Académique Documents

Professionnel Documents

Culture Documents

WP 1148

Transféré par

augustinhodjDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WP 1148

Transféré par

augustinhodjDroits d'auteur :

Formats disponibles

Document. . . Frame title . Document date Printed at. .

Page - 1

. . . .

. . . .

.: .: .: .:

TM 1-1520-237-23 INSTALLATION [4 of Mon Nov 08 13:46:42 Sat Oct 20 23:53:46

[WP 1148 00] - 30 JULY 2010, FORWARD BELLCRANK 4] 2010 2012

INSTALLATION

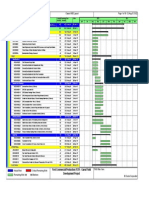

QA 1. Install replacement forward bellcrank in forward bellcrank support with long arm (with rigging pin hole) down. Install spacer through inboard side of support (Figure 1).

Warning

Cleaning compound is combustible and toxic to the eyes, skin and respiratory tract. Wear protective gloves and goggles/face shield. Avoid repeated or prolonged contact. Use only in well ventilated areas (or use approved respirator as determined by local safety/industrial hygiene personnel). Keep away from open flames, sparks, hot surfaces or other sources of ignition.

Caution

If resistance or binding of the retaining ball mechanism is observed when pin is actuated, do not apply corrosion preventive compound to free the mechanism. The inner core of the bolt is corroded and must be rejected. 2. Clean special self-retaining bolt using a cleaning cloth, WP 2012 00, Item 86, moistened with cleaning compound solvent, WP 2012 00, Item 71. a. Inspect special self-retaining bolt for evidence of corrosion in the area of retaining balls, threads, cotter pin hole, retaining pin hole in bolthead, and hole in threaded end of special self-retaining bolt. b. Visually inspect special self-retaining bolt for cracks in area of retaining balls and threads. c. Replace any special self-retaining bolt with visible corrosion or cracks. 3. Release retaining balls by holding retaining pin in. Apply corrosion preventive compound, WP 2012 00, Item 105, to special self-retaining bolt as follows: a. Work corrosion preventive compound through one retaining ball hole until excess is seen at opposite ball hole. Rotate bolt 180 degrees and repeat procedure. b. While working retaining pin, spray corrosion preventive compound, WP 2012 00, Item 105, into hole in bolthead and hole in end of special self-retaining bolt. c. Wipe excessive corrosion preventive compound from bolt using cleaning cloth, WP 2012 00, Item 86, prior to installation. d.

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Document. . . . . .: Frame title . . . .: Page - 2

TM 1-1520-237-23 - [WP 1148 00] - 30 JULY 2010, FORWARD BELLCRANK INSTALLATION [4 of 4]

Apply corrosion preventive compound, WP 2012 00, Item 101, to the exterior retaining ball area and threads.

Warning

CSI Verification of proper hardware installation, torque, safety installation and proof torque of special self-retaining bolts are critical characteristics.

Note

Turn eccentric bushings as necessary to line up boltholes. Add recessed washer (beveled side against head) under bolthead first. Add flat washers as necessary, to ensure nut is bottomed against control rod and not on bolt. QA 4. Install special self-retaining bolt and washers (maximum of 3 washers under bolthead) through eccentric bushings and bellcrank to provide correct grip length and cotter pin position. 5. Check bolt for free axial motion and that impedance feature is not restrained in part. If bolt binds and impedance feature is depressed, change washer stackup. 6. Install nut. TORQUE NUT TO 925 - 1350 INCH-POUNDS.

Note

QA

If unable to proof torque bolthead, use a crowfoot attachment to torque nut, without disturbing cotter pin, and without restraining bolthead. QA 7. APPLY TIGHTENING TORQUE (PROOF LOAD) OF 630 - 650 INCH-POUNDS in tightening direction. If bolt rotates adjust by adding washers (WP 1047 00) and reinstall, repeating step 6. and step 7. Install cotter pin. 8. Apply torque stripe (WP 0389 00 and TM 55-1500-345-23). 9. Install control rod and link on forward bellcrank (WP 1138 00 and WP 1142 00). 10. Turn on all electrical and hydraulic power. QA 11. Raise collective and remove wood blocks from between swashplate and main gear box. 12. Turn off all electrical and hydraulic power. 13. Check area for cleanliness and foreign material. QA 14. Install transmission fairings. 15. Close main rotor pylon sliding cover.

