Académique Documents

Professionnel Documents

Culture Documents

Eil - Elect - Spec - VCB & Control Panel Specification

Transféré par

Damodharan ChandranTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eil - Elect - Spec - VCB & Control Panel Specification

Transféré par

Damodharan ChandranDroits d'auteur :

Formats disponibles

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 1

Vacuum circuit Breaker

< Vacuum Circuit Breaker

It is a mechanical switching device in that arc-quenching medium due current interruption is vacuum. EnerconIndia Ltd using different voltage system likes 11KV & 33KV Vacuum Circuit breakers in electrical infrastructure for providing safe switching and protection of grid and equipments. High vacuum has two out standing properties 1.the highest insulating strength known and 2.When an a.c. circuit is opened by the separation of contacts in a vacuum, interruption occurs at first zero, with the dielectric strength across the contacts building up at a rate thousands times higher than the obtained with the conventional circuit breakers. A high vaccum gap recovers most of its dielectric strength within 10micro seconds. These properties obliviously make the VCB more efficient, less bulky and cheaper. The moving contact in a vacuum interrupter is connected to the housing of the chamber through the bellows. The travel of the moving contact is of the order of a few millimeters Inside the chamber a screen is provided to collect he vapour. The bellows is protected form metallic deposits by its own shields. The pressure in Vaccum Interrupter is at 10q6 Torr, Where 1 Torr= 1mm of mercury. The material is usually employed for the interrupter components are as follows. Envelops: Alumina ceramic or glass ceramic. Bellows: Stainless stell or Beryllium copper. Shields: Stainless steel or OFHC copper. Contacts: Copper bismuth copper chromium or copper-tungsten alloy. The protection class for switchgear Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03 Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 2

Vacuum circuit Breaker The protection class identified by a compound symbol made up of the two code letters IP, Which always remain the same two digits denoting the degree of protection and if the required, the supplementary code letter B. the supplementary code letter must be stated if in the case of switchgear and distribution equipment the protection class is attained only through taking certain measures when the apparatus is installed. The term Production class denotes the complete compound symbol (code letters, code digits, and the supplementary letter if applicable.) Protection class Code IP 4 3 B

First Digit Degree of protection against contact and ingress of foreign bodies Second digits Degree of protection against ingress of water Supplementary Sealing material between code letter floor, ceiling or wall If an addition to the code letters IP only one code digit for the degree of protection is used, the missing digit is to be replaced by dash. Eg IP 4 (Protection class splash proof) Degree of protection against contact and foreign

Degree of protection against contact and foreign

First Digit 0 1 Description No protection Protection against large foreign bodies Protection against medium seized foreign bodies

Degree of protection against water

Second Digit 0 1 2 Description No protection Protection against vertically galling water droplet. Protection against obliquely water falling droplet.

Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03

Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 3

Vacuum circuit Breaker

3 4 5 6 Protection against small foreign bodies Protection against granular foreign bodies Protection against dust deposit Protection against ingress of dust 3 4 5 6 7 8 Protection against sprayed water (spray proof) Protection Protection Protection Protection Protection against against against against against splashing (splash proof) water jet (Hot Proof) inundation immersion in water indefine immersion in water

Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03

Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 4

Vacuum circuit Breaker

The specification of Out door Vacuum Circuit Breaker as per IS 13118:1991 Sr.No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Specification Rated system voltage Highest system voltage Rated frequency No of Poles Rated normal current Rated symmetrical breaking current Peak Making capacity Rated short time current for 3sec DC components Rated Power frequency withstand voltage for 1min Rated impulse withstand voltage at 1.2/50MS Motor voltage Coil voltage Opening time Total breaking time Rated operating sequence Applicable standard 0.03sec-CO3min-CO IS: 13118:1991,IEC 60056 11KV 12KV 50Hz 3 12.5KA 22KV 33KV 24KV 36KV 50Hz 50Hz 3 3 400/800/1250/1600/2000A 18KA 25KA 62.5KA peak 25KA 50% 70KV rms 170KV Peak 110/220VAC/DC 110V DC 110/220VAC/DC 110/220VAC/DC 110V DC 110V DC

Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03

Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 5

Vacuum circuit Breaker

The installation and requirement of VCB as per load calculation and distribution of the grid and sub station isolation requirement. As per standard for 11KV, or 33KV VCB required when connected load reach >5MW. Vacuum circuit breakers for outdoor application shall have fixed type of construction and the vacuum interrupter units together with the HV connections shall be enclosed in a sealed housing (preferably of porcelain) conforming to IP-65 protection (IS: 2147). The operating mechanism, links, etc. shall be housed in a suitable cubicle and should be accessible for maintenance. The relays, meters, indicators and operating handle etc. shall be provided on the front side with a hinged door and locking device. The door shall open upwards (with hinge at the top) for protection against rain (when in open position). 1.CLOSING/TRIPPING MECHANISM The circuit breakers shall be provided with hand operated spring-closing mechanism. Provision to make for 230 V single-phase AC motor for springclosing mechanism with provision for manual closing. 2.Requisation of Remote Control Panel The control panel is required for remote operation to be supply by same supplier of VCB. The control panel must have some basic requirement 1. HRC fuse/MCB of proper rating for each circuit individually 2. Control switch for AC & DC, heater circuit and Internal Illumination. 3. Over current IDMT relay (50-200%) 4. Earth Fault relay (20-80%) Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03 Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 6

5. 6. 7. 8. 9.

Vacuum circuit Breaker Digital measuring meter for Current, Voltage and Power. Indication LED lamp for ON, OFF, Spring Charged, Trip circuit healthy, Trip, Heater ON. Etc All in coming and out going circuits connection done through terminal strip and ferruling. T-N-C switch at both VCB and Control panel. Power converter power pack for 110V AC to DC.

10. Control panel should be double door type glass window (transparent cut window). Design for out door used. 11. The thermostate and heater must have in side of control panel to control in temperature and humidity.

Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03

Approved By : BN Lunavia

Enercon India Limited

S

Spec No Page IST-S-03 of 7 Date 10.05.05

Technical specification Electrical external

Revision 1 Page 7

Vacuum circuit Breaker

Specification of VCB Specification

Rated voltage Rated lightning impulse withstand voltage (BIL) Rated power frequency withstand voltage Rated current (up to) Rated short-time current (3s) (up to) Rated short-circuit making current (up to) Rated short-circuit breaking current (up to) Rated frequency

Unit

kV kV

11KV

12 75

22KV

24 125

33KV

36 170

kV A kA kA kA Hz

28 400 12.5 125 50 50 10 000

50 400 ? 100 40 50 10 000

70 400/600/800/1600 25 100 40 50 10 000

Number of mechanical operating-cycles of drive mechanism Number of electrical switching-cycles with rated current

10 000

10 000

10 000

Controlled By : SN Kawishwar ,K.Rajakumar Form No. : SYS-F-13 / 00 / 01.04.03

Approved By : BN Lunavia

Vous aimerez peut-être aussi

- Rexeoth Control Panel BF-1Document4 pagesRexeoth Control Panel BF-1Hrvoje ŠkaricaPas encore d'évaluation

- IAI EtherCAT Pcon Acon SpecsheetDocument2 pagesIAI EtherCAT Pcon Acon SpecsheetElectromatePas encore d'évaluation

- Imcc - EtsDocument7 pagesImcc - EtssutanuprojectsPas encore d'évaluation

- Softstarter Altistart 22Document85 pagesSoftstarter Altistart 22離子0% (1)

- Production (Utilities) Heavy Water Plant (Manuguru) Gautaminagar - 507 116 Khammam Dist. Telangana StateDocument52 pagesProduction (Utilities) Heavy Water Plant (Manuguru) Gautaminagar - 507 116 Khammam Dist. Telangana StatePvk Itsa BrandnamePas encore d'évaluation

