Académique Documents

Professionnel Documents

Culture Documents

Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 Mech

Transféré par

philipyapDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 Mech

Transféré par

philipyapDroits d'auteur :

Formats disponibles

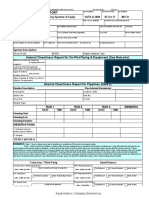

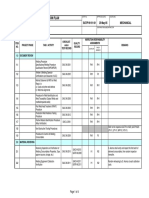

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Installation of Fire Water Isolation Valves

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2056

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA General Requirements: Steel body valves shall be used for above ground firewater system block valves to avoid failure due to fire, and AG to be equipped with position indicator or showing full open and close positions. Isolation valves between the hydrant and fire water main, if provided, shall be buried in accordance with SAES-S-040. Each utility line shall be provided with an isolation valve just upstream of the specified hose connector at the termination. A branch piping of a raw/firewater combined distribution system, serving firewater systems of a building or a facility is connected upstream of the isolation valve of the raw water supply piping. Each pressure control valve shall be provided with an upstream and downstream manual isolation valves, designated "locked open". Installation of isolation valves serving mains or branch piping to fire fighting equipment or any firewater system shall meet the requirements of SAES-B-017. Isolation valves between the hydrant and fire water main, if provided, shall be buried Underground piping, valves, and fittings shall be externally protected against corrosion per SAES-X-600. The spray system shall be considered to start at the inlet flange of the isolation valve connecting to the distribution piping. The spray system shall consist of an isolation valve, a strainer, actuation valve, and spray system piping. Isolation and actuation valves shall be accessible from grade and shall otherwise meet the access requirements of SAES-B-054 The entire spray system downstream of the isolation valve shall be capable of being drained by low point drains The deluge system shall be considered to start at the inlet flange of the isolation valve connecting to the distribution piping The system shall consist of an isolation valve, deluge valve, piping, and deluge heads.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-L-008 Para 8.2 SAES-B-017, Para. 7.2.2 g SAES-L-310, Para. 19.8 SAES-S-040, Para. 5.5.17 SAES-B-017, Para. 14.4.2 SAES-S-040, Para. 5.7.3 SAES-B-017, Para 7.2.2 SAES-B-017, Para 7.3.4 SAES-B-017, Para 10.5.1

A2

A3

A4

A5

A6

A7 A8

A9

A10

SAES-B-017, Para 10.5.2 SAES-B-017, Para 10.5.4 SAES-B-017, Para 11.6.1 SAES-B-017, Para 11.6.2 SAES-B-017, Para 11.7.1 SAES-B-009, Para 4.8.6.7

A11

A12

A13

A14 Deluge valves may be manually operable except as specified in Section. Sectionalizing valve handwheels shall be accessible from deck level and A15 located at a convenient operating height, hand wheels or other extension shall not obstruct walk ways or equipment access ways.

Page 1 of 2

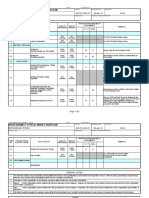

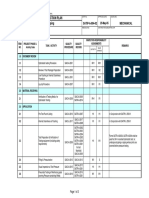

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

0

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

0

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A16

Flanged valves shall be provided at the ends of Fire Water loops to sectionalizing/Flushing upon completion of construction and at intervals. Buried sectionalizing valves in FW system shall be provided with indicator posts. Chain wheel operation shall not be installed on emergency isolation valves. Gate valves are used above ground, they shall be installed so that the stems are horizontal. Block valves shall be provided in piping to isolate line failures for repair,and assure flow of FW to all risk areas in case of failure in fire.

