Académique Documents

Professionnel Documents

Culture Documents

Lab. Pollution

Transféré par

Melissa MartinezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lab. Pollution

Transféré par

Melissa MartinezDroits d'auteur :

Formats disponibles

Fact Sheet

Number 16 November 2005

Laboratory Pollution Prevention

be educated in P2 and green chemistry concepts during their academic training in order for it to become standard practice in the laboratory industry. In addition, addressing P2 and green chemistry concepts in the classical chemistry curriculum can greatly speed the incorporation of P2 into industrial manufacturing processes. Professional chemists are often knowledgeable about P2 concepts and are able to identify, develop and implement effective P2 technologies. However, for P2 to be most effective, it needs to be an integral part of laboratory management. Laboratories have unique waste management problems because they generate diverse waste streams, although not necessarily in large quantities. Literally thousands of wastes are generated in laboratories which are comparable to other operations such as arts, printing, photography, maintenance and vocational programs. Laboratories have often turned to using lab packs to dispose of small quantities of hazardous waste. Lab packs provide a simple, short-term solution for disposing small quantities of chemicals. However, the increasing long-term costs and liability associated with disposing lab packs makes this option less desirable than exploring ways to reduce waste. Successful P2 begins with a strong commitment to prevent generation of wastes. The following sections describe several areas labs can look at in identifying strategies to reduce wastes, including material handling, operating practices and policies, employee training and loss prevention.

Reducing the emission of pollutants in research, educational and commercial laboratories is important for several reasons. Adopting pollution prevention practices results in direct environmental benefits, and is an important objective consistent with both national and state environmental policies. In addition, exploring and adopting pollution prevention measures in laboratory settings carries a tremendous potential for reducing pollution in future industrial processes. In 1989, U.S. EPA shifted its focus from controlling pollution after the fact to preventing it at the source. The Pollution Prevention Act of 1990 emphasizes this shift. Laboratory pollution prevention (P2) is at the center of the overall green chemistry initiative established by U.S. EPA.

Management Practices

Establish annual goals for institution wide and departmental waste reduction. First determine past annual waste generation totals, then assess economic and technical feasibility for establishing and achieving specific reduction goals. Centralize waste management and appoint a safety/waste management officer. This will facilitate a coordinated and efficient implementation of regulations, institutional policies and waste reduction goals. It also provides an information clearinghouse. Because of the independent climate in which most research is conducted, development of an organizational mind set is extremely important. Without this, further efforts may have little or no effect.

P2 in Research, Educational and Commercial Laboratories

Implementing P2 practices can help you develop an awareness of efficient waste management, reduce liability, lower worker exposure and save operating costs. It is imperative that laboratory professionals from all disciplines

Office of Compliance Assistance & Pollution Prevention, 122 South Front Street, Columbus, Ohio 43215 (800) 329-7518 www.epa.state.oh.us/ocapp

Laboratory Pollution Prevention

Establish an inventory control program to trace chemical usage from cradle to grave. Always be aware of the status of hazardous waste. Consider setting up a computer tracking and inventory system to track hazardous waste generation. An inventory program also can promote common users sharing chemicals, identify extremely hazardous materials and high volume users and delineate points where waste reduction options are needed. A challenge for labs is that decentralized decision-making is characteristic of the management structure. This means that special considerations, such as a coordinated inventory system, may be needed when designing a P2 program. Initiate a waste exchange when the material to be disposed could be reused. In labs, a waste exchange is generally limited to unopened containers which have not been contaminated. A periodic newsletter can be used to alert laboratory personnel to chemicals that are available. Having a strong inventory program can also promote sharing of chemicals by common users. If an on-site waste exchange is not practical, there are several regional waste exchanges. Ohio EPA maintains information on waste exchanges in your area at www.epa.state.oh.us/ocapp/p2/ omex/omex.html. Conduct routine self-audits to minimize reagent accumulation and maximize recycling and sharing surplus materials. Ohio EPA has a laboratory P2 checklist at www.epa.state.oh.us/ocapp/ p2/labp2checklist.pdf. ultimate disposal costs. Reduced disposal costs can often offset savings from buying in bulk. Consider handling and disposal requirements. If the facility does not have adequate storage and safety provisions for a chemical, its purchase should be discouraged. Try to use nonhazardous chemicals or those that are suitable for reuse. Reduce expired stock. Negotiate chemicals expiration dates with suppliers based on their intended use. Order reagents only in amounts required and stock smaller containers to help prevent waste due to surplus or shelf life expiration. Use up old stock. Rotate chemical stocks to avoid shelf life expiration. Use a first in, first out policy to keep chemicals from becoming outdated. Avoid donated chemicals. Do not accept donated chemicals or free samples unless they meet a specific need, since they can become a future waste problem.