- ABB RMU Tech SpecificationDocument4 pagesABB RMU Tech SpecificationJuned HamzaviPas encore d'évaluation

- I MCCDocument4 pagesI MCCJawaharPas encore d'évaluation

- DV9800E - 24 Channel Universal Input Data ScannerDocument2 pagesDV9800E - 24 Channel Universal Input Data ScannerBalu MPas encore d'évaluation

- Intelligent Mcc-White PaperDocument5 pagesIntelligent Mcc-White PaperMadhukar ParikhPas encore d'évaluation

- Practical File of PLC and SCADADocument17 pagesPractical File of PLC and SCADAvara prasadPas encore d'évaluation

- JT3D (TF33) S3P4Document16 pagesJT3D (TF33) S3P4junmech-1Pas encore d'évaluation

- E2308 - 305B - Wiring Diagram of PLC Panel - R0Document13 pagesE2308 - 305B - Wiring Diagram of PLC Panel - R0sujitPas encore d'évaluation

- Section-7.1, 33KV GISDocument49 pagesSection-7.1, 33KV GISBRB CABLEPas encore d'évaluation

- Super Cool Technical Specification UniversalDocument5 pagesSuper Cool Technical Specification UniversalSunil SinghPas encore d'évaluation

- Motortronics Training 2012Document95 pagesMotortronics Training 2012Erasmo Colona100% (1)

- Electrical Wiring EstimateDocument17 pagesElectrical Wiring EstimateTahameeali ShaikhPas encore d'évaluation

- Iocl City Gas Distribution Project For GADocument4 pagesIocl City Gas Distribution Project For GAsubudhiprasannaPas encore d'évaluation

- Installation Instructions EPLAN Education 2023 enDocument16 pagesInstallation Instructions EPLAN Education 2023 enSachin ShikotraPas encore d'évaluation

- Enquiry For HT PANELDocument5 pagesEnquiry For HT PANELPrasenjit MaityPas encore d'évaluation

- 316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFDocument33 pages316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFMahmoud ChihebPas encore d'évaluation

- O & M Manual NewDocument14 pagesO & M Manual NewFanuel PinedaPas encore d'évaluation

- Type TestDocument89 pagesType Testeagles1109Pas encore d'évaluation

- Electronic Hooter Bell Buzzer Siren PDFDocument1 pageElectronic Hooter Bell Buzzer Siren PDFArif Rahman HakimPas encore d'évaluation

- Alarm Annunciator ManualDocument24 pagesAlarm Annunciator Manualmni066Pas encore d'évaluation

- IOC Tr. Oil Test ReportDocument3 pagesIOC Tr. Oil Test ReportMalini VenkatesanPas encore d'évaluation

- Allen Bradley NEMA PDFDocument214 pagesAllen Bradley NEMA PDFtajamul husainPas encore d'évaluation

- Rudolf RTXDocument15 pagesRudolf RTXNuengruthai WeerawattanaPas encore d'évaluation

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaPas encore d'évaluation

- Data Sheet For Cable Glands and LugsDocument8 pagesData Sheet For Cable Glands and LugsBasabRajPas encore d'évaluation

- Voltage Drop and Circuit Sizing CalculatorsDocument5 pagesVoltage Drop and Circuit Sizing Calculatorsdarsh2001patelPas encore d'évaluation

- IEC StandardDocument3 pagesIEC StandardSharath KotaPas encore d'évaluation

- Siemens Vacumm Contactor 3tl6Document15 pagesSiemens Vacumm Contactor 3tl6Yong Ee VonnPas encore d'évaluation

- Vs1 en 150dpiDocument13 pagesVs1 en 150dpiPatrik PulungPas encore d'évaluation

- LT Panel Brochure SudhirDocument6 pagesLT Panel Brochure SudhirAbhishek RaiPas encore d'évaluation

