Académique Documents

Professionnel Documents

Culture Documents

Comsol Article

Transféré par

Shaykkh ShahbaawzCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Comsol Article

Transféré par

Shaykkh ShahbaawzDroits d'auteur :

Formats disponibles

MEMS-based biosensor brings the hope of disposable DNA detector

Wouldnt it be a great service to diagnosing and treating genetic diseases if physicians had a disposable instrument for detecting DNA that worked as simply and quickly as todays home-pregnancy tests? Or if we could have other inexpensive biosensors that could look for specific blood proteins or other biological substances? This isnt such a farfetched proposition thanks to advances in microfluidic-based Lab-on-a-Chip concepts. Professor Carl Meinhart at University of California, Santa Barbara (UCSB) is leading a research team that is examining how to design microfluidic devices for enhanced performance of biosensors that can quickly detect biological molecules.

B Y P A U L G S C H RE I E R

1 0

CO M S O L

N E W S

N O. 1

2 0 0 5

Dr. Meinhart labels himself as being primarily an experimentalist, but hes equally well known as an expert numerical modeler. He uses FEMLAB to develop and verify theories that explain what he observes, to pinpoint which theories agree with observed experimental results. In this way, he feels hell be better prepared to expand his findings to a large number of application areas that involve the stirring, pumping, and mixing of small (nanoliter) volumes of fluids. Dr. Meinhart began his work on microfluidic devices thinking it might be applicable to biosensors, an area with great commercial potential. When a sample has a low concentration of the analyte (the species to be analyzed), todays tests can require tens of hours. In contrast, hes developed some microchannel devices that can potentially reduce this time by a factor of 10by micro-stirring the fluid through the action of applying an appropriate voltage to electrodes.

main transport perpendicular to the flow and to the surface is through the process of diffusion. If the reaction is limited by diffusion, the detection process can take as long as roughly 10 hours. Dr Meinhart and his team have developed a method for improving flow near the reaction surface to increase the transport of analyte using ac electrokinetic flow. Here they place two electrodes on the channel wall opposite the binding surface. When they apply a voltage, the AC electrokinetic forces generate a swirling pattern in the fluid that transports a higher concentration of the analyte towards the binding surface, increasing the reaction rate. Explains Meinhart, By adding carefully designed electrodes and the optimal driving voltage, we can potentially reduce the detection time by a factor of ten, from ten hours to just one. For a laboratory that needs to perform a large number of tests, this reduction in time is significant.

Six physics involved Find the perfect match

Before looking at the modeling process, first consider the physics of hybridization (to form base pairs between complementary regions). Many DNA tests use this technique to detect the concentration or presence of specific-sequence oligio-nucleotides (the basic building blocks of DNA). One detection technique functionalizes a microchannel surface with a known single-stranded DNA. The flow in the microchannel delivers unknown single-stranded DNA molecules to the functionalized surface. If a complementary match exists, the DNA hybridizes to the functionalized surface, producing either an electrical or optical signal related to analyte concentration. Theory would have it that the diffusion of DNA to the surface limits the rate of hybridization, so the detection system will enhance the reaction by micro-stirring the fluid. Although Dr. Meinhart hasnt yet experimentally confirmed this idea with DNA, he believes it holds promise, and his team is working on bringing this technology to industrially relevant sensors. To implement his novel approach, Dr Meinhart is designing a microchannel device (Figure 1) with a diameter of 40 m and a length of 250 m. Without adding any electrical excitation, the transport of the analyte to the reaction surface can be slow because the laminar flow in the channels is parallel to this surface and zero at the surface itself. Thus the The method by which electrical forces stir the fluid is relatively complex, involving a number of physics. In particular, three major phenomena are involved. First is a dielectrophoresis (DEP) force, whereby a molecule acting as an electric dipole reacts to an applied voltage.

Dr. Carl D. Meinhart is an Associate Professor in the Department of Mechanical and Environmental Engineering at the University of California, Santa Barbara. He is also Director of the UCSB Microfluidics Laboratory, which conducts research in two primary areas: the investigation of fluid mechanics at the microscale, and its application to optimize MEMSbased biosensors.

By adding carefully designed electrodes and the optimal driving voltage, we can potentially reduce the detection time by a factor of ten.