Chemical Purchasing Policies

Institute a chemical review process. Constantly evaluate the opportunity to use less hazardous chemicals. Tools such as U.S. EPAs Green Chemistry Expert System, can help you find less toxic alternatives. Institute procedures to restrict hazardous chemical purchases to only those absolutely needed for the current commercial, instructional or research programs and in minimal amounts needed for short term use. Do not buy chemicals in bulk. Bulk chemical purchases often lead to large volumes of expired materials which are costly to treat and or dispose of. A centralized purchasing program can monitor requests for chemicals. Stagger deliveries of chemicals and implement policies that address sharing of chemicals among common users and plans for leftover chemicals. Consider disposal costs at time of purchase. Many chemicals deteriorate with time. The disposal cost for expired materials may be 20 to 50 times the original purchase price. The real cost of chemicals should be regarded as the initial purchase price plus any

Employee Involvement and Training

Provide employee training. Training programs for those who may generate or handle chemicals should include minimizing chemical hazards, spill prevention, preventive maintenance and emergency preparedness and response.

Laboratory Pollution Prevention

Educate employees about the benefits of waste minimization and specific techniques for reducing waste generation. Communicate through departmental meetings, memos, seminars, presentations and brochures. Provide special training for procurement staff in order to raise awareness of the full costs of hazardous and unused chemicals. Ohio EPA has online P2 training at www.epa.state.oh.us/opp/ LabP2training_files/frame.htm. Solicit employee suggestions for green chemistry and waste reduction ideas and promote employee participation in your P2 program. Create an incentive program for employees who propose P2related ideas. Increase use of instrumentation and alternative teaching methods. Modern instrumentation not only achieves more reliable results, but also reduces chemical usage. Alternative teaching methods, such as computer simulation or interactive video chemistry lab, offer an alternative to the traditional wet chemistry laboratory, reducing chemical usage and associated potential hazards. Substitute less toxic or hazardous compounds and/or use an entirely different experiment is often practical. For example: substitute sodium hypochlorite for sodium dichromate; use alcohol for benzene; substitute cyclohexane for carbon tetrachloride in the standard quantitative test for halide ions; replace acetamide with stearic acid in phase change and freezing point depression experiments; and use specialty detergents such as potassium hydroxide or sonic baths in place of chromic acid solutions to clean glassware. Utilize green chemistry to eliminate waste. Redesign experiments to eliminate steps which create hazardous end products, this often results in more efficient processes. This has the additional benefit of teaching students to avoid generating hazardous wastes while improving chemical processes. Pre-weigh chemicals for student use in teaching labs when appropriate. This will reduce waste by spills and other mishandling. Students can participate in preweighing and handling exercises. Reuse or recycle spent solvent. When cleaning with solvent, reuse spent solvent for the initial cleaning and use fresh solvent only for the final rinse. Employ on-site distillation and reuse. Advantages include reducing disposal costs and purchasing large quantities of new solvent. Distill and reuse solvent for classroom experiments or as a cleaning agent where ultra pure solvent is not required. Small solvent distillers are available. Check with fire and worker safety regulations regarding on-site solvent distillation operation. Segregate waste streams. Provide a properly labeled container for each waste stream for better waste management at lower cost. Do not dilute or mix hazardous and nonhazardous waste. Segregate recyclable and nonrecyclable wastes. Segregate solvent in a closed-top drum and recycle. Segregate used oil from other wastes. Include waste segregation as part of the educational process. Segregate precious metal wastes, such as those containing platinum, palladium and rhodium, since they can be recovered using chemical procedures specific to those metals. Send silver containing

Laboratory Practices

Microscale or nanoscale experiments. These processes are specifically designed to scale down the volume of chemicals used in laboratory experiments and generate less hazardous waste. The scale of analytical material can be reduced immensely, leading to additional reductions in reagents, catalysts and solvents required for these experiments. Microscale or nanoscale practices can decrease fire and explosion hazards, reduce exposure to hazardous chemicals and drastically reduce waste disposal costs.