- LV PFC PB Guide (Print) PDFDocument76 pagesLV PFC PB Guide (Print) PDFionutPas encore d'évaluation

- 1151 RBDocument54 pages1151 RBManuel A. Silva PainénPas encore d'évaluation

- Microstar Company Profile PDFDocument6 pagesMicrostar Company Profile PDFDell GarciaPas encore d'évaluation

- EN - PDW3000 Gutor UpsDocument4 pagesEN - PDW3000 Gutor Upsperumal1312Pas encore d'évaluation

- Ts of 33 KV in Door Switch Board-IDocument29 pagesTs of 33 KV in Door Switch Board-ISunil SinghPas encore d'évaluation

- ASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsDocument17 pagesASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsVishwanath TodurkarPas encore d'évaluation

- Apt Aerox III 3.2kw - Manual 20181224Document41 pagesApt Aerox III 3.2kw - Manual 20181224atif jabbarPas encore d'évaluation

- Sepam 10 Seped307026en Int PDFDocument22 pagesSepam 10 Seped307026en Int PDFJeffrey Reynaldo RidwanPas encore d'évaluation

- Installation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPDocument120 pagesInstallation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPHans MortenPas encore d'évaluation

- Logix Hot Backup SolutionsDocument2 pagesLogix Hot Backup SolutionsiedmondPas encore d'évaluation

- Precon Training BrochureDocument12 pagesPrecon Training BrochurechintanPas encore d'évaluation

- Electrical Unpriced BOQ-23 07 2019Document13 pagesElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaPas encore d'évaluation

- I6s UPS Catalogue (Domestic)Document8 pagesI6s UPS Catalogue (Domestic)SagarPas encore d'évaluation

- Check ListDocument6 pagesCheck ListdevcharuPas encore d'évaluation

- Transformer ProtectionDocument19 pagesTransformer ProtectionBassem MostafaPas encore d'évaluation

- 11kV SF6Document6 pages11kV SF6ahmadgce04Pas encore d'évaluation

- Pressure-Tranmitter ABB 266HSHDocument30 pagesPressure-Tranmitter ABB 266HSHalamsyah_syamPas encore d'évaluation

- Seal of BushingDocument6 pagesSeal of BushingB.k. BirtiaPas encore d'évaluation

- Rittal Ri4Power Technical SpecificationDocument14 pagesRittal Ri4Power Technical SpecificationarkupiPas encore d'évaluation

- (2013 - ) WX-98FT User ManualDocument36 pages(2013 - ) WX-98FT User ManualOscar Omar Quintanilla100% (1)

- P12x Ent f65Document518 pagesP12x Ent f65Adip Chy100% (1)

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- Electromagnetic Foundations of Electrical EngineeringD'EverandElectromagnetic Foundations of Electrical EngineeringPas encore d'évaluation

- Tech Spec SS - IIDocument253 pagesTech Spec SS - IIkrcdewanewPas encore d'évaluation

- AC Combiner Box Specification 400vac)Document7 pagesAC Combiner Box Specification 400vac)emilPas encore d'évaluation

- Detail Technical SpecificationDocument39 pagesDetail Technical Specificationshivmishra229Pas encore d'évaluation

- T&D SystemsDocument60 pagesT&D SystemsDamodharan ChandranPas encore d'évaluation

- Chapter 3 Planning PhilosophyDocument5 pagesChapter 3 Planning Philosophyraul_bsuPas encore d'évaluation

- Key Apps UtilitiesDocument12 pagesKey Apps UtilitiesDamodharan Chandran100% (1)

- Ren PowerDocument77 pagesRen PowerDamodharan ChandranPas encore d'évaluation

- EarthDocument9 pagesEarth0b0biyd,u,uPas encore d'évaluation

- Radiator Test CertificateDocument1 pageRadiator Test CertificateDamodharan ChandranPas encore d'évaluation