Second is an electrothermal force on the fluid. The electrodes create an AC electric field that nonuniformly Joule heats the fluid. Electrical conductivity and permittivity are functions of temperature, so gradients in these parameters due to the heating give rise to Coulomb and dielectric forces, which act as an electrothermal force that changes the fluids motion (see reference). A third force arises due to electroosmosis. The fluid is a conductor, so a voltage applied to the electrode triggers ions in the fluid to counterbalance the potential. The result is a very thin layer of ions at the electrode surfaces only a few nanometers thick. The electric field leaves at a direction normal to the electrode surface, but if the layer is only tens of na-

COMSOL

NEWS

NO.1

2005

11

Binding surface (Antibody is immobilized here)

Analyte is introduced here

40m

Electrodes Figure 1Fluid flows through a microchannel from left to right, and an optimized AC voltage applied at the electrodes on the bottom improves the rate of absorption at the binding surface.

model simultaneously couples six equations: Solve the base electrostatics problem using Laplaces equation. Solve the thermal-energy equation with Joule heating from the electric field as a source term. Calculate the nonlinear electrothermal force using results from electrostatics and temperature simulations. Solve the fluid-velocity field in the channel using the Navier-Stokes equations with the electrothermal force added as a source term. From the electrothermal force equation, the Coulomb force dominates at low frequencies and the dielectric force dominates at high frequencies.

Research assistant Gaurav Soni (left) and Prof. Carl Meinhart (right) examine a microchannel device in their laboratory.

nometers thick the field has a slight tangential component, and this electroosmotic force contributes to fluid motion. Dr. Meinharts team has conducted experiments to investigate these forces and their results. They then combine experimental results with numerical simulations to examine the validity of various

Use the time-dependent diffusion-convection scalar equation to predict the analytes suspended concentration within the microchannel. Solve the 1D heterogeneous reaction equation and couple the 1D binding surface to the 2D microchannel. To assist in creating an accurate mathematical model that would incorporate all these factors in the biosensor, Dr. Meinharts team first started using FEMLAB in 2000. Before that time, he notes, there were no commercial packages that could solve all of these physics. Im aware of a researcher who developed his own code to examine flow in a microchannel, but he spent years doing it. With FEMLAB, a knowledgeable user can code it up in a week. Meanwhile, some other commercial packages have come around with multiphysics capabilities, but you can only hope that the one you pick includes the needed combination of physics, which it might not depending on the physics youre studying, especially if its a narrow field. In fact, with such narrow disciplines theres rarely a commercial code. Even if you get lucky and find one, it can be very

These FEMLAB models should enable the biosensor industry to get innovative products based on this breakthrough technology to market even faster.

theories. Creating such a numerical model is quite complex because the problem has a large number of physics, including the behavior of electrical potential, electric field, temperature, electrical conductivity and permittivity, fluid velocity, analyte concentration, and a first-order heterogeneous reaction. The

1 2

CO M S O L

N E W S

N O. 1

2 0 0 5

difficult to link the physics together in such environments. FEMLAB, in contrast, is very advanced and flexible. If youre not certain of the governing equations, you can try any number of equations or terms or even build your own until you find the set that does the job.

When built-in equations arent enough

Dr. Meinhart points to the odd couplings that this problem involves, especially the electrothermal stirring that must account for the electric field, the heating of the fluid, and the nonuniform binding forces. When examining some effects, he found that no package had the necessary equations prewritten. For instance, in calculating the DEP forces he had to take a first and a second derivative of the potential field on a boundary. In that case he was able to type the equations into FEMLABs free-form direct-entry equation fields straight from the keyboard. The most challenging aspect of creating the model, though, was dealing with the chemical reaction. His team coupled a 1D geometry for the binding surface to a 2D geometry that represents the microchannel. At first we were stumped as to how to couple physics on these two geometries, comments Dr. Meinhart. We ended up learning how to do it in a FEMLAB course where they had an example similar to our case. We quickly discovered that these hands-on classes are absolutely invaluable when working with sophisticated models. In his model, developed with the assistance of team members Gaurav Soni, Marin Sigurdson and Dahzi Wang, the incoming flow has a small concentration of the biological analyte, which flows from left to right. Without any voltage applied to the two electrodes on the bottom, the flow profile is characteristic for fully-developed laminar flow, that is, parabolic velocity profile with zero velocity at the channel walls. The analyte is transported with the fluid and is absorbed by the reaction surface on the upper boundary, and any remaining concentration exits the channel on the right side with the fluid. The model solves the steady-state flow interacting with the given electric field and the resulting electrothermal force. Then, for comparison, the team ran a transient simulation of the material balance assuming that the initial concentration is zero and a given concentration is injected at the inlet.

Quickly investigate new combinations

With the knowledge the team is gaining through modeling with FEMLAB, they can quickly and efficiently examine the effects of various geometries for the microchannel as well as placement of the binding surface and the electrodes; they can also investigate what happens with various excitation voltages. In this way, they can quickly optimize the basic principles for particular biosensor applications that examine a wide range of analytes injected into various fluids. These models, in turn, should enable the biosensor industry to create innovative products based on this breakthrough technology and get them to market even faster. In addition, Dr. Meinhart works as an independent consultant in the bio-MEMS field, and FEMLAB has made it possible for him as an experimentalist to get involved with the underlying theories and numerics. FEMLAB has a flexibility far beyond anything else on the market, and that makes it a valuable tool for me because I never know exactly what physics I will need to solve.

