Académique Documents

Professionnel Documents

Culture Documents

Pipe Reinforcing at Support

Transféré par

Seungmin Paek100%(3)100% ont trouvé ce document utile (3 votes)

2K vues12 pagesPipe Reinforcement

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPipe Reinforcement

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(3)100% ont trouvé ce document utile (3 votes)

2K vues12 pagesPipe Reinforcing at Support

Transféré par

Seungmin PaekPipe Reinforcement

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 12

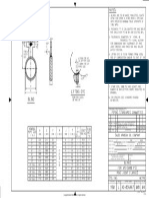

0 = Outside diameter

t = Piping wall thickness not

inc Judi ng corrosion a Jlowance } As per ASME 836-10

Pipe diameter 0/t rat1o Minimum reinforcement required

0<8

11

All None

0/t<70

None

D = 8

11

+40'' D/t = 70795

Pad

(1) Saddle(2)

D/t>95 Saddle

0>40''

All Saddle

Notes 1) Use pads for supports spans lower than 12m.

2) Use saddles for supports spans greater than 12m.

30o

<!> 3mm hole

Re1nforc1ng plate

Re1nforc1ng whit saddle

Attached to:

PIPE REINFORCING AT SUPPORT

Form. Scale Job Document Sheet Rev.

A4 01 of 01

FOR PIPES 40" THRU 76"

INSUlATION BAND SLOT

THRU ALL PlATES.

1-L...:...../2_

SECTION A- A

PIPE SIZE A B t1 t2 R PIPE SIZE A 8

20" 180 440 12 16 254 36" 340 730

24" 215 510 12 16 305 40" 250 810

26" 230 530 12 16 331 42" 260 850

28" 255 570 12 16 356 44" 280 905

30"

275 610 12 16 381 48" 310 990

32" 295 650 12 16 407 50" 340 1080

34"

320 690 12 16 432 54" 350 1100

MEMBER

NO. REQ'D

DESCRIPTION

NO. PER UNIT

CD

11 PLATE C.S., A-36 OR EQUAL, t1

@ 6 PLATE C.S., A-36 OR EQUAL, t1

0

1 PLATE C.S., A-36 OR EQUAL, t2

@ 1

REPAD, MATERIAL SAME AS PIPE

'----"

(CUT FROM RUN PIPE)

PONENTS SHALL

I PIPE WALL THICKNESS

t1 t2

14 16

14 16

14 16

14 16

14 16

14 16

14 16

THK.

THK.

THK.

L/2

SECTION 8 - 8

R PIPE SIZE A B t1 t2 R

458 60" 385 1210 14 16 762

508 62" 390 1240 14 16 788

535 64" 410 1280 14 16 813

560 66" 430 1340 14 16 840

610 72" 470 1470 14 16 917

635 74" 480 1530 14 16 942

686 76" 480 1530 14 16 966

ASSEMBLY SUPPORT EXAMPLES:

S4F-300-36 (H=c35) NOTE-S

SHOE ACTUAL HEIGHT

PIPE SIZE,36" PIPE

SHOE LENGTH, L= 300

450

600

750

8 E INSTALL ED. ,..__...__..___.....__......___..--....__--""--

3. REPAD IS REQUIRED ON LINE SIZE 40" AND

LARGER.

4. ALL DIMENSIONS ARE IN MILLIMETERS.

5. MAX. HEIGHT 20" 28" - 400mm

: 30" 36" - 500mm

SHOE FOR SLOPE LINES

FOR PIPE SIZES 20" THRU 76"

SCAlE:---- DWG. NO : REV.

MEMBER NO. REQ'D

NO. PER UNIT

CD

1

NOTES :

w

n.

~ a :

PAD CUT FROM

150

DESCRIPTION

RUN PIPE.

PIPE

150

300

1. THIS PAD SHALL BE USED ON UNINSULATED METALLIC PIPE IF D/t VALUE IS GREATER THAN 66 AND

EQUAL OR LESS THAN 95.

PAD SHALL NOT BE REQUIRED IF D/t VALUE IS EQUAL OR LESS THAN 65.

PAD AND SADDLE(SHOE) SHALL BE USED TOGETHER IF D/t VALUE IS EQUAL OR GREATER THAN 96.

( D = O.D. OF THE PIPE, t = WALL THICKNESS OF THE PIPE )

2. SUPPORT SPAN SHALL NOT EXCEED 12 METERS

.3. PAD SHALL BE PAINTED IN ACCORDANCE WITH SES- 0-.301

REV.

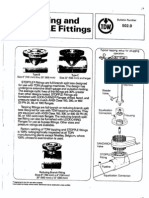

Design of Plant Piping

Wear Pads and Saddles

Piping in hazardous services where condensation can form on the pipe,

or operating within 30m of the sea shall have wear pads or corrosion

bars welded to the pipe at each support (see Standard Drawing

AE-036252 and AD-036555.

2 Excluded from this requirement are low pressure systems with hoop

stress at design pressure below 20% of Specified Minimum Yield

Strength (SMYS) of the pipe.

