Académique Documents

Professionnel Documents

Culture Documents

Rotary Encoder

Transféré par

alesysCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rotary Encoder

Transféré par

alesysDroits d'auteur :

Formats disponibles

4: Reading Rotary Encoders

PIC Application Notes

Reading Rotary Encoders

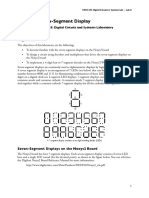

Introduction. This application note covers the use of incremental rotary encoders with PIC microcontrollers. It presents an example program in TechTools assembly language for reading a typical encoder and displaying the results as an up/down count on a seven-segment LED display. Background. Incremental rotary encoders provide a pair of digital signals that allow a microcontroller to determine the speed and direction of a shafts rotation. They can be used to monitor motors and mechanisms, or to provide a control-knob user interface. The best-known application for rotary encoders is the mouse, which contains two encoders that track the x- and y-axis movements of a ball in the devices underside. Rotary encoders generally contain a simple electro-optical mechanism

APPS

CLOCKWISE

Phase 1

Phase 2

COUNTER CW

Figure 1. Quadrature waveforms from a rotary encoder contain directional information.

CLOCKWISE

Phase 1 Phase 2 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1

COUNTER CW

Figure 2. Sequence of two-bit numbers output by the phases of a rotary encoder.

TechTools PIC Application Notes Page 23

PIC Application Notes

4: Reading Rotary Encoders

consisting of a slotted wheel, two LEDs, and two light sensors. Each LED/sensor pair is arranged so that the devices face each other through the slots in the wheel. As the wheel turns, it alternately blocks and passes light, resulting in square wave outputs from the sensors. The LED/sensor pairs are mounted offset relative to one another, so that the output square waves are offset 90 degrees in phase. This is known as quadrature, because 90 degrees amount to one-quarter of a full 360degree cycle.

Vcc Rotary Encoder

(Digi-Key GH6102)

1k 1k

V+ p1 p2 gnd

18

6 5 4 1

Vcc

2 3

RA2 RA3 RTCC

4

RA1

17

RA0

16

220 pF

15 NC 14 13 NC 12 470

OSC1

MCLR

5

Vss

6

PIC OSC2 16C54

10k

Vcc

Vdd

RB0

7

RB7 RB6

RB1

8

a

11

470 470

RB2

9

RB5

10

b c

f a b g e d c

RB3

RB4 470 470 470 470

d e f g

Common-Cathode LED Display

This phase relationship provides the information needed to determine the encoders direction of rotation (see figure 1).

Page 24 PIC Application Notes TechTools

4: Reading Rotary Encoders

PIC Application Notes

The dotted lines in figure 1 indicate a common method of reading direction. For instance, if phase 1 is high and phase 2 is rising, the direction is clockwise (CW). If phase 1 is low and phase 2 is rising, the direction is counterclockwise (CCW). For the sake of interpreting this output with a PIC or other microcontroller, its probably more useful to look at the changing states of the phases as a series of two-bit numbers, as shown in figure 2 above. When the encoder shaft is turning CW, you get a different sequence of numbers (01,00,10,11) than when it is turning CCW (01,11,10,00). You may recognize this sequence as Gray code. It is distinguished by the fact that only one bit changes in any transition. Gray code produces no incorrect intermediate values when the count rolls over. In normal binary counting, 11 rolls over to 00. If one bit changed slightly before the other, the intermediate number value could be incorrectly read as 01 or 10 before settling into the correct state of 00. Interpreting this code amounts to comparing the incoming sequence to the known sequences for CW and CCW rotation. A lookup table would do the trick. However, this approach, while easy to understand, is inefficient. The shortcut method uses an interesting property of the twobit Gray code sequence. Pick any pair of two-bit numbers from the CW sequence shown in figure 2; for instance, the first two: 10, 11. Compute the exclusive-OR (XOR) of the righthand bit of the first number with the lefthand bit of the second. In this case, that would be 0 XOR 1 = 1. Try this for any CW pair of numbers from the table, and youll always get 1. Now reverse the order of the number pair: 11, 10. XOR the right bit of the first with the left of the second (1 XOR 1 = 0). Any CCW pair of numbers will produce a 0. How it works. The schematic in figure 3 shows a typical rotary encoder connected to the lower two bits of port RA, and a seven-segment LED display to port RB. The circuit performs a simple task: the count displayed on the LED goes up when the control is turned CW, and down when it is turned CCW. The display is in hexadecimal, using seven-segment approximations of the letters: A, b, C, d, E, and F.