SAES-B-009, Para 4.8.6.8 SAES-L-008 Para 7.7 SAES-B-009, Para 4.8.6.2 SAES-B-017, Para 12.4c SAES-B-017, Para 9.2

A17

A18

A19

A20

REMARKS:

REFERENCE DOCUMENTS:y g ( y ) 2. SAES-B-009, Fire Protection and Safety Requirements for Offshore Production Facilities, (30 January, 2002)

4. SAES-S-040, Saudi Aramco Water Systems, 31 December 2003

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 2

Vous aimerez peut-être aussi

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishPas encore d'évaluation

- SignageDocument4 pagesSignagephilipyapPas encore d'évaluation

- Swimming PoolDocument4 pagesSwimming PoolphilipyapPas encore d'évaluation

- Saudi Aramco Piping ChecklistDocument3 pagesSaudi Aramco Piping ChecklistphilipyapPas encore d'évaluation

- SAIC-A-2013 Rev 0Document2 pagesSAIC-A-2013 Rev 0philipyapPas encore d'évaluation

- Saic K 4010Document3 pagesSaic K 4010mohamadPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalPas encore d'évaluation

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocument2 pagesSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22Pas encore d'évaluation

- Pipework Pretest Checklist (Empty)Document1 pagePipework Pretest Checklist (Empty)Jorge GarciaPas encore d'évaluation

- SATIP-K-001-03 - HVAC Metal Duct System - Rev. 6Document3 pagesSATIP-K-001-03 - HVAC Metal Duct System - Rev. 6imrankhan220% (1)

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandPas encore d'évaluation

- SATIP S 060 04 Plumbing FixturesDocument2 pagesSATIP S 060 04 Plumbing FixturesMuhammad Farukh ManzoorPas encore d'évaluation

- SATIP K 001 07 Refrigerant - PipingDocument2 pagesSATIP K 001 07 Refrigerant - Pipingimrankhan22100% (1)

- Satip-K-001-12 - Tab of Hvac SystemDocument2 pagesSatip-K-001-12 - Tab of Hvac Systemimrankhan22Pas encore d'évaluation

- Saudi Aramco Test Report Pre-Test Punch List Form: Testing Mech-SATR-A-2007Document1 pageSaudi Aramco Test Report Pre-Test Punch List Form: Testing Mech-SATR-A-2007Anonymous S9qBDVky100% (1)

- HT-04 Heat Treatment - ProcedureDocument7 pagesHT-04 Heat Treatment - ProcedureRam ThevarPas encore d'évaluation

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadPas encore d'évaluation

- WeldingDocument73 pagesWeldingTeodor EzaruPas encore d'évaluation

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159Pas encore d'évaluation

- 00 Saip 51Document5 pages00 Saip 51Rodolius LibaoPas encore d'évaluation

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaPas encore d'évaluation

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshPas encore d'évaluation

- 175 000003 PDFDocument1 page175 000003 PDFSohail TisekarPas encore d'évaluation

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishPas encore d'évaluation

- Checklist - Damper - Non Pressure Parts Drgs.Document2 pagesChecklist - Damper - Non Pressure Parts Drgs.Ramalingam PrabhakaranPas encore d'évaluation

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05Document1 pageSaudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05philipyapPas encore d'évaluation

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominPas encore d'évaluation

- Saudi Aramco HDPE Liner Inspection PlanDocument10 pagesSaudi Aramco HDPE Liner Inspection PlanJagdishPas encore d'évaluation

- Con DuctbankDocument25 pagesCon DuctbankLimuel EspirituPas encore d'évaluation

- NDE Requirements for Header Box WeldsDocument9 pagesNDE Requirements for Header Box Weldsrony16novPas encore d'évaluation

- Masinloc Power Plant Ducting Project Inspection PlanDocument9 pagesMasinloc Power Plant Ducting Project Inspection PlanResearcher100% (2)

- ME430 Air Conditioning Quiz and Exam QuestionsDocument9 pagesME430 Air Conditioning Quiz and Exam Questionskakajssh yhsusuaiwPas encore d'évaluation

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanPas encore d'évaluation

- 00-Saip-06 Pressure TestDocument4 pages00-Saip-06 Pressure TestUzair AhmadPas encore d'évaluation

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinPas encore d'évaluation

- Piping System Hydraulic Test Procedure R0Document6 pagesPiping System Hydraulic Test Procedure R0cmc261185Pas encore d'évaluation