- Lightning Protection TGelDocument0 pageLightning Protection TGelamcaaPas encore d'évaluation

- Windtest: Kaiser-Wilhelm-Koog GMBHDocument2 pagesWindtest: Kaiser-Wilhelm-Koog GMBHDamodharan ChandranPas encore d'évaluation

- Dental Fillings Facts FullDocument6 pagesDental Fillings Facts FullentistdePas encore d'évaluation

- Application of Vegetable Oil-Based Insulating Fluids To Hermetically Sealed Power TransformersDocument8 pagesApplication of Vegetable Oil-Based Insulating Fluids To Hermetically Sealed Power TransformersR0B0T2013Pas encore d'évaluation

- Indian Electricty Rules 1956Document148 pagesIndian Electricty Rules 1956Damodharan ChandranPas encore d'évaluation

- 01 35 Current Electricity StudyDocument34 pages01 35 Current Electricity StudyChandan SinghPas encore d'évaluation

- Resistance and Impedance... An Explanation1Document5 pagesResistance and Impedance... An Explanation1Damodharan ChandranPas encore d'évaluation

- ShimuraDocument18 pagesShimuraDamodharan ChandranPas encore d'évaluation

- Wiretec Hot and Black ConductorDocument18 pagesWiretec Hot and Black ConductorDamodharan ChandranPas encore d'évaluation

- Rare Photographs IndiaDocument30 pagesRare Photographs IndiaSwaminathan AdaikkappanPas encore d'évaluation

- Building infrastructure and industry with quality steel tubesDocument6 pagesBuilding infrastructure and industry with quality steel tubesDamodharan ChandranPas encore d'évaluation

- Fluids For Transformer Cooling PDFDocument7 pagesFluids For Transformer Cooling PDFgirish19Pas encore d'évaluation

- 01 35 Current Electricity StudyDocument34 pages01 35 Current Electricity StudyChandan SinghPas encore d'évaluation

- Facts About FillingsDocument4 pagesFacts About FillingsDamodharan ChandranPas encore d'évaluation

- Elect Energy GenDocument19 pagesElect Energy GenDamodharan ChandranPas encore d'évaluation

- Hand Book The Indian Electricity Rules1956Document148 pagesHand Book The Indian Electricity Rules1956Vivek Kumar100% (8)

- Approved Connector Installation Guide PresentationDocument35 pagesApproved Connector Installation Guide PresentationDamodharan ChandranPas encore d'évaluation

- Datsun GO Brochure 4pgDocument3 pagesDatsun GO Brochure 4pgDamodharan ChandranPas encore d'évaluation

- Expenditure of Children From Childhood To GrownDocument1 pageExpenditure of Children From Childhood To GrownDamodharan ChandranPas encore d'évaluation

- Indian Electricty Rules 1956 - CBDocument1 pageIndian Electricty Rules 1956 - CBDamodharan ChandranPas encore d'évaluation

- 1250490 வந்தார்கள் வென்றார்கள்Document188 pages1250490 வந்தார்கள் வென்றார்கள்Susai Ajan100% (1)

- Grid CodeDocument74 pagesGrid CodeDamodharan ChandranPas encore d'évaluation

- Substation Earthing Design CalculationsDocument4 pagesSubstation Earthing Design CalculationsFriday OnojaPas encore d'évaluation

- EEE121 Lecture 10Document20 pagesEEE121 Lecture 10Veshal Purshothama Seelan0% (1)

- Cable Current Carrying Capacities PDFDocument3 pagesCable Current Carrying Capacities PDFNavami VbPas encore d'évaluation

- Circuits at The Nanoscale - Communications, Imaging, and SensingDocument635 pagesCircuits at The Nanoscale - Communications, Imaging, and SensingAnkurPas encore d'évaluation