APPS

TechTools PIC Application Notes Page 25

PIC Application Notes

4: Reading Rotary Encoders

The program begins by setting up the I/O ports and clearing the variable counter. It gets an initial input from the encoder, which goes into the variable old, and strips off all but the two least-significant bits (LSBs). The body of the program, starting with :loop, calls check_encoder and then displays the latest value of counter on the LED display. Most of the interesting business happens in check_encoder itself. Here, the program gets the latest value at the encoder inputs, strips all but the two LSBs, and XORs the result into a copy of the old value. If the result is zero, the encoder hasnt moved since its last reading, and the routine returns without changing the value of counter. If the value has changed, the routine moves the value in old one bit to the left in order to align its LSB with the high bit of the two-bit value in new. It XORs the variables together. It then examines the bit old.1. If the bit is 1, counter is incremented; if its 0, counter is decremented. Modifications. To avoid slippage errors (where a change in encoder position does not change the counter, or results in the wrong change), check_encoder must be called at least once every 1/(encoder resolution max revs per second). For instance, if the encoder might turn 300 rpm * (5 revs per second) and its resolution is 32 transitions per turn, check_encoder must be called every 1/(32*5) seconds, or 6.25 milliseconds. For a user interface, bear in mind that generally the larger the knob, the slower the input. Substitution of a larger control knob may be all thats required to reduce the sampling rate. In circumstances where electrical noise might be a problem, Microchips PIC data sheet indicates that it might be wise to move the port I/O assignments to the beginning of check_encoder. Electrostatic discharge (ESD) from the users fingertips, or some other electrical noise, could corrupt an I/O control register. This would prevent the routine from reading the encoder. Program listing. This program may be downloaded from our Internet ftp site at ftp.tech-tools.com. The ftp site may be accessed directly or through our web site at http://www.tech-tools.com.

Page 26 PIC Application Notes TechTools

4: Reading Rotary Encoders

PIC Application Notes

; PROGRAM: Read Rotary Encoder (RD_ENCDR.SRC) ; This program accepts input from a rotary encoder through bits RA.0 and RA.1, ; determines the direction of rotation, and increments or decrements a counter ; appropriately. It displays the hexadecimal contents of the four-bit counter on a ; seven-segment LED display connected to port RB. ; Remember to change device info when programming a different PIC. device pic16c54,rc_osc,wdt_off,protect_off reset start encoder display = = ra rb

APPS

; Variable storage above special-purpose registers. org 8 temp counter old new ds ds ds ds 1 1 1 1

; Set starting point in program ROM to zero. org 0 start mov mov clr mov and call mov call mov goto !rb, #0 !ra, #255 counter old, encoder old, #00000011b chk_encoder w, counter sevenseg display, w :loop new, encoder new, #00000011b temp, new temp, old :return ; Set rb to output. ; Set ra to input.

:loop

chk_encoder mov and mov xor jz clc rl xor jb :down dec

; Get latest state of input bits. ; Strip off all but the encoder bits. ; ; ; ; ; ; ; Is new = old? If so, return without changing counter. Clear carry in preparation for rotate-left instruction. Move old to the left to align old.0 with new.1.

old old, new old.1, :up counter

; If the XOR resut is 1, increment ; counter, otherwise decrement.

TechTools PIC Application Notes Page 27

PIC Application Notes

:up skip inc and mov ret jmp retw retw counter counter, #00001111b old,new

4: Reading Rotary Encoders

:return sevenseg

pc+w ; display lookup table 126, 48, 109, 121, 51, 91, 95, 112 127, 115, 119, 31, 78, 61, 79, 71

Page 28 PIC Application Notes TechTools

Vous aimerez peut-être aussi

- ECE222 DP1 Binary MultiplierDocument8 pagesECE222 DP1 Binary Multiplierprasad357Pas encore d'évaluation

- Digital Pulse Counter - Two Digits: DescriptionDocument7 pagesDigital Pulse Counter - Two Digits: DescriptionAsgher KhattakPas encore d'évaluation