B_total / x_length

The image in Figure 2 shows that when an AC voltage is applied to the electrodes, the velocity profile is no longer parabolic and is displaced towards the binding surface. This implies that the analyte concentration is transported towards the binding surface much faster in the presence of an electric field. A study revealed that 14 V rms applied to strategically placed electrodes can increase the binding rate in the first few minutes by a factor of almost five. Optimization of the electrode geometry and placement through the aid of simulations with FEMLAB can render this technique useful for a large variety of microfluidic immuno-sensors. The team also wanted to quantify the enhancement of the binding reaction, so they compared the binding rates in two cases: with and without the electric field (Figure 3). Applying 10 V rms to the electrodes enhances the bound concentration by a factor of 1.5 within the first five seconds, and this factor keeps on increasing with time. In addition, the binding rate, as seen in the slope of the curves, is almost 1.5 times higher in the case of electrokinetic flow.

Figure 2The flow 5 sec after applying a specific voltage to the electrodes stirs the fluid flow so that it focuses the analyte on a narrow path near the reaction surface. The color plot shows the analyte concentration and the arrows show the velocity field.

B_total / x_length

Time

Figure 3A FEMLAB plot of average concentration (mol/liter) vs. time (seconds) illustrates that applying a 10 V rms signal to the electrodes enhances the bound concentration by a factor of 1.5 within the first 5 sec; this factor continues to increase with time. The curves slope gives the binding rate, which is also almost 1.5 times higher in the case of the electrokinetic flow.

Note: The full FEMLAB model for the teams microchannel biosensor is available for review; it comes automatically as part of the Model Library that ships with the FEMLAB MEMS Module, but it is also available separately by sending a request to info@comsol.com. We will supply you with the model as well as a copy of the free FEMLAB Multiphysics Viewer, which allows you to explore the model and perform postprocessing of the results. Reference: Ramos, SPA., H. Morgan, N.G. Green and A. Castellanos, 1998. AC electrokinetics: a review of forces in microelectrode structures. J. Phys. D: Appl. Phys. 31, 2338-2353.

COMSOL

NEWS

NO.1

2005

13

Vous aimerez peut-être aussi

- Sheikh Shahbaz ResumeSShDocument2 pagesSheikh Shahbaz ResumeSShShaykkh ShahbaawzPas encore d'évaluation

- Sheena HSMDocument8 pagesSheena HSMdesign12Pas encore d'évaluation

- Instruction Academic Arrangement 2014Document1 pageInstruction Academic Arrangement 2014Shaykkh ShahbaawzPas encore d'évaluation

- CV NewDocument7 pagesCV NewCh WaqasPas encore d'évaluation

- Sylabbus For CsirDocument6 pagesSylabbus For CsirShaykkh ShahbaawzPas encore d'évaluation

- ) Urp%Lrvhqvruvwr/Derq&Kls'Hyhorslqj &Klsedvhg%Lrvhqvruviru (Qylurqphqwdodqg &Olqlfdo$SsolfdwlrqvDocument1 page) Urp%Lrvhqvruvwr/Derq&Kls'Hyhorslqj &Klsedvhg%Lrvhqvruviru (Qylurqphqwdodqg &Olqlfdo$SsolfdwlrqvShaykkh ShahbaawzPas encore d'évaluation

- 01220596Document1 page01220596Shaykkh ShahbaawzPas encore d'évaluation

- Theory and Experiments of MEMS Thermal Biosensors: Li Wang and Qiao LinDocument4 pagesTheory and Experiments of MEMS Thermal Biosensors: Li Wang and Qiao LinShaykkh ShahbaawzPas encore d'évaluation

- Shaykkh Shahbaaz Project PPT Zeroth ReviewDocument13 pagesShaykkh Shahbaaz Project PPT Zeroth ReviewShaykkh ShahbaawzPas encore d'évaluation

- Smart Dust - by Shaykkh Shayhbaawz.Document14 pagesSmart Dust - by Shaykkh Shayhbaawz.Shaykkh ShahbaawzPas encore d'évaluation

- Session 20 Displays, Sensors, and MEMS - Biosensors and 3D Hetero IntegrationDocument1 pageSession 20 Displays, Sensors, and MEMS - Biosensors and 3D Hetero IntegrationShaykkh ShahbaawzPas encore d'évaluation