- Hybrid Solar Wind Trainer Generates Renewable EnergyDocument3 pagesHybrid Solar Wind Trainer Generates Renewable EnergySasa VrtunicPas encore d'évaluation

- Serie GMD06Document2 pagesSerie GMD06Popescu IonicaPas encore d'évaluation

- NAFSA Serie Ech40 10bd 24vdc 25%Document1 pageNAFSA Serie Ech40 10bd 24vdc 25%Iker BasqueAdventurePas encore d'évaluation

- T 6360Document4 pagesT 6360Ivan ArdiyanPas encore d'évaluation

- Green-Mode PWM Controller With Frequency Trembling and Integrated ProtectionsDocument18 pagesGreen-Mode PWM Controller With Frequency Trembling and Integrated ProtectionsAndres AlegriaPas encore d'évaluation

- Main Air CompressorDocument4 pagesMain Air CompressorArun SPas encore d'évaluation

- Arduino Nano 3.x BOMDocument2 pagesArduino Nano 3.x BOMBA BIa100% (1)

- Masteroppgave PDFDocument104 pagesMasteroppgave PDFbacuoc.nguyen356Pas encore d'évaluation

- Vladimir Poliakov's Simple 1-Transistor Superregenerative Shortwave ReceiverDocument8 pagesVladimir Poliakov's Simple 1-Transistor Superregenerative Shortwave ReceiverbaymanPas encore d'évaluation

- EC8252 Question BankDocument11 pagesEC8252 Question BankPalaniappan Muthu TPas encore d'évaluation

- G8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted ApplicationsDocument6 pagesG8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted Applicationsyocus_ooiPas encore d'évaluation

- Device Lab Report 10 PDFDocument6 pagesDevice Lab Report 10 PDFScribble RiYaDPas encore d'évaluation

- ABB REG 650 ManualDocument740 pagesABB REG 650 ManualMysha ShaqeenaPas encore d'évaluation

- 03 JM EFIE ControllerDocument1 page03 JM EFIE Controllerskyman05100% (1)

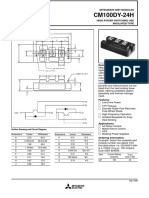

- Cm100dy 24hDocument4 pagesCm100dy 24hJulianoLuterek100% (1)

- Ec 1 FinalDocument6 pagesEc 1 FinalRaushan RaazPas encore d'évaluation

- JKM590 615N 66HL4M BDV F1C1 enDocument2 pagesJKM590 615N 66HL4M BDV F1C1 enLuka KosticPas encore d'évaluation

- Circuit Breakers DiscriminationDocument4 pagesCircuit Breakers DiscriminationVirendra Sahdev100% (1)

- An920 Rev2Document38 pagesAn920 Rev2glamuraPas encore d'évaluation

- Irfs7530 7ppbfDocument11 pagesIrfs7530 7ppbfAnidiobi OkwudiliPas encore d'évaluation

- Boss CE-2BDocument4 pagesBoss CE-2BtransilvanpopPas encore d'évaluation

- UM1943 User ManualDocument28 pagesUM1943 User ManualFrancescoPas encore d'évaluation

- Power Socket Strip PSS300: Instructions For UseDocument16 pagesPower Socket Strip PSS300: Instructions For UseJesus DunoPas encore d'évaluation

- Window Space Factor KW - Design of Transformers PDFDocument1 pageWindow Space Factor KW - Design of Transformers PDFnaresh kumarPas encore d'évaluation

- Townsend DischargeDocument5 pagesTownsend Dischargehermas67Pas encore d'évaluation

- Microwind3.1 Design Rules For 45NM Cmos TechnologyDocument44 pagesMicrowind3.1 Design Rules For 45NM Cmos TechnologyOkta_BSD100% (1)

- Chetan Waghchoure BxeDocument10 pagesChetan Waghchoure BxeHimanshu BhusariPas encore d'évaluation