Laboratory Pollution Prevention

solutions from photographic and xray facilities to commercial firms that specialize in recovering silver. Many local photo shops will take photo waste free of charge. Apply waste minimization technologies to management of metallic wastes and their solutions. Waste mercury can be easily recycled depending on the type or degree of contamination. Information about commercial mercury recyclers is available from Ohio EPA at www.epa.state.oh.us/opp/ recyc/mercrec.html. Provide a designated safe facility for waste storage, segregation and treatment to promote proper management of hazardous waste and aid in waste reduction. Label incoming chemicals. When stocking new chemicals, label with purchasing date and add storage code and safety precautions. Maintain containers and labels. Routinely inspect and clean old containers, tighten lids and maintain legible labels. Re-label as needed. Unidentified reagents and wastes cannot be legally shipped for disposal and present a difficult waste management problem.

Conclusion

Under current regulations, all generators are responsible for safely managing their hazardous waste from cradle-to-grave. Laboratories recognize that they must reassess existing chemical waste management to alleviate the pressure of skyrocketing disposal costs, improve worker safety and reduce future liability. The best way to manage waste is prevention. For more information, see the resource list below. Ohio EPAs Office of Compliance Assistance and Pollution Prevention is available to help identify P2 strategies. OCAPP can also help with your regulatory compliance needs. For more information, call 800329-7518.

References and Resources

Online P2 Training for Laboratory Managers & Staff www.epa.state.oh.us/opp/ LabP2training_files/frame.htm Laboratory P2 Checklist www.epa.state.oh.us/ocapp/p2/ labp2checklist.pdf Laboratory P2 Training Reference Guide www.epa.state.oh.us/ocapp/p2/ labp2refguide.pdf U.S. EPA Green Chemistry Program www.epa.gov/greenchemistry/ U.S. EPAs Green Chemistry Expert System (GCES) www.epa.gov/greenchemistry/ tools.html American Chemical Society, Green Chemistry Institute http://chemistry.org/ greenchemistryinstitute/ William R. Wiley Environmental Molecular Sciences Laboratory, Nanoscale Chemistry & Processing www.emsl.pnl.gov/proj/ nanoscale.html

Ohio EPA is an Equal Opportunity Employer

Vous aimerez peut-être aussi

- Chemical Projects Scale Up: How to go from Laboratory to CommercialD'EverandChemical Projects Scale Up: How to go from Laboratory to CommercialPas encore d'évaluation

- Laboratory Waste Minimization and Pollution Prevention: BanelleDocument49 pagesLaboratory Waste Minimization and Pollution Prevention: Banellejordy745Pas encore d'évaluation

- Implementing A CFH ProgramDocument2 pagesImplementing A CFH ProgramCarolWestinghousePas encore d'évaluation

- Chemical Process Development and EngineeringDocument36 pagesChemical Process Development and EngineeringKrupali Umeshkumar KapadiyaPas encore d'évaluation

- Pollution Prevention Initiatives 9-17Document13 pagesPollution Prevention Initiatives 9-17Aarya PandeyPas encore d'évaluation

- Waste Minimization / Pollution Prevention: The Waste Management HierarchyDocument39 pagesWaste Minimization / Pollution Prevention: The Waste Management HierarchyDanielle Ann Joyce ValenciaPas encore d'évaluation

- Chemical Waste Minimization TipsDocument4 pagesChemical Waste Minimization TipsCris LegaspiPas encore d'évaluation

- ChemDocument13 pagesChemShivam SidhuPas encore d'évaluation

- 2.principle and Design of Waste MinimizationDocument27 pages2.principle and Design of Waste MinimizationFx NiubiePas encore d'évaluation

- Green Chemistry in The Curriculum: An Introduction To Green ChemistryDocument8 pagesGreen Chemistry in The Curriculum: An Introduction To Green ChemistryMihaela Sarateanu BiltacPas encore d'évaluation

- Common Laboratory Hazards and Lab ToolsDocument8 pagesCommon Laboratory Hazards and Lab ToolsDaphne SabalonesPas encore d'évaluation

- Waste ManagementDocument24 pagesWaste ManagementAlthea TuazonPas encore d'évaluation

- Waste Management and Pollution ControlDocument18 pagesWaste Management and Pollution Controltrippic2396Pas encore d'évaluation