- CH 7Document23 pagesCH 7Anonymous 7WsOWImuPas encore d'évaluation

- Counters and Shift RegDocument24 pagesCounters and Shift RegRakesh Kumar D100% (1)

- CPR E 381x/382x Lab11aDocument10 pagesCPR E 381x/382x Lab11aHelenPas encore d'évaluation

- ADC TutorialDocument17 pagesADC TutorialNagabhushanam KoduriPas encore d'évaluation

- TMS320F2812-Analogue To Digital ConverterDocument26 pagesTMS320F2812-Analogue To Digital ConverterPantech ProLabs India Pvt LtdPas encore d'évaluation

- Circuit Can Be Used For Many PurposesDocument1 pageCircuit Can Be Used For Many PurposesAszhar Al AmbaryPas encore d'évaluation

- IR Sensor Based Distance Measurement SystemDocument5 pagesIR Sensor Based Distance Measurement SystemRajkeen ChamanshaikhPas encore d'évaluation

- Adc Lab Pic18Document23 pagesAdc Lab Pic18Bolarinwa Joseph100% (1)

- Unit - Iii MPMC-1Document79 pagesUnit - Iii MPMC-1gunda manasa100% (1)

- Quadrature Encoder Receiver Module: An Implementation On FPGADocument12 pagesQuadrature Encoder Receiver Module: An Implementation On FPGAสหายดิว ลูกพระอาทิตย์Pas encore d'évaluation

- Microcontroller2Document73 pagesMicrocontroller2pankaj gargPas encore d'évaluation

- Advanced Logic Circuits ProjectDocument13 pagesAdvanced Logic Circuits ProjectLymen LagumbayPas encore d'évaluation

- Analog-To-Digital Converter (ADC) Interfacing With MicrocontrollerDocument4 pagesAnalog-To-Digital Converter (ADC) Interfacing With MicrocontrollerSridhar DineshPas encore d'évaluation

- 7-Segment Display & ADC Controls With 8051: LABORATORY - Experiment 5Document12 pages7-Segment Display & ADC Controls With 8051: LABORATORY - Experiment 5Vikas Ravi TPPas encore d'évaluation

- Mini Project Report-2Document26 pagesMini Project Report-2Remya Ramakrishnan0% (2)

- Digital Thermometer Using 8051 Microcontroller Project ReportDocument18 pagesDigital Thermometer Using 8051 Microcontroller Project Reportjs18ps56% (9)

- Chapter 5: Counters: Ee 202 Digital ElectronicsDocument59 pagesChapter 5: Counters: Ee 202 Digital ElectronicsSyazreen RahmanPas encore d'évaluation

- Digital ThermometerDocument12 pagesDigital Thermometershahpatel19Pas encore d'évaluation

- Table of Content: Digital OhmmeterDocument23 pagesTable of Content: Digital OhmmeterLow Koon Yee100% (1)

- Rotary Encoders - 0928Document17 pagesRotary Encoders - 0928tecnoelectronica789Pas encore d'évaluation

- PIC PPT 13104022 (4th Year)Document41 pagesPIC PPT 13104022 (4th Year)Daman Deep Singh100% (1)

- ADC InterfacingDocument37 pagesADC InterfacingSaurav ChaudharyPas encore d'évaluation

- Digital Thermometer Using 8051 PDFDocument3 pagesDigital Thermometer Using 8051 PDFAditya Prakash100% (1)

- Construction of Microcontroller Based Digital Voltmeter: Md. Imran Hossain Jony, Md. Moshiur RahmanDocument4 pagesConstruction of Microcontroller Based Digital Voltmeter: Md. Imran Hossain Jony, Md. Moshiur Rahmanshiva kumarPas encore d'évaluation

- Simple VFD DesignDocument13 pagesSimple VFD DesignMianShahzadKokabPas encore d'évaluation

- AVR242: 8-Bit Microcontroller Multiplexing LED Drive and A 4 X 4 KeypadDocument26 pagesAVR242: 8-Bit Microcontroller Multiplexing LED Drive and A 4 X 4 KeypadDemeter Robert Es IzabellaPas encore d'évaluation

- Applications of Handshake ModeDocument3 pagesApplications of Handshake Modevyshnu3006Pas encore d'évaluation

