Master Data Step by Step Process - SAP BlogsshamsPas encore d'évaluation

- CCW-1037 MiraDRI 860-861 TDS 03-18-14Document2 pagesCCW-1037 MiraDRI 860-861 TDS 03-18-14meetvinayak2007Pas encore d'évaluation

- How Custody Transfer Works: Accuracy Critical for Financial ExposureDocument4 pagesHow Custody Transfer Works: Accuracy Critical for Financial ExposureJoanna George - Joseph100% (1)