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalPas encore d'évaluation

- Saic D 2022Document7 pagesSaic D 2022sureshPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajPas encore d'évaluation

- 1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFDocument4 pages1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFWIZKHALIFAPas encore d'évaluation

- SATIP-K-001-11 - AC Split Systems - DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems - DX Typeimrankhan22Pas encore d'évaluation

- Qcf301 Tp05 Pressure Test ChecklistDocument1 pageQcf301 Tp05 Pressure Test ChecklistminhnnPas encore d'évaluation

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LonePas encore d'évaluation

- Design and fabrication requirements for scraper trapsDocument13 pagesDesign and fabrication requirements for scraper trapsJeck MaquitedPas encore d'évaluation

- Plumbing Rfi Front SheetDocument14 pagesPlumbing Rfi Front SheetMD SHARIQUEPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanPas encore d'évaluation

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDocument11 pagesIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedPas encore d'évaluation

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainPas encore d'évaluation

- HRSG ITP Rev E 2Document5 pagesHRSG ITP Rev E 2Hamid Taghipour ArmakiPas encore d'évaluation

- Aramco Plumbing Interview QuestionsDocument6 pagesAramco Plumbing Interview QuestionsMohanad Suliman100% (1)

- Mechanical Works Sections for Plumbing and Fire FightingDocument239 pagesMechanical Works Sections for Plumbing and Fire FightingmasahinPas encore d'évaluation

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapPas encore d'évaluation

- SAUDI ARAMCO Scraper Trap Installation ChecklistDocument9 pagesSAUDI ARAMCO Scraper Trap Installation ChecklistphilipyapPas encore d'évaluation

- SAIC-K-2026 Rev 0Document2 pagesSAIC-K-2026 Rev 0philipyapPas encore d'évaluation

- SAIC-D-2012 Rev 2Document4 pagesSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- Panel BoardDocument7 pagesPanel BoardphilipyapPas encore d'évaluation

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Raceway Selection GuideDocument10 pagesRaceway Selection GuidephilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- Finish CarpentryDocument17 pagesFinish CarpentryphilipyapPas encore d'évaluation

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapPas encore d'évaluation

- Resilent FlooringDocument7 pagesResilent FlooringphilipyapPas encore d'évaluation

- Chilled Water PumpDocument6 pagesChilled Water PumpphilipyapPas encore d'évaluation

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapPas encore d'évaluation

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapPas encore d'évaluation

- Control SystemDocument21 pagesControl SystemphilipyapPas encore d'évaluation

- Exterior LightingDocument8 pagesExterior LightingphilipyapPas encore d'évaluation

- Low Voltage Wires and Cables SpecificationDocument9 pagesLow Voltage Wires and Cables SpecificationphilipyapPas encore d'évaluation

- FanDocument7 pagesFanphilipyap100% (1)

- Fan Coil UnitsDocument3 pagesFan Coil UnitsphilipyapPas encore d'évaluation

- Saudi Aramco Ductwork SpecificationsDocument5 pagesSaudi Aramco Ductwork SpecificationsphilipyapPas encore d'évaluation

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapPas encore d'évaluation

- DuctworksDocument7 pagesDuctworksphilipyapPas encore d'évaluation

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- Metal FramesDocument4 pagesMetal FramesphilipyapPas encore d'évaluation

- Variable Air UnitDocument4 pagesVariable Air UnitphilipyapPas encore d'évaluation

- G.furniture & FixturesDocument2 pagesG.furniture & FixturesphilipyapPas encore d'évaluation

- 03210-Epoxy Coated Conc ReoDocument7 pages03210-Epoxy Coated Conc ReophilipyapPas encore d'évaluation

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapPas encore d'évaluation

- Roof and Deck InsulationDocument3 pagesRoof and Deck InsulationphilipyapPas encore d'évaluation

- Floor MatsDocument3 pagesFloor MatsphilipyapPas encore d'évaluation

- Off Grid PV Systems Design GuidelinesDocument24 pagesOff Grid PV Systems Design GuidelinestantibaPas encore d'évaluation