- Digital Voltmeter Using Pic MicrocontrollerDocument38 pagesDigital Voltmeter Using Pic MicrocontrollerTaramba kossiPas encore d'évaluation

- Adc InterfacingDocument17 pagesAdc Interfacing21ecuog059Pas encore d'évaluation

- NEC 022 External Paper SolutionDocument13 pagesNEC 022 External Paper SolutionSachin PalPas encore d'évaluation

- Adc PWMDocument26 pagesAdc PWMShivaram Reddy ManchireddyPas encore d'évaluation

- Analog To DigitalDocument46 pagesAnalog To DigitalSaleem HaddadPas encore d'évaluation

- Adcanddac 210216095501Document24 pagesAdcanddac 210216095501Kiran GPas encore d'évaluation

- Industrial Production Counter Using At89S52 MicrocontrollerDocument24 pagesIndustrial Production Counter Using At89S52 MicrocontrollerrajkiritiPas encore d'évaluation

- Analog To Digital ConversionDocument4 pagesAnalog To Digital ConversionAnkit MittalPas encore d'évaluation

- Lab 8Document8 pagesLab 8Anonymous yG7oj20% (1)

- ESD1Document227 pagesESD1Mr. RAVI KUMAR IPas encore d'évaluation

- Es 1Document60 pagesEs 1vamsi kiranPas encore d'évaluation

- Decode A Quadrature Encoder in SoftwareDocument4 pagesDecode A Quadrature Encoder in SoftwarerdiakurPas encore d'évaluation

- Laboratory Manual Course Code:Ece 201Document41 pagesLaboratory Manual Course Code:Ece 201Er Sacchu SrivastavaPas encore d'évaluation

- AN #35 - Low Cost LCD Frequency MeterDocument6 pagesAN #35 - Low Cost LCD Frequency Meterarroyo62Pas encore d'évaluation

- ADCDocument18 pagesADCYogha Satria LaksanaPas encore d'évaluation

- Digital Theromometer Using 8051Document17 pagesDigital Theromometer Using 8051BALASUBRAMANIAN N BALASUBRAMANIAN NPas encore d'évaluation

- Experiment No. 4 ADC PDFDocument16 pagesExperiment No. 4 ADC PDFRia Cordova0% (1)

- 6 Adc0804Document5 pages6 Adc0804esther_kakani919Pas encore d'évaluation

- Ee446 Embedded Systems Lab #01: InstructionsDocument4 pagesEe446 Embedded Systems Lab #01: InstructionsMuhammad ShafeeqPas encore d'évaluation

- Using Quadrature Encoders With E Series DAQ Boards: Application Note 084Document11 pagesUsing Quadrature Encoders With E Series DAQ Boards: Application Note 084Heriberto Flores AmpiePas encore d'évaluation

- National Institute of Technology, Rourkela: Embedded Systems LaboratoryDocument13 pagesNational Institute of Technology, Rourkela: Embedded Systems Laboratoryprateekkumardash2002Pas encore d'évaluation

- BER MeterDocument8 pagesBER Metersakti prasad nandaPas encore d'évaluation

- M4 Micro OneNoteDocument6 pagesM4 Micro OneNoteAryan RaiPas encore d'évaluation

- PIC Analog To Digital Converter TutorialDocument5 pagesPIC Analog To Digital Converter TutorialSharath MunduriPas encore d'évaluation

- Line Follower Robot Using 8051 Micro ControllerDocument34 pagesLine Follower Robot Using 8051 Micro Controllerm.abdullah100% (2)

- Interfacing of 8051: Unit 4Document44 pagesInterfacing of 8051: Unit 4radhika patelPas encore d'évaluation

- Programming Pic Microcontrollers in Picbasic Pro - LCD Lesson 1 Cornerstone Electronics Technology and Robotics IiDocument15 pagesProgramming Pic Microcontrollers in Picbasic Pro - LCD Lesson 1 Cornerstone Electronics Technology and Robotics IiDomDoretoPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Projects With Microcontrollers And PICCD'EverandProjects With Microcontrollers And PICCÉvaluation : 5 sur 5 étoiles5/5 (1)

- DataDog - Nano - MusicDocument2 pagesDataDog - Nano - MusicalesysPas encore d'évaluation