END OF WORK PACKAGE

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Yates CatalogDocument92 pagesYates CatalogaugustinhodjPas encore d'évaluation

- Google Search Tips For HackingDocument9 pagesGoogle Search Tips For HackingVa Ru N100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- CySA+ Study Guide PublicDocument63 pagesCySA+ Study Guide PublicJimmy Sembhi100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Format of A Standard SOPDocument3 pagesFormat of A Standard SOPJefry LimbongPas encore d'évaluation

- WP 1047 ADocument14 pagesWP 1047 AaugustinhodjPas encore d'évaluation

- Swashplate assembly componentsDocument2 pagesSwashplate assembly componentsaugustinhodjPas encore d'évaluation

- भारत की राजव्यवस्था एम लक्ष्मीकांत 6वा संस्करणDocument626 pagesभारत की राजव्यवस्था एम लक्ष्मीकांत 6वा संस्करणgetgateclose100% (1)

- Masterpact ManualDocument152 pagesMasterpact Manual322399mk7086100% (2)

- Main Rotor Hub Assembly DrawingsDocument10 pagesMain Rotor Hub Assembly Drawingsaugustinhodj100% (2)

- FF C 450F PDFDocument9 pagesFF C 450F PDFCristina CoceasuPas encore d'évaluation

- Project Report on SQL Injection Vulnerability Detection and Attacking Using IRONWASPDocument14 pagesProject Report on SQL Injection Vulnerability Detection and Attacking Using IRONWASPburhanshafaat1984Pas encore d'évaluation

- Authentication and Single Sign-OnDocument48 pagesAuthentication and Single Sign-Onrengasamys100% (2)

- Garraf FCP DD ScheduleDocument19 pagesGarraf FCP DD ScheduleSalman HussainPas encore d'évaluation

- Cause & Effect DiagramDocument4 pagesCause & Effect DiagramviqibagasPas encore d'évaluation

- EMV v4.3 Book1 ICC To Terminal Interface 2011113003541414Document189 pagesEMV v4.3 Book1 ICC To Terminal Interface 2011113003541414ashishkarPas encore d'évaluation

- Discos Novos - Hiphop - AlbumsDocument11 pagesDiscos Novos - Hiphop - AlbumsaugustinhodjPas encore d'évaluation

- Vestax VCI-400 Quickstart GuideDocument10 pagesVestax VCI-400 Quickstart GuideaugustinhodjPas encore d'évaluation

- 60fpdftol106h2u20101 11122012153528Document64 pages60fpdftol106h2u20101 11122012153528augustinhodjPas encore d'évaluation

- Manual Servico TV LCD Sony KDL 55ex525 Chassis Az2wDocument86 pagesManual Servico TV LCD Sony KDL 55ex525 Chassis Az2waugustinhodjPas encore d'évaluation

- WP 1047 VDocument2 pagesWP 1047 VaugustinhodjPas encore d'évaluation

- WP 1047 IIIDocument2 pagesWP 1047 IIIaugustinhodjPas encore d'évaluation

- Active Subs SeriesDocument8 pagesActive Subs SeriesaugustinhodjPas encore d'évaluation

- Flight Control Rod Tri-Pivot Connections GuideDocument4 pagesFlight Control Rod Tri-Pivot Connections GuideaugustinhodjPas encore d'évaluation

- Prx600 SeriesDocument36 pagesPrx600 SeriesaugustinhodjPas encore d'évaluation

- WP 1047 VDocument2 pagesWP 1047 VaugustinhodjPas encore d'évaluation

- WP 1047 VDocument2 pagesWP 1047 VaugustinhodjPas encore d'évaluation

- wp1142II XMLDocument1 pagewp1142II XMLaugustinhodjPas encore d'évaluation

- wp1148 IVDocument1 pagewp1148 IVaugustinhodjPas encore d'évaluation

- Aviation Unit Level Maintenance Airframe Cabin Floor: Initial Setup: Tools and Special ToolsDocument1 pageAviation Unit Level Maintenance Airframe Cabin Floor: Initial Setup: Tools and Special ToolsaugustinhodjPas encore d'évaluation

- WP 0640 ADocument2 pagesWP 0640 AaugustinhodjPas encore d'évaluation

- Linksys WRT54G User GuideDocument33 pagesLinksys WRT54G User GuideKevin Severud88% (16)