- Zerowastetoolkit 2018Document52 pagesZerowastetoolkit 2018consultormarcosouzaPas encore d'évaluation

- 16 - Chapter 8Document5 pages16 - Chapter 8SanskrutiPas encore d'évaluation

- Term Paper On Green ChemistryDocument5 pagesTerm Paper On Green Chemistryaflsmawld100% (1)

- Waste Management69420Document10 pagesWaste Management69420NorticPas encore d'évaluation

- Abstract:: Keywords: Drug Design, Drug Discovery, Green ChemistryDocument5 pagesAbstract:: Keywords: Drug Design, Drug Discovery, Green ChemistryRajendra SinhaPas encore d'évaluation

- Green Chemistry Essay PDFDocument7 pagesGreen Chemistry Essay PDFm2_zakyPas encore d'évaluation

- Green Chemistry: by Mina Marie MitaniDocument21 pagesGreen Chemistry: by Mina Marie MitaniFree Escort ServicePas encore d'évaluation

- Industrial Applications of Green ChemistryDocument12 pagesIndustrial Applications of Green ChemistryArun kumar.v100% (1)

- Life Cycle AssessmentDocument10 pagesLife Cycle AssessmentWade Coleman100% (1)

- The Environmental Audit: BS EN ISO 19011 Guidelines For Quality and Environmental Management Systems AuditingDocument17 pagesThe Environmental Audit: BS EN ISO 19011 Guidelines For Quality and Environmental Management Systems AuditingPuma LunaPas encore d'évaluation

- Policy On Industrial Waste in The Soft Drink IndustryDocument7 pagesPolicy On Industrial Waste in The Soft Drink IndustryjohnPas encore d'évaluation

- Khan - Cleaner ProductionDocument6 pagesKhan - Cleaner ProductionJean Carlos Arias SaldañaPas encore d'évaluation

- Environmental Management PracticesDocument14 pagesEnvironmental Management Practiceshamara12171Pas encore d'évaluation

- Last PartDocument5 pagesLast PartQueenie SanchezPas encore d'évaluation

- Isl Minggu 13: Microscale ChemistryDocument6 pagesIsl Minggu 13: Microscale ChemistryChe Mat Mohd NorPas encore d'évaluation

- Task 2Document13 pagesTask 2OchaOngPas encore d'évaluation

- Dissertation On Hospital Waste ManagementDocument4 pagesDissertation On Hospital Waste ManagementCollegePaperGhostWriterUK100% (1)

- Waste Segregation Blah Blah BlahDocument2 pagesWaste Segregation Blah Blah BlahAngelica Marie JacintoPas encore d'évaluation

- Group 9 Final ProjectDocument6 pagesGroup 9 Final Projectzeerish faisalPas encore d'évaluation

- SWM - Final Exam SheetsDocument7 pagesSWM - Final Exam SheetsAaron David ReidPas encore d'évaluation

- Waste Mangement 1. Materials Management Overview: Executive Order 13514Document11 pagesWaste Mangement 1. Materials Management Overview: Executive Order 13514Pompy JoePas encore d'évaluation

- Environmental ComplianceDocument30 pagesEnvironmental ComplianceM FarmanPas encore d'évaluation

- Cleaner ProductionDocument23 pagesCleaner ProductionSendi Aryadi100% (1)

- Validation of Cleaning Programs PDFDocument24 pagesValidation of Cleaning Programs PDFNani Z. IntriagoPas encore d'évaluation

- Managing WasteDocument1 pageManaging WasterichypatPas encore d'évaluation

- Pollution Prevention PracticesDocument27 pagesPollution Prevention PracticesGrandlanzerPas encore d'évaluation

- HSE Waste Management HandbookDocument5 pagesHSE Waste Management HandbookPaul Uwaya100% (1)

- Factsheet1 Clean ProductionDocument10 pagesFactsheet1 Clean ProductionCharith LiyanagePas encore d'évaluation

- Green Chemistry Lecture 1 & 2Document25 pagesGreen Chemistry Lecture 1 & 2Muhammad IrshadPas encore d'évaluation

- Sree Sastha Institute of Engineering and Technology: Green Audit ReportDocument11 pagesSree Sastha Institute of Engineering and Technology: Green Audit ReportCandida DhasonPas encore d'évaluation