- Power Lines Filters For SPSDocument6 pagesPower Lines Filters For SPSalesysPas encore d'évaluation

- An 221 Adding An ADC To A Raspberry PiDocument11 pagesAn 221 Adding An ADC To A Raspberry PialesysPas encore d'évaluation

- 277 - PI AmplifierDocument2 pages277 - PI AmplifieralesysPas encore d'évaluation

- Bd9397efv eDocument30 pagesBd9397efv eGiovanni Carrillo VillegasPas encore d'évaluation

- IT144 ICT WorkshopDocument4 pagesIT144 ICT WorkshopDeep ShakhiyaPas encore d'évaluation

- Configure Eap Tls Flow With IseDocument24 pagesConfigure Eap Tls Flow With IseKash BarlasPas encore d'évaluation

- Philips DVDR985 2022Document270 pagesPhilips DVDR985 2022Doru RazvanPas encore d'évaluation

- Adc 128 S 022Document29 pagesAdc 128 S 022Subhrajit MitraPas encore d'évaluation

- Critical System ValidationDocument13 pagesCritical System ValidationDheeraj SrinathPas encore d'évaluation

- EEL 4140 Lab ManualDocument136 pagesEEL 4140 Lab ManualalproviePas encore d'évaluation

- S221 NTLWDocument17 pagesS221 NTLWCarlos JimenezPas encore d'évaluation

- Robot Project NevonDocument5 pagesRobot Project NevonEr. Aditya KapoorPas encore d'évaluation

- Cics Abend CodesDocument825 pagesCics Abend Codesjoshna30Pas encore d'évaluation

- MSDN Mag 0710Document102 pagesMSDN Mag 0710AlexandrePas encore d'évaluation

- Clover Health PatentDocument20 pagesClover Health PatentCharles GrossPas encore d'évaluation

- SIP5 Operating V09.30 Manual C003-J enDocument290 pagesSIP5 Operating V09.30 Manual C003-J enMarcelo FukujiPas encore d'évaluation

- AO4486Document6 pagesAO4486senjinatorPas encore d'évaluation

- Oracle 1z0 1084 20 PDFDocument6 pagesOracle 1z0 1084 20 PDFSaquib.MahmoodPas encore d'évaluation

- Esab Caddy Tig-2200i Ac-Dc 718-xxx To 843-xxxDocument64 pagesEsab Caddy Tig-2200i Ac-Dc 718-xxx To 843-xxxhitano12100% (1)

- MMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.Document16 pagesMMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.jakalae5263Pas encore d'évaluation

- CST307Document12 pagesCST307Ajnamol N RPas encore d'évaluation

- Arithmetic Logic UnitDocument5 pagesArithmetic Logic UnitNarendra AchariPas encore d'évaluation

- Lab Manual LicDocument66 pagesLab Manual LicUppum Mulakam FansPas encore d'évaluation

- Chapter 4 - Asynchronous MOD Up CountersDocument7 pagesChapter 4 - Asynchronous MOD Up CountersMinh PhúPas encore d'évaluation

- System Physical ArchitectureDocument5 pagesSystem Physical ArchitectureSanjay SharmaPas encore d'évaluation

- Laboratory 2 BEEDocument11 pagesLaboratory 2 BEE22-03844Pas encore d'évaluation

- Technology Concepts1Document9 pagesTechnology Concepts1drosbeastPas encore d'évaluation

- 25Q32BVDocument78 pages25Q32BVVictor GarciaPas encore d'évaluation

- Things To Know : Instruction Format Instructions Can Have 1, 2 or No OperandsDocument9 pagesThings To Know : Instruction Format Instructions Can Have 1, 2 or No OperandsMS. AYESHA SIDDIKA TONNYPas encore d'évaluation

- 18 DiplexorDocument3 pages18 DiplexorFernando GutiérrezPas encore d'évaluation

- 5500-192 Power Strip LEVITONDocument3 pages5500-192 Power Strip LEVITONEdwin G Garcia ChPas encore d'évaluation

- LGD Lm238wf1-Sla1 PDFDocument34 pagesLGD Lm238wf1-Sla1 PDFAgdael DominguezPas encore d'évaluation

- Historico Doc. Por Tipo Doc - HistoDocument2 pagesHistorico Doc. Por Tipo Doc - HistoLeandro FariaPas encore d'évaluation