- NovapDocument128 pagesNovapaugustinhodjPas encore d'évaluation

- Vestax VCI-400 Quickstart Guide For Serato DJDocument9 pagesVestax VCI-400 Quickstart Guide For Serato DJaugustinhodjPas encore d'évaluation

- UH-60A EH60A: RemovalDocument2 pagesUH-60A EH60A: RemovalaugustinhodjPas encore d'évaluation

- WRT54Gv7-EU UGDocument819 pagesWRT54Gv7-EU UGSiske33Pas encore d'évaluation

- Figure 1, Sheet 3: AssemblyDocument1 pageFigure 1, Sheet 3: AssemblyaugustinhodjPas encore d'évaluation

- Control Rod Corrosion ProtectionDocument1 pageControl Rod Corrosion ProtectionaugustinhodjPas encore d'évaluation

- Figure 1, Sheet 3: AssemblyDocument1 pageFigure 1, Sheet 3: AssemblyaugustinhodjPas encore d'évaluation

- Figure 1, Sheet 3: AssemblyDocument1 pageFigure 1, Sheet 3: AssemblyaugustinhodjPas encore d'évaluation

- Product Specification: (V) Preliminary Specifications Final SpecificationsDocument36 pagesProduct Specification: (V) Preliminary Specifications Final SpecificationsKent CaoPas encore d'évaluation

- Westermo DR-250 & GreenBow IPSec VPN ConfigurationDocument10 pagesWestermo DR-250 & GreenBow IPSec VPN ConfigurationgreenbowPas encore d'évaluation

- Bus Pass System Project: Software RequirementsDocument2 pagesBus Pass System Project: Software RequirementsRakesh PatilPas encore d'évaluation

- List of Dropbox Student in Udise - 2023-24 Page Udise Code: School Name: Udise Block: DistrictDocument1 pageList of Dropbox Student in Udise - 2023-24 Page Udise Code: School Name: Udise Block: Districtjaimaati038Pas encore d'évaluation

- Ebiz Batch 3 HandoutDocument102 pagesEbiz Batch 3 HandoutjerjaiwinPas encore d'évaluation

- ASEBA - Mtoken - GladstoneDocument2 pagesASEBA - Mtoken - GladstonesantiagomatamorosPas encore d'évaluation

- Verbal Consent FormDocument2 pagesVerbal Consent FormAshley OstrootPas encore d'évaluation

- Tamil Nadu E-District: Application Training ManualDocument23 pagesTamil Nadu E-District: Application Training ManualHarish MahadevanPas encore d'évaluation

- 16.1 Write A JSP Page To Display The Current Date and Time. Date - JSPDocument8 pages16.1 Write A JSP Page To Display The Current Date and Time. Date - JSPKarthik SuryanarayananPas encore d'évaluation

- TOR Admin Assistant SC - 4Document1 pageTOR Admin Assistant SC - 4newarakanPas encore d'évaluation

- Log of Network and Backend Status ChangesDocument22 pagesLog of Network and Backend Status ChangesbitadminaccPas encore d'évaluation

- ProblemsDocument133 pagesProblemsatkawa7Pas encore d'évaluation

- Application Submitted: Appointment StatusDocument1 pageApplication Submitted: Appointment Statusprint arenaPas encore d'évaluation

- Extra - Exercises Unistall InformixDocument14 pagesExtra - Exercises Unistall InformixМихаи БонцалоPas encore d'évaluation

- Final TIBER-EU Guidance For The Red Team Test Plan July 2020Document13 pagesFinal TIBER-EU Guidance For The Red Team Test Plan July 2020martial dibiPas encore d'évaluation

- Republic of The Philippines Professional Regulation Commission ManilaDocument2 pagesRepublic of The Philippines Professional Regulation Commission ManilaFrederick GellaPas encore d'évaluation

- Augmenting Zero Trust Architecture To Endpoints UsDocument18 pagesAugmenting Zero Trust Architecture To Endpoints UsRajnish SharmaPas encore d'évaluation

- Password and Authentication (PPT Final)Document14 pagesPassword and Authentication (PPT Final)Rohit PatilPas encore d'évaluation

- Geovision 8.5 DVR NVR Software ManualDocument664 pagesGeovision 8.5 DVR NVR Software ManualDiego KalikPas encore d'évaluation

- Legal Notice UKDocument4 pagesLegal Notice UKRakesh ShekhawatPas encore d'évaluation