- Cleaner Production CompleteDocument39 pagesCleaner Production CompleteAlyssa AdamsPas encore d'évaluation

- Arnaldo M4 DQ PDFDocument2 pagesArnaldo M4 DQ PDFRadie ArnaldoPas encore d'évaluation

- Current Practices and Operations and Opportunities For Sustainability ImprovementDocument6 pagesCurrent Practices and Operations and Opportunities For Sustainability ImprovementBrian WerePas encore d'évaluation

- Green Cleaning PolicyDocument3 pagesGreen Cleaning PolicyCarol WestinghousePas encore d'évaluation

- D.P. Bhosale College, Koregaon: Dr. Valmik KapaseDocument25 pagesD.P. Bhosale College, Koregaon: Dr. Valmik KapaseDanielPas encore d'évaluation

- Assignment 1Document6 pagesAssignment 1Ange JoPas encore d'évaluation

- Sustainable ProcurementDocument66 pagesSustainable ProcurementSandeep ChatterjeePas encore d'évaluation

- Assignment No.6Document5 pagesAssignment No.6Faraz IshaniPas encore d'évaluation

- Green Chemistry Research Papers PDFDocument7 pagesGreen Chemistry Research Papers PDFgz7y9w0s100% (1)

- Hazardous Waste DisposalDocument5 pagesHazardous Waste DisposalKamlesh MistriPas encore d'évaluation

- Thesis On Medical Waste ManagementDocument6 pagesThesis On Medical Waste Managementclaudiabrowndurham100% (2)

- Source Reduction: Waste MinimisationDocument12 pagesSource Reduction: Waste MinimisationRaman BainsPas encore d'évaluation

- Green ChemistryDocument7 pagesGreen Chemistrysyakirin mnPas encore d'évaluation

- Waste Management Thesis IdeasDocument6 pagesWaste Management Thesis Ideasl0dakyw1pon2100% (2)

- GSCM & Ems HardDocument19 pagesGSCM & Ems Hardpoorna_mpcPas encore d'évaluation

- GSCMDocument13 pagesGSCMAbraham JosephPas encore d'évaluation

- CC1 - Lab SuppliesDocument5 pagesCC1 - Lab SuppliesJ Pao Bayro LacanilaoPas encore d'évaluation

- Soil Science Lab 5Document4 pagesSoil Science Lab 5Joshua Ruel NalzaroPas encore d'évaluation

- Sodium Phosphate Solution, Saturated: Safety Data SheetDocument6 pagesSodium Phosphate Solution, Saturated: Safety Data Sheetxyz7890Pas encore d'évaluation

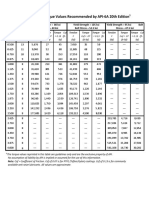

- Flange Bolting Torque Values API 6ADocument1 pageFlange Bolting Torque Values API 6Aparthameister100% (1)

- List of Approved Venders For Rggvy Work in Puvvnl: S.No Material Name Vendor Name 1 2 3Document6 pagesList of Approved Venders For Rggvy Work in Puvvnl: S.No Material Name Vendor Name 1 2 3Karthick MahadevanPas encore d'évaluation

- Silt CurtainDocument3 pagesSilt CurtainarvindkaushikPas encore d'évaluation

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarPas encore d'évaluation

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (1)

- Hydraulic, Thermodynamics Economic AnalysisDocument34 pagesHydraulic, Thermodynamics Economic AnalysisEr. Ramji TripathiPas encore d'évaluation

- Technical Specification FOBDocument6 pagesTechnical Specification FOBANDRESPas encore d'évaluation

- Bomba de Vacio Sihi LPHX 40516Document12 pagesBomba de Vacio Sihi LPHX 40516Dante Coloma JimenezPas encore d'évaluation

- CLS ENG 23 24 XI Che Target 1 Level 1 Chapter 2Document36 pagesCLS ENG 23 24 XI Che Target 1 Level 1 Chapter 2sarthakyedlawar04Pas encore d'évaluation

- Alfa Laval FilterStrainer - PDDocument4 pagesAlfa Laval FilterStrainer - PDBayu RahmansyahPas encore d'évaluation

- The Fundamentals of Coating Thickness MeasurementDocument3 pagesThe Fundamentals of Coating Thickness MeasurementTeoTyJayPas encore d'évaluation