3 Wear pads are also required for structural reinforcement as indicated in

Standard Drawing AC-036697. Wear pads shall be fully welded to

avoid ingress of moisture.

4 Saddle-type supports: Saddle-type supports with pads shall be provided

or piping 30-inch NPS and larger. In case saddle pipe support cannot

be installed, the line shall be analyzed for localized stresses. The

analysis shall be submitted to the Piping Specialist of CSD for review

and approval.

Pnge of

100

-1--

0

_j __

SEE NOTE 5

FULL ENCIRCLEMENT SLEEVE

....

.....

SEE STD. DWG.

AD-036697::..../"

SEGMENTAL WEAR PAD

.....__....._,.'-'--< T YP IC A L

NOTES:

I. TOLERANCES: R!

THICKNESS:

ANGLE: 2

2. MAXIMUM SPANS FOR VARIOUS PIPE

DIAMETERS AND WALL THICKNESSES

ARE LISTED ON AD-036697.

3. REFER TO AD-036990 FOR DETAILS OF

STANDARD SADDLES.

4. METRIC VALUES OF LINEAR DIMENSION

ARE IN MILLIMETERS.

5. USE BACK-UP STRIP 16 GA. x 12mm WIDE

SEE NOTE 5 6. FULL ENCIRCLEMENT SLEEVES SHALL BE

SEGMENTAL PAD

USED ON ALL CROSS COUNTRY PIPELINES

DESIGNED TO OPERATE AT OR IN EXCESS

OF 50% OF SPECIFIED MINIMUM YIELD

STRENGTH CSMYSl SEGMENTAL PADS MAY

BE USED ON PIPE DESIGNED TO OPERATE

AT LESS THAN 50% OF SMYS.

DRAYI!NG RESPONSI BILITY:

PIPING STANDARDS COMMITTEE

II: HT' _ __;:. J o;;.. G. ,__ CHCO'.rD HY _ _,C::..:.: W..:...T__

OAT[ S':'AR iO -----OAT Cil UPL[ H Q -----

c:rR:;. r...r r. -------n.c-. ncr r. _____ _

J.. PPO. CO,.,S T"-

no;,. ocr ro 111 01

!71 f or!

... 1,011 : .. r,. ,")llo f r !l , ,... , , , , .,

CtHTlfl[O ORiG. CERT!F!EO

HY

n.:. H __

STANDARD WEAR PADS FOR

UNRESTRAINED PIPELINES

STD. OWG. METRIC

Pl .&.NT N\). lt{l[K

1 100 !

12 I l12

-l i -1 - i i--

- r-=

I

' }:, 1' :_<- i E I .

L : _fl_.l):J; . : I_ I, v.

/-11-\ di

I

-- I - .,'-,- r.CJIHINUCUS

. 50C: f'IFt. O SEAL _ .

1-----==-=---i . ..,. E L D T 0 S T c. E L

TYPE 1

FOR USE WITH

SLIDE BEARINGS

PL A; :0 DR BEAR!\C

ELEC T.

iviAX.

t

1 355 !

121

1

166,165 1 l 12

- 11 I I J -

1

L/ a.o. L. t:LEV.

:T\ ai

__ _.__ ,

i2_L_JLP

'u5zj

' '

TYPE 2

FOR USE WITHOUT

SLIDE BEARINGS

CIEL O + -- ;:sco:NTAI SAOOI E

:>D tE'

. . I

Si''- I ONL. Y FOR

DIMENSIONS <MMl IMX.AASS KG.

SIZE R

lNCH MM I A B

I c D E

I

F T'fPE 1ITYPE 2

20 175415201 50 1178 100 12 10 75

<:(,1

22J27C1560 58 190 1021 12 10 85 45

24 13051600 7t. 1204 1210 12 10 88 48

26 133015501 85 1218 100 12 10 95150

28 I35SIG90 93 230 100 12 lV.l 10:) 5!J

30 I 3Bll7--;0ll02 2-1411 00 15

I

12 143 80

32l406l790ll15 256 100 15 12 150 85

34I432IRH?; 1251?55 100 15 1 12 Hi0 l90

35 14 5/IBGVJ 126 280 l00 15 !2 lt70 I 9::J

3BI483I9i 0 151 280 1021 15 12 180 100

40 150819601151 1305 100 15 12 190 ll 07

42l533l1tHl 151 330 100 15 1 12 200 113

48l510li ifi0 150 405 100 !5 112 230 130

54 168511370 176 485 100 ! 5 112 2601 145

60 206 5HiJ 100 15 12 283 153

v_, \

1

1 sAoot_cs f 3rz

.. F::::LD SEAL 'tiE_D

""! 1 - -jl/ ___ c SlEEL PLATE BEARING

l lJSE ::lACK-lJP STRIP

w; 'r 3Mr'-1 ELECTR.ODE MAX.

I

.L _ _ _ F

X ;SMM \!IDE J

! 2 B c I c 8 12

- i - -.---- - -r -------;;

-:---- > ' -l vp

-I "' . .