- DadoDocument4 pagesDadoShaykkh ShahbaawzPas encore d'évaluation

- ProjectDocument3 pagesProjectShaykkh ShahbaawzPas encore d'évaluation

- Etection of Breast Cancer Cells in Tri-Culture UsingDocument3 pagesEtection of Breast Cancer Cells in Tri-Culture UsingShaykkh ShahbaawzPas encore d'évaluation

- MUZADocument3 pagesMUZAShaykkh ShahbaawzPas encore d'évaluation

- Mems and Asic Design CapabilitiesDocument18 pagesMems and Asic Design CapabilitiesShaykkh ShahbaawzPas encore d'évaluation

- selecStudFr ReportNewDocument147 pagesselecStudFr ReportNewShaykkh Shahbaawz0% (1)

- 5x6 SourcesDocument5 pages5x6 SourcesShaykkh ShahbaawzPas encore d'évaluation

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentShaykkh ShahbaawzPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Classical Theory of DetonationDocument20 pagesClassical Theory of Detonationalexander.lhoistPas encore d'évaluation

- LZ96a Dist - Relay1Document40 pagesLZ96a Dist - Relay1RK K0% (1)

- Exploring The Lalitha Sahasranamam: (Where Spirituality Guides Science)Document9 pagesExploring The Lalitha Sahasranamam: (Where Spirituality Guides Science)ShraddhamritaChaitanyaPas encore d'évaluation

- 2 Torsion of ThinWalled StructuresDocument12 pages2 Torsion of ThinWalled StructuresJ.p. ZhuPas encore d'évaluation

- Road Construction NotesDocument19 pagesRoad Construction NotesVanessa Apolinario100% (7)

- MIDAS SteelCompositeCurvedBridgeTutorialDocument41 pagesMIDAS SteelCompositeCurvedBridgeTutorialOscar Mendoza100% (1)

- A4-P 4.0 enDocument32 pagesA4-P 4.0 enmkpqPas encore d'évaluation

- Rubik's Revenge (4x4x4)Document5 pagesRubik's Revenge (4x4x4)Febbi Abdul MuktiPas encore d'évaluation

- Studies of Refractive Index of Different LiquidsDocument13 pagesStudies of Refractive Index of Different LiquidsSamrat HalderPas encore d'évaluation

- 6.1.5 - Well Control Worksheet & Pump DataDocument4 pages6.1.5 - Well Control Worksheet & Pump DatadagingoPas encore d'évaluation

- Sensors: A New Approach For Improving Reliability of Personal Navigation Devices Under Harsh GNSS Signal ConditionsDocument21 pagesSensors: A New Approach For Improving Reliability of Personal Navigation Devices Under Harsh GNSS Signal ConditionsRuddy EspejoPas encore d'évaluation

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanPas encore d'évaluation

- Learn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeDocument4 pagesLearn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeSuman SamantaPas encore d'évaluation

- Divided Wall Column 496Document6 pagesDivided Wall Column 496GeorgePas encore d'évaluation

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyPas encore d'évaluation

- How To Carry Out Tack WeldingDocument2 pagesHow To Carry Out Tack WeldingwentropremPas encore d'évaluation

- Junior Design Project Meat Grinder 2016 2Document44 pagesJunior Design Project Meat Grinder 2016 2api-328800450100% (10)

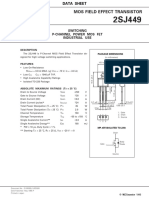

- 2SJ 449 - NecDocument9 pages2SJ 449 - NecStevenPas encore d'évaluation

- Eh tw480Document12 pagesEh tw480fefotroncitoPas encore d'évaluation

- Bionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWDocument148 pagesBionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWbicarbonat100% (2)

- Biomechanical Analisys of Military BootsDocument42 pagesBiomechanical Analisys of Military Bootsbungureanu_6100% (1)

- CS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaDocument3 pagesCS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaZhichaoWangPas encore d'évaluation

- SI-E1-2009-R001-Structural Calculation-15-05-20 PDFDocument138 pagesSI-E1-2009-R001-Structural Calculation-15-05-20 PDFரதி சுரேஷ்100% (1)

- Deep BeamDocument59 pagesDeep BeamNumair Ahmad FarjanPas encore d'évaluation

- Shepard Metzler 1971Document4 pagesShepard Metzler 1971Tobias CavalcantiPas encore d'évaluation

- HW 5 SolDocument20 pagesHW 5 SolKhoa Le TienPas encore d'évaluation

- D6937 4047 PDFDocument2 pagesD6937 4047 PDFEmily MurilloPas encore d'évaluation

- Chemical Engineering Past Present and FutureDocument2 pagesChemical Engineering Past Present and FutureArinjayKumarPas encore d'évaluation

- Cambridge IGCSE: Physics 0625/11Document16 pagesCambridge IGCSE: Physics 0625/11Jyotiprasad DuttaPas encore d'évaluation