- Measurement of Thin Chromium Coatings by Spot Test: Standard Guide ForDocument3 pagesMeasurement of Thin Chromium Coatings by Spot Test: Standard Guide ForTuanbk NguyenPas encore d'évaluation

- Domestic Greywater Treatment by Electrocoagulation Using Hybrid Electrode Combinations PDFDocument11 pagesDomestic Greywater Treatment by Electrocoagulation Using Hybrid Electrode Combinations PDFIbrahim TabashPas encore d'évaluation

- Hidrant Exterior 15 Ls PDFDocument3 pagesHidrant Exterior 15 Ls PDFNicolae CretuPas encore d'évaluation

- Cambridge IGCSE: CHEMISTRY 0620/52Document12 pagesCambridge IGCSE: CHEMISTRY 0620/52PanAtaraxPas encore d'évaluation

- SURFACTANTS ppt-1Document33 pagesSURFACTANTS ppt-1Ashraf Shaikh75% (4)

- SCL Instruction Manual R2 09 18 PDFDocument28 pagesSCL Instruction Manual R2 09 18 PDFCLAUDIOPas encore d'évaluation

- Stock As On 05 Jul, 21Document147 pagesStock As On 05 Jul, 21Ahmad MukhtarPas encore d'évaluation

- CE 302 - Conc - Lecture 1 - Wk1 PDFDocument18 pagesCE 302 - Conc - Lecture 1 - Wk1 PDFIsraelPas encore d'évaluation

- Astm b86.5503 ZamakDocument7 pagesAstm b86.5503 ZamakJosé SierraPas encore d'évaluation

- IC-TGD-100 User's ManualDocument29 pagesIC-TGD-100 User's ManualJboy SchlossPas encore d'évaluation

- Industrial Chemistry PDFDocument168 pagesIndustrial Chemistry PDFHafiz Hamza100% (1)

- C1334-05 (Reapproved 2016) E1Document3 pagesC1334-05 (Reapproved 2016) E1Mohamad ZandiPas encore d'évaluation

- Chem Workshop - Question Paper CompilationDocument197 pagesChem Workshop - Question Paper Compilations1672snehil6353Pas encore d'évaluation

- Aluminum Bronze, UNS C61300: Component Wt. %Document3 pagesAluminum Bronze, UNS C61300: Component Wt. %AbbasPas encore d'évaluation

- Two Proposal To Calculate Bagasse Boiler EfficiencyDocument10 pagesTwo Proposal To Calculate Bagasse Boiler EfficiencyMario Melo100% (1)

- Properties of Fresh and Hard ConcreteDocument13 pagesProperties of Fresh and Hard Concretemudasir afzal100% (1)

- ASTM D4817-88 Rubber Compounding SterDocument2 pagesASTM D4817-88 Rubber Compounding SterLuisa Fernanda Carvajal RamírezPas encore d'évaluation

- The Courage to Be Free: Florida's Blueprint for America's RevivalD'EverandThe Courage to Be Free: Florida's Blueprint for America's RevivalPas encore d'évaluation

- Modern Warriors: Real Stories from Real HeroesD'EverandModern Warriors: Real Stories from Real HeroesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Crimes and Cover-ups in American Politics: 1776-1963D'EverandCrimes and Cover-ups in American Politics: 1776-1963Évaluation : 4.5 sur 5 étoiles4.5/5 (26)

- The Russia Hoax: The Illicit Scheme to Clear Hillary Clinton and Frame Donald TrumpD'EverandThe Russia Hoax: The Illicit Scheme to Clear Hillary Clinton and Frame Donald TrumpÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Stonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonD'EverandStonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Red and the Blue: The 1990s and the Birth of Political TribalismD'EverandThe Red and the Blue: The 1990s and the Birth of Political TribalismÉvaluation : 4 sur 5 étoiles4/5 (29)

- Socialism 101: From the Bolsheviks and Karl Marx to Universal Healthcare and the Democratic Socialists, Everything You Need to Know about SocialismD'EverandSocialism 101: From the Bolsheviks and Karl Marx to Universal Healthcare and the Democratic Socialists, Everything You Need to Know about SocialismÉvaluation : 4.5 sur 5 étoiles4.5/5 (42)

- Slouching Towards Gomorrah: Modern Liberalism and American DeclineD'EverandSlouching Towards Gomorrah: Modern Liberalism and American DeclineÉvaluation : 4 sur 5 étoiles4/5 (59)