- Jet PumDocument122 pagesJet PumCluis KePas encore d'évaluation

- Jotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Document8 pagesJotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Riski FebriantoPas encore d'évaluation

- en 20211124Document26 pagesen 20211124chaky212Pas encore d'évaluation

- A Comparative Study of The Provisions OF ACI: 318-08 AND IS: 456-2000 BUILDING Codes For Design of Flat SlabsDocument3 pagesA Comparative Study of The Provisions OF ACI: 318-08 AND IS: 456-2000 BUILDING Codes For Design of Flat Slabswafiullah sayedPas encore d'évaluation

- Park To Playa Trail Feasibility Study and Wayfinding PlanDocument153 pagesPark To Playa Trail Feasibility Study and Wayfinding PlanEmpowerment Congress West Area Neighborhood Development CouncilPas encore d'évaluation

- Onkyo TX SR705Document116 pagesOnkyo TX SR705klynch71100% (3)

- ICT - PPTX (Repaired)Document290 pagesICT - PPTX (Repaired)Samuel Benson Sesay100% (1)

- SL07 480Document5 pagesSL07 480GianPas encore d'évaluation

- How To Setup KodiDocument20 pagesHow To Setup KodiGerardo RodríguezPas encore d'évaluation

- DR Reporting Made Easy With Report Builder 3.0Document132 pagesDR Reporting Made Easy With Report Builder 3.0robertorojasfeijoPas encore d'évaluation

- D4B805D88AC-Generic Scan Tool PDFDocument1 000 pagesD4B805D88AC-Generic Scan Tool PDFandrew smith100% (1)

- SAUDI ARAMCO VESSEL CLOSURE CERTIFICATEDocument1 pageSAUDI ARAMCO VESSEL CLOSURE CERTIFICATEAnonymous S9qBDVkyPas encore d'évaluation

- Sap Ehp 7 For Sap Erp 6Document9 pagesSap Ehp 7 For Sap Erp 6fiestamixPas encore d'évaluation

- Blackrock Methods of Delay AnalysisDocument36 pagesBlackrock Methods of Delay AnalysisAhmed MoubarkPas encore d'évaluation

- Hull Survey MethodsDocument21 pagesHull Survey MethodsSanta Clara100% (2)

- Portal KombatDocument13 pagesPortal KombatspereiracunhaPas encore d'évaluation

- Mitsubishi Lifts BrochureDocument28 pagesMitsubishi Lifts Brochurenaveenarora298040Pas encore d'évaluation

- 7150 DD RL InstallationDocument6 pages7150 DD RL InstallationMIGUELPas encore d'évaluation

- 700 td557 - TIMERDocument8 pages700 td557 - TIMER_golob_Pas encore d'évaluation

- Rapport Pa ConsultingDocument34 pagesRapport Pa ConsultingLong NguyenPas encore d'évaluation

- Canning 160513032223Document28 pagesCanning 160513032223Nitin SinghalPas encore d'évaluation

- Sheet 19 NCSPA Design Data SheetDocument12 pagesSheet 19 NCSPA Design Data SheetVietanh PhungPas encore d'évaluation

- Diesel QSC8.3 GEM DisplayDocument48 pagesDiesel QSC8.3 GEM Displayedwin100% (4)

- Checklist BizTalk Application MigrationDocument11 pagesChecklist BizTalk Application MigrationMadhusudhan AkulaPas encore d'évaluation

- T3200Document2 pagesT3200kylegaze0% (1)

- Case Study Extension of The East London Line enDocument4 pagesCase Study Extension of The East London Line enPedro HenriquesPas encore d'évaluation

- Profile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEDocument12 pagesProfile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEShalimarPas encore d'évaluation

- Disc ValveDocument6 pagesDisc ValvemohamedroyaleyeuaePas encore d'évaluation

- BioTime 7.0 Installation Guide V1.1 APR 2018Document13 pagesBioTime 7.0 Installation Guide V1.1 APR 2018Muhammad Rizwan WaliPas encore d'évaluation