I

FULL ENCIRCLEMENT

SADDLE PLATE

(SEE NOTE 2l

NOTES:

I. TOL ERANCE: A +1%. -2

OTHER DIMENSIONS :-1.5MM EXC'OPT PL.ATE"

Tl ilCKNES ANGI.E 11 I 4

2.FULL ENCIRCLEMENT SADDLE PLATES

SHALL BE USED ON ALL CROSS

PIPELINES DESI GNED TO OPERATE AT OR

IN E:<CESS OF 50% 0" :V:IN. SPECIFIED

YIELD STr<CNGT H.

3. FOR '1AXIMUM Si'ANS OF PJPEL UES

USING SADDLES SCE STD. OWG. A0-036697.

4,PIPE SUDPORT OR SLEEPER

SADJL. E S;IALL.. 3E CESl G\C: D 10 ACCJ etODC. I L

FULL AXIAL or- TI-'E PF't:Uc;t.

ANJ SADDLE.

5. VEIH HOLE PER ASi1E 331.3 PARA 328.5.4.

G. TOP Pi.ATC: OF SUPPORT CR SL CEPC:R UNOF.R

SNJOL[ SHALL NO I" BE U:SS 111'\\i lci0 11H \;L)[ ,

7. MAX. AXIAL MOVEMENT ON iS

32121MM. 1!50,MM EAC H DTRECTJONI A:n

MAX. TRANSVERSE MOVEMEN T ON SLPPOR i IS

! 75MM C. AC H DIRFCTTONl . IF .'1Xlr, i ..

liO':C.MENi IS TN EXCESS Or 31'-r>-MM Tl lf

RASE W!DTH BE I NCREASED

ACCCRDINGL. '1.

8. ALL D!MENSIO\S ARE IN

UNLESS NOTEJ OTHERWI SE.

r----------------------------------;

TYPICAL INSTALLATION DRAWING

+-1-

I I

I i

! SY JO/EI>:O

\'( ---- f.H[CKE:) Flf ---- f.CrJ , r;:

;;j:.f'IT[:J ------ o:. ;;: COHf' LE"':"::J -----

Gi'R:.OfP7. -------f.!\(" . D!:P:. -----

T" IS ;)> .... lo< OS lo(l! IC tc

t:t7to >.l I.Lt l:-o :)l ';:fl!

I

6"

SADDLE DETAILS

FOR LARGE DIAMETERS

UNRESTRAINED PIPELINES

STD. OWG. METRIC

1 001 1

LL

FIXED POINT

D

SADDLE SPAN

SECTION A-A

NOTE 2

PAD PLATE

SEE NOTE 3

SO" J" (MIN 14)

.. o 4t M FLUSH

v ~ ; -

DETAIL 2

STANDARD

J

SADDLE SPAN

SLIDING PLATE

SADDLES AND SLIDING PLATES

FOR APPARATUS 0.0. 1200 - 6000 mm

STIFF RING

SEE NOTE 4

- ~ - PROFILE "X"

E 250 I

DATE PAl

1/ 3

SADDLES ANCHOR BOLTS WEIGHT MAX MAX.

o D. kg LOAD kN SHEAR

VESSEL

A B

(

D E F F1 G J

U.NC METR.

d

No

(NOTE 51 !NOTE 7) LOAD kN

THREAD THREAD REO D

!NOTE 8)

1200 875 960 640

~ ~

140 140

1300 925 1040 720 220 10

1880

300 14 3/4" M20 24 160 160 90

1400 975 1120 800 960 170 190

1500 1025 1200 810 1010 240 220

1600 1075 1280 900

:1090

16 260 260

1700 1125 1360 990 11180

1-

4 280 300

1800 1175 1440 1050 250 12 1250 380 300 350 210

1900 1225 1520 1140

:mo

18 320 400

2000 1275 1600 1230 11420

-

330 460

2100 1325 1680 1290 1490

1-

360 520

2200 1375 1760 1380

1

1570

20

380 590

2300 1425 1840 1350 11600

22

480 660

2400 1475 1920 1440 1680 510 740

2500 1525 2000 1530 14

:mo

1-

6 550 820 320

2600 1575 2080 1590 11840 24 570 910

2700 1625 2160 1680 1920

1-

590 1000

2800 1675 2240 1760 2000 440 1" M24 28 720 1100

2900 1725 2320 1840 280 16 2080 460 450 26 750 1200

3000 1775 2400 1920 2160 480

1-

780 1300

3100 1825 2480 2000 2240 500 820 1400

3200 1875 2560 2080 2320 520 920 1500 450

3300 1925 2640 2160 2400 540 28 950 1600

3400 1975 2720 2240 18 2480 560 980 1700

3500 2025 2800 2320 2560 580 1010 1800

3600 2075 2880 2400 2640 600 "10 1070 1900

3800 2175 3040 2480 2760 620 1330 2100

4000 2275 3200 2640 2920 660 32

8

1400 2300

4200 2375 3360 2800 320 20 3080 700 480 1480 2500 500

4400 2475 3520 2960 3240 740

-

1600 2700

4600 2575 [3680 3120 3400 780

34

1680 2900

4800 2675 [3840 3150 3500 1260 2100 3100

5000 2775 [4000 3350 3680 1340 36 2210 3300

5200 2875 [4160 3500 3830 1400

-

1-1/4 II

2310 3500

5400 2975 4320 3650 360 22 3990 1t.60 530 M30 36 2460 3100 710

5600 3075 4480 3800 4140 1520 38 2560 3900

5800 3175 4640 3950 4300 1580 2670 4100

6000 3275 4800 4150 4480 1660 2790 4300

O.D VESSEL

No.OF K L M u v PROFILE WELD POCKET

RIB N MIN. X

y

1200 TO 1400 3 120 350 60 130 150 L60x60x6

1500 TO 2200 4 150 460 80 145 170 L80x80x8

4 0150

2300 TO 2700 180 530 90 160 195 L 100x100x10

2800 TO 3600 5 100

5 0200

3800 TO 4600 220 580 120 180 220 HEB 120

4800 TO 6000 6 260 630 130 200 250

STANDARD

SADDLES AND SLIDING PLATES

FOR APPARATUS O.D. 1200 - 6000 mm

DAlY PM

2/3

NOTES:

1. MATERIAL

PLATE : DESIGN TEMPERATURE O"C TO 300"C : A-283( OR S235JRG2 EN 10025

301"C TO 400"(: A-285C OR P265GH EN 10028-2

BELOW O"C : AS PER REQUIREMENTS OF THE APPLICABLE CODE

PAD PLATE: SAME MATERIAL AS SHELL

SLIDING PLATE : A-283C OR S235JRG2 EN 10025

ANCHOR BOLT: MINIMUM QUALITY A-307A OR CLASS 4.6 EN 10025.

2. WELD DETAILS :

SADDLE SUPPORT : CONTINUOUS FILLET WELDS WITH THROAT THICKNESS OF>O.SE.

PAD PLATE: CONTINUOUS FILLET WELDS WITH THROAT THICKNESS EQUAL TO 0.7t1.

FOR DESIGN TEMPERATURE BELOW o C SADDLE IS TO BE

BUTT WELDED TO PAD PLATE.

3. PAD PLATE THICKNESS "t1" SHALL BE THE SMALLER OF "E" AND "t".

4. FOR SADDLES REQUIRING STIFFENING RINGS SEE STANDARD ES-22005.

5. APPROXIMATE WEIGHT FOR 2 SADDLES, EXCLUDING PAD PLATE AND SLIDING PLATE.

6. THE STRESSES IN THE VESSEL SHELL CAUSED BY THE SADDLE SUPPORT SHOULD

BE CHECKED BY THE APPLICABLE CODE OR L.P. ZICK.

7. MAXIMUM PERMISSIBLE LOAD PER SADDLE SUPPORT UP TO A DESIGN TEMPERATURE OF 400"C

(IF LOAD ON ONE SADDLE IS EXCEEDING THE MAX. LOAD THE SADDLE MUST BE REDESIGNED).

8. MAXIMUM PERMISSIBLE SHEAR LOAD AT SADDLE BASE UP TO A DESIGN TEMPERATURE OF 400"(.

IF SHEAR LOAD AT SADDLE BASE (IS MAX. OPERATING LOAD ON SLIDING SADDLE TIMES

0.4 (=FRICTION COEFFICIENT)) IS EXCEEDING THE MAX. SHEAR LOAD LOW-FRICTION PADS

MUST BE USED AT THE SLIDING SADDLE SEE STANDARD ES-22003.

9. FOR INTERMEDIATE VESSEL D.O.'S THE SADDLE DIMENSIONS FOR ONE SIZE

LARGER TO BE TAKEN.

STANDARD

SADDLES AND SLIDING PLATES

FOR APPARATUS O.D. 1200-6000 mm

DATE Pill.

3 /3

SADDLE SPAN

fA cl_

....Y" SEE DETAIL 3 II

FIXED POINT

E

LL -+--*-4=1= LJ I

E

NOTE 2

PAD PLATE

SEE NOTE 3

SQw J" (MIN. 14)

M FLUSH

/"---- -------?

-------------- ___.)

STANDARD

SLIDING PO=tn.:.......-__

B!l T HOLES FOR

FIXED POINT ONLY

SECTION A-A

I 1 I

I I 1--r-

1 . I

I I

I I I

l I :

! Ll :

--!-

: I' : co

I I

: 'I :

: \ :

I I I

SEE DETAIL 2

iU 1-

SADDLE SPAN I

-----1

SECTION B-B

SADDLES FOR APPARATUS

D.O. 1200 - 3600 mm

ON STEEL BASE

OAT[

STIFF. RING

SEE NOTE 4

TELL TALE

to.E

PIH

1 I 3

SAOOlES ANCHOR BOLTS WEIGHT MAX. MAX.

0.0. kg LOAD kN SHEAR

VESSEL A B

(

0 E F F1 G J

UN. C. METR

d

No (NOTE Sl (NOTE 7l LOAD kN

THREAD THREAD REQ.O

(NOTE 8l

1200 875 960 640

~ -R-

140 140

1300 925 1040 720 220 10 BBO 300 14 3/4" M20 24 160 160 90

1400 975 1120 BOO %0 170 190

1500 1025 1200 810

~

240 220

1600 1075 1280 900 1090 16 260 260

1700 1125 1360 990

~

4 280 300

1800 1175 1440 1050 250 12 1250 380

-

300 350 210

1900 1225 1520 1140

~ -

18 320 400

2000 1275 1600 1230 1420 330 460

2100 1325 1680 1290

~

-

360 520

2200 1375 1760 1380 1570

20

380 590

2300 1425 1840 1350

~

22

480 660

2400 1475 1920 1440

~ -

510 740

2500 1525 2000 1530 14 1770

1" M24 28

6 550 820 320

2600 1575 2080 1590 1640 24 570 910

2700 1625 2160 1680 1920 590 1000

-

2800 1675 2240 1760 2000 440 720 1100

2900 1725 2320 1840 280 16 2080 460 450 26 750 1200

3000 m5 2400 1920 2160 480 780 1300

3100 1825 2480 2000 2240

-

500 820 1400

3200 1875 2560 2080 2320 520 B 920 1500 450

3300 1925 26'0 2160 2400 540 28 950 1600

3400 1975 2720 2240 18 2480 560 980 1700

3500 2025 2800 2320 2560 580 1010 1800

3600 2075 2880 2400 2640 600

ry

1070 1900

DD.VESSEL

No. OF K L u v

RIB N MIN. MIN. MIN.

1200 TO 1400 3 120 350 120 145

1500 TO 2200 4 150 460 135 165

2300 TO 2700 180 530 150 190

2800 TO 3600 5

STANDARD

SADDLES FOR APPARATUS

O.D. 1200- 3600 mm

DATI PIH.

ON STEEL BASE

2 /3

NOTES:

1. MATERIAL

PLATE : DESIGN TEMPERATURE O"C TO 300"C: A- 283C OR S235JRG2 EN 10025

3WC TO 400"C: A- 285C OR P265GH EN 10028-2

BELOW oc : AS PER REQUIREMENTS OF THE APPLICABLE CODE

PAD PLATE : SAME MATERIAL AS SHELL.

ANCHOR BOLT :MINIMUM QUALITY A- 307B OR CLASS 5.6 EN 10025.

2. WELD DETAILS :

SADDLE SUPPORT : CONTINUOUS FILLET WELDS WITH THROAT THICKNESS OF>O.SE.

PAD PLATE: CONTINUOUS FILLET WELDS WITH THROAT THICKNESS EQUAL TO 0.7t1.

FOR DESIGN TEMPERATURE BELOW o C SADDLE IS TO BE

BUTT WELDED TO PAD PLATE.

3. PAD PLATE THICKNESS "t1" SHALL BE THE SMALLER OF "E" AND "t".

4. FOR SADDLES REQUIRING STIFFENING RINGS SEE STANDARD ES-22005.

5. APPROXIMATE WEIGHT FOR 2 SADDLES, EXCLUDING PAD PLATE.

6. THE STRESSES IN THE VESSEL SHELL CAUSED BY THE SADDLE SUPPORT SHOULD

BE CHECKED BY THE APPLICABLE CODE OR L.P. ZICK.

7. MAXIMUM PERMISSIBLE LOAD PER SADDLE SUPPORT UP TO A DESIGN TEMPERATURE OF 400"C

IJF LOAD ON ONE SADDLE IS EXCEEDING THE MAX. LOAD THE SADDLE MUST BE REDESIGNED).

B. MAXIMUM PERMISSIBLE SHEAR LOAD AT SADDLE BASE UP TO A DESIGN TEMPERATURE OF 400"C.

IF SHEAR LOAD AT SADDLE BASE (IS MAX. OPERATING LOAD ON SLIDING SADDLE TIMES

0.4 (=FRICTION COEFFICIENT)) IS THE MAX. SHEAR LOAD LOW-FRICTION PADS

MUST BE USED AT THE SLIDING SADDLE SEE STANDARD ES-22003.

9. FOR INTERMEDIATE VESSEL D.O.'S THE SADDLE DIMENSIONS FOR ONE SIZE

LARGER TO BE TAKEN.

STANDARD

SADDLES FOR APPARATUS

D.O. 1200 - 3600 mm

ON STEEL BASE

PAH PA(i(

3 /3

Vous aimerez peut-être aussi

- Pipe Support ManualDocument77 pagesPipe Support ManualDion07100% (10)

- Pipe Support As Per Asme 31.1Document1 pagePipe Support As Per Asme 31.1udaysaichand kollipara100% (1)

- Pipe Support FluorDocument79 pagesPipe Support FluorWaldomiroCano100% (8)

- Specification For Pipe SupportDocument330 pagesSpecification For Pipe Supportaibek92% (13)

- FW Pipe Support Drawings PDFDocument231 pagesFW Pipe Support Drawings PDFJoby GeorgePas encore d'évaluation

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- BASF Engineered Pipe Support CatalogueDocument108 pagesBASF Engineered Pipe Support CatalogueHITESH100% (1)

- Selection of Pipe SupportDocument77 pagesSelection of Pipe SupportRobert Nixon86% (7)

- Process Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingDocument17 pagesProcess Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingMidhun K Chandrabose100% (2)

- A204TPL-AISH-L-STD-0001-C3-Application of Standards Pipe Supports & Pipe Support Note PDFDocument77 pagesA204TPL-AISH-L-STD-0001-C3-Application of Standards Pipe Supports & Pipe Support Note PDFAjadPas encore d'évaluation

- 45 Deg Branch SIFsDocument1 page45 Deg Branch SIFsayoungaPas encore d'évaluation

- Pipe SupportDocument31 pagesPipe SupportrezaPas encore d'évaluation

- Pipe Support StandardDocument319 pagesPipe Support StandardAntoshal92% (75)

- Pipe Span ChartDocument4 pagesPipe Span ChartAnonymous oVRvsdWzfBPas encore d'évaluation

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pipe Supports Standard Aux Steel Arrangement KBRDocument160 pagesPipe Supports Standard Aux Steel Arrangement KBRzahoorPas encore d'évaluation

- Virtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IIDocument4 pagesVirtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IImartin_blackmanPas encore d'évaluation

- Special Pipe SupportsDocument293 pagesSpecial Pipe SupportsVijay_Damam100% (2)

- Design Practise Piping Support SystemDocument46 pagesDesign Practise Piping Support SystemOkondu Chiedu100% (1)

- Pipe Supports PDFDocument10 pagesPipe Supports PDFleotvrdePas encore d'évaluation

- Pipe Supports Design CriteriaDocument11 pagesPipe Supports Design CriteriaJaykumar75% (4)

- Technip - Pipe Support STDDocument320 pagesTechnip - Pipe Support STDfloayzav568475% (8)

- Pipe SupportDocument10 pagesPipe Supportmohammed kadhimPas encore d'évaluation

- PIP PNFS0001 Pipe Supports DetailsDocument167 pagesPIP PNFS0001 Pipe Supports DetailsSeungmin Paek67% (6)

- Flanges ASME B16.47Document18 pagesFlanges ASME B16.47Saifulla Baig67% (3)

- 6.1 Purpose of Pipe SupportDocument10 pages6.1 Purpose of Pipe SupportRaju NaiduPas encore d'évaluation

- Pipeline DrawingsDocument1 pagePipeline Drawingsravish ravindranPas encore d'évaluation

- Expansion Joint ModelDocument1 pageExpansion Joint ModelnirgaPas encore d'évaluation

- Piping Elbow or Bend SIFDocument2 pagesPiping Elbow or Bend SIFgpskumar22Pas encore d'évaluation

- Pipe Saddle Support CalculationsDocument1 pagePipe Saddle Support CalculationsAbir Baran HandaPas encore d'évaluation

- SP-50-017 - 2 - Pipe SupportsDocument136 pagesSP-50-017 - 2 - Pipe SupportsTem Batbold100% (2)

- Wall Thickness and MITERDocument1 pageWall Thickness and MITERnirgaPas encore d'évaluation

- COPNO AKER Pipe Support ProcedureDocument51 pagesCOPNO AKER Pipe Support Procedurejeddij100% (3)

- Few Important Points For Stress Analysis Based On ASME B 31Document4 pagesFew Important Points For Stress Analysis Based On ASME B 31Nilesh GohelPas encore d'évaluation

- Piping Stress Analysis Design BasisDocument38 pagesPiping Stress Analysis Design BasisNjoku Stephen100% (3)

- Support Standard QUATAR PETROLEUM-PETROFACDocument218 pagesSupport Standard QUATAR PETROLEUM-PETROFACzahoor100% (1)

- Piping SupportDocument268 pagesPiping SupportVictor RojasPas encore d'évaluation

- Pipe Support Span CalculationDocument14 pagesPipe Support Span Calculationrajeevfa100% (3)

- Work Instruction - Expansion Joint Modelling in CAESAR IIDocument11 pagesWork Instruction - Expansion Joint Modelling in CAESAR IIChanPas encore d'évaluation

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta0% (1)

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinPas encore d'évaluation

- BP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassDocument17 pagesBP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassOSDocs2012Pas encore d'évaluation

- Lug Sup'tDocument2 pagesLug Sup'tSeungmin PaekPas encore d'évaluation

- Notes: P.T. Badak N.G.L. Bontang L.N.G. PlantDocument10 pagesNotes: P.T. Badak N.G.L. Bontang L.N.G. PlantAdidtya Budhi SaputraPas encore d'évaluation

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarPas encore d'évaluation

- JopDocument10 pagesJopAnonymous nHT1rzjmcPas encore d'évaluation

- Siemens LLC: Earth Switch ClosedDocument2 pagesSiemens LLC: Earth Switch ClosedBala MPas encore d'évaluation

- Pipe Support Span PDFDocument5 pagesPipe Support Span PDFSeungmin PaekPas encore d'évaluation

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216Pas encore d'évaluation

- GeneratorDocument55 pagesGeneratorVlad Iulian100% (3)

- Ust Drawing Typical EN12285-1Document1 pageUst Drawing Typical EN12285-1vonipkoPas encore d'évaluation

- KS Se3Document6 pagesKS Se3Jefferson Damian PradaPas encore d'évaluation

- Hs Bolt SpecificationDocument6 pagesHs Bolt SpecificationncristiPas encore d'évaluation

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell93% (15)

- Wheel Horse Mower Parts ManualDocument26 pagesWheel Horse Mower Parts ManualastroltravlerPas encore d'évaluation

- Class Aae ('Joffre Polyolefins')Document4 pagesClass Aae ('Joffre Polyolefins')Zvonko BešlićPas encore d'évaluation

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamPas encore d'évaluation

- (D-A G (Qine O Onvstru Gttoni: You Are Required ToDocument3 pages(D-A G (Qine O Onvstru Gttoni: You Are Required ToMostafaPas encore d'évaluation

- Hot TappingDocument6 pagesHot TappingbravoalfadeltaPas encore d'évaluation

- 13 - Copes-Vulcan ValvesDocument7 pages13 - Copes-Vulcan ValvesshalegpPas encore d'évaluation

- (CAT) 메가플랙슨 - Rubber Expansion JointDocument10 pages(CAT) 메가플랙슨 - Rubber Expansion JointSeungmin PaekPas encore d'évaluation

- (CAT) 성화산업 - Pipe Support & Hanger (Acessories)Document199 pages(CAT) 성화산업 - Pipe Support & Hanger (Acessories)Seungmin Paek100% (1)

- A Review of Water Hammer Theory and PracticeDocument28 pagesA Review of Water Hammer Theory and Practicejulio49Pas encore d'évaluation

- SimonFreese Journal ArticleDocument9 pagesSimonFreese Journal ArticleSeungmin PaekPas encore d'évaluation

- Velocity of Flow and Water Hammer: by Michael B. Haener, C.I.DDocument2 pagesVelocity of Flow and Water Hammer: by Michael B. Haener, C.I.DSeungmin PaekPas encore d'évaluation

- (CAT) 유니슨 - Pipe Hangers & SupportsDocument174 pages(CAT) 유니슨 - Pipe Hangers & SupportsSeungmin PaekPas encore d'évaluation

- CAESAR II Training - WRC 107 INPUTDocument5 pagesCAESAR II Training - WRC 107 INPUTSeungmin Paek100% (1)

- Riser Lug: 150A and Smaller 175A and LargerDocument1 pageRiser Lug: 150A and Smaller 175A and LargerSeungmin PaekPas encore d'évaluation

- 12 Allowable Pipe Span Formulas and TablesDocument10 pages12 Allowable Pipe Span Formulas and TablesSeungmin Paek91% (11)

- Why An Expansion Joint Works Part 1Document1 pageWhy An Expansion Joint Works Part 1Seungmin Paek100% (1)

- Valve Weight (From Vendor's Catalog)Document2 pagesValve Weight (From Vendor's Catalog)Seungmin PaekPas encore d'évaluation

- Why An Expansion Joint Works Part 2Document1 pageWhy An Expansion Joint Works Part 2Seungmin Paek100% (1)

- Steel Line Blanks & Spacer Dimension TableDocument5 pagesSteel Line Blanks & Spacer Dimension TableSeungmin PaekPas encore d'évaluation

- The Magic of Vanstone FlangesDocument2 pagesThe Magic of Vanstone FlangesSeungmin PaekPas encore d'évaluation

- Obsessive Compulsive Ways To Extend Expansion Joint LifeDocument1 pageObsessive Compulsive Ways To Extend Expansion Joint LifeSeungmin PaekPas encore d'évaluation

- Van Stone BellowsDocument1 pageVan Stone BellowsSeungmin PaekPas encore d'évaluation

- Steam Extraction Expansion JointsDocument1 pageSteam Extraction Expansion JointsSeungmin PaekPas encore d'évaluation

- Refurbished Expansion Joints-1Document1 pageRefurbished Expansion Joints-1Seungmin PaekPas encore d'évaluation

- Metal Rectangles That Out PerformDocument2 pagesMetal Rectangles That Out PerformSeungmin Paek100% (1)

- The Liberating Effects of Tied Universal Expansion JointsDocument2 pagesThe Liberating Effects of Tied Universal Expansion JointsSeungmin PaekPas encore d'évaluation

- PRV Flex ConnectorsDocument1 pagePRV Flex ConnectorsSeungmin PaekPas encore d'évaluation

- Multiple Ply BellowsDocument1 pageMultiple Ply BellowsSeungmin PaekPas encore d'évaluation

- Pressure Balanced Expansion JointsDocument1 pagePressure Balanced Expansion JointsSeungmin PaekPas encore d'évaluation

- Metal Vs Fabric Ducting Expansion JointsDocument1 pageMetal Vs Fabric Ducting Expansion JointsSeungmin PaekPas encore d'évaluation

- Inspecting Bellows DamageDocument1 pageInspecting Bellows DamageSeungmin PaekPas encore d'évaluation

- Hinged Expansion Joints in FRP PipingDocument1 pageHinged Expansion Joints in FRP PipingSeungmin PaekPas encore d'évaluation

- Maintaining 2 Ply Testable BellowsDocument1 pageMaintaining 2 Ply Testable BellowsSeungmin PaekPas encore d'évaluation

- Metallurgy of Metal Bellows FailuresDocument1 pageMetallurgy of Metal Bellows FailuresSeungmin PaekPas encore d'évaluation

- Insider Secrets of Bellows RepairDocument1 pageInsider Secrets of Bellows RepairSeungmin PaekPas encore d'évaluation

- Got LinersDocument1 pageGot LinersSeungmin PaekPas encore d'évaluation

- 01 - Motor Protection Circuit Breakers - 01 - 20 PDFDocument20 pages01 - Motor Protection Circuit Breakers - 01 - 20 PDFMostafa ShannaPas encore d'évaluation

- 5th Issue October 10Document12 pages5th Issue October 10The TartanPas encore d'évaluation

- Tquins Resources Training Template For MT Work Programme SCS RevisedDocument12 pagesTquins Resources Training Template For MT Work Programme SCS RevisedLileth LagasimPas encore d'évaluation

- Munday CH 5.3-5.3.1 Skopos TheoryDocument11 pagesMunday CH 5.3-5.3.1 Skopos TheoryEvelina Tutlyte100% (1)

- Study of Deduru OyaDocument9 pagesStudy of Deduru OyaJGonPas encore d'évaluation

- Troubleshooting: Fully Automated Urine Particle AnalyzerDocument108 pagesTroubleshooting: Fully Automated Urine Particle Analyzerjw lPas encore d'évaluation

- TG Synchronization Connections For RbsDocument11 pagesTG Synchronization Connections For RbsJack Sprw67% (3)

- Civil Engineering and SocietyDocument23 pagesCivil Engineering and Societyyeah100% (3)

- Company CFODocument602 pagesCompany CFOgouravbhatia200189Pas encore d'évaluation

- Assignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Document26 pagesAssignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Mosabbir Ahmed0% (1)

- Piping SpecificationDocument3 pagesPiping SpecificationShashi RanjanPas encore d'évaluation

- Project Based Learning Is A Student Centered Pedagogy ThatDocument3 pagesProject Based Learning Is A Student Centered Pedagogy ThatPayel DaluiPas encore d'évaluation

- Sorona - Product InformationDocument4 pagesSorona - Product InformationchristianPas encore d'évaluation

- HCF Spec 190 1.0 PDFDocument31 pagesHCF Spec 190 1.0 PDFvikulovPas encore d'évaluation

- How To Export Resource Assignment Data To Excel From P6Document9 pagesHow To Export Resource Assignment Data To Excel From P6artletPas encore d'évaluation

- Parthiban Kanavu Part 3Document98 pagesParthiban Kanavu Part 3ambalvananPas encore d'évaluation

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocument2 pages6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianPas encore d'évaluation

- Unit 1 Module 2 Air Data InstrumentsDocument37 pagesUnit 1 Module 2 Air Data Instrumentsveenadivyakish100% (1)

- Personal Data Sheet: Criminology Intern UnitDocument1 pagePersonal Data Sheet: Criminology Intern UnitJoseph RychePas encore d'évaluation

- GCCE RaptorDocument4 pagesGCCE RaptorSayidina PanjaitanPas encore d'évaluation

- Manual M810Document38 pagesManual M810romiyuddinPas encore d'évaluation

- ProKlima Entfeuchter ManualDocument336 pagesProKlima Entfeuchter ManualJonPas encore d'évaluation

- Measuring Apparent Viscosity of Lubricating Greases: Standard Test Method ForDocument8 pagesMeasuring Apparent Viscosity of Lubricating Greases: Standard Test Method ForAhmedPas encore d'évaluation

- Report On SURFACE CONSTRUCTION OF THE REICHSTAGDocument19 pagesReport On SURFACE CONSTRUCTION OF THE REICHSTAGkylikeschoco100% (3)

- HDPE Pipe InstallationDocument7 pagesHDPE Pipe InstallationJeferson Binay-an100% (1)

- Water System Validation ExampleDocument6 pagesWater System Validation Exampledvdynamic1100% (2)

- Usermanual en Manual Arium Bagtanks WH26010 ADocument33 pagesUsermanual en Manual Arium Bagtanks WH26010 AԳոռ ԽաչատրյանPas encore d'évaluation

- Angoca Db2 Cheat Sheet For DevelopmentDocument3 pagesAngoca Db2 Cheat Sheet For DevelopmentTanveer AhmedPas encore d'évaluation

- PDFDocument16 pagesPDFmayankPas encore d'évaluation