- Game Change: Obama and the Clintons, McCain and Palin, and the Race of a LifetimeD'EverandGame Change: Obama and the Clintons, McCain and Palin, and the Race of a LifetimeÉvaluation : 4 sur 5 étoiles4/5 (572)

- The Great Awakening: Defeating the Globalists and Launching the Next Great RenaissanceD'EverandThe Great Awakening: Defeating the Globalists and Launching the Next Great RenaissanceÉvaluation : 4 sur 5 étoiles4/5 (8)

- The Next Civil War: Dispatches from the American FutureD'EverandThe Next Civil War: Dispatches from the American FutureÉvaluation : 3.5 sur 5 étoiles3.5/5 (50)

- Power Grab: The Liberal Scheme to Undermine Trump, the GOP, and Our RepublicD'EverandPower Grab: The Liberal Scheme to Undermine Trump, the GOP, and Our RepublicPas encore d'évaluation

- The Science of Liberty: Democracy, Reason, and the Laws of NatureD'EverandThe Science of Liberty: Democracy, Reason, and the Laws of NaturePas encore d'évaluation

- The Deep State: How an Army of Bureaucrats Protected Barack Obama and Is Working to Destroy the Trump AgendaD'EverandThe Deep State: How an Army of Bureaucrats Protected Barack Obama and Is Working to Destroy the Trump AgendaÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- UFO: The Inside Story of the US Government's Search for Alien Life Here—and Out ThereD'EverandUFO: The Inside Story of the US Government's Search for Alien Life Here—and Out ThereÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- To Make Men Free: A History of the Republican PartyD'EverandTo Make Men Free: A History of the Republican PartyÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Magnificent Medills: The McCormick-Patterson Dynasty: America's Royal Family of Journalism During a Century of Turbulent SplendorD'EverandThe Magnificent Medills: The McCormick-Patterson Dynasty: America's Royal Family of Journalism During a Century of Turbulent SplendorPas encore d'évaluation

- A Short History of the United States: From the Arrival of Native American Tribes to the Obama PresidencyD'EverandA Short History of the United States: From the Arrival of Native American Tribes to the Obama PresidencyÉvaluation : 3.5 sur 5 étoiles3.5/5 (19)

- Stonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonD'EverandStonewalled: My Fight for Truth Against the Forces of Obstruction, Intimidation, and Harassment in Obama's WashingtonÉvaluation : 4.5 sur 5 étoiles4.5/5 (43)

- The Invisible Bridge: The Fall of Nixon and the Rise of ReaganD'EverandThe Invisible Bridge: The Fall of Nixon and the Rise of ReaganÉvaluation : 4.5 sur 5 étoiles4.5/5 (32)

- Corruptible: Who Gets Power and How It Changes UsD'EverandCorruptible: Who Gets Power and How It Changes UsÉvaluation : 4.5 sur 5 étoiles4.5/5 (45)

- Parliament of Whores: A Lone Humorist Attempts to Explain the Entire U.S. GovernmentD'EverandParliament of Whores: A Lone Humorist Attempts to Explain the Entire U.S. GovernmentÉvaluation : 3.5 sur 5 étoiles3.5/5 (246)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (52)

- Witch Hunt: The Story of the Greatest Mass Delusion in American Political HistoryD'EverandWitch Hunt: The Story of the Greatest Mass Delusion in American Political HistoryÉvaluation : 4 sur 5 étoiles4/5 (6)

- WARNING! Graphic Content: Political Cartoons, Comix and the Uncensored Artistic MindD'EverandWARNING! Graphic Content: Political Cartoons, Comix and the Uncensored Artistic MindÉvaluation : 4 sur 5 étoiles4/5 (2)

- U.S. Constitution for Dummies: 2nd EditionD'EverandU.S. Constitution for Dummies: 2nd EditionÉvaluation : 3.5 sur 5 étoiles3.5/5 (8)

- Operation Gladio: The Unholy Alliance Between the Vatican, the CIA, and the MafiaD'EverandOperation Gladio: The Unholy Alliance Between the Vatican, the CIA, and the MafiaÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- American Government 101: From the Continental Congress to the Iowa Caucus, Everything You Need to Know About US PoliticsD'EverandAmerican Government 101: From the Continental Congress to the Iowa Caucus, Everything You Need to Know About US PoliticsÉvaluation : 4 sur 5 étoiles